Alternating type cascade treatment method for high-salinity wastewater

A technology for high-salt wastewater and a treatment method, applied in the field of environmental engineering, can solve the problems of increasing initial investment and operating costs, increasing operating costs such as power consumption, and insufficient adsorption effect of adsorbents, and is conducive to mass popularization and application, reducing operation. Cost and human input, the effect of good engineering application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

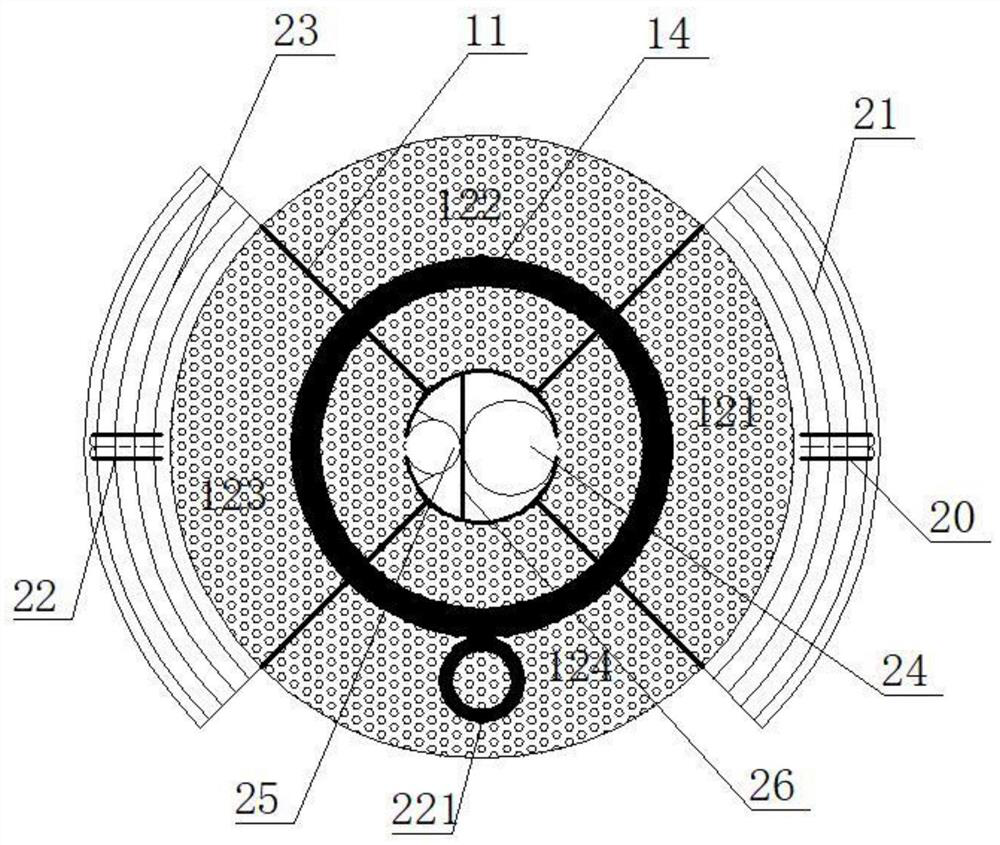

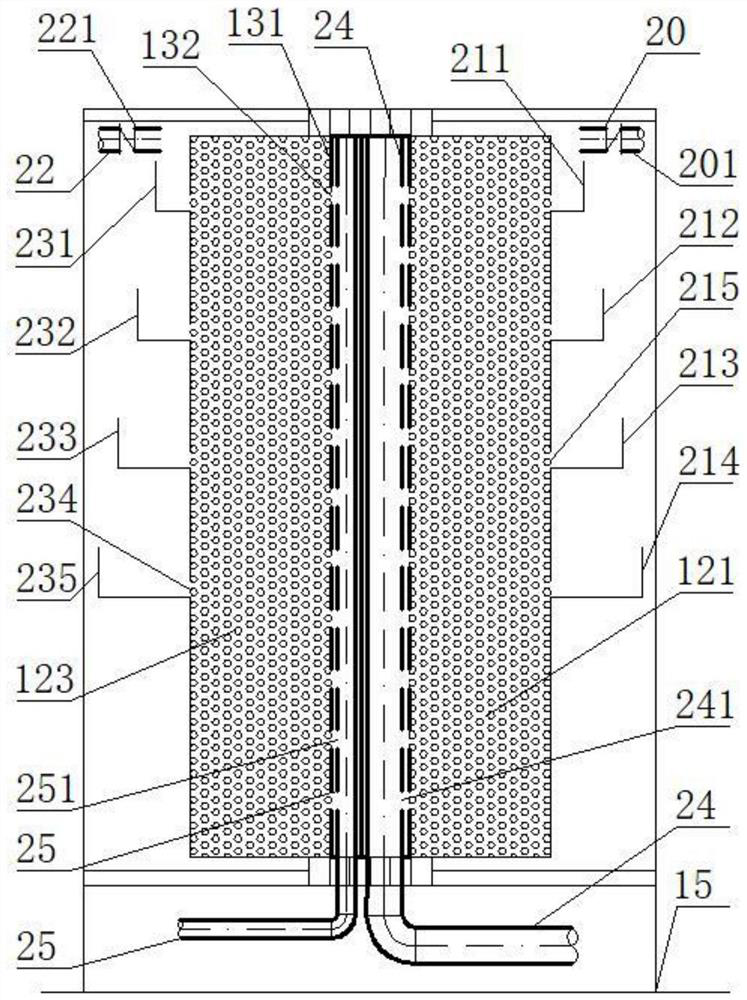

[0047] Such as figure 1 As shown, the system adopted for the alternate cascading treatment method of the high-salt wastewater provided by the present invention is operated, such as Figure 1-2 As shown, the system includes a pollutant removal system 1 and an alternating cascade system water delivery system 2 nested in the pollutant removal system 1;

[0048] The pollutant removal system 1 includes four partition plates 11, a pollutant removal area 12 of hollow cylindrical structure, a cylindrical water outlet chamber 13 located at the axis of the pollutant removal area 12, and a rotating shaft fixedly connected to the four partition plates 11 14. The motor 18 that drives the rotating shaft 14 to rotate, and the fixed bracket 15 that is fixedly connected with the motor 18 and used to support the system;

[0049] Four partition plates 11 are evenly distributed in the pollutant removal area 12 of the pollutant removal system 1, and the pollutant removal area 12 is evenly divided...

Embodiment 2

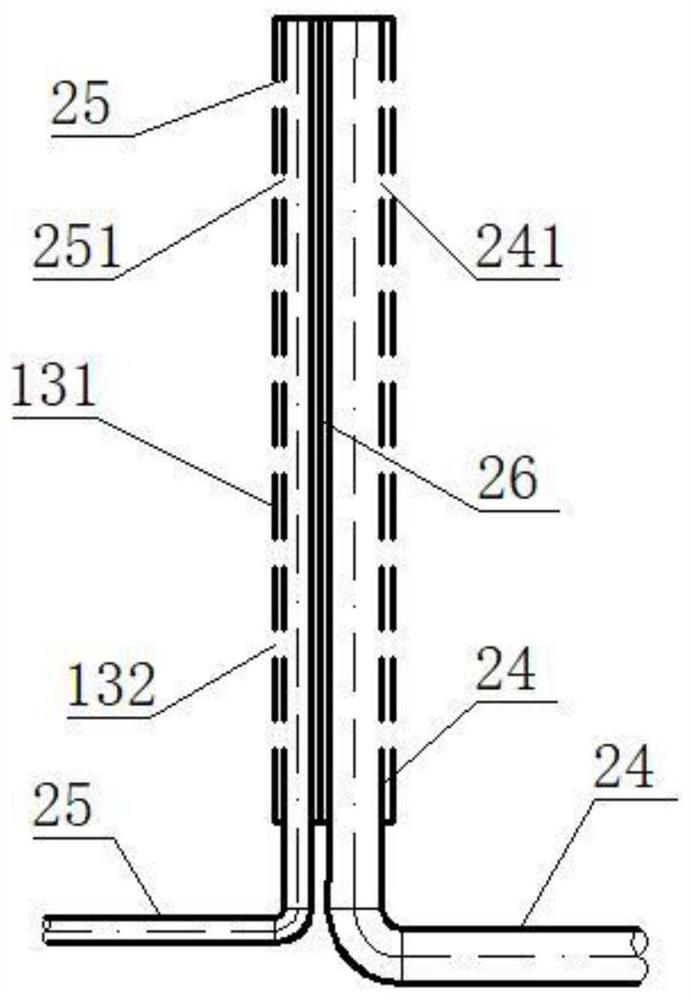

[0079] The difference between this embodiment and Embodiment 1 is that in the alternate cascading treatment system for high-salt wastewater used in this embodiment, the diameter of the outlet bin 13 is 200mm, and the diameter of the filter screen 17 is the outlet bin cloth water hole 132 35%, the diameter of the purified water outlet hole 241 is 112% of the diameter of the corresponding water outlet hole 132; the diameter of the purified water outlet hole 241 is 5.5mm, and the diameter of the water inlet delivery pipe 20 is 13 33% of the diameter.

[0080] The thickness of the hydrogel filler in the pollutant removal zone is 750mm, and the filling rate of the built-in hydrogel material is 75%. The outlet casing 131 of the outlet chamber 13 is cylindrical in shape, with a diameter of 1100mm and made of stainless steel.

Embodiment 3

[0082] The difference between this embodiment and Embodiment 1 is that in the alternate cascading treatment system for high-salt wastewater used in this embodiment, the diameter of the outlet bin 13 is 280 mm, and the diameter of the filter screen 17 is the outlet bin cloth water hole 132 55%, the diameter of the purified water outlet hole 241 is 115% of the diameter of the corresponding water outlet hole 132; the diameter of the purified water outlet hole 241 is 8mm, and the diameter of the water inlet delivery pipe 20 is the diameter of the water outlet 13 45%.

[0083] The thickness of the hydrogel filler in the pollutant removal zone is 1000mm, and the filling rate of the built-in hydrogel material is 85%. The water outlet shell 131 of the water outlet chamber 13 is cylindrical, with a diameter of 2000mm, and is made of stainless steel.

[0084] It should be noted that the descriptions in this application such as “first” and “second” are used for description purposes only,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com