Inverted denitrification process film bioreactor

A membrane bioreactor and reactor technology, which is applied in the field of inverted denitrification process membrane bioreactors, can solve the problems of non-sealed reactors, uneven film formation, poor oxygen transmission rate, etc., so as to save operating costs and energy. Consumption, good effluent quality, and the effect of reducing sludge load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

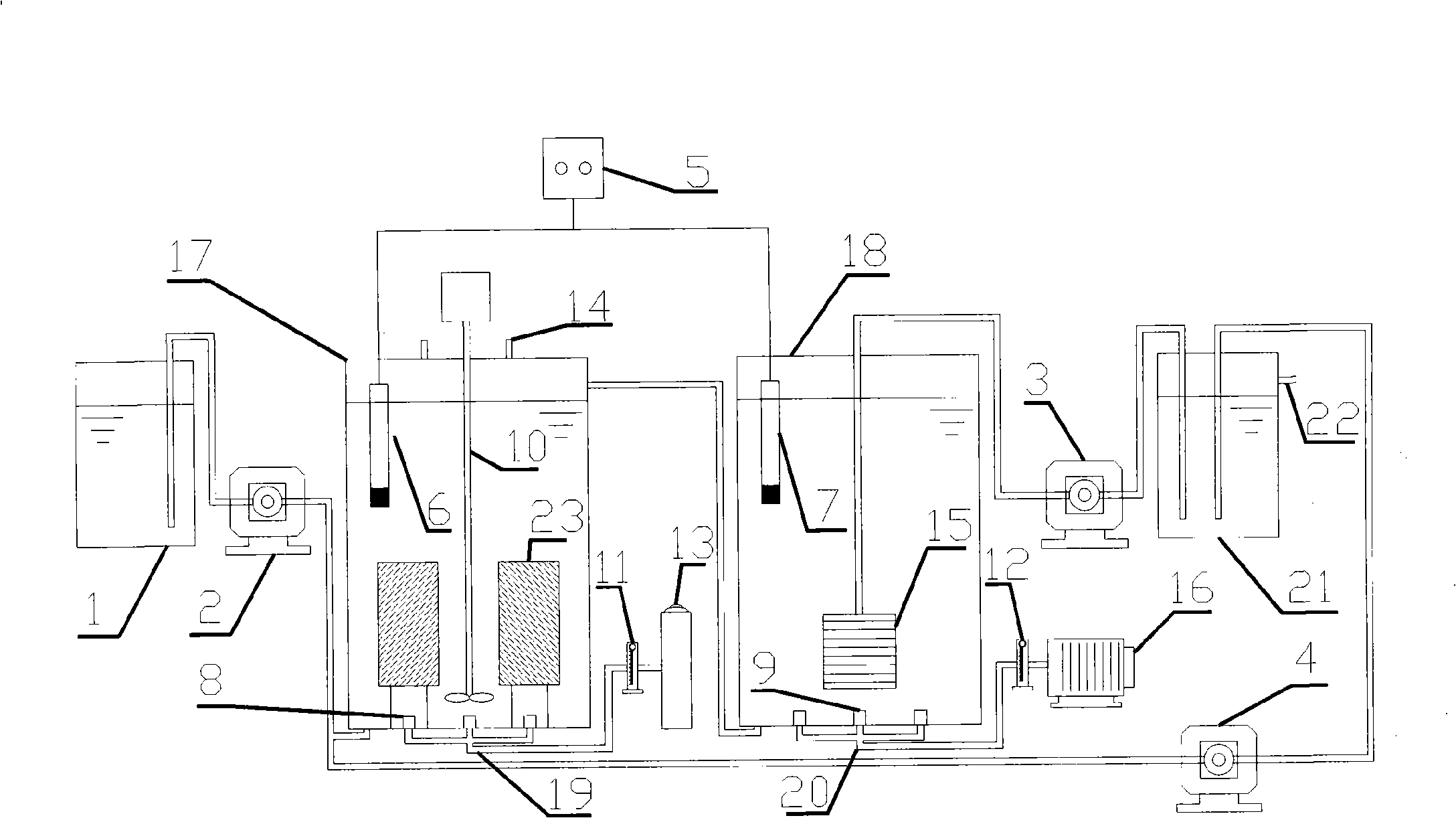

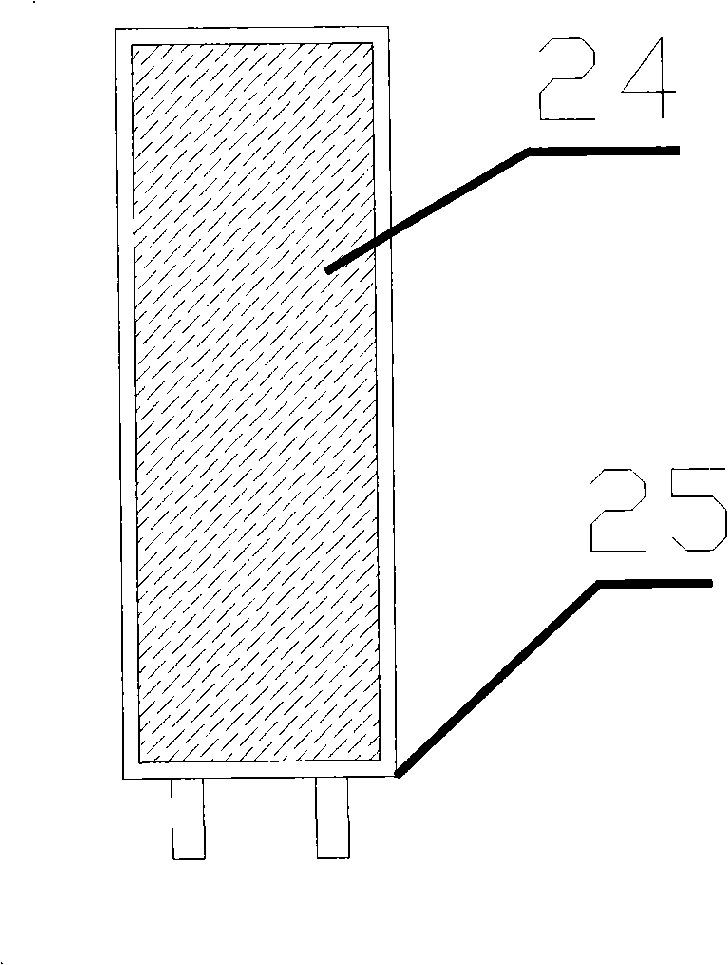

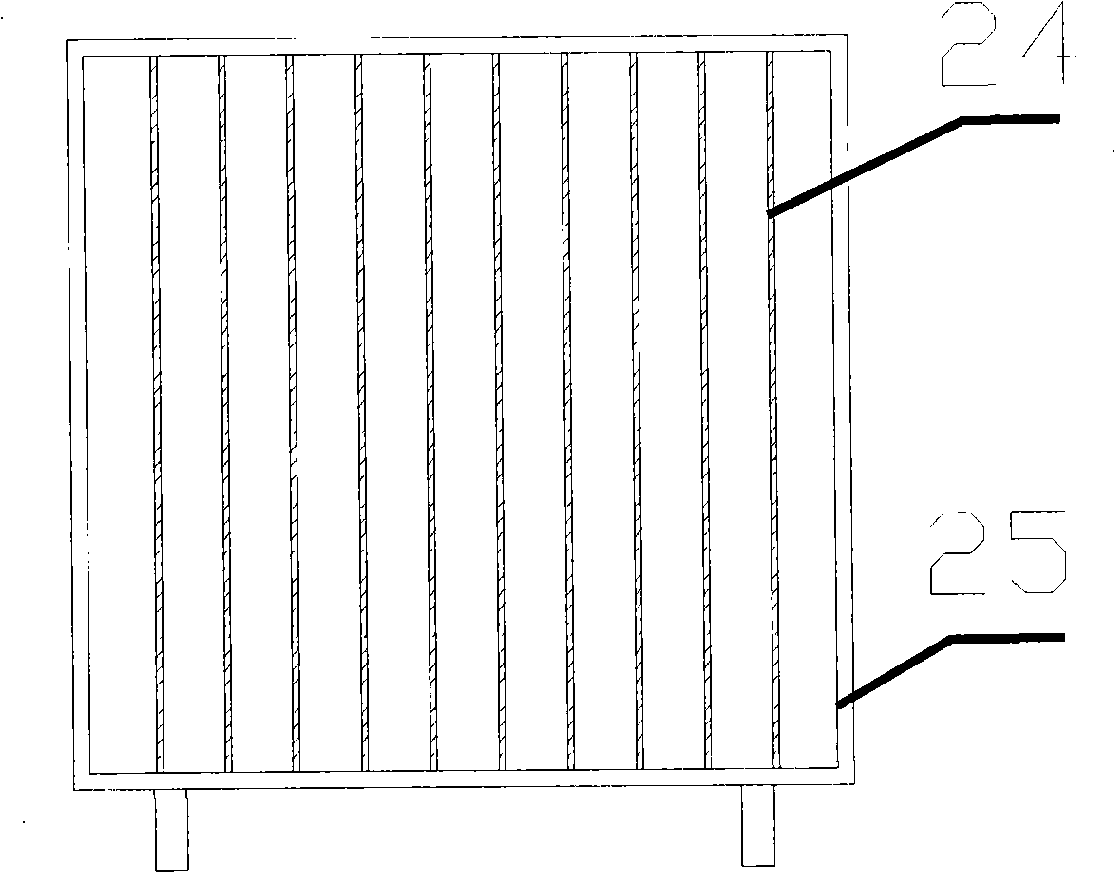

[0024] It can be seen from the flow diagram of the anammox-nitrosation process of the inverted membrane bioreactor that the reactor consists of an anammox reactor 17, a nitrosation reactor 18, and aeration devices 8, 9, 11, 12 , 13, 16, 19, 20, temperature control device 5, 6, 7, stirring device 10, filler 23 is composed of, the top of the anaerobic ammonium oxidation reactor is provided with vent hole 14, ANAMMOX bacterium adheres to growth in no Spin cloth filler 24, and fix by stainless steel frame 25, nitrosation reactor effluent adopts hollow fiber membrane 15. The temperature control device is composed of a temperature controller 5 and heating rods 6 and 7. The aeration device is composed of aeration heads 8, 9, gas flow meters 11, 12, nitrogen cylinder 13, air pump 16 and aeration pipes 19, 20 at the bottom of the reaction vessel. The volume of the two reactors is 14L respectively, and the total area of the non-woven packing is 0.33m 2 , the maximum biomass per unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com