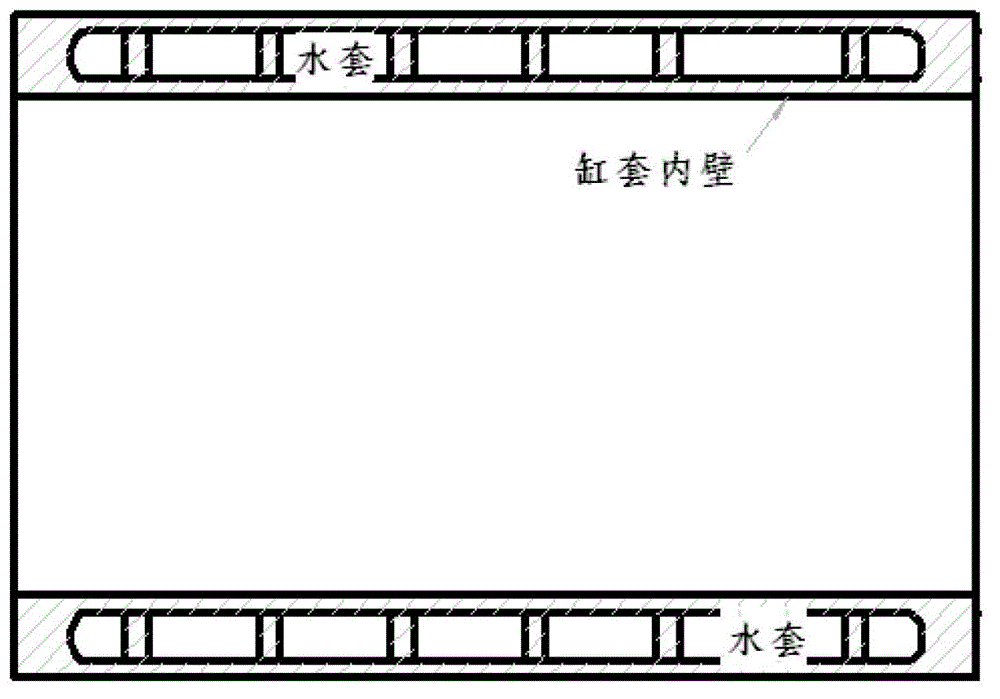

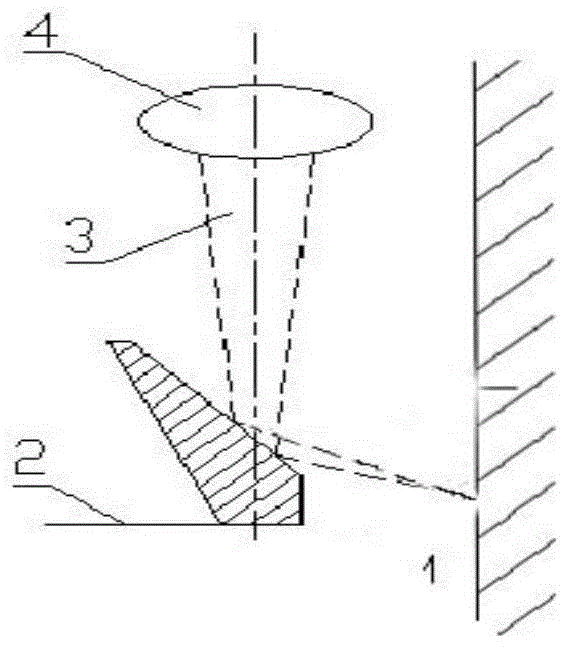

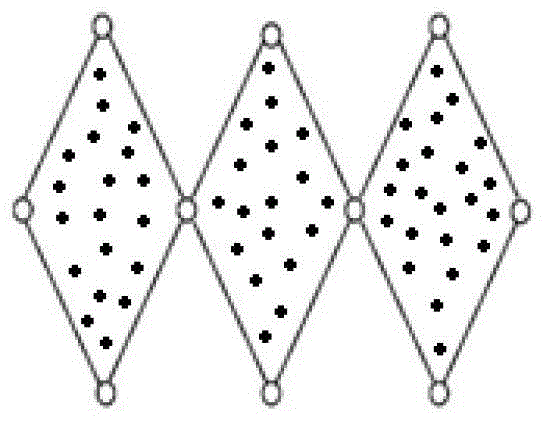

Cylinder sleeve inner wall oil circuit structure and production method thereof

A cylinder liner and oil circuit technology, which is applied in the direction of cylinders, mechanical equipment, manufacturing tools, etc., can solve the problems of increasing the oil storage capacity of the inner wall of the cylinder liner, the smoothness of the inner wall of the cylinder liner, and the wear of the engine liner, so as to reduce the emission. , The method is simple, and the effect of increasing the oil storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0037] Examples 1-5, a cylinder liner inner wall oil passage structure and its preparation method, the parameters of the cylinder liner inner wall oil passage structure are shown in Table 1 below; the laser process parameters are shown in Table 2 below.

[0038] Table 1. Structural parameters of the oil circuit on the inner wall of the cylinder liner in the embodiment

[0039]

[0040]

[0041] Table 2 embodiment laser process parameter

[0042]

[0043] The wear rate of the inner wall of the cylinder liner is 0.04-0.05mm / kh, and the oil consumption is 1.0-1.4g / kw.h; the surface of the inner wall of the cylinder liner of the present invention has regularly distributed point-shaped and linear lubricating oil passages Structure, the wear rate is 0.025~0.03mm / kh, the wear resistance is 1~2 times higher than the original, the fuel consumption is reduced by 20%~25%, the cylinder liner wear is reduced from 5um to 2.5um, and the emission of hydrocarbon particles is reduced b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com