An anoxic denitrification fluidized bed treatment device

A treatment device and fluidized bed technology, applied in anaerobic digestion treatment, biological treatment equipment, biological water/sewage treatment, etc., can solve the problems of mixing, packing loss, damage to the pump head, etc., to increase microbial biomass and increase volume load , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with the accompanying drawings.

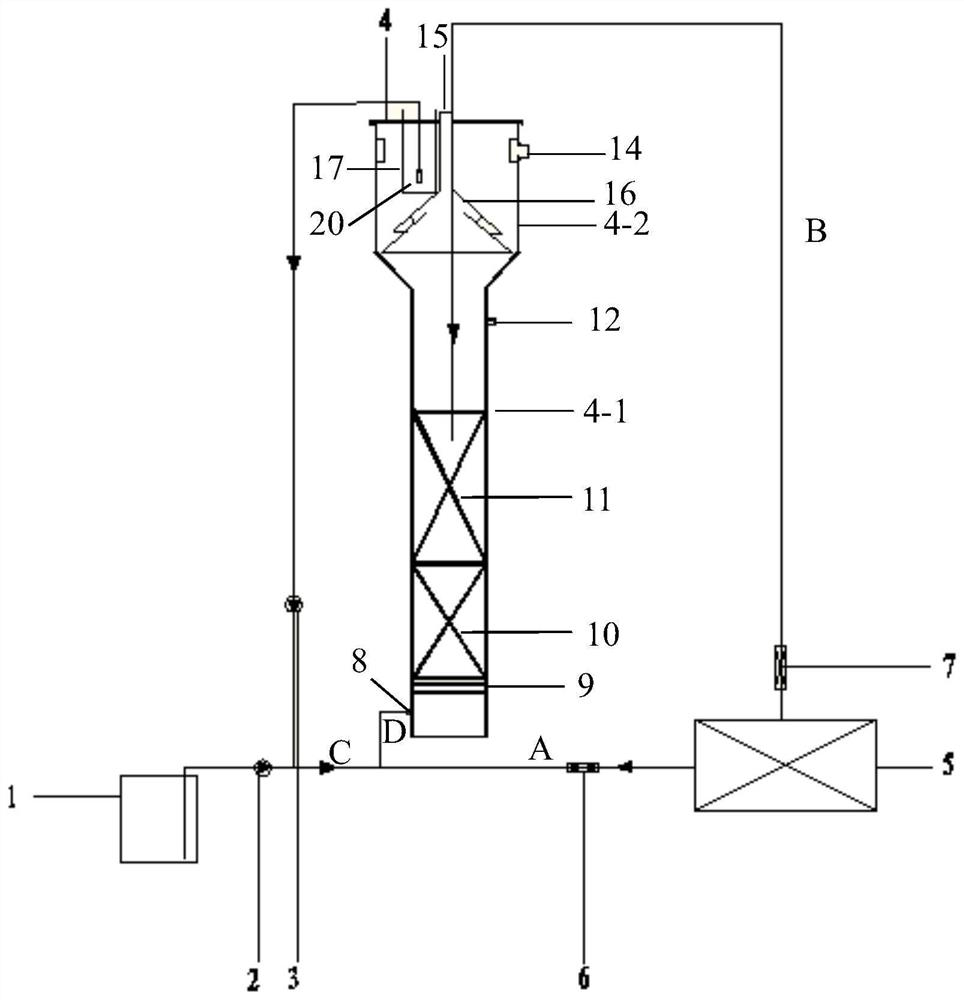

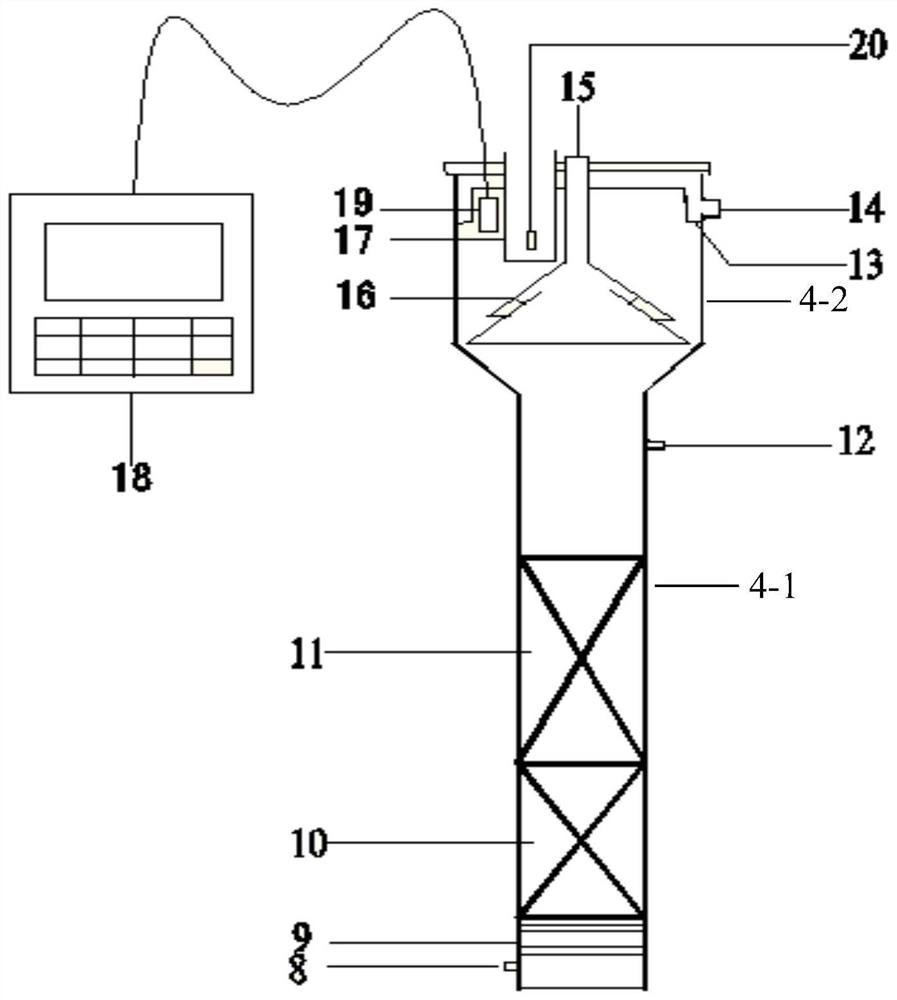

[0055] Such as figure 1Shown in -4, the wastewater treatment device of the present invention is an anoxic denitrification fluidized bed treatment device is a full-automatic high-efficiency organic denitrification device composed of a reactor main body (anoxic fluidized bed) 4, an ultrasonic oscillator and a nitrogen making system 5, etc. A wastewater treatment device, specifically as follows: an anoxic denitrification fluidized bed treatment device, comprising:

[0056] Reactor body (i.e. anoxic fluidized bed) 4, including tower body 4-1 and tower head 4-2;

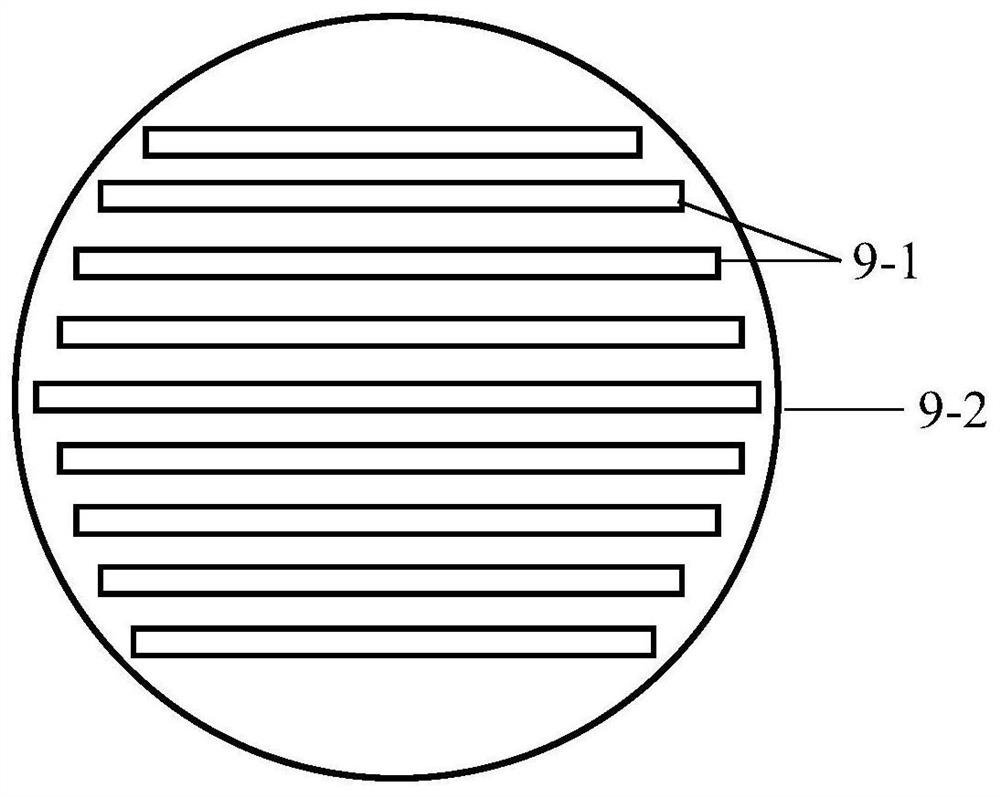

[0057] The bottom of the tower body 4-1 is equipped with a water flow distributor 9,

[0058] The water flow distributor 9 includes a bottom plate 9-2 provided with several strip-shaped channels 9-1, and the strip-shaped channels 9-1 are strip-shaped through holes, which are evenly and parallelly distr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com