Preparation method of loofah sponge bio-filler for wastewater treatment

A biological filler and sewage treatment technology, applied in the field of water treatment, can solve the problems of inability to achieve rapid and effective enrichment of microorganisms, lack of affinity, and inability to maintain microbial activity, etc., to enhance the activity of biological fillers to retain microorganisms, hydrophilic Good performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

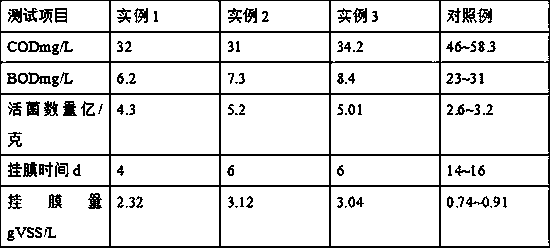

Examples

preparation example Construction

[0023] Preparation of modified nano-titanium dioxide: Weigh about nano-titanium dioxide powder and add it to γ-chloropropyltriethoxysilane ethanol solution at a mass ratio of 1:9, disperse on an ultrasonic instrument for 15 minutes, and place the dispersion solution at 50°C React in a water bath for 1-2 hours, filter with filter paper, wash with ethanol, dry in an oven at 80°C and grind carefully to obtain modified nano-titanium dioxide powder.

[0024] Penicillium simplex liquid medium: by mass parts, take 40~50 parts of glucose, 0.01~0.02 parts of KCl, KH 2 PO 4 0.01~0.015 parts, MgSO 4 •7H 2 O 0.01~0.012 parts, (NH 4 ) 2 HPO 4 0.04~0.06 parts, 0.2~0.3 parts of yeast extract, 0.1~0.4 parts of peptone, sterilized at 115 ℃ for 15 minutes, and the pH value was natural.

[0025] Fermentation medium: by mass parts, take 80~100 parts of glucose, 2~8 parts of peptone, 5~8 parts of sodium nitrate, KH 2 PO 4 2~4 parts, MgSO 4 0.4~0.8 parts, CaCO 3 1.5~3.5 parts, KCl 0.3~...

example 1

[0031] Preparation of ethanol solution of γ-chloropropyl triethoxysilane coupling agent: mix ethanol and water evenly at a mass ratio of 9:1 to make an ethanol solution, stir continuously, and add γ-chloropropyl at a mass fraction of 5% Triethoxysilane, the solution was adjusted to pH 3 with acetic acid, and hydrolyzed at room temperature for 1 hour to obtain an ethanol solution of γ-chloropropyltriethoxysilane.

[0032] Raw materials: Common loofah on the market, after drying, cut the loofah into long and square strips with a width of about 1 cm.

[0033] Preparation of modified nano-titanium dioxide: Weigh about nano-titanium dioxide powder and add it to γ-chloropropyltriethoxysilane ethanol solution at a mass ratio of 1:9, disperse on an ultrasonic instrument for 15 minutes, and place the dispersion solution at 50°C React in a water bath for 1 hour, filter with filter paper, wash with ethanol, dry in an oven at 80°C and grind carefully to obtain modified nano titanium dioxi...

example 2

[0041] Preparation of ethanol solution of γ-chloropropyl triethoxysilane coupling agent: mix ethanol and water evenly at a mass ratio of 9:1 to make an ethanol solution, stir continuously, and add γ-chloropropyl at a mass fraction of 5% Triethoxysilane, the solution was adjusted to pH 4 with acetic acid, and hydrolyzed at room temperature for 1 hour to obtain an ethanol solution of γ-chloropropyltriethoxysilane.

[0042] Raw materials: Common loofah on the market, after drying, cut the loofah into long and square strips with a width of about 1 cm.

[0043] Preparation of modified nano-titanium dioxide: Weigh about nano-titanium dioxide powder and add it to γ-chloropropyltriethoxysilane ethanol solution at a mass ratio of 1:9, disperse on an ultrasonic instrument for 15 minutes, and place the dispersion solution at 50°C React in a water bath for 2 hours, filter with filter paper, wash with ethanol, dry in an oven at 80°C and carefully grind to obtain modified nano titanium diox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com