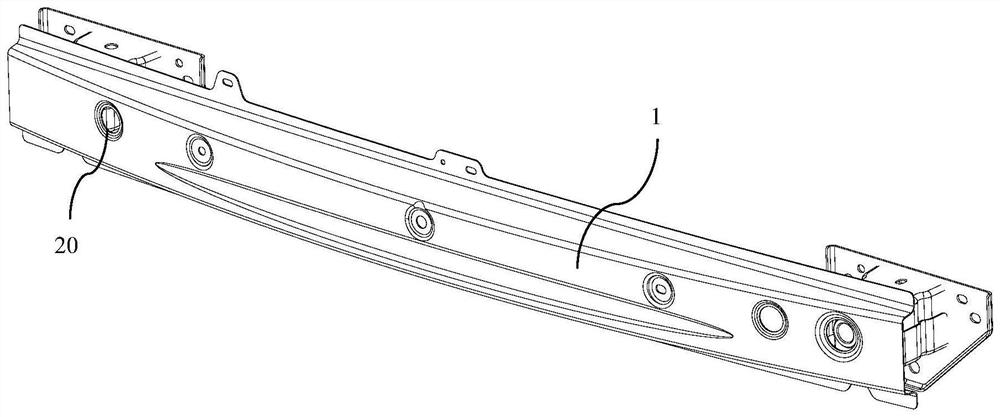

Tow hook installation structure

A technology of installation structure and tow hook, which is applied in the direction of vehicle components, transportation and packaging, traction connector, etc. It can solve the problems of position deviation, time-consuming and labor-intensive, affecting the screw-in of the tow hook, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

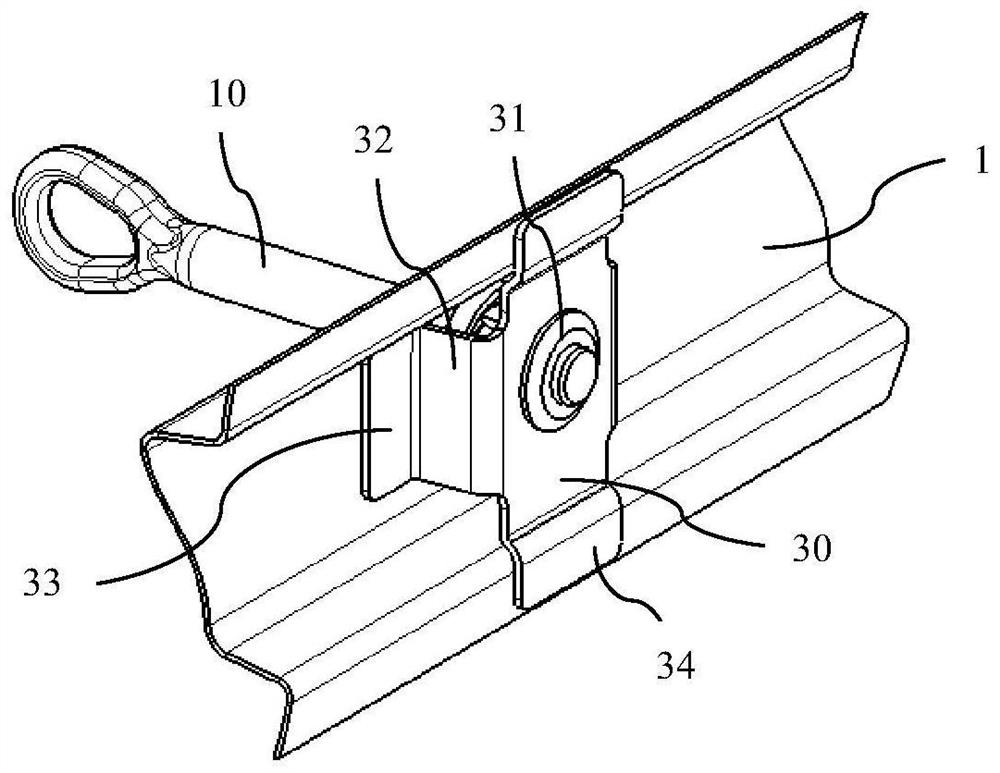

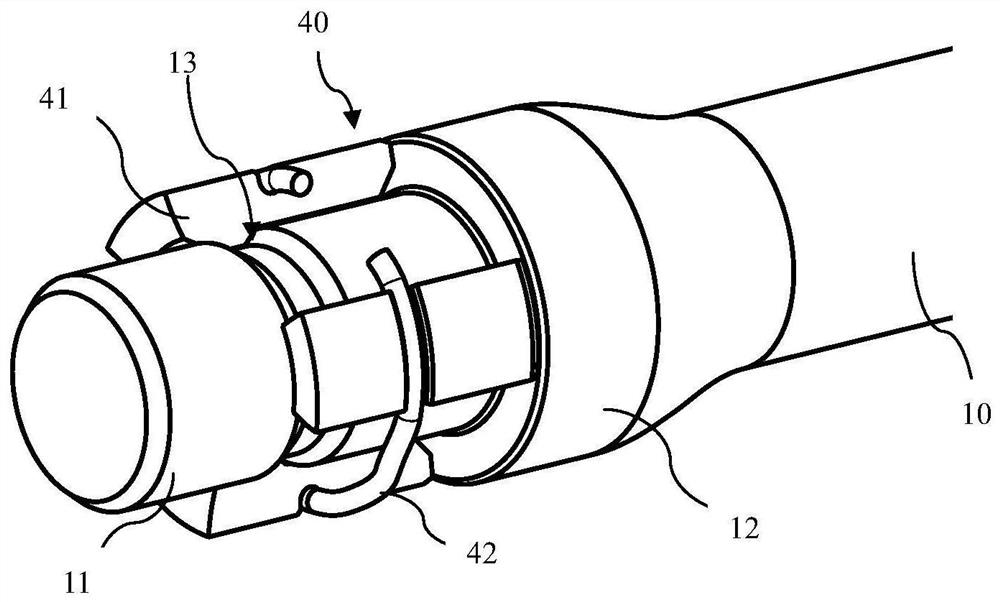

[0017] Embodiment 1: The expansion unit 40 includes at least two shoe-shaped blocks 41 that are evenly spaced circumferentially in front of the threaded section 11 of the tow bar 10 , and a C-shaped clamp spring 42 is provided at the rear of the outer middle of the shoe-shaped blocks 41 Constraint tile block 41 abuts on tow bar 10, and tow bar 10 is provided with outwardly protruding step shaft 12 adjacent to the front end of tile block 41. After threaded section 11 of tow bar 10 is screwed into nut seat 31, tile block 41 is The nut seat 31 and the step shaft 12 are squeezed to drive the shoe block 41 around its rear end to form a swing away from the tow bar 10 at the front end, and the front end of the shoe block 41 far away from the tow bar 10 abuts against the groove of the front anti-collision beam 1 The bottom and it form a position-limiting fit that limits the forward displacement of the tow bar 10 relative to the front anti-collision beam 1 . In the above scheme, at lea...

Embodiment 2

[0022] Embodiment 2: The expansion unit 40 includes an elastic sleeve 43 provided in front of the threaded section 11 of the tow bar 10 , the tow bar 10 is provided with an outwardly protruding stepped shaft 12 adjacent to the front end of the elastic sleeve 43 , and the threaded section 11 of the tow bar 10 After being screwed into the nut seat 31, the elastic sleeve 43 is squeezed between the nut seat 31 and the step shaft 12 to drive the front end of the elastic sleeve 43 to expand and fit on the step shaft 12, and the front end of the elastic sleeve 43 on the step shaft 12 is against the front end. The bottom of the groove of the anti-collision beam 1, or the elastic sleeve 43 on the step shaft 12 is embedded by the hole edge of the through hole 20 and the front anti-collision beam 1 constitutes a limit fit to limit the forward displacement of the tow bar 10 relative to the front anti-collision beam 1 . In the above solution, the extrusion of the nut seat 31 and the steppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com