Bending-resistant metal hose with connector protection device

A protection device and metal hose technology, which is applied in the direction of hose connection devices, pipes/pipe joints/fittings, hoses, etc., can solve the problems of large local stress of hoses, tearing of net sleeves, damage to metal hoses, etc. Achieve the effect of eliminating potential safety hazards, avoiding excessive local stress, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

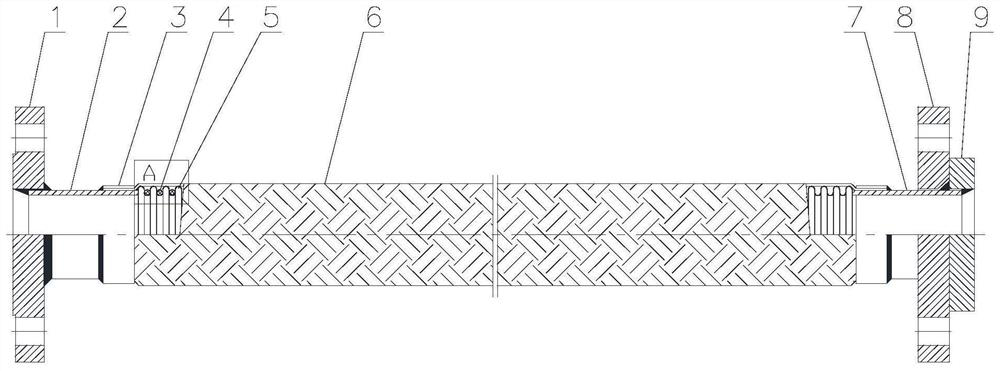

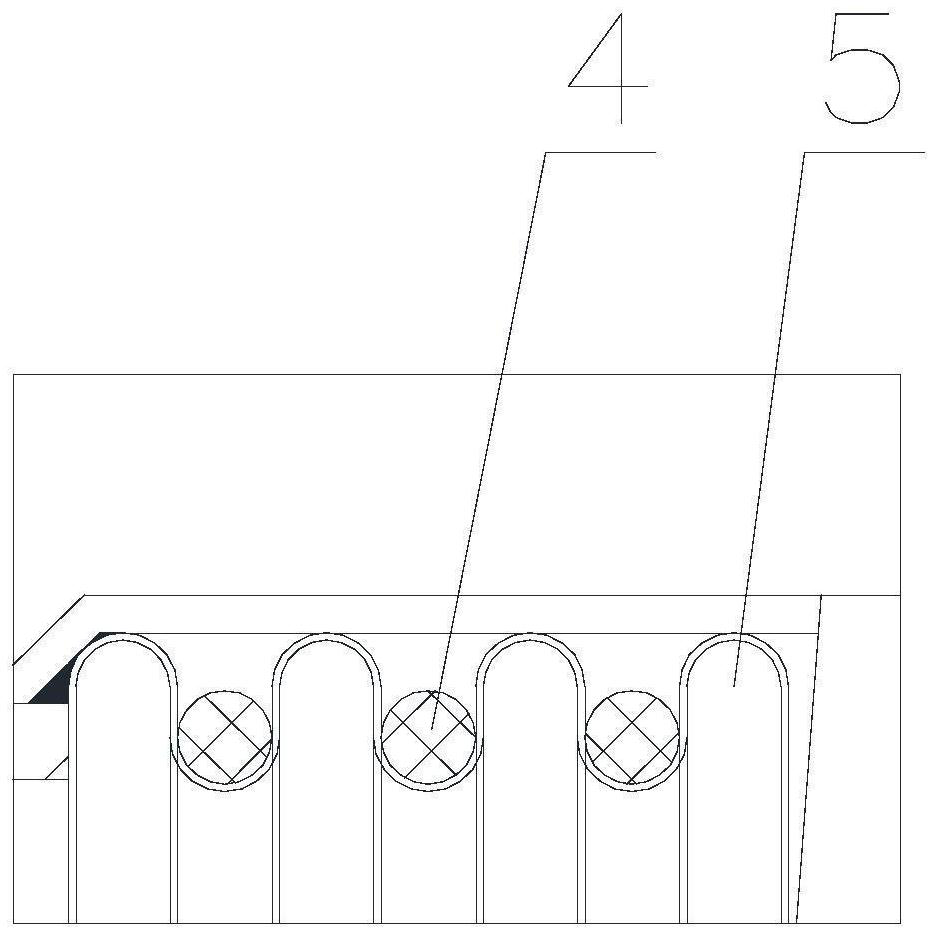

[0022] The joint protection device in this embodiment is mainly a flexible ring embedded in the trough of the bellows 5, the flexible ring is a rubber ring 4, and the flexible rubber ring 4 is nested in the trough of the bellows 5 near the end of the short connection pipe 2, nested The number of troughs with rubber rings is usually 3 to 6. The mesh sleeve 6 on the outer surface of the bellows 5 is a metal braided mesh sleeve, and the two ends of the metal mesh sleeve 6 are welded and fixed to the short connection pipe 2 and the long connection pipe 7 through the metal sheath 3 respectively.

Embodiment 2

[0024] The joint protection device of this embodiment is mainly a spring (not shown in the drawings) wound on the outer surface of the mesh sleeve 6. The mesh sleeve 6 on the outer surface of the bellows 5 is a metal braided mesh sleeve, and the two ends of the metal mesh sleeve 6 The short connection pipe 2 and the long connection pipe 7 are welded and fixed through the metal sheath 3 respectively. The spring is wound on the net sleeve 6 close to the fixed flange 1, the metal sheath 3 is welded and fixed with one end of the spring, and the other end of the spring is a free end, and the length of the spring is greater than that between two adjacent bellows crests the distance.

Embodiment 3

[0026] The joint protection device of this embodiment is mainly a flexible sheath wrapped on the outer surface of the mesh sleeve 6 (not shown in the drawings), the mesh sleeve 6 on the outer surface of the bellows 5 is a metal braided mesh sleeve, The ends are welded and fixed to the short connection pipe 2 and the long connection pipe 7 through the metal sheath 3 respectively. The outer surface of the net sleeve 6 close to the short connection pipe 2 is wrapped with a flexible sheath, the flexible sheath includes a non-metallic hose, one end of the flexible sheath is connected and fixed to the outer surface of the short connection pipe 2 through a metal hoop, and the other end of the flexible sheath For free ends, the length of the flexible sheath is greater than the distance between two adjacent corrugated pipe crests.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com