Multistation processing tool for strong-suction-type eccentric upper sealing head flange

A multi-station, heart-on-seal technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of partial accumulation of coolant, long clamping time, low efficiency, etc., and reduce the occupied space , Improve the cooling effect and simplify the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

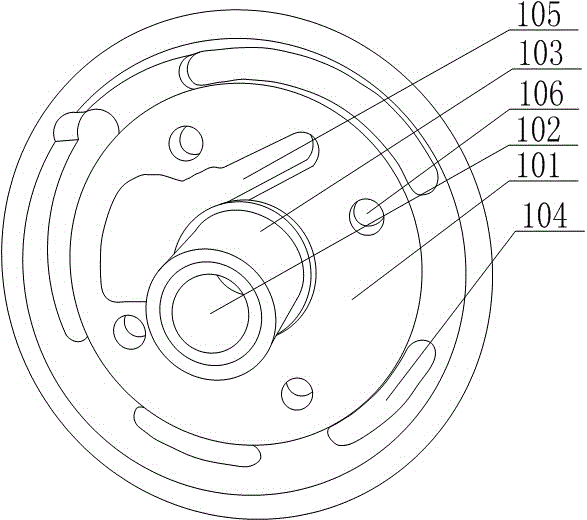

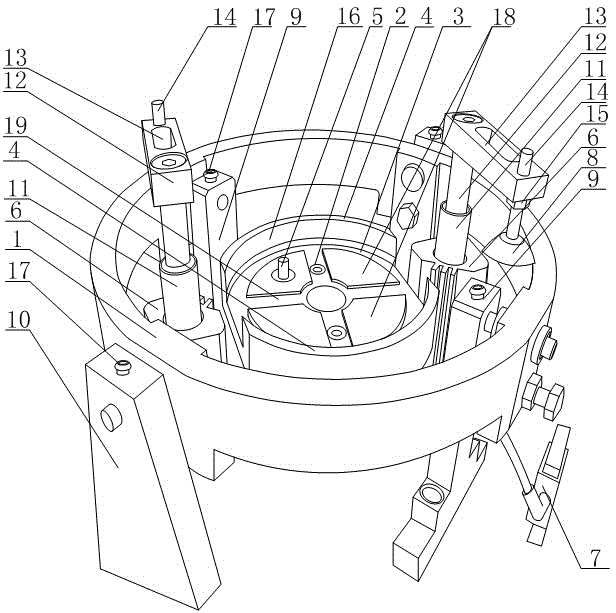

[0022] Such as figure 2As shown, the multi-station processing tooling of a strong suction type eccentric upper head flange of the present invention includes a positioning ring 1, the positioning ring 1 is in the shape of a ring, and a pair of inner columns 9 and a positioning ring are installed on the inside of the positioning ring 1. 1 is equipped with an outer column 10, the inner column 9 and the outer column 10 are evenly arranged on the positioning ring 1, and the connecting line of the inner column 9 and the connecting line of the outer column 10 are basically vertically distributed, and the positioning ring 1 passes through the inner column 9 Installed on the milling machine with the outer column 10, the inside of the inner column 9 and the outer column 10 are equipped with coolant pipes, and the inner column 9 and the outer column 10 are equipped with quick-connect plugs 17 communicated with the coolant pipes. The inner side of 1 is equipped with a cylinder 6 correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com