Water-proof heat-insulation cabin with simple corner structure in ship-supporting structure

A support structure and thermal insulation technology, applied in the direction of ship hull, ship construction, ship hull components, etc., can solve the problems of increasing manufacturing cost and unable to effectively prevent corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

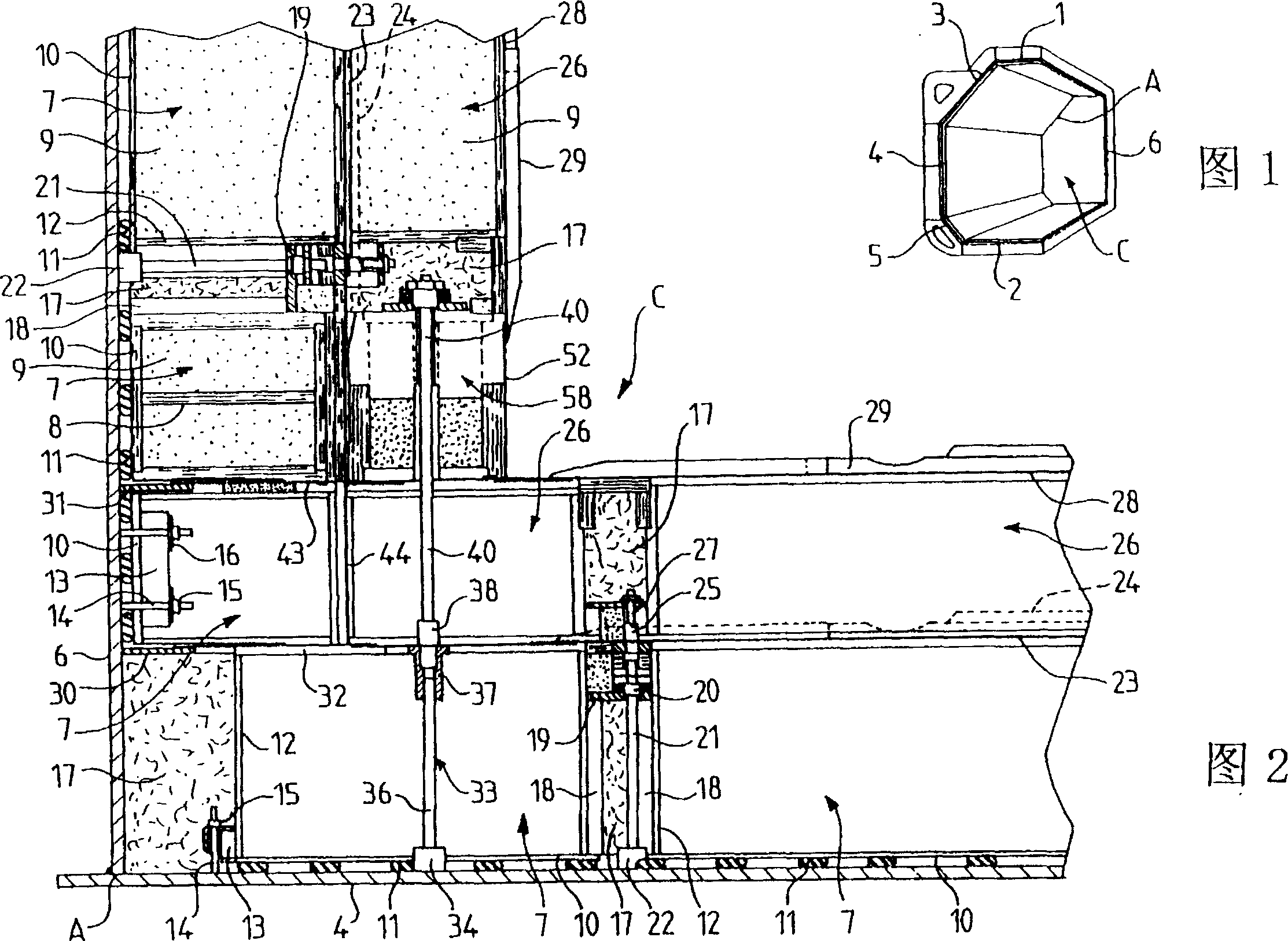

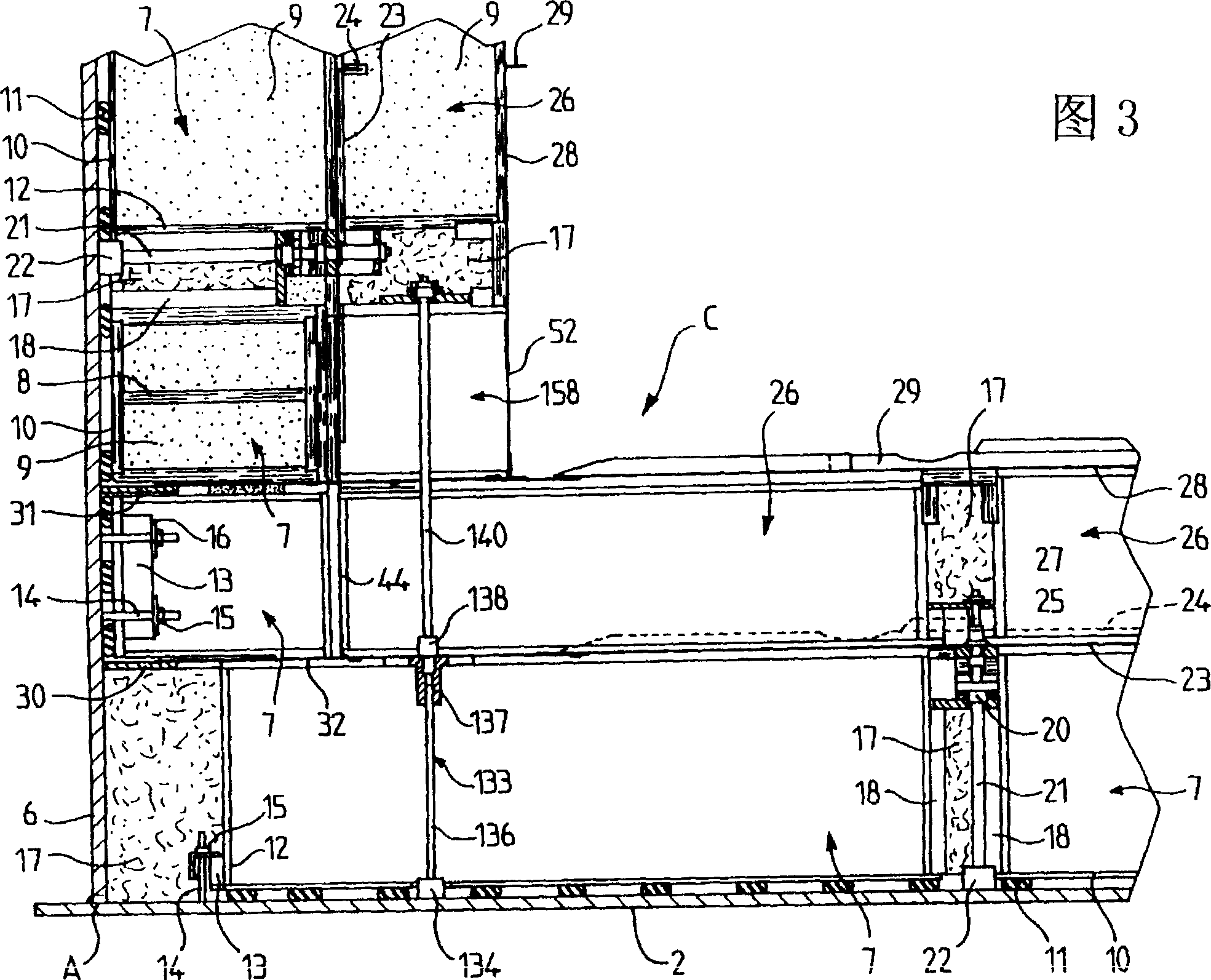

[0031] Figure 2 partially shows a corner of a tank C of the invention formed between a transverse bulkhead 6 of a double bulkhead separating the two tanks and an internal side 4 of the double hull of the ship , the transverse partitions 6 and side walls 4 forming part of the supporting structure of the tank form between them an angle of 90° and define a solid angle of intersection A. These transverse bulkheads are assembled on the longitudinal walls of the tank by welding.

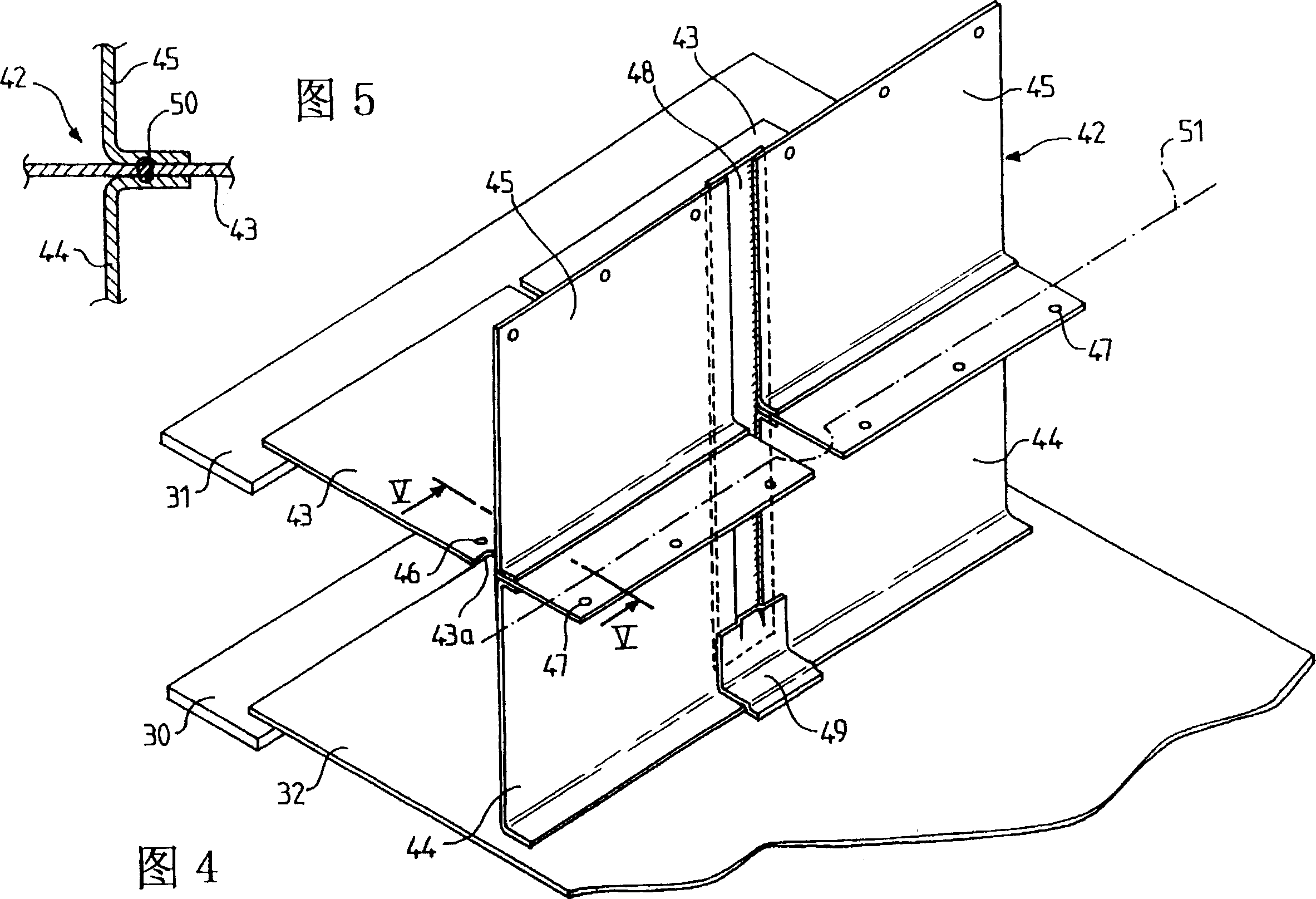

[0032] In a well-known manner, the tank has a second insulating barrier mounted on the supporting structure of the ship. This second insulating barrier comprises a plurality of parallelepiped thermally insulating and watertight boxes 7 arranged side by side so as to substantially cover the inner surface of the support structure. Each second heat-insulating and waterproof box 7 consists of a parallelepiped box made of plywood, for example, with dimensions of 1.2 m x 1 m. Each watertight box comprises in i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com