A method for optimal configuration of cooling water pipes and a water pipe structure with uniform distribution

A technology of cooling water pipes and shunt pipes, which is applied to cooling devices and other directions, can solve the problem of uneven distribution of water in the internal cooling wall, and achieve the effects of improving the uniformity of water distribution, improving service life and reducing construction difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] At present, the water supply mode adopted by the blast furnace cooling system in China is not uniform in the circumferential direction and the vertical direction, so it is urgent to improve the water supply mode of the blast furnace cooling system. And at present, there are few studies on the uniformity of blast furnace water supply system at home and abroad, and the research is mainly concentrated on the small tuyere, blast furnace water station monitoring, and water supply stability. The research on the water supply uniformity of blast furnace stave water supply system is almost is blank.

[0069] For this reason, this embodiment provides a method for optimizing the configuration of cooling water pipes in the blast furnace cooling system. The method first establishes a three-dimensional model of the blast furnace cooling system, and then performs numerical simulation on it through the existing ANSYS software; The speed of several velocity measuring points in the flow ...

Embodiment 2

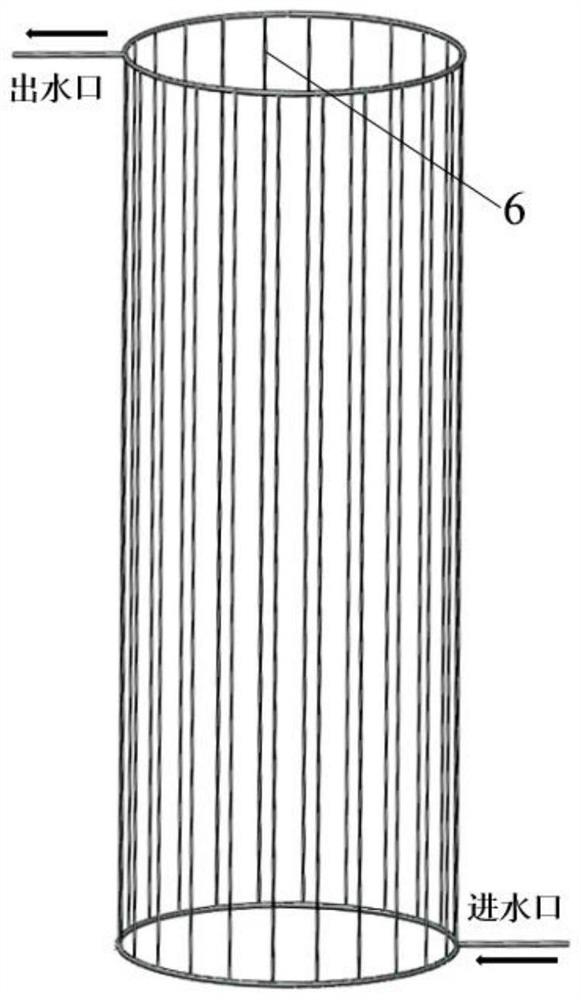

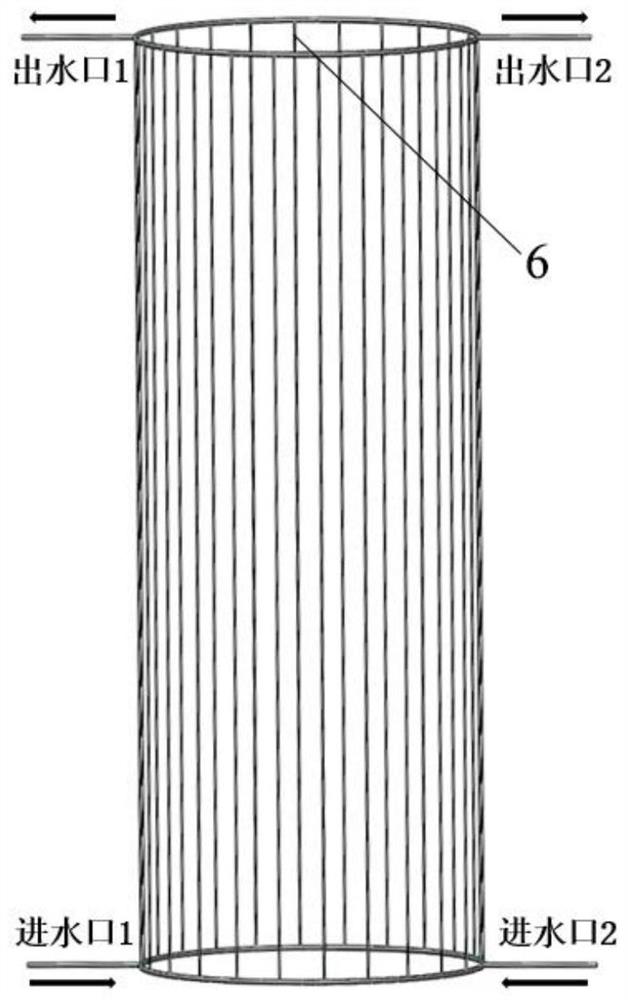

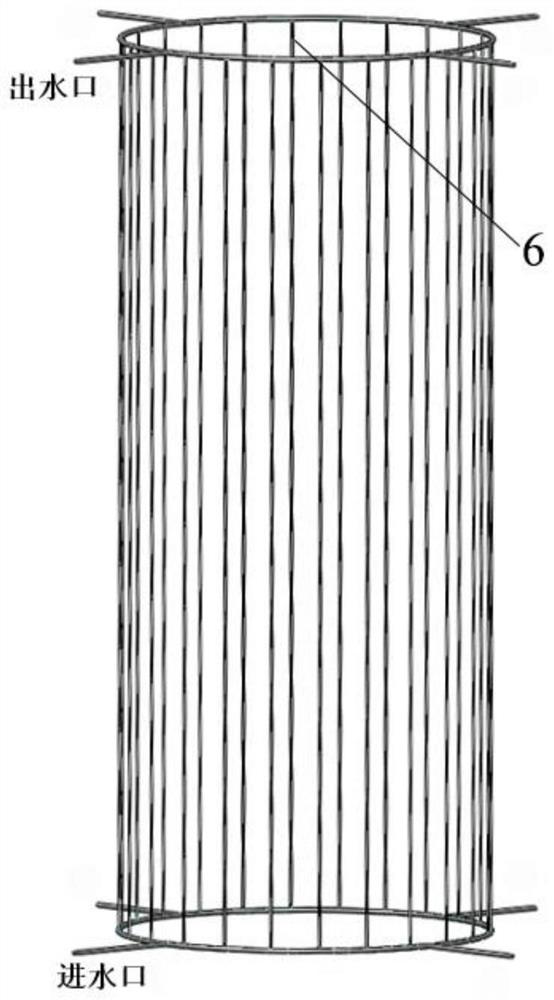

[0102] like Figure 7 As shown, the method for optimizing the configuration of cooling water pipes in the blast furnace cooling system described in Embodiment 1 is used to obtain a uniformly distributed water pipe structure, and the uniformly distributed water pipe structure includes:

[0103]The first large ring, the first large ring is connected to the total water inlet / total water outlet and the inner diameter of the first large ring is the same as the inner diameter of the total water inlet / total water outlet;

[0104] horizontal shunt pipe;

[0105] vertical shunt pipe;

[0106] a second large ring, the second large ring is connected to the vertical shunt pipe and the horizontal shunt pipe;

[0107] The third large ring, the third large ring is connected with the vertical distribution pipe and the stave water pipe;

[0108] The first large ring, the horizontal shunt pipe, the second large ring, the vertical shunt pipe and the third large ring are sequentially connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com