An anoxic fluidized bed device for treating industrial wastewater

A technology of industrial wastewater and fluidized bed, applied in anaerobic digestion treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. In order to improve the biological reaction efficiency, optimize the water distribution method, reduce the damage of the circulating pump and the possibility of blocking the circulating pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below in conjunction with the accompanying drawings.

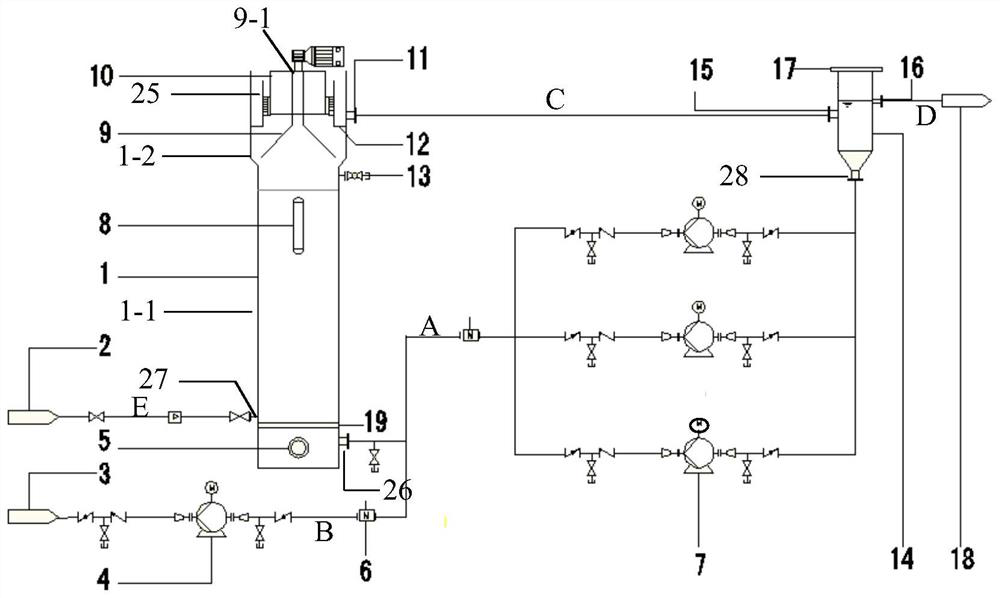

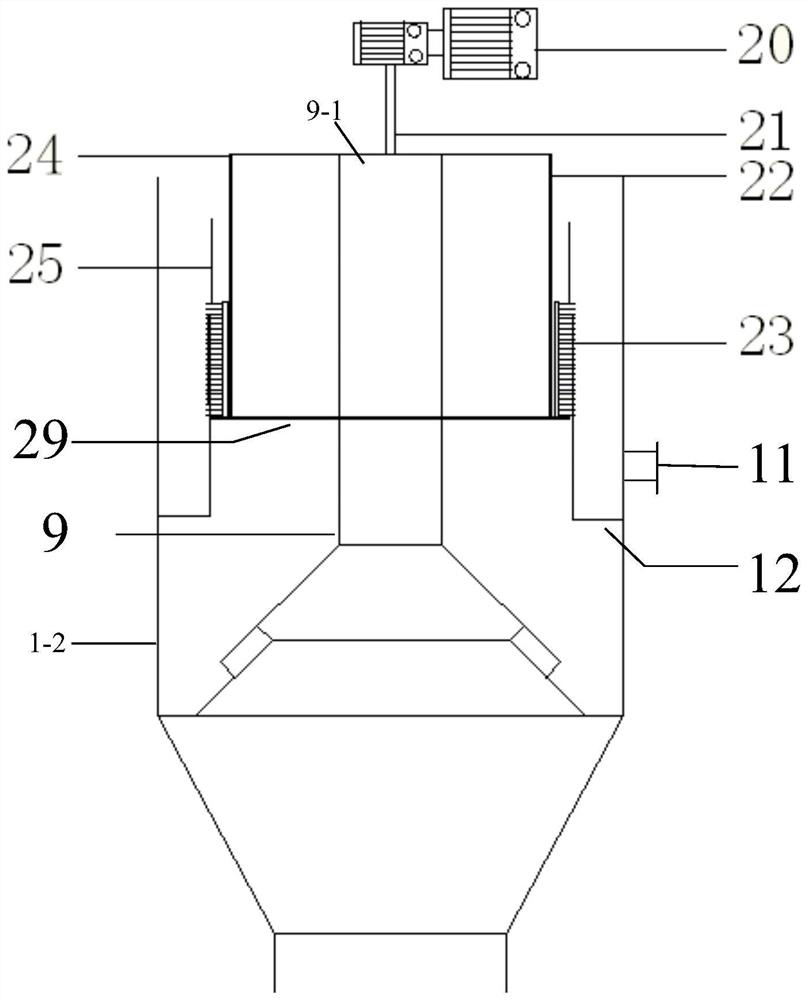

[0063] Such as figure 1 Shown in -3, the anoxic fluidized bed device for industrial waste water treatment of the present invention is a full-automatic high-efficiency organic wastewater treatment device composed of anoxic fluidized bed and self-cleaning filter etc., specifically as follows:

[0064] An anoxic fluidized bed device for treating industrial wastewater, comprising:

[0065] The main body 1 of the anoxic fluidized bed device includes a tower body 1-1 and a tower head 1-2;

[0066] The tower body 1-1 is a hollow cylinder, and the tower head 1-2 is located at the upper part of the tower body 1-1 and is a hollow cylinder with a diameter larger than the tower body 1-1;

[0067] An anoxic fluidized bed water inlet 26 is arranged on the lower side wall of the tower body 1-1,

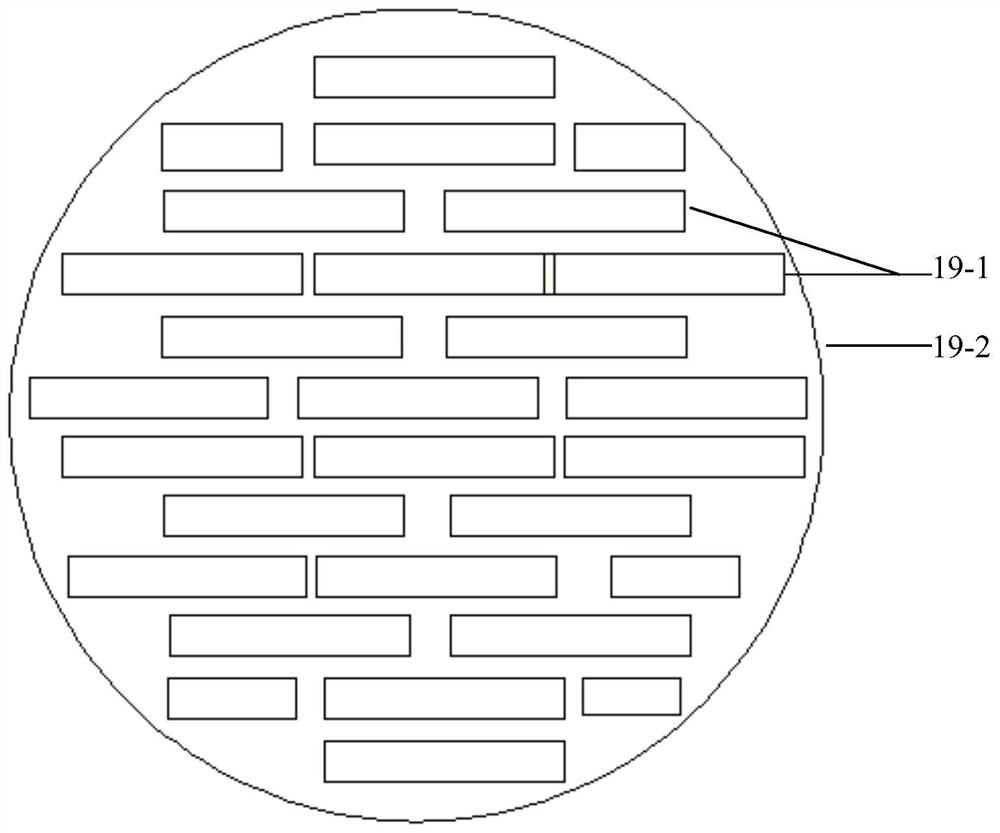

[0068] In the tower body 1-1, a water flow distributor 19 is arranged above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com