High-speed mixing bed adopting spiral fluid director water distribution plate and hexagonal unit perforated plate

A high-speed mixed bed and hexagonal technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of limited hole uniformity, affecting purification efficiency, and poor uniformity of raw water and other problems, so as to avoid excessive local stress, improve the uniformity of water distribution, and achieve the effect of high water distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

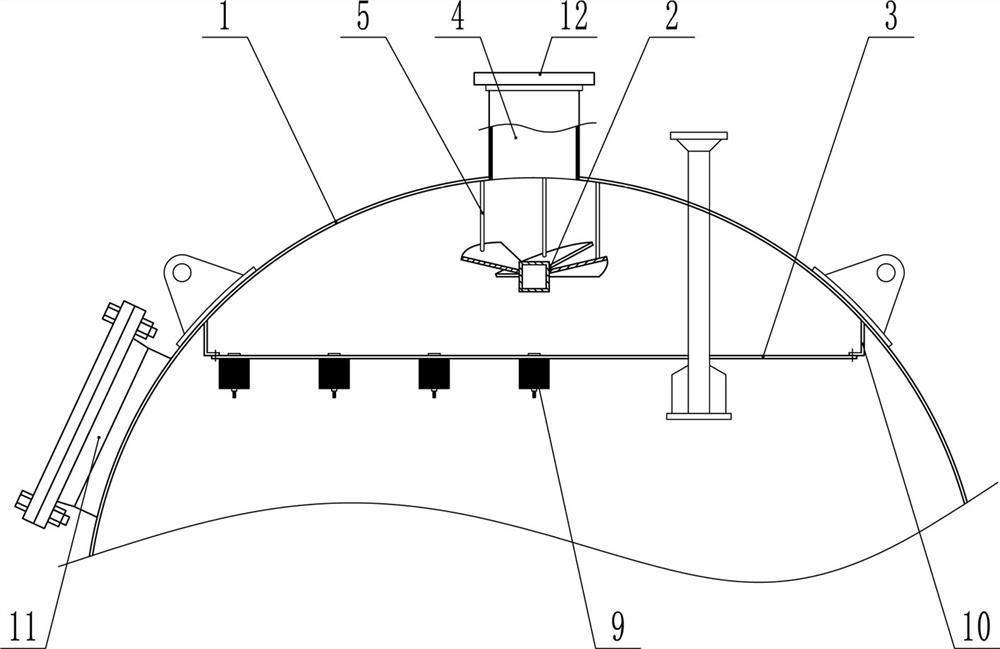

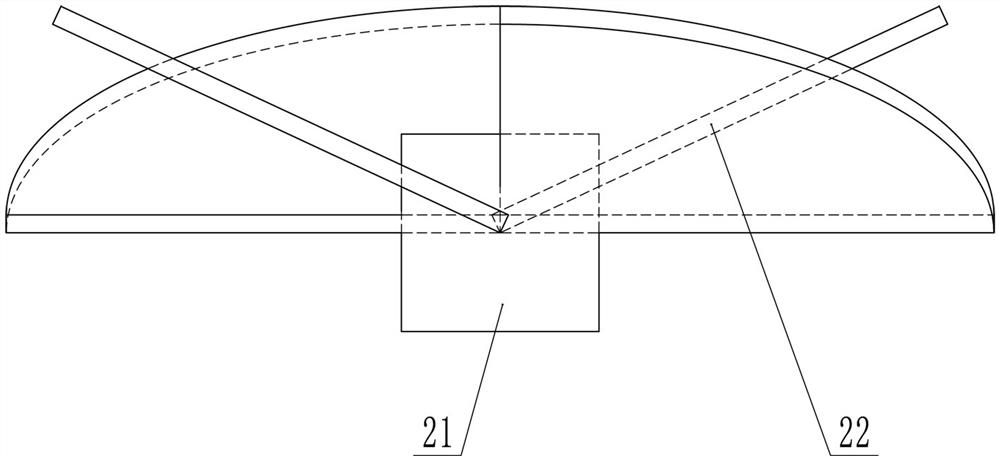

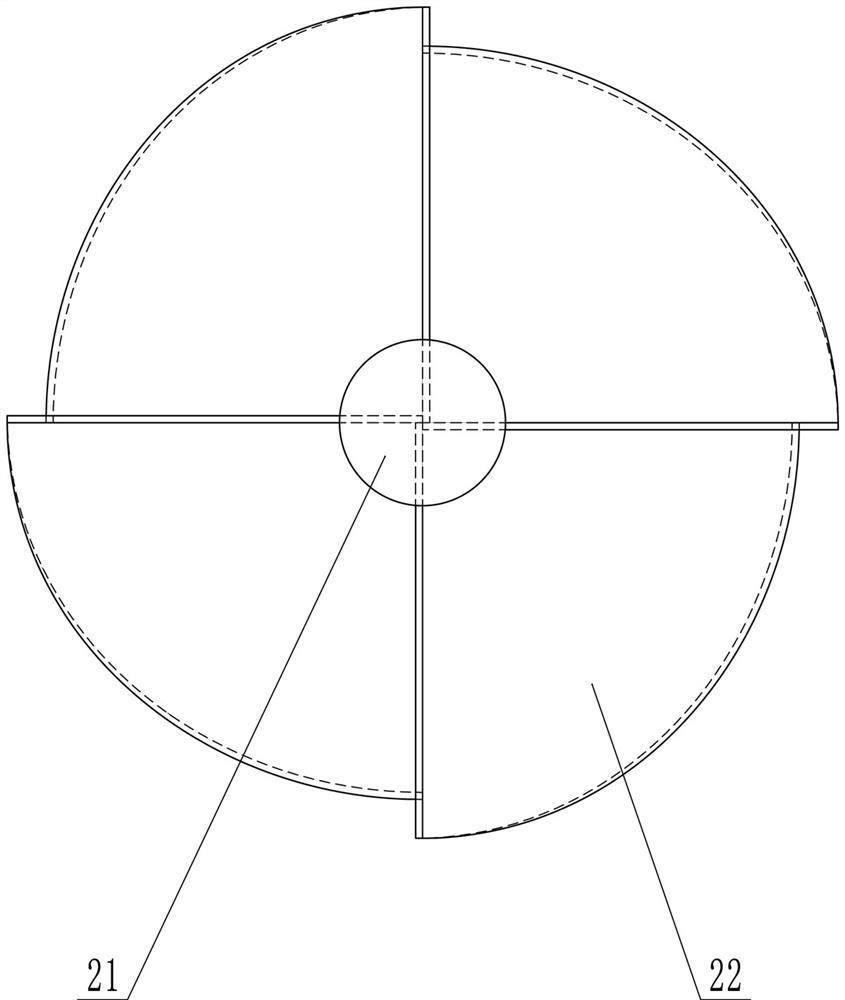

[0025] Such as Figure 1-9 As shown, a high-speed mixed bed adopts a spiral deflector water distribution plate and a hexagonal unit porous plate, including an arc-shaped top shell 1, a fan-shaped water distribution plate 2 and a water distribution porous plate 3. The circular The top of the arc-shaped top shell 1 is provided with a water inlet 4, the fan blade type water distribution plate 2 is arranged directly below the water inlet 4, and the water distribution porous plate 3 is arranged on the fan blade type water distribution plate 2, the blade-type water distribution plate 2 includes a central block 21 and four upturned fan blades 22 evenly connected to the central block 21, and each of the upturned fan blades 22 is Tilting at a certain angle clockwise or counterclockwise, the orthographic projections of the sides of two adjacent up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com