Hybrid anaerobic reactor

An anaerobic reactor and hybrid technology, applied in anaerobic digestion treatment and other directions, can solve the problems of uneven water distribution, low anaerobic reaction efficiency, fouling and blockage of internal pipes, and improve the uniformity of water distribution. , Relieve the effect of running mud, easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

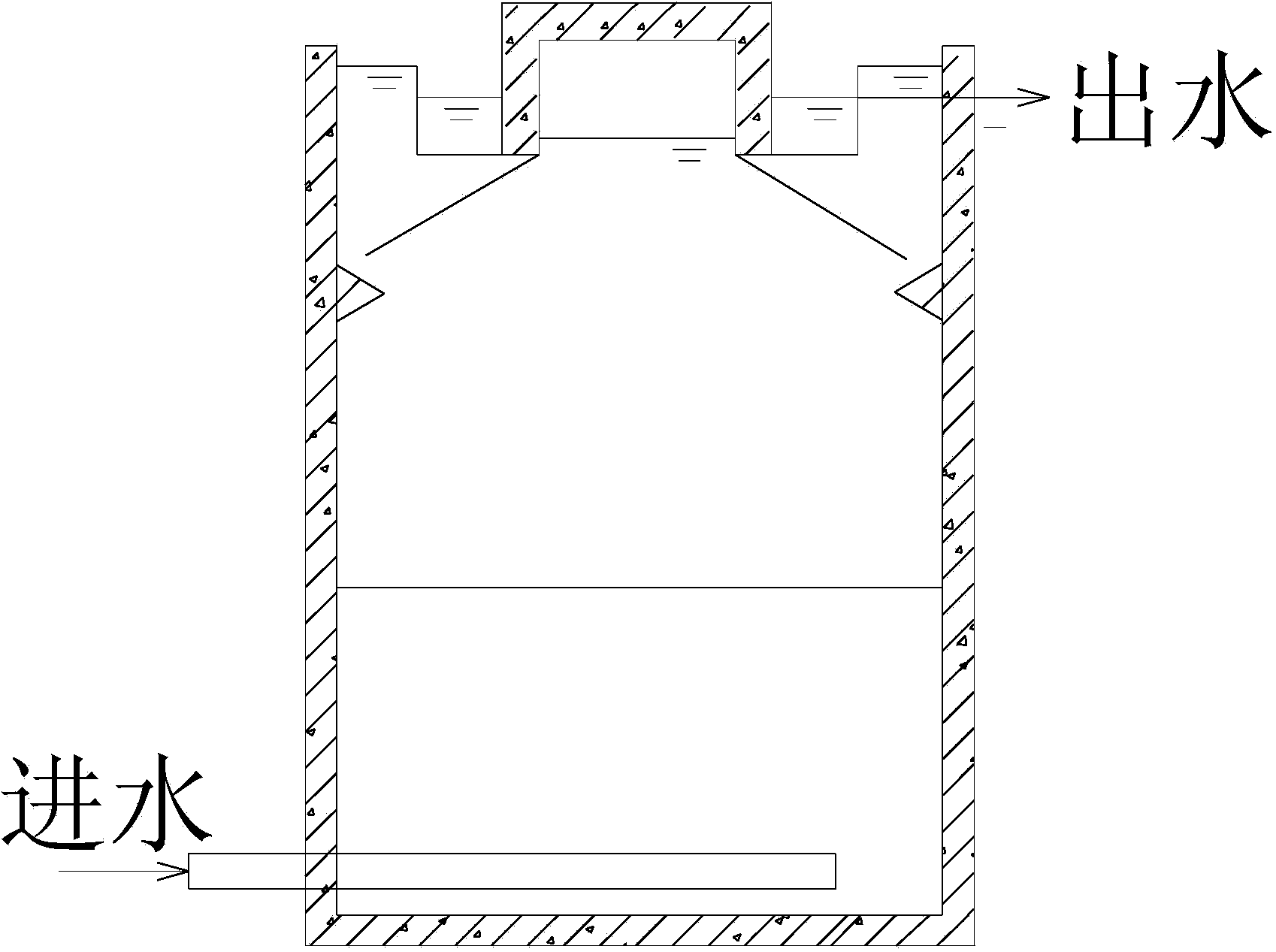

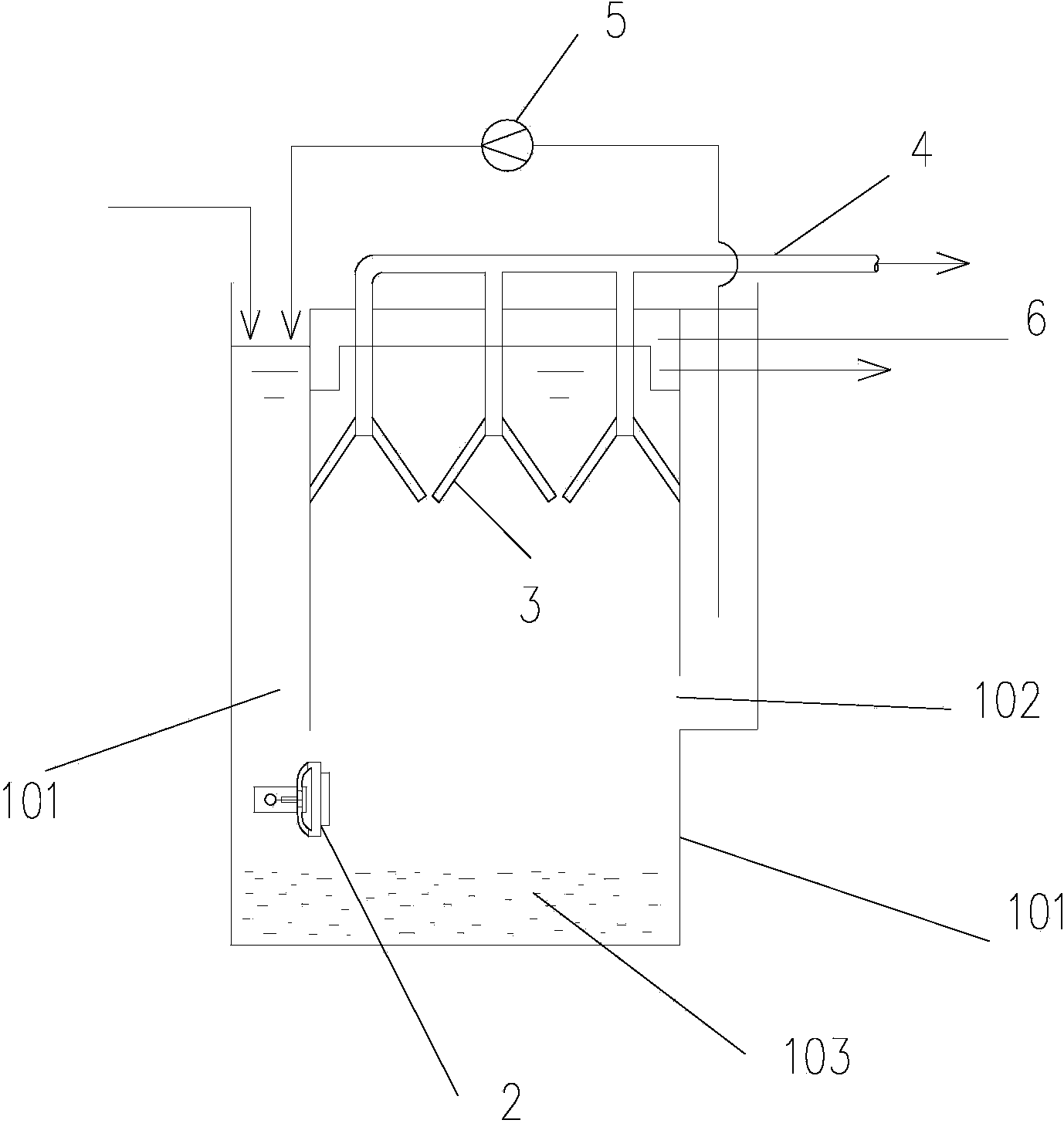

[0020] as attached figure 2 As shown, a hybrid anaerobic reactor, which includes an anaerobic reactor body 1, is characterized in that: the anaerobic reactor body 1 is provided with a diversion tank 101, the diversion tank 101 communicates with the outside world, and the diversion tank Below 101, a mixer 2 is installed at the bottom of the anaerobic reactor body 1. A three-phase separator 3 is arranged above the mixer 2 in the inner cavity of the anaerobic reactor body 1. The gas output end of the three-phase separator 3 is connected to a gas collecting pipe 4. The gas collecting pipe 4 extends out of the anaerobic reactor body 1, and the anaerobic reactor body 1 is located below the three-phase separator 3 and above the mixer 2. There is a water intake 102 connected to the circulation pump 5 and the output port of the circulation pump 5. Connect back to the diversion tank 101;

[0021] The anaerobic reactor body 1 is provided with a water collection tank 6 above the three-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com