Patents

Literature

154results about How to "Guaranteed drilling accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process method of pipe whip restraint steel structure of main power house of nuclear power station conventional island

ActiveCN101862942AImprove perforation rateReduce distortionArc welding apparatusBoring/drilling machinesNumerical controlGusset plate

The invention belongs to the technical field of pipe whip restraint steel structures of main power houses of nuclear power station conventional islands, in particular to a production process method of the pipe whip restraint steel structure of the main power house of the nuclear power station conventional island, which comprises the lofting process, the marking-off and scribing process, the cutting processing process, the bevel processing process, the hole-making process, the correction process, the polishing surface, the material splicing process, the pre-splicing process of a steel member, the assembly process, the processing process of a friction surface, the welding process of the steel structure and the anti-slip test of the friction surface of the steel member before leaving a factory, sandblasting, derusting and coating of a base coat are carried out in the factory, and the production of the steel structure is divided into the production processing of a welded H-shaped steel column, the production of a steel beam, the assembly and the welding of a support part, the production of a combined steel beam, the assembly and the welding of a girder box body and an inclined support below the girder box body, and the assembly and the welding of a pipe whip restraint key. The production process method can improve the drilling precision, utilize a numerical control planar drilling machine to complete the drilling on a gusset plate, determine a variety of processing processes and welding process parameters, and ensure the dimension of the member after the assembly and the smooth proceeding of field installation.

Owner:EAST STEEL STRUCTURE BRIDGE

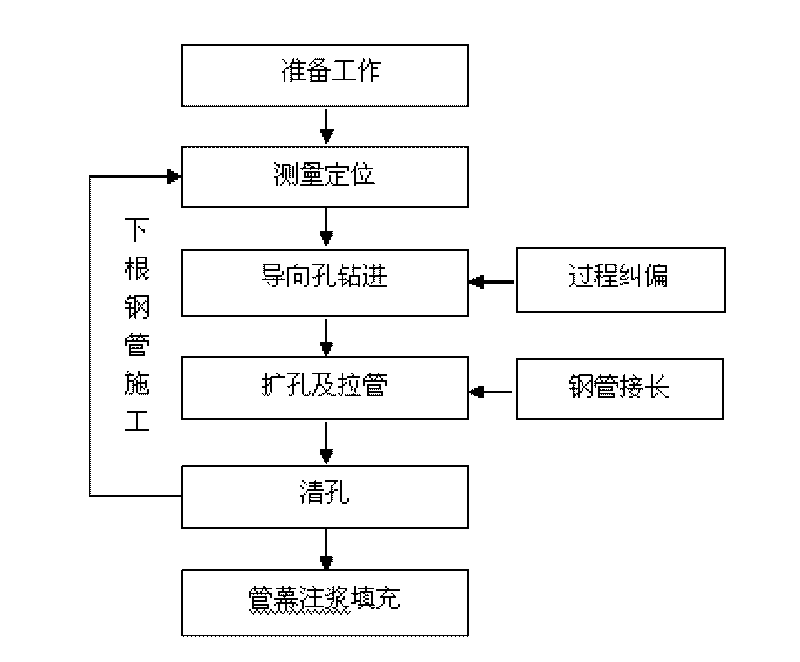

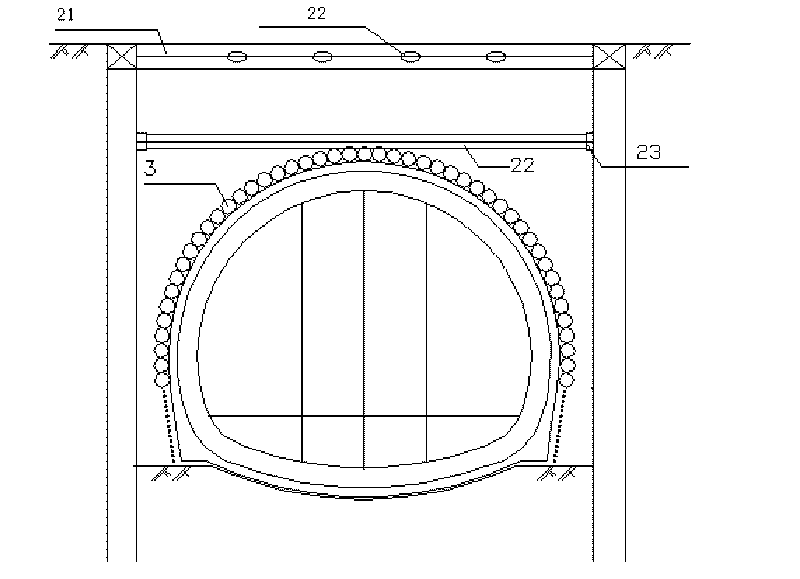

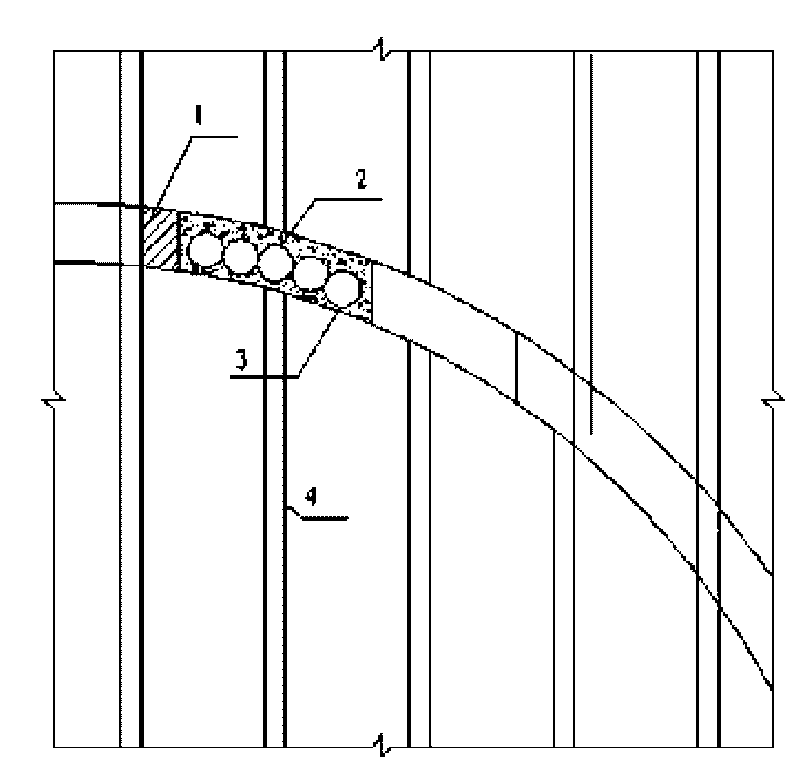

Beneath-soil through-tunnel superlarge diameter pipe curtain construction method

ActiveCN101737060AAvoid disturbanceGuaranteed drilling accuracyUnderground chambersDirectional drillingSoil massLevel crossing

The invention discloses a beneath-soil through-tunnel superlarge diameter pipe curtain construction method. The method comprises the following construction steps of: preparation, measurement and positioning, guide hole drilling, process correction, reaming and pipe drawing, hole cleaning and pipe curtain grouting. In the method, the guide hole is constructed in a soil layer first, and a steel tube in superlarge diameter is drawn in the guide hole in a mode of reaming and drawing the tube at the same time, so that the disturbance on the soil layer in construction is effectively avoided; and a wedge-shaped drill bit provided with a guide plate is used for the process correction in the construction of the guide hole, so that the drilling precision and the hole forming quality are highly guaranteed. In the construction, the sedimentation of the soil mass on the middle-upper part meets the safety requirements of the existing line. After excavation, the steel pipes are nearly flat and straight, no phenomenon of level-crossing and interchanging occurs and the construction method of the invention creates conditions for water resistance and lining construction of the tunnel.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

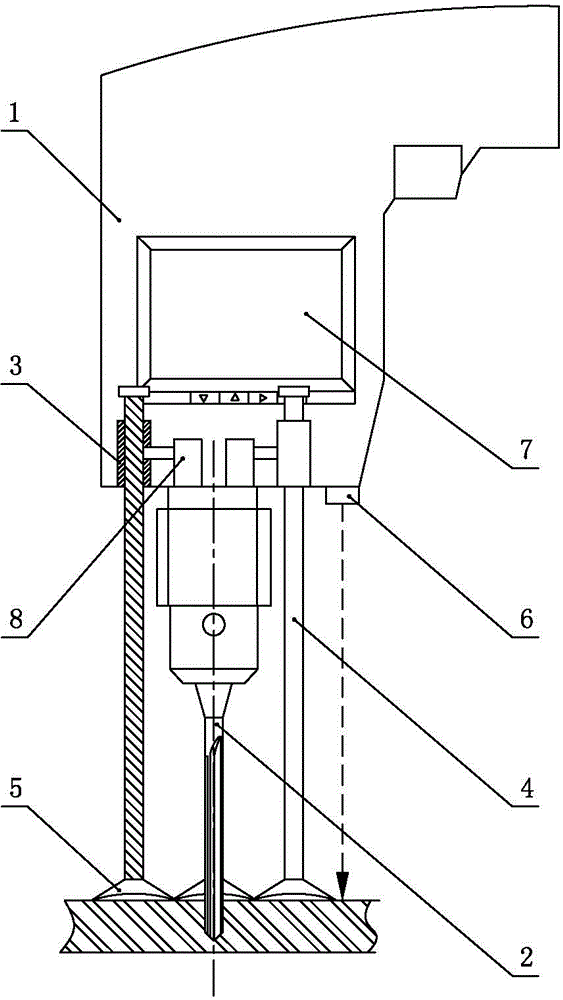

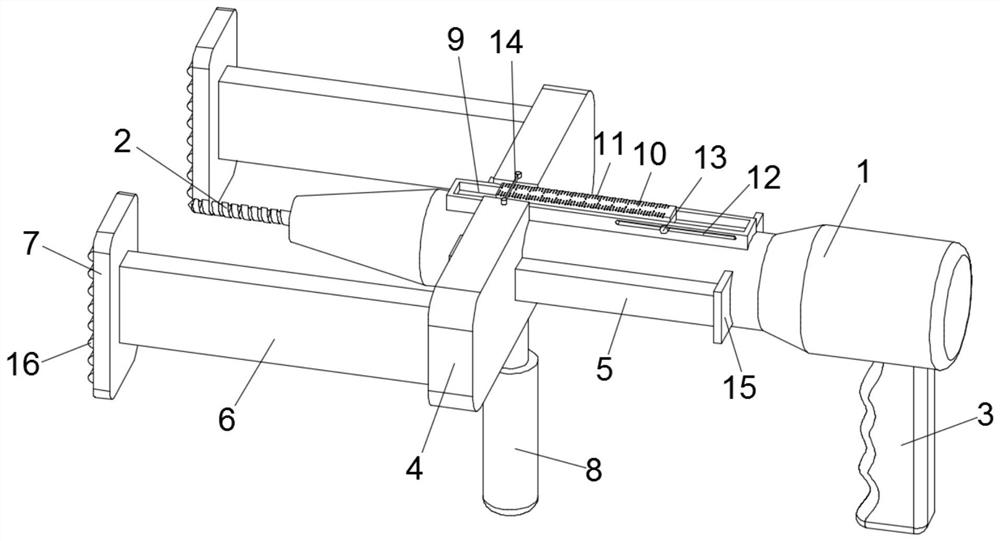

High-precision electric drill capable of conducting positioning

InactiveCN104526010AGuaranteed accuracyGuaranteed drilling accuracyDrilling/boring measurement devicesMeasurement/indication equipmentsDrill bitElectrical and Electronics engineering

The invention discloses a high-precision electric drill capable of conducting positioning. The high-precision electric drill comprises a shell, a drill bit, a motor and a transmission mechanism, wherein the motor and the transmission mechanism are arranged in the shell, the drill bit is connected with the motor in a transmission mode through the transmission mechanism, a sleeve is arranged on the shell, a positioning rod is arranged in the sleeve, the positioning rod and the sleeve are vertically connected in a sliding mode, and a positioning piece can conduct positioning on the surface of a workpiece is arranged at the lower end of the positioning rod. When the high-precision electric drill is used, the positioning rod is installed near a hole to be machined first, switch-on of a motor power supply is subjective to to-be-machine hole coverage achieved by the shallow, on the surface of the workpiece, of the drill bit, the sleeve arranged on the positioning rod in a sleeving mode plays a role in guiding the drill bit, and therefore the accuracy of the drilling position and the perpendicularity of a hole are ensured.

Owner:滁州用朴合金工具有限公司

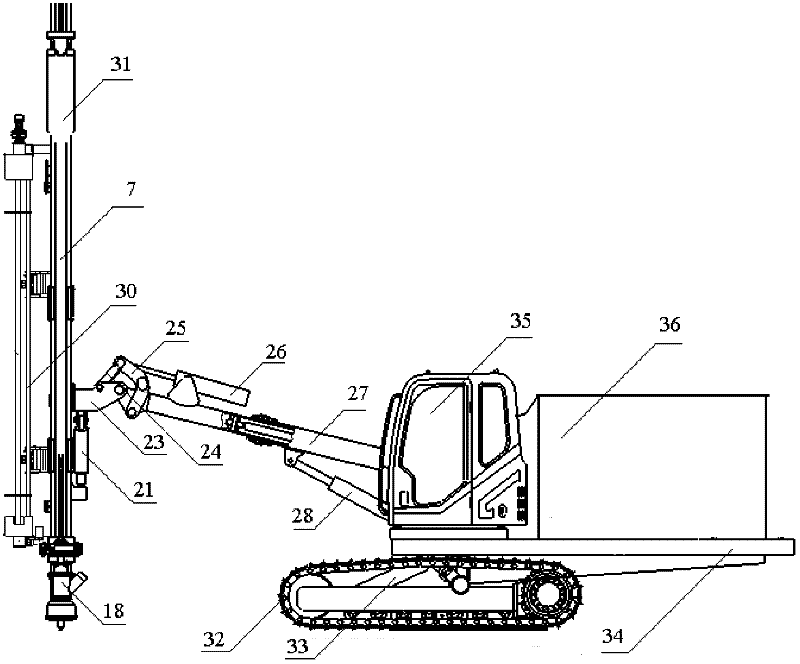

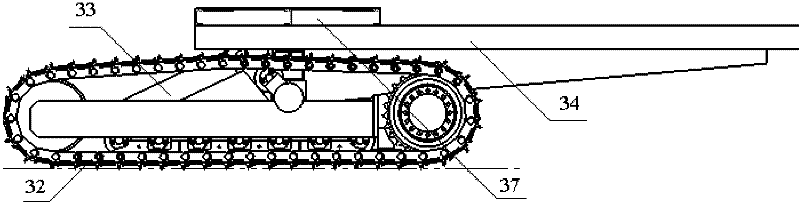

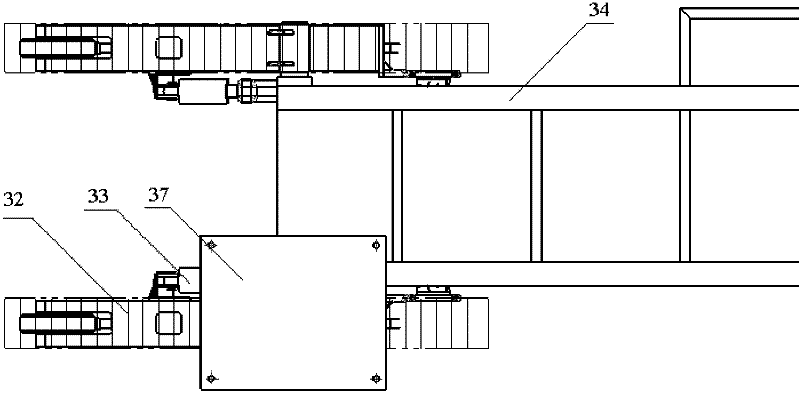

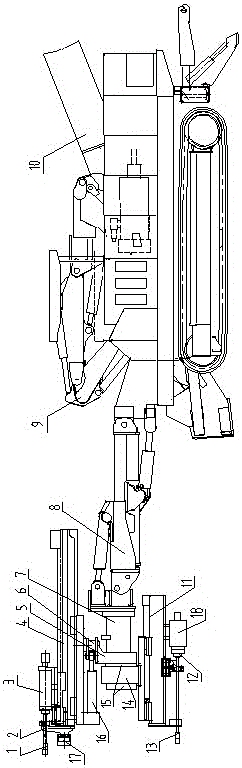

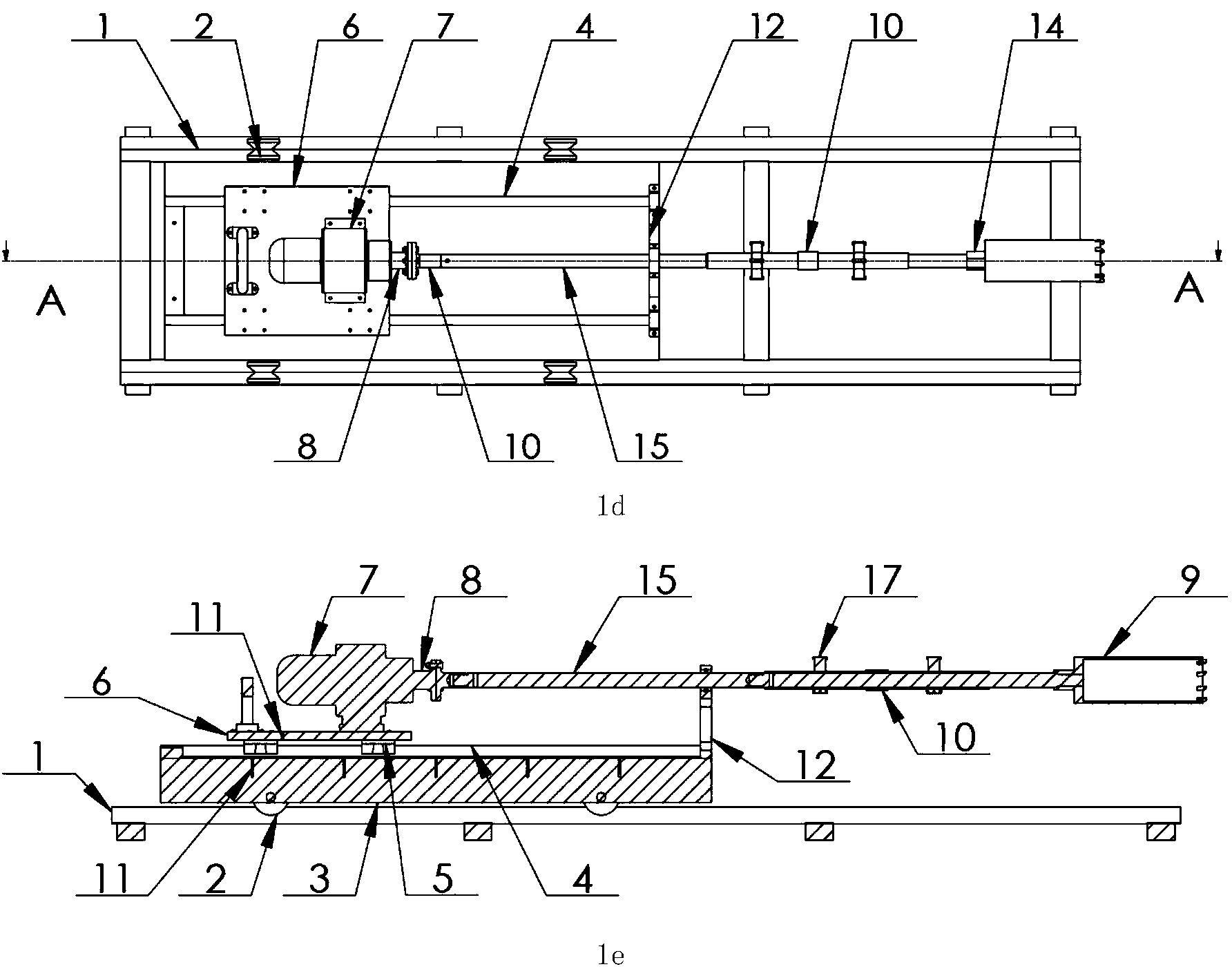

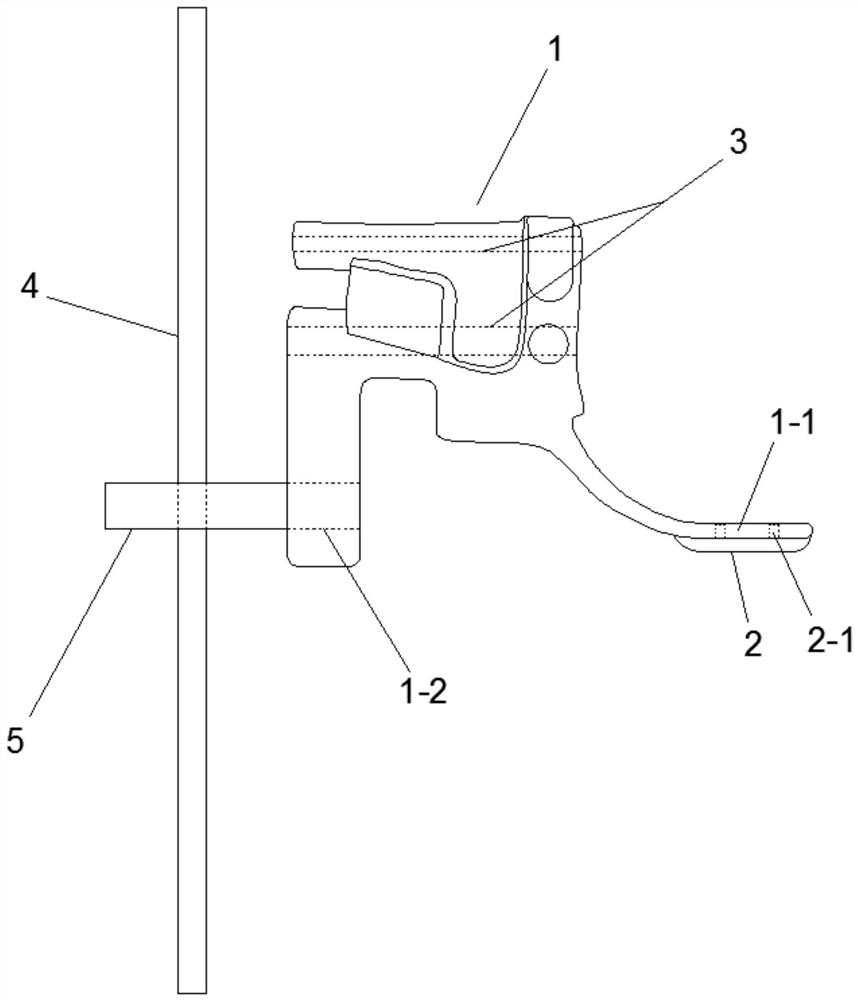

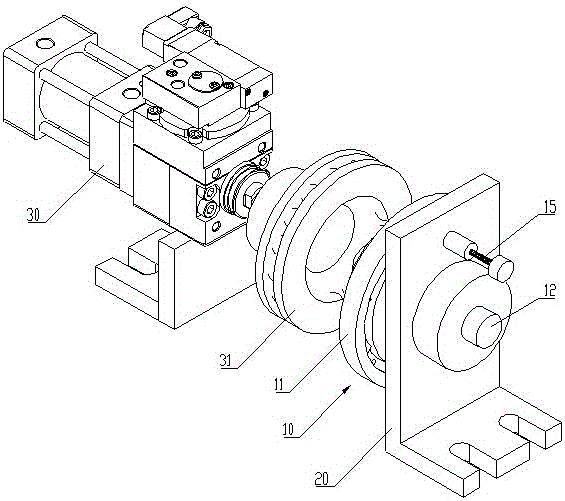

Telescopic arm open-cut rock drilling jumbo with drill rod replacing device

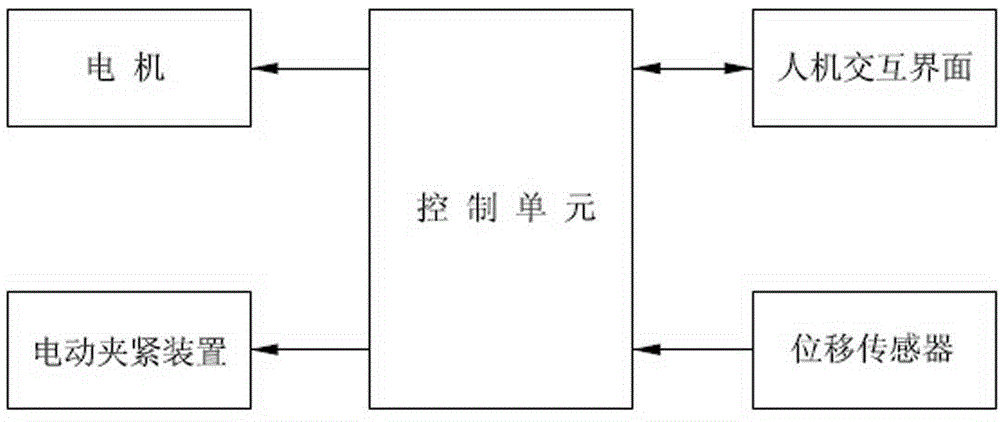

InactiveCN102418475AReduce design sizeReduce wearDrilling rodsDrilling casingsControl systemPropeller

The invention relates to a telescopic arm open-cut rock drilling jumbo with a drill rod replacing device. The telescopic arm open-cut rock drilling jumbo comprises a cab, a chassis assembly, a propeller assembly, a telescopic arm, the drill rod replacing device, a rock drill, a control system and a power and air control system 36; the cab is arranged on a cab bottom plate of the chassis assembly, the control system is arranged in the cab, and the control system is connected with the power and air control system; the telescopic length, the pitching angle and the deflection angle of the telescopic arm, the elongation of a propelling beam and the pitching angle of the cab are controlled by the control system; the arm seat of the telescopic arm is fixedly arranged at the front end of the cab, the propelling beam is in sliding fit with the telescopic arm through a bracket on a compensation cylinder, the telescopic end of the compensation cylinder is fixedly connected to the propelling beam, and extending compensation of the propelling beam can be realized by stretching of the compensation cylinder; and the drill rod replacing device is fixed on the propelling beam and positioned below a transmission rod, and the rock drill is fixed at the upper end of the propelling beam. The multi-azimuth drilling requirement of the jumbo can be met, and the gravity center of the whole jumbo is kept stable.

Owner:CSIC ZHONGNAN EQUIP

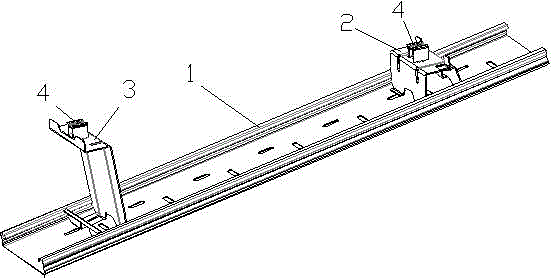

Multi-angle coal petrography drilling machine

The invention discloses a multi-angle coal petrography drilling machine relating to a drilling machine used for pumping gas under a coal mine. The multi-angle coal petrography drilling machine mainly comprises a horizontal guide rail, a lifting guide rail, a base, a drill rod and a motor, wherein the horizontal guide rail is connected with the lifting guide rail by a sliding sleeve arranged on the lifting guide rail, the sliding sleeve is symmetrically provided with two obliquely stretching supporting arms connected with the horizontal guide rail, two ends of the horizontal guide rail are provided with downward stretching supporting arms which are vertically downward, a drill rod driving seat is arranged in a track groove of the horizontal guide rail, and a thrust cylinder is also arranged in the track groove of the horizontal guide rail. The machine simplifies the structure of the drilling machine, and saves cost; and the drilling machine has a small volume, is convenient to use in a narrow mine, and can realize the drilling operation at various angles under the condition that the position of the drilling machine is not moved.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD

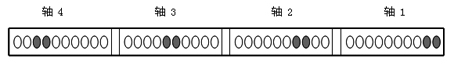

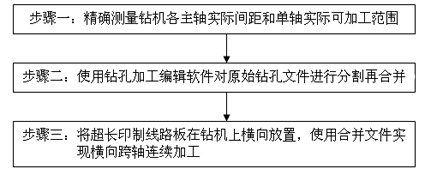

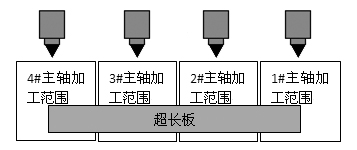

Method for transverse shaft-crossing drilling of drilling machine

InactiveCN101947659AReduce scratchesAvoid Positioning EffectsPrinted circuit manufacturePrinted circuit boardMachining

The invention relates to the field of manufacturing of printed circuit boards, in particular to a method for transverse shaft-crossing drilling of a drilling machine. The method comprises the following steps of: measuring, namely measuring the interval between every main shaft of the drilling machine and an actual machinable range of a single shaft; merging a file, namely partitioning an original drilling file by using drilling editing software, and merging the partitioned original drilling file to form a merged file for the transverse shaft-crossing drilling; and machining, namely transversely placing an overlong printed circuit board on the drilling machine for continuous transverse shaft-crossing machining by using the merged file. The method for the transverse shaft-crossing drilling of the drilling machine has the advantages of continuously finishing drilling the overlong printed circuit board on a common multi-shaft drilling machine at one time, avoiding repeatedly positioning by pins and operation of disassembling and assembling plates, reducing scratches on the plate surface, guaranteeing the drilling precision, simultaneously improving the production efficiency and product passing rate to the utmost.

Owner:GCI SCI & TECH

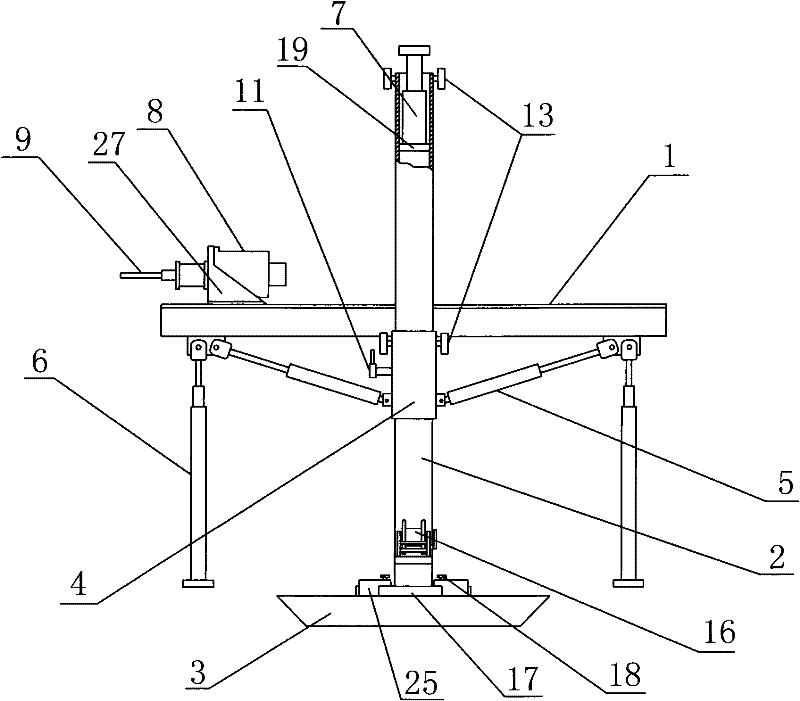

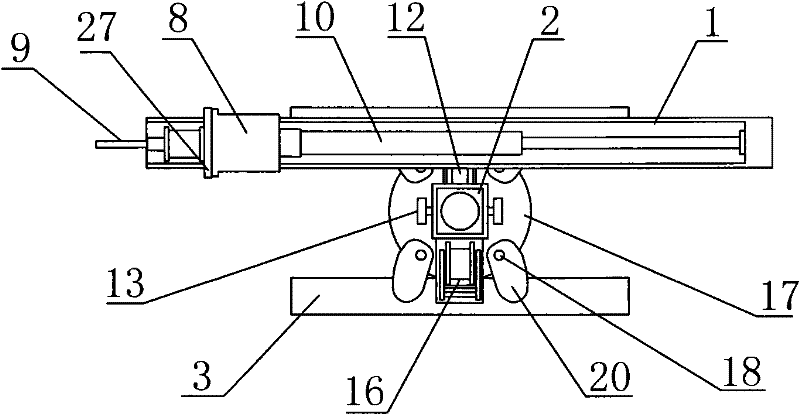

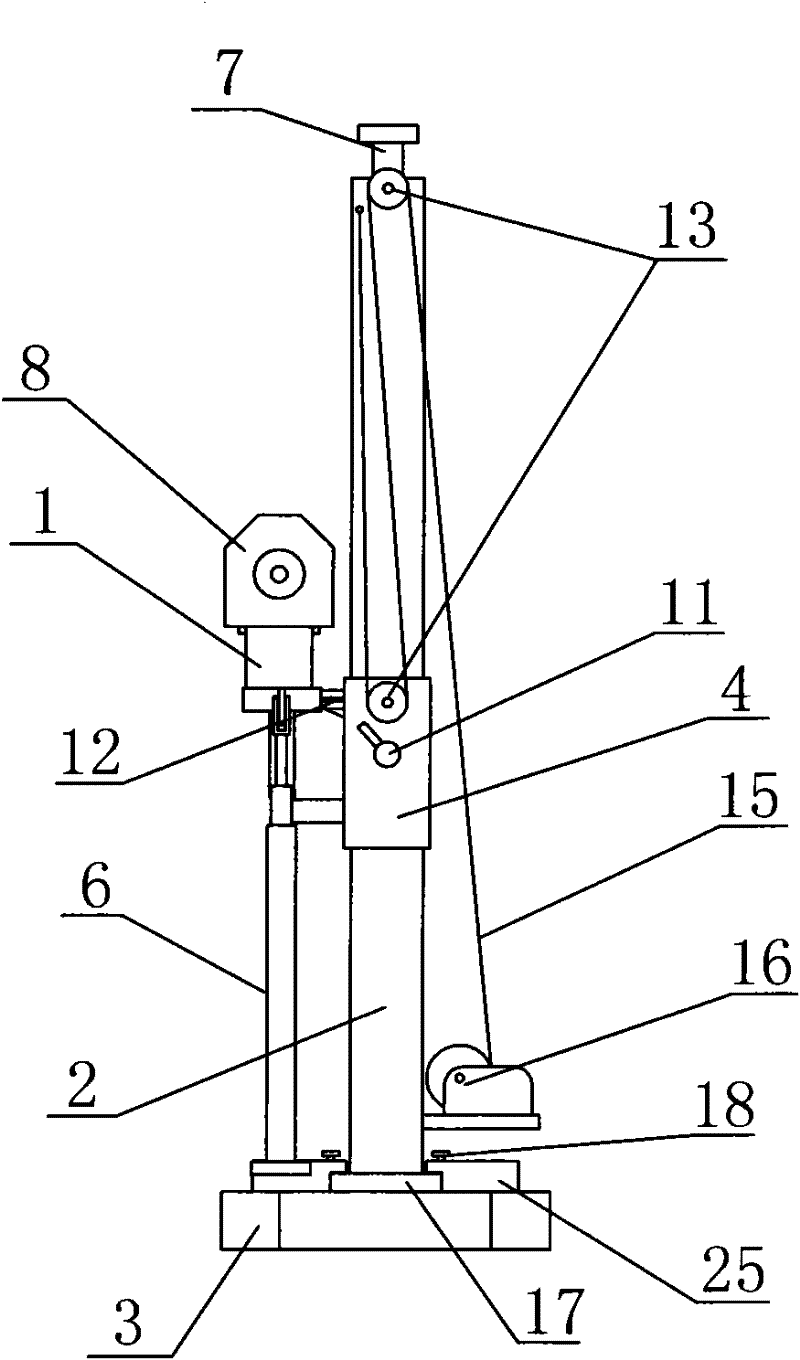

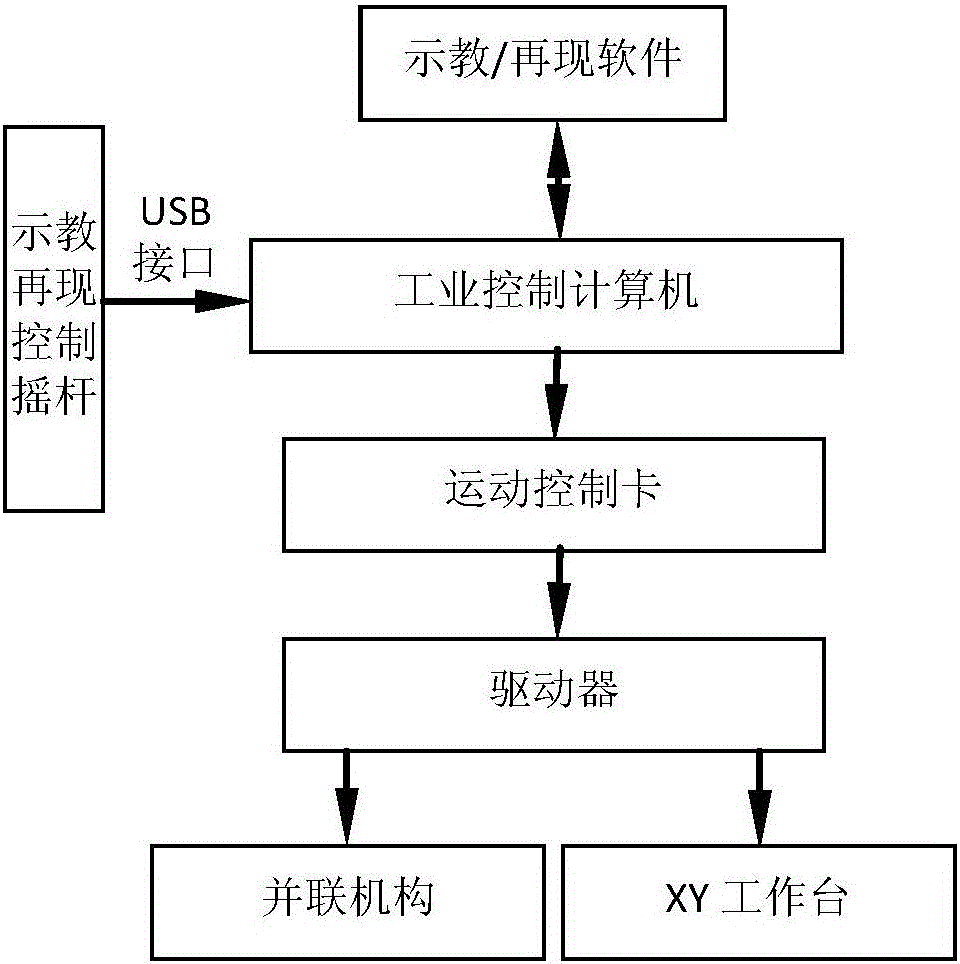

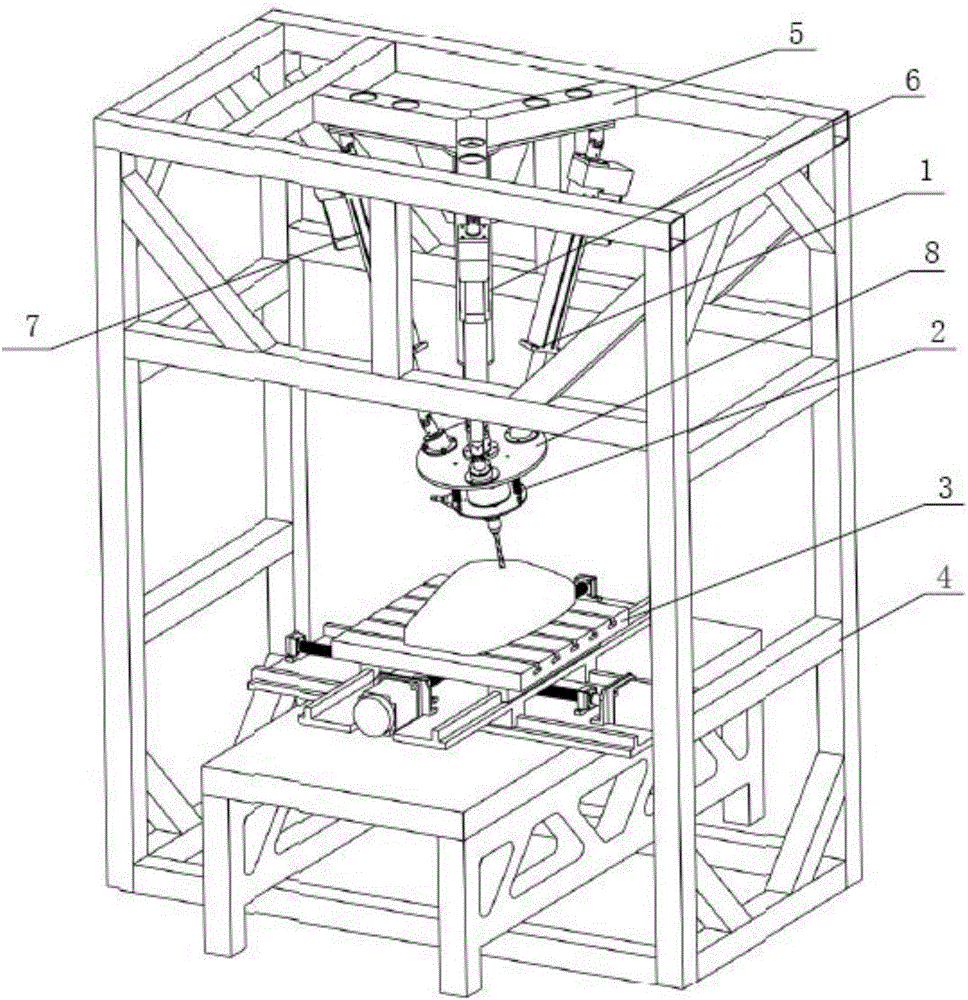

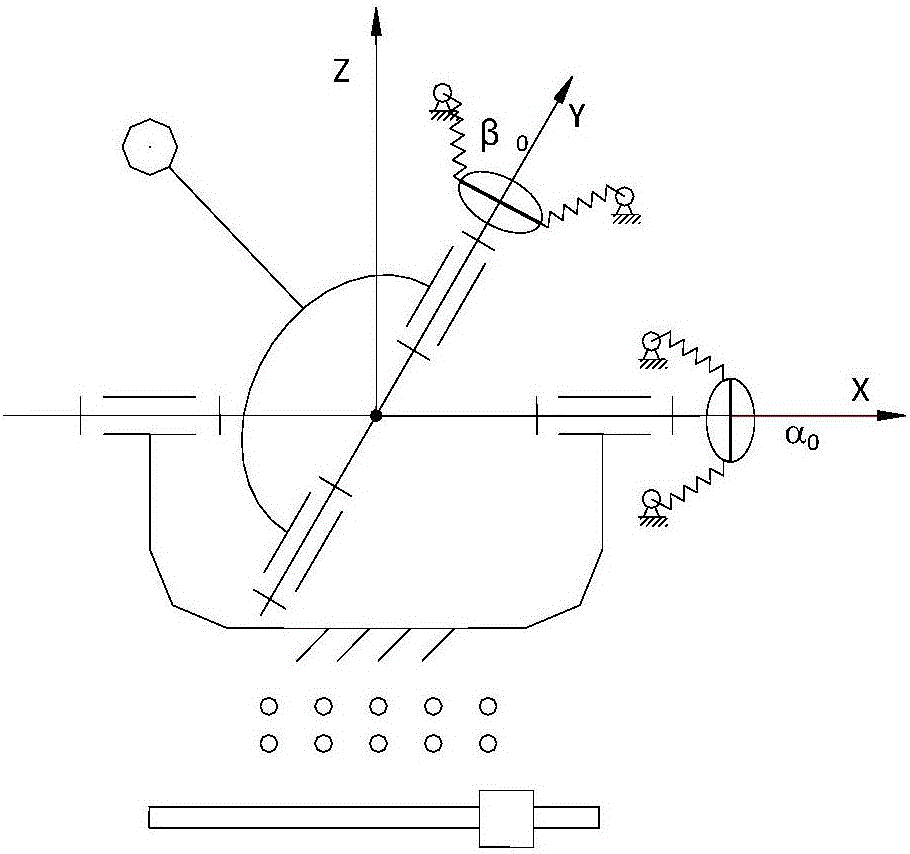

Parallel drilling machine teaching/playback system

InactiveCN106313007ASolving Rapid Repeat Drilling ProblemsImprove ergonomicsProgramme-controlled manipulatorAttitude controlEngineering

The invention discloses a parallel drilling machine teaching / playback system which comprises an industrial control computer, a motion control card, a teaching / playback control rocker and a parallel drilling machine, wherein a teaching / playback system is arranged in the industrial control computer; the teaching / playback control rocker is connected with the industrial control computer through an interface; according to a control instruction of the teaching / playback system, all drivers on the parallel drilling machine are controlled by the motion control card to perform corresponding action; and the teaching / playback system comprises a parallel mechanism attitude control module, an XY workbench translation control module, a teaching point memory module, an action playback module, a teaching point insertion module and a teaching point deletion module. By adoption of the parallel drilling machine teaching / playback system disclosed by the invention, a hole drilling process of the parallel drilling machine under the condition of the same workpiece can be repeatedly played back, so that a series of holes with different attitudes can be repeatedly drilled by the parallel drilling machine on the same workpiece, and the working efficiency of the hole drilling operation can be improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

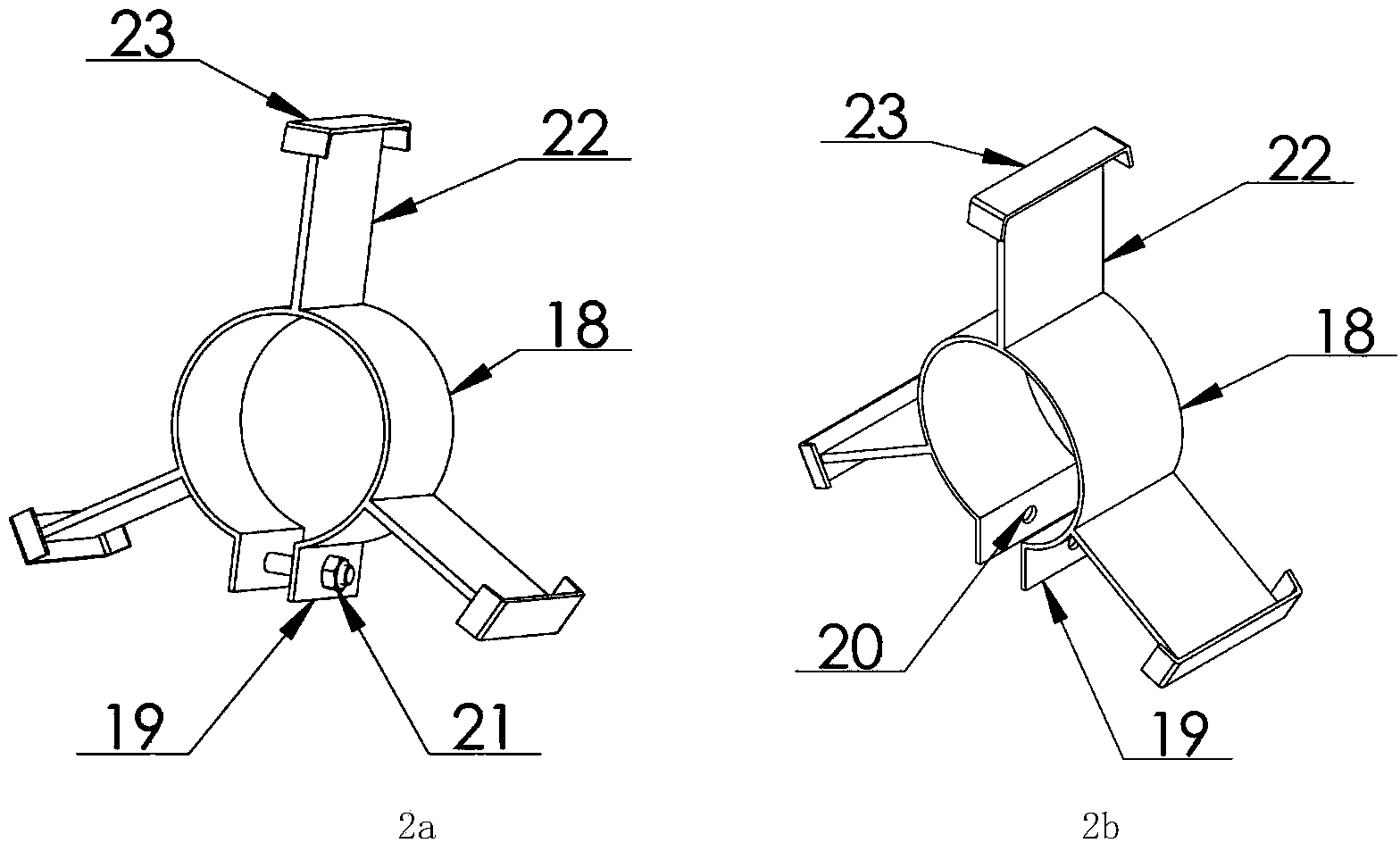

Double-arm four-drill drilling, anchoring and loading integrated machine

ActiveCN105781415AWith translation functionGuaranteed drilling accuracyDerricks/mastsAnchoring boltsCantileverDrill

The invention discloses a double-arm four-drill drilling, anchoring and loading integrated machine. The double-arm four-drill drilling, anchoring and loading integrated machine comprises two drilling arms (8), one excavation work arm (9) and a scraper conveying groove (10), wherein a long sliding rack (4) and a short sliding rack (11) are arranged on each drilling arm, a rock drill (3) for drilling a roadway head-on blasthole and a water and gas exploring engineering hole is arranged on the long sliding rack, a jumbolter (18) for drilling an anchor bolt hole or an anchor rope hole in a roofing and two roadway sides is arranged on the short sliding rack, the drilling arms are connected with the long sliding rack and the short sliding rack by a connecting mechanism, the connecting mechanism comprises a front-rear screw swinging mechanism (7) connected with the drilling arms, a support base (5) is arranged at one end of the front-rear screw swinging mechanism, the long sliding rack is movably connected with the support base by a connecting base (6), a cantilever support (15) with adjustable height is arranged at one side of the support base, and a horizontal screw swinging mechanism (14) is arranged on the cantilever support. The double-arm four-drill drilling, anchoring and loading integrated machine has complete drilling function, can perform excavation, loading and deslagging and has wide operation range.

Owner:JIANGXI LANXIANG HEAVY IND +1

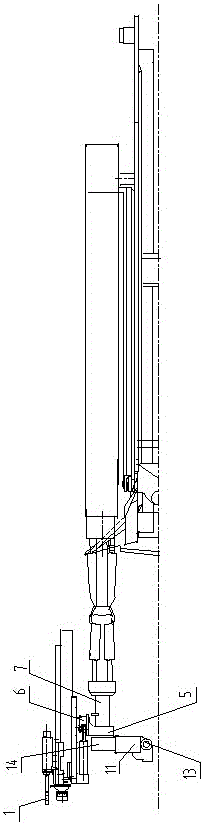

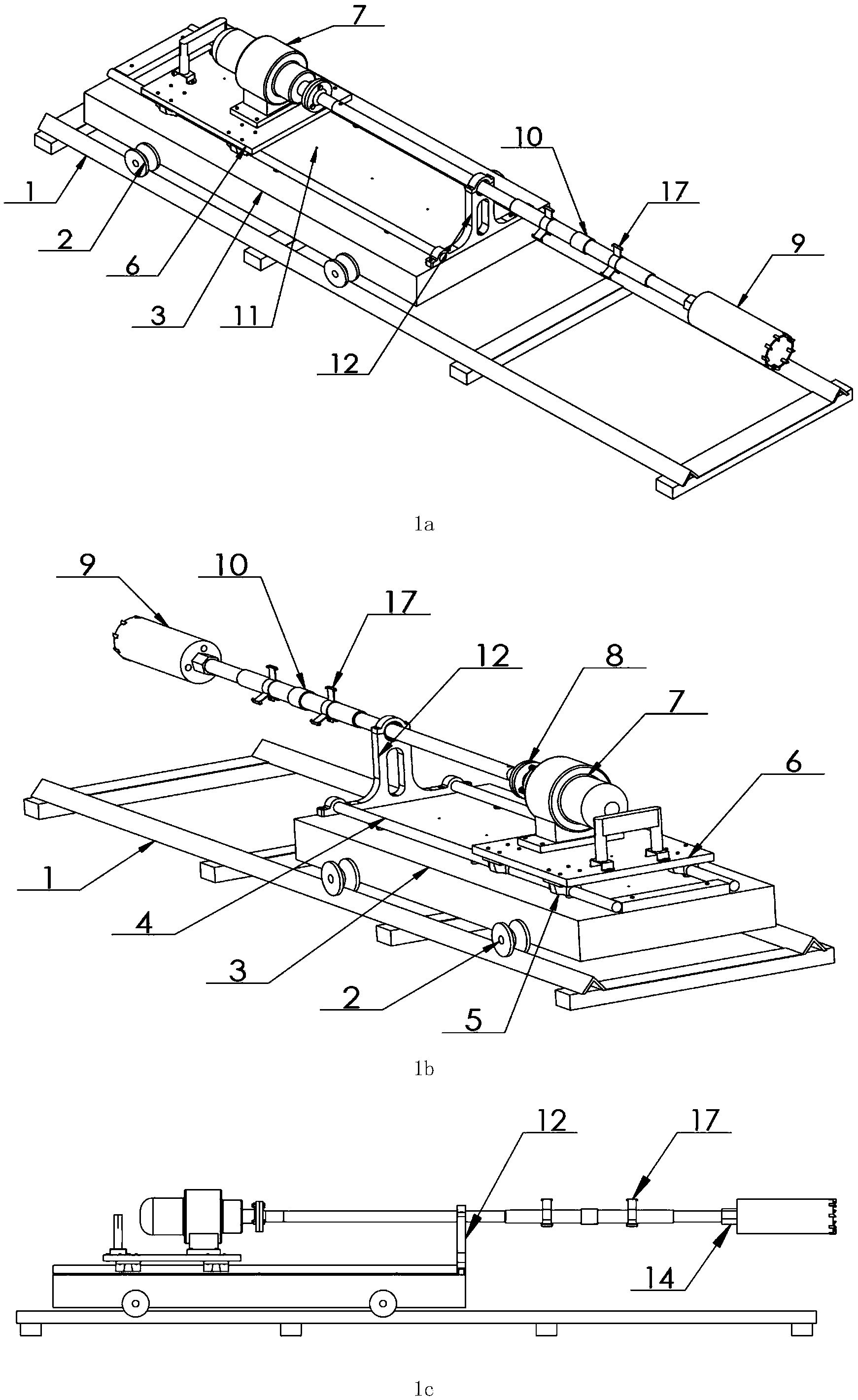

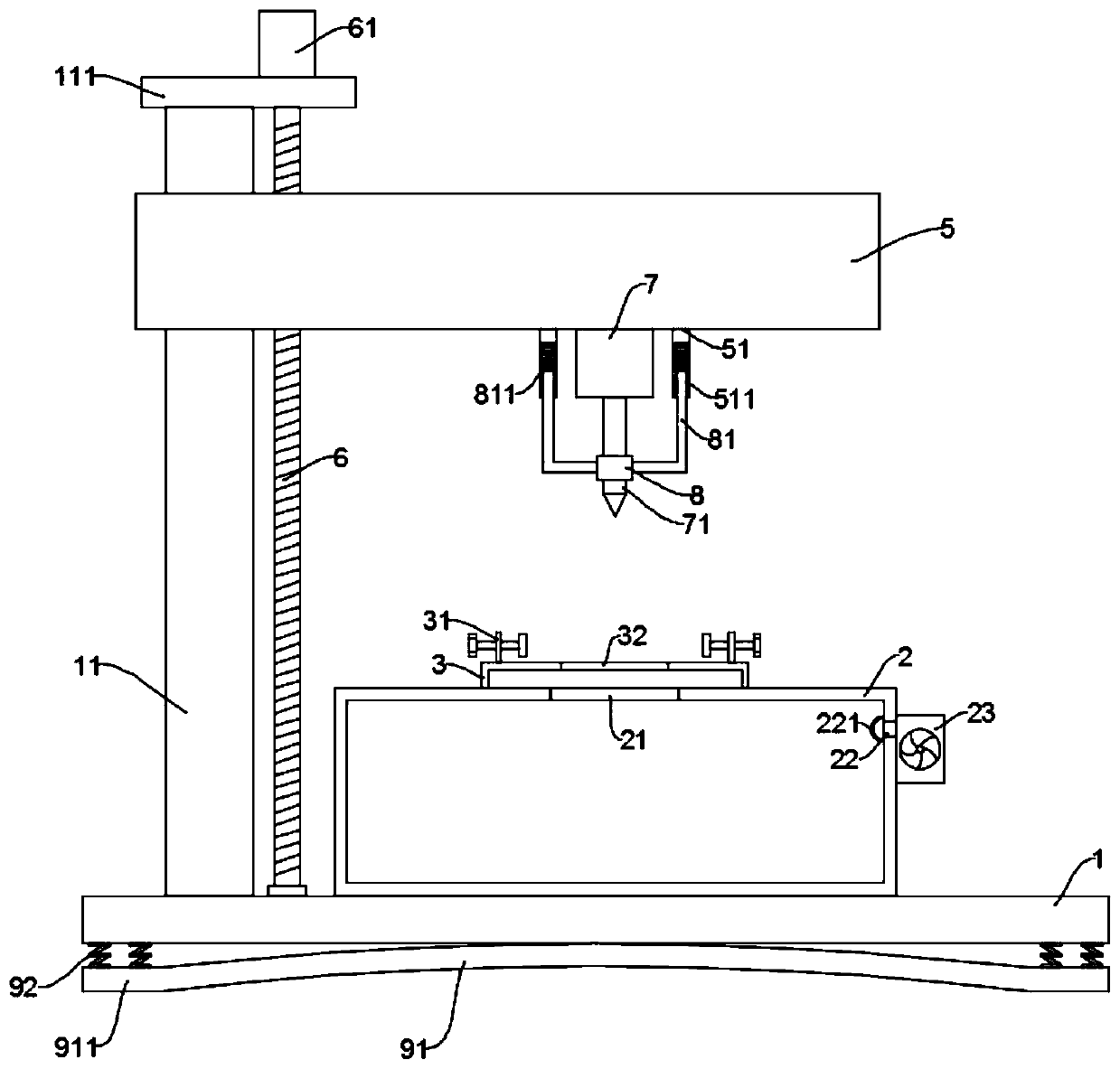

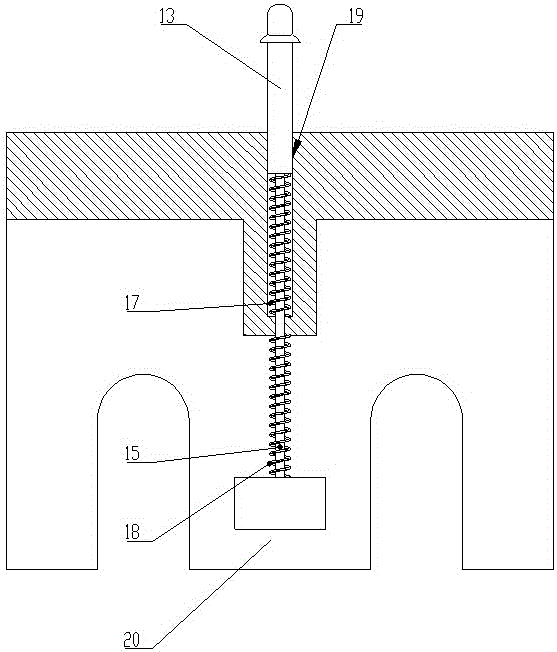

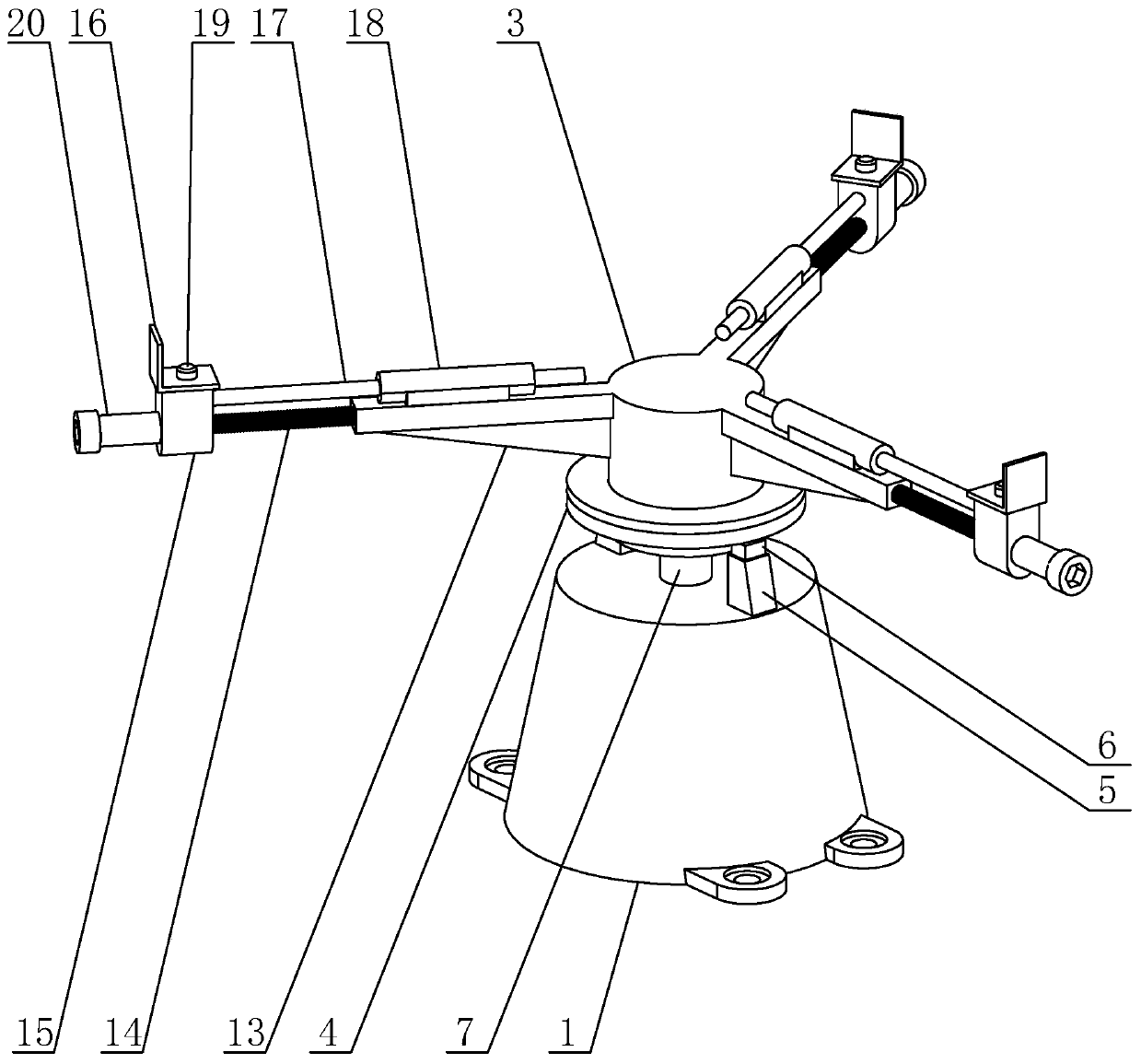

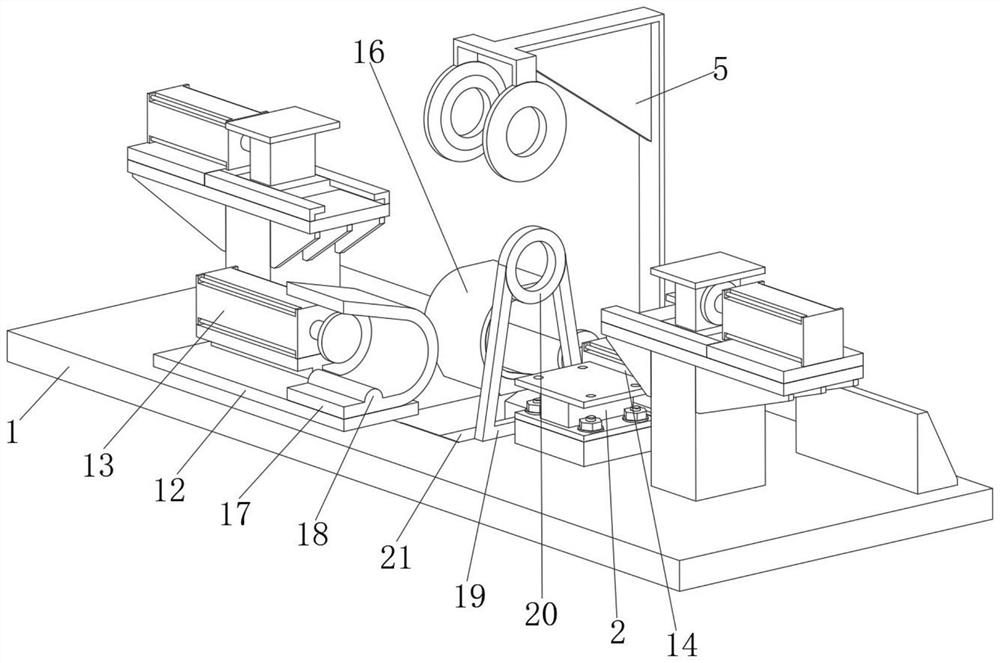

Drilling device for earthen archaeological site

ActiveCN104343383AGuaranteed drilling accuracyWork efficientlyDrill bitsConstructionsGeotechnical engineeringDrill pipe

The invention discloses a drilling device for an earthen archaeological site. The drilling device is characterized in that a bottom plate is mounted on the upper surface of a slideway through two groups of bottom plate rollers; a pair of round guide rails is fixed on the bottom plate, and a motor mounting plate is mounted on the round guide rails through sliders; a gear motor is fixed on the motor mounting plate; a rotating connector is mounted on an output shaft of the gear motor in a sleeving manner; one end of a connecting sleeve is fixedly connected with the rotating connector through a flange, and the other end of the connecting sleeve is in sleeve joint with one end of a drill rod through threads; the other end of the drill rod is connected with a drill; and the drilling rod, the round guide rails and the slideway are parallel. According to the drilling device for the earthen archaeological site, when a drill tube penetrates into the earthen archaeological site continuously, a drill rod jacket arranged on the drill rod in a sleeving manner goes deep into earth mass with the drill rod and is supported on the earth mass through a drill rod support frame, further, the drill rod jacket can move forwards continuously with the drill rod, so that the drill rod is prevented from shaking in a drilling process, the drilling accuracy is guaranteed, safety and reliability are achieved, and the drilling device has the characteristics of convenience, fastness and high work efficiency.

Owner:SHAANXI NORMAL UNIV

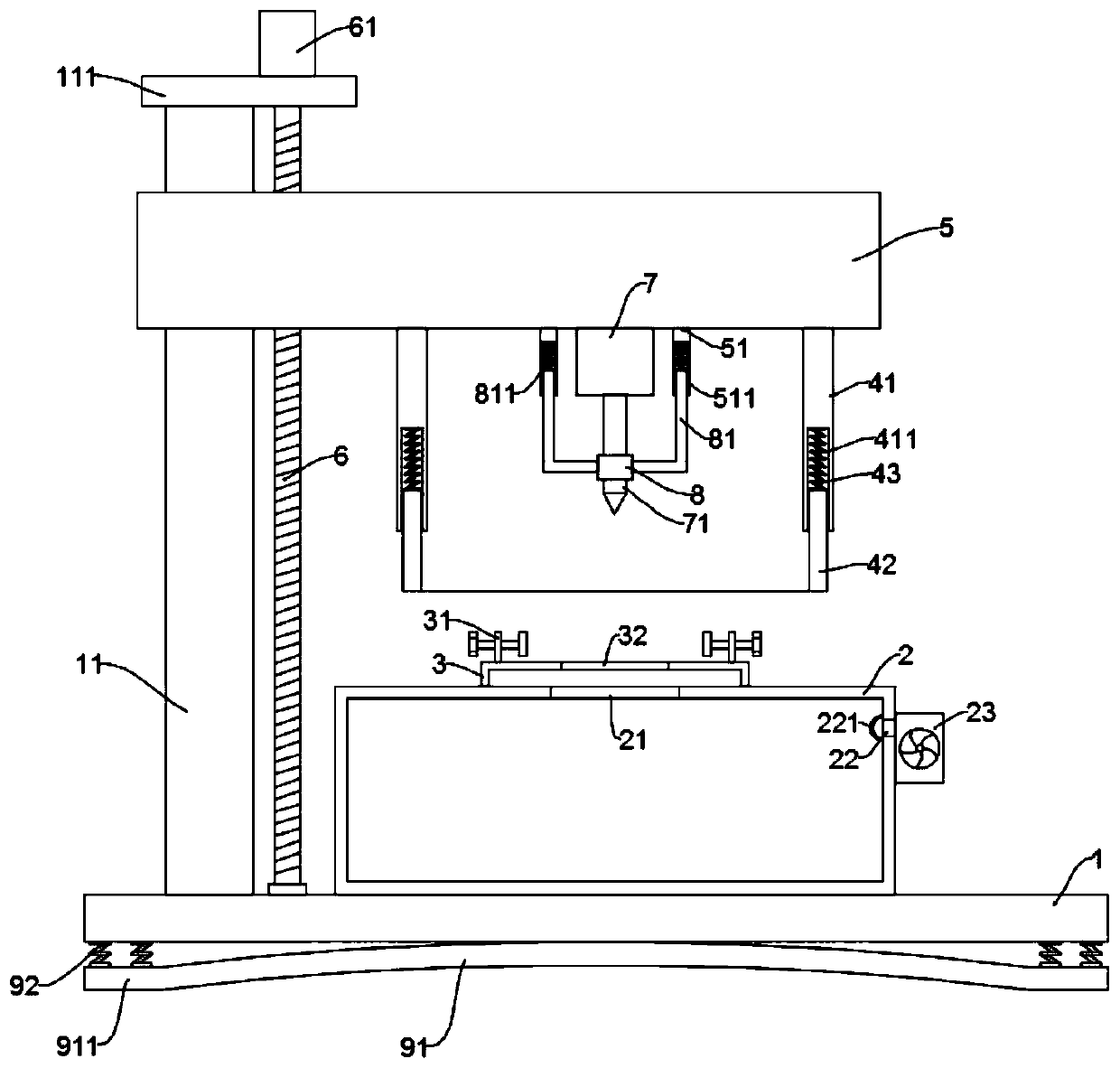

Drilling device for construction metal plates

InactiveCN110052647APrevent slippingGuaranteed drilling accuracyFeeding apparatusPositioning apparatusArchitectural metalsGeotechnical engineering

The invention discloses a drilling device for construction metal plates, and relates to the field of machining. By adoption of the drilling device for the construction metal plates, the problem that atraditional drilling device only positions plates, and consequentially, the drilling precision cannot be ensured is mainly solved. The drilling device comprises a base, a workbench and a movable frame, wherein a rotary motor is mounted at the position, right facing a storage table, of the bottom of the movable frame, and a shaft stretching end of the rotary motor is connected with a drill stem; the periphery of a stem body of the drill stem is slidably sleeved with a positioning sleeve, and L-shaped rods are symmetrically fixed to the two sides of the positioning sleeve; and connecting columns matched with the L-shaped rods are fixed to the bottom of the movable frame and are provided with insertion grooves which are open downwards, and vertical rod bodies of the L-shaped rods are slidably clamped in the insertion grooves. According to the drilling device for the construction metal plates, the positioning sleeve is arranged to position the drill stem when the drill stem makes contactwith the plates, so that slipping of the drill stem is prevented, and the drilling precision is ensured; and meanwhile, the positioning sleeve moves synchronously when the drill stem is fed, so that feeding of the drill stem is avoided.

Owner:吕谋

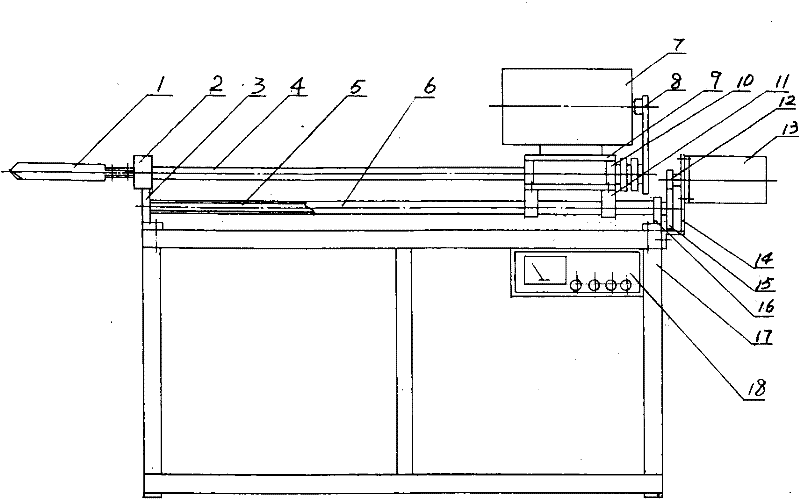

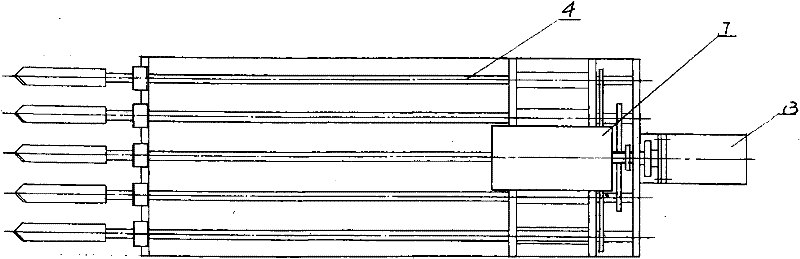

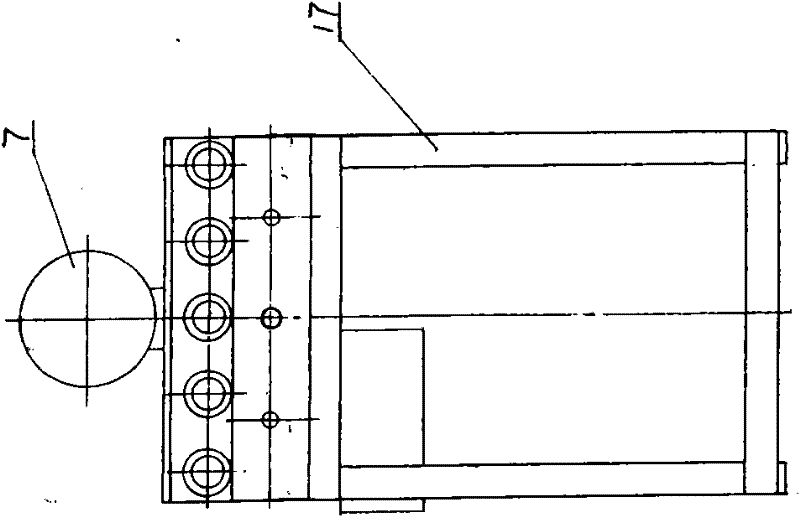

Aerated Concrete Block Horizontal Deep Hole Group Drilling Machine

InactiveCN102259392AMeet the requirements of drilling 1 meter deep holeEasy to assemble and disassembleStone-like material working toolsElectrical controlEngineering

The invention discloses a horizontal deep hole group drilling machine for aerated concrete blocks capable of drilling multiple deep holes on aerated concrete blocks. , Drilling motor, transmission system, motor base, movable drill frame, linear slider, pinion gear, automatic advance and retreat knife motor, motor bracket, large gear, screw bracket, rack, electrical control box, the twist drill is drilled together The rods are connected together, the composite bearing is connected with the guide rod bracket, installed on the left side of the frame, the rear of the drill pipe is connected to the movable drill frame, the drilling motor is connected to the motor base on the movable drill frame, and the knife advances and retreats automatically The motor is fixed on the motor bracket and connected to the upper right side of the frame. The large gear is connected to the automatic advance and retreat knife motor and the screw control. The movable drill frame connected to the linear slider moves forward and backward on the guide rod. The guide rod and the screw rod are installed on the screw rod. On the bracket, the electrical control box is installed on the upper right side of the rack.

Owner:郝钰 +1

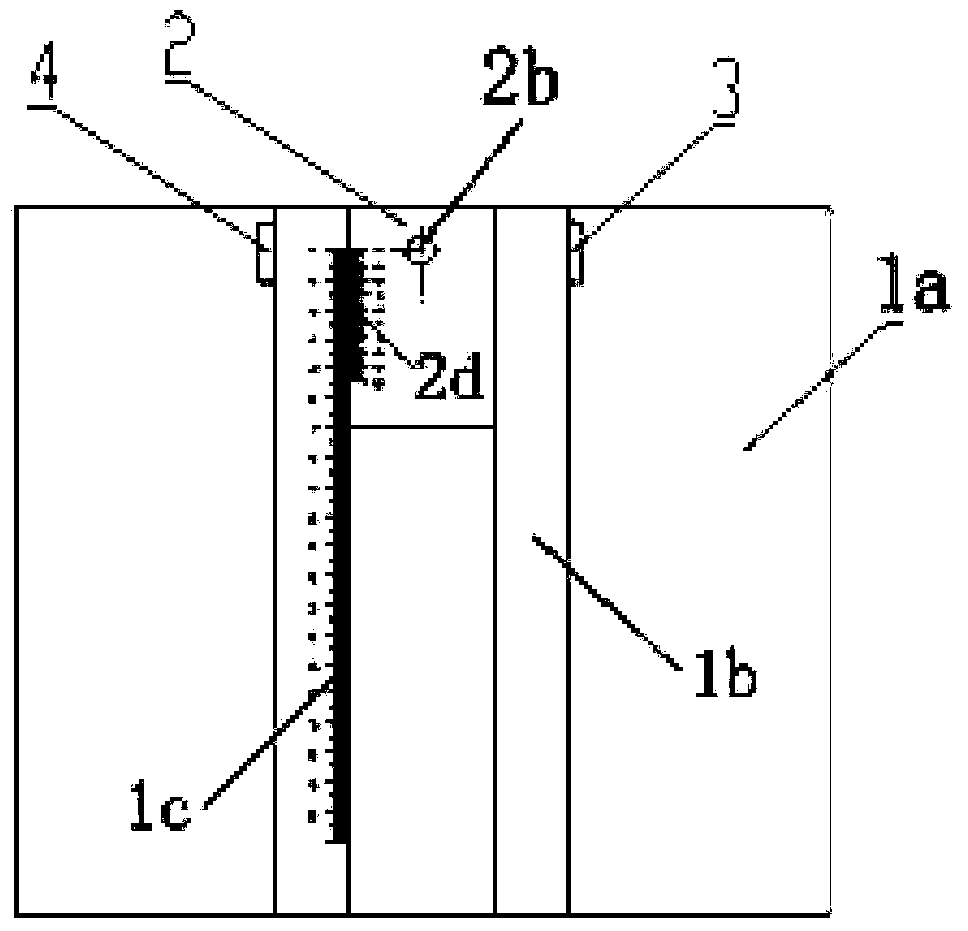

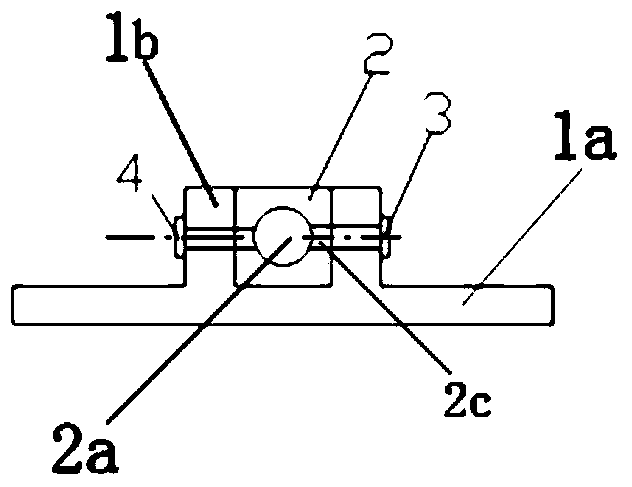

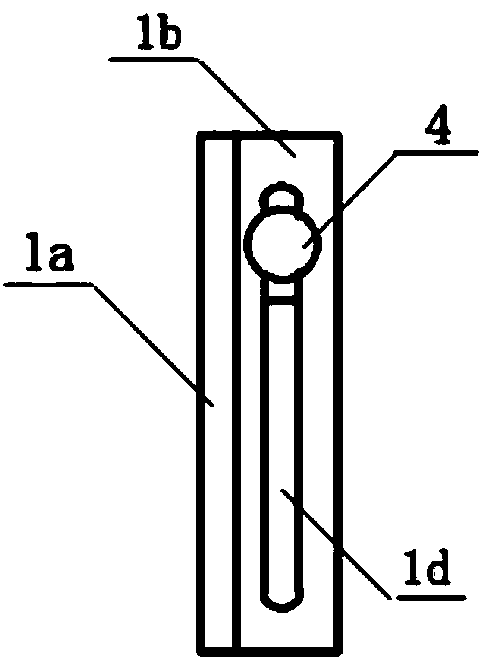

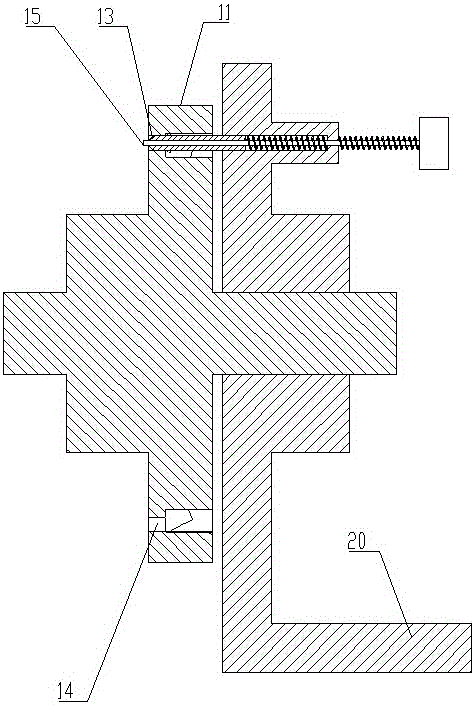

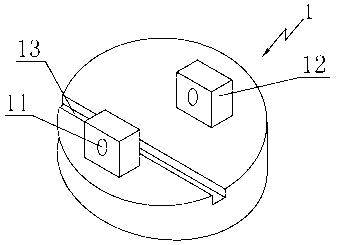

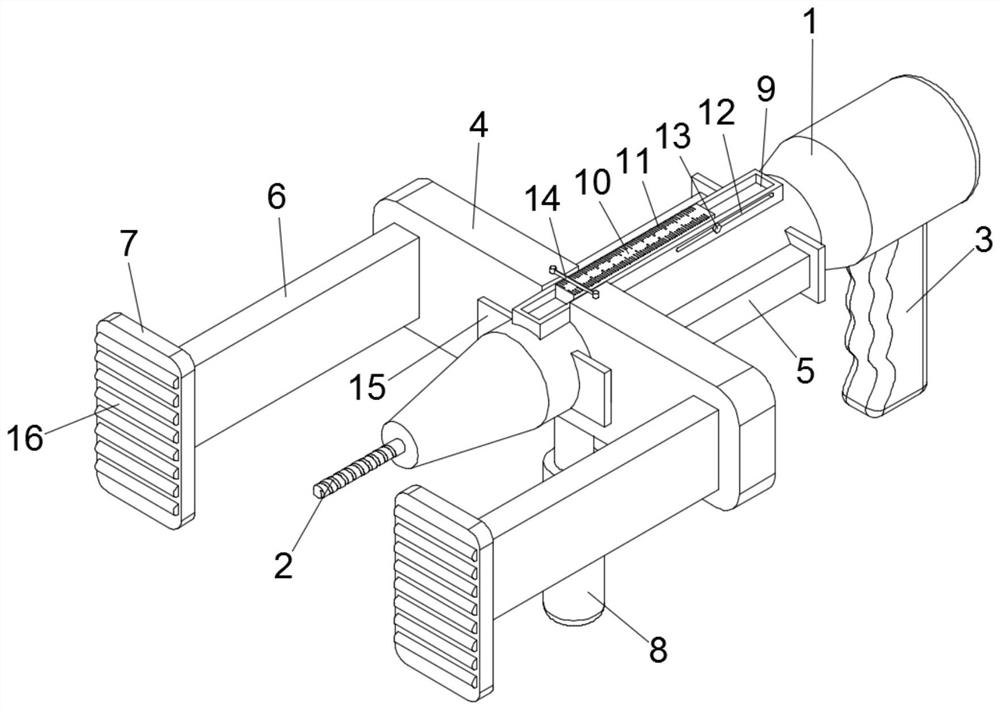

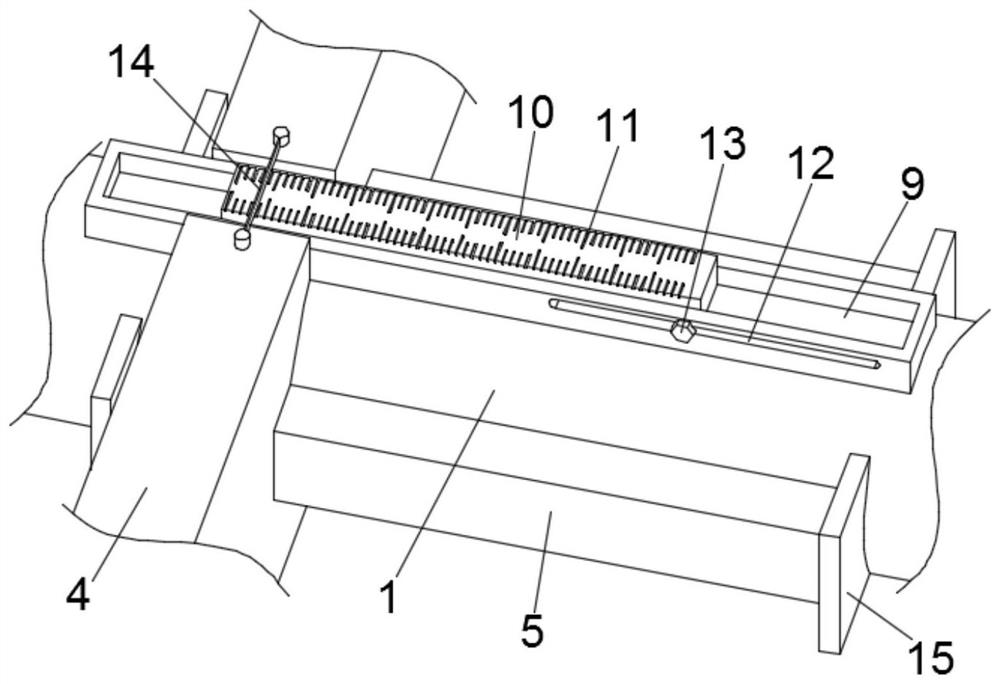

Graduated adjustable drilling guide tool

ActiveCN103909296AGuaranteed drilling accuracyImprove processing efficiencyPositioning apparatusDrill jigsEngineeringMachining

The invention belongs to machining technology and relates to a graduated adjustable drilling guide tool. The graduated adjustable drilling guide tool is characterized by comprises a base (1), a slider (2), a workpiece fastening screw (3) and a slider fastening screw (4). The graduated adjustable drilling guide tool has the advantages that shaft workpiece drilling precision is guaranteed, machining efficiency is increased, and machining cost is lowered.

Owner:HARBIN

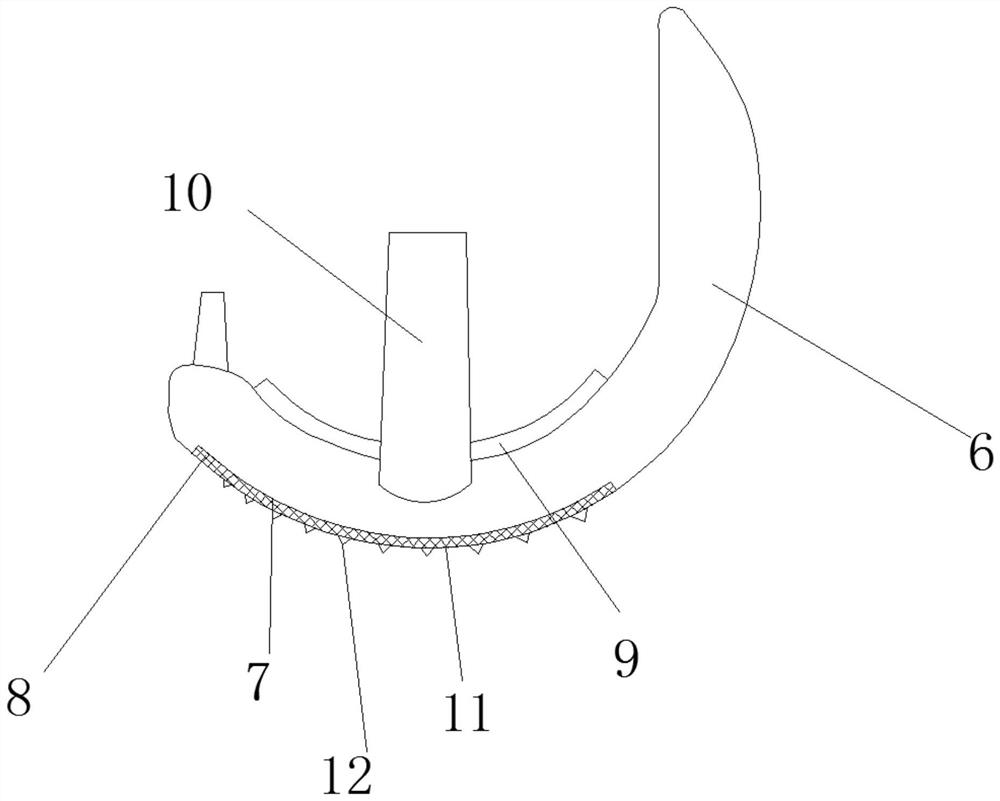

Method for positioning longitudinal osteotomy position of tibia in unicompartmental knee arthroplasty

ActiveCN113397651AAvoid collisionGood compatibilityDiagnostic markersBone drill guidesUnicompartmental knee arthroplastyKnee Joint

The invention provides a method for positioning longitudinal osteotomy position of tibia in unicompartmental knee arthroplasty, an intramedullary positioning rod and a thighbone drilling guide auxiliary device are used for determining the drilling position of a fixing hole used for mounting a thighbone prosthesis on the thighbone, the fixing hole is prepared under the guiding effect of the thighbone drilling guide auxiliary device, the postartis of the thighbone is cut off, the meniscus is cut off, a thighbone test mold with the appropriate thickness of the distal condyle is selected and installed after bone surface primary forming, the knee joint is bent and stretched repeatedly, and the longitudinal osteotomy position of the tibia is determined through the thighbone test mold. By capturing the motion trail of the tibia joint during relative normal motion, reference is provided for longitudinal osteotomy of the tibia platform, so that the longitudinal osteotomy position of the tibia is determined, the rotation alignment of the tibia prosthesis is closer to the motion trail of the tibia joint, collision between the prostheses is avoided, the motion compatibility and coincidence of the thighbone and tibia prostheses are better, the postartis of the thighbone is preferentially cut off, so that the meniscus on the tibial plateau is cut off more easily, and the collateral ligament is prevented from being damaged.

Owner:袁海浪

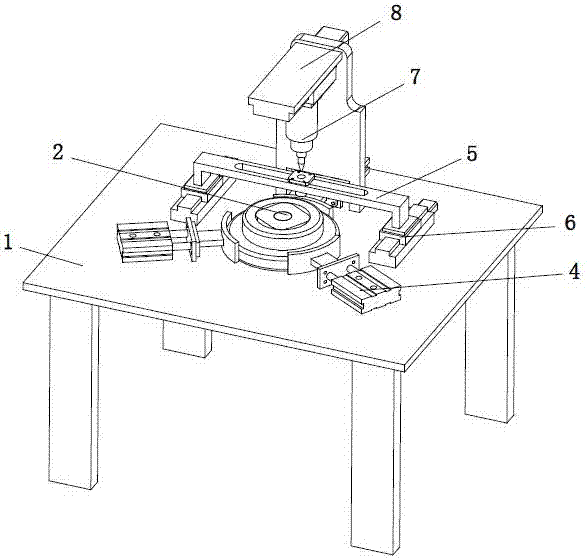

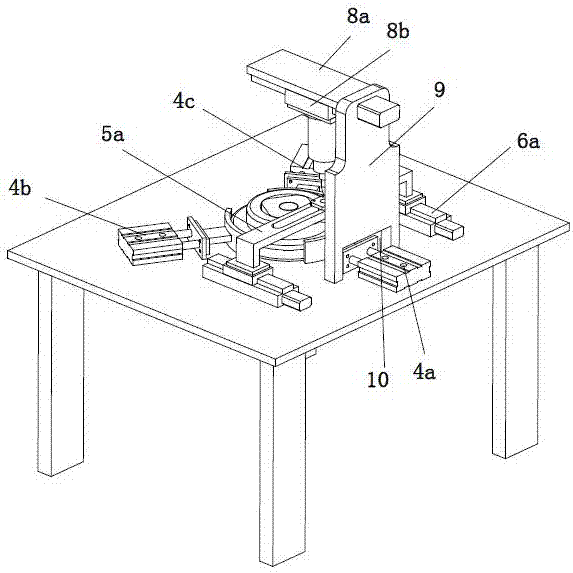

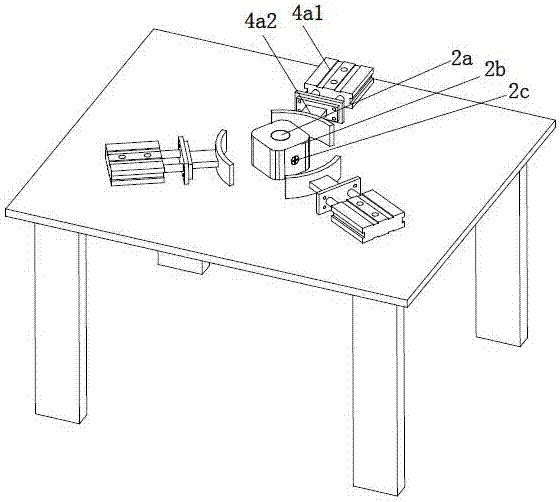

Flange plate drilling equipment

InactiveCN108000177AGuaranteed drilling accuracyMeet the needs of different drilling diametersLarge fixed membersDrill jigsEngineeringPositioning system

The invention relates to the field of flange plate machining, in particular to flange plate drilling equipment. The flange plate drilling equipment comprises a workbench. A limiting assembly is arranged in the center of the top of the workbench. A first driving mechanism is arranged at the bottom of the limiting assembly. A positioning mechanism is arranged at the top of the workbench and comprises a first positioning assembly, a second positioning assembly and a third positioning assembly which are distributed along the axis of an adjusting assembly with equal angle differences. The adjustingassembly is arranged above the first positioning assembly. A second driving mechanism is arranged at the bottom of the adjusting assembly. A drilling device is arranged above the adjusting assembly.A third driving mechanism is arranged at the top of the drilling device. A supporting plate is arranged at the top of the workbench. A receding notch is formed in the bottom of the supporting plate. The flange plate drilling equipment is simple in structure and can be applicable to the positioning procedure and the drilling procedure of flange plates with difference inner diameters, drill bits anddrill hole die sleeves can be replaced rapidly, the demands for difference drilling diameters of the flange plates are met, and the practicability is higher.

Owner:饶琼珊

Strengthening technology for soft plastic collapse body karst tunnel

InactiveCN108331595AImprove reinforcementTargetedUnderground chambersTunnel liningKarst tunnelCoring

The invention discloses a strengthening technology for a soft plastic collapse body karst tunnel. The strengthening technology comprises the steps that S1, surveying is carried out, a jet grouting pile technology is adopted at a soft foundation, and a steel flower pipe pile technology is adopted at a rock layer; S2, drilling is carried out by using the jet grouting pile technology , and a hole isdrilled at a positioning position through a rotary vibration drilling machine; S3, a grouting pipe is lowered, and drilling and lowering the grouting pipe are completed at the same time; S4, jet grouting is carried out, after a jet pipe is inserted into a predetermined depth, jetting operation is carried out from bottom to top, and a columnar jetting pile solidified body is formed after jetting construction is finished; S5, drilling is carried out by using the steel flower pipe pile technology, the position of the rock layer is confirmed, and a deep hole drilling machine is used for drilling;S6, lowering a pipe and grouting are carried out, and a steel flower pipe is grouted through a horn grouting pump until completely dense grouting is achieved; and S7, testing process is carried out, and a geological drill drilling and coring method is used for testing. By adopting a composite foundation treatment method combining a jet grouting pile and a steel flower pipe pile, the strengtheningtechnology overcomes the defect of " paying attention to a vault and making light of a tunnel bottom" in the prior tunnel construction, and thus the operation safety is ensured.

Owner:三丈信息(深圳)有限公司

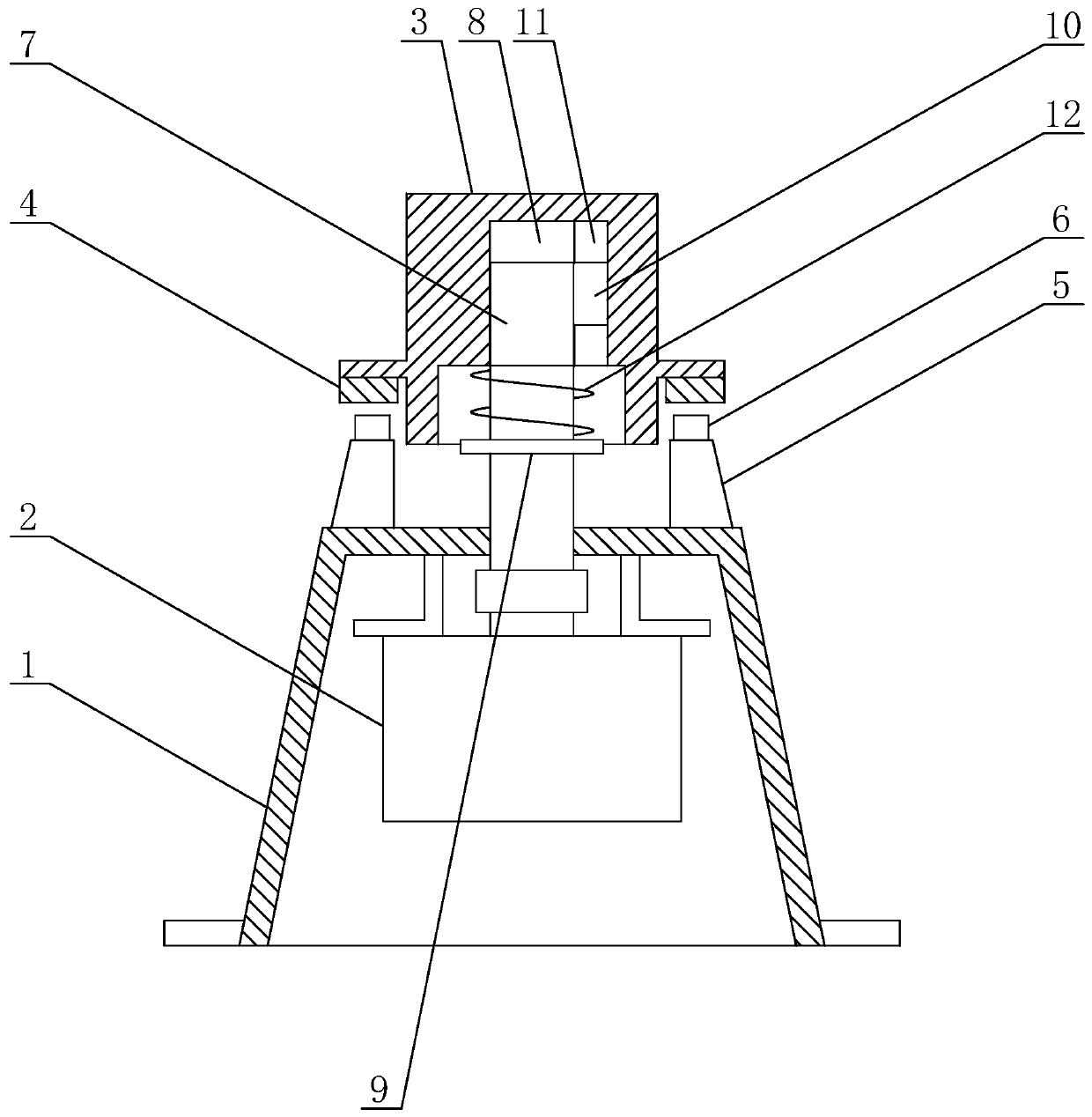

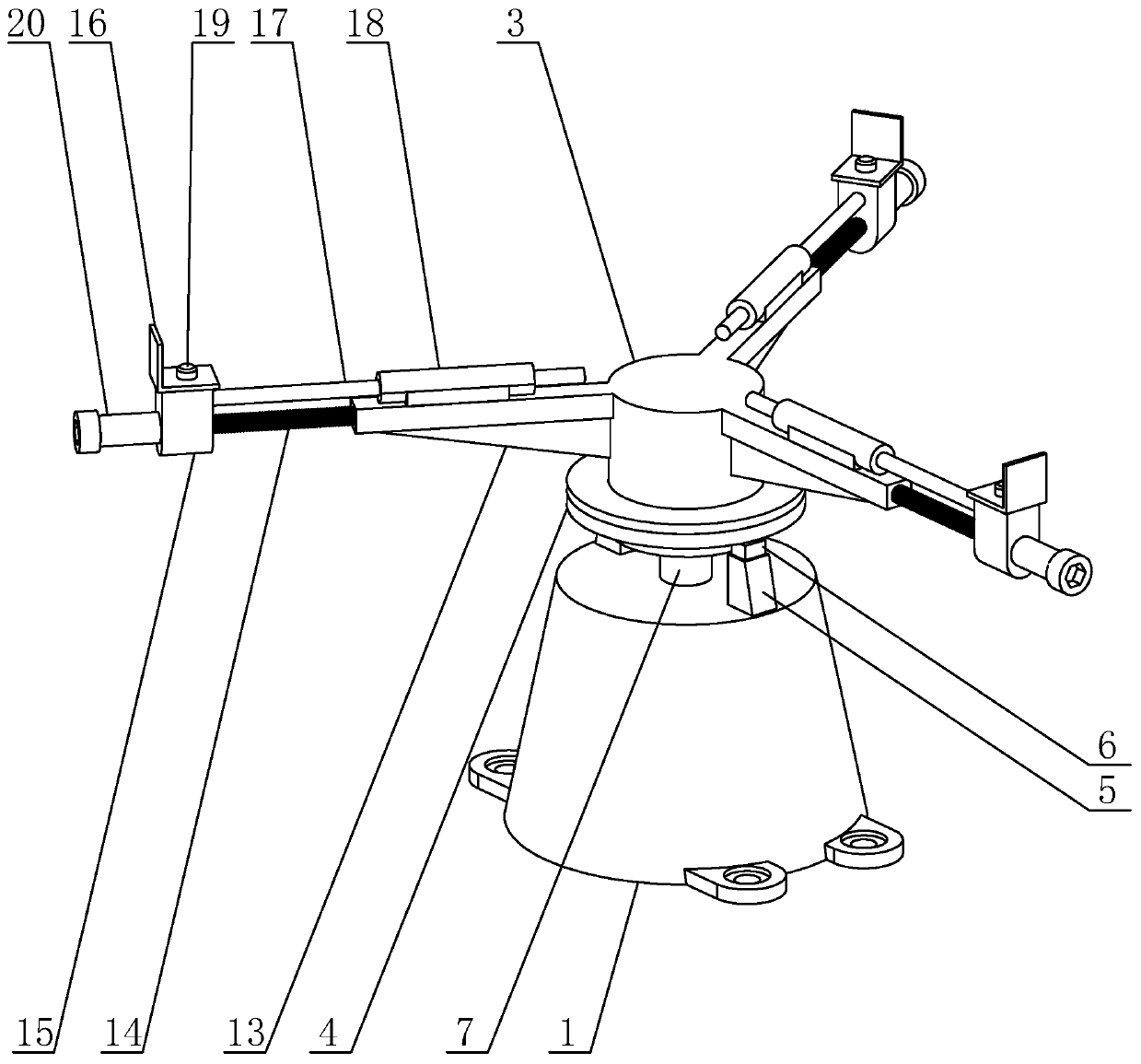

Support with fixable front end for horizontal directional drilling machine

InactiveCN102943622AImprove stabilityGuaranteed drilling accuracyDerricks/mastsDirectional drillingHydraulic motorEngineering

The invention discloses a support with a fixable front end for a horizontal directional drilling machine. The support comprises a base, a sliding sleeve rod, a hydraulic oil cylinder, a sliding sleeve, a hydraulic motor, a drilling rod and a reversing valve, wherein the base is fixedly arranged at the front end of the horizontal directional drilling machine through a clamping rack; the sliding sleeve rod and the hydraulic oil cylinder are fixedly mounted on the base, and are connected with the sliding sleeve; the hydraulic motor is connected with the drilling rod and the sliding sleeve respectively; and the reversing valve is connected with the hydraulic motor through a hydraulic oil tube. When the front end of the drilling machine is fixed, the hydraulic motor positively rotates so as to drive the drilling rod to rotate. Meanwhile, the hydraulic oil cylinder does withdraw motion; the sliding sleeve drives the hydraulic motor to move in a base direction through a connection piece; furthermore, the drilling rod gradually and rotatably drills into soil, so that the front end of the drilling machine can be fixedly arranged; and otherwise, the hydraulic motor reversely rotates, the hydraulic oil cylinder extends out, and the drilling rod gradually retreats from the soil. The support provided by the invention has the advantages that the drilling machine can be prevented from being up-warped at the front end in a working process, and the offset phenomenon can be prevented from occurring in a drilling process, so that the drilling precision and the drilling efficiency can be ensured.

Owner:CHTC JOVE HEAVY IND

Automatic automobile metal plate drilling device with positioning function

ActiveCN114643378AGuaranteed drilling accuracyDrilling helpsPositioning apparatusMetal-working holdersElectric machineStructural engineering

The automobile metal plate automatic drilling device with the positioning function comprises a mounting table, an L-shaped frame is mounted in the middle of one side of the mounting table, an electric push rod is mounted in the middle of the top in the L-shaped frame, and a rotating motor is mounted at the output end of the electric push rod; a drill bit is mounted at the output end of the rotating motor, a transverse moving assembly is arranged at the top of the mounting table, and two first moving plates are arranged at the top of a moving part of the transverse moving assembly. Two sets of first moving plates are designed, when two sets of first lead screws are controlled to synchronously rotate, the machining tables on the two sets of first moving plates can alternately move to the position below an L-shaped frame, and therefore in the machining process of automobile metal plates on one set of machining tables, the machining efficiency is improved, and the machining efficiency is improved. And an operator can replace the machined automobile metal plates on the other set of machining table, and the machining efficiency of the drilling device on the automobile metal plates is further improved.

Owner:CHENGDU UNIV

Tapping method of Y-type steel anchor box cableway pipe of cable-stayed bridge

ActiveCN101913064AGuaranteed drilling accuracyGuaranteed machining accuracyCable stayedSoftware system

The invention discloses a tapping method of a Y-type steel anchor box cableway pipe of a cable-stayed bridge, belonging to the construction technology of bridge steel structures and comprising the steps of: 1, determining a protective line of a center point of a ropeway pipe and a steel anchor box intersected on the steel anchor box, and determining the center point of an opening; 2, carrying out three-dimensional modeling by using a computer, penetrating by using a small-diameter steel pipe (the diameter is 100-300mm less than the diameter of the ropeway pipe) and the steel anchor box, making the penetrating and cutting data of the small-diameter steel pipe and the steel anchor box by using a penetrating line cutting software system; 3, cutting the penetrating line of the small-diameter steel pipe on a penetrating line cutting machine; 4, pot-welding and fixing the small-diameter steel pipe on the steel anchor box to ensure the accuracy of the center point; and 5, placing a magnetic cutter on the small-diameter steel pipe, and tapping around the steel pipe by the magnetic cutter.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

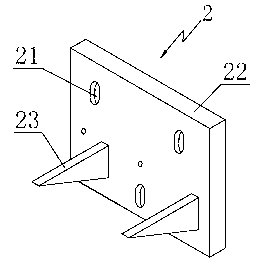

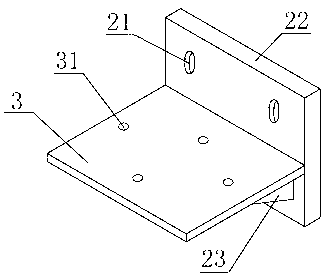

Fixture for conducting rough machining on water plugging holes of engine cylinder block

ActiveCN104959856AWon't shakeEasy loadingDrilling/boring measurement devicesWork clamping meansEngineeringCylinder block

The invention discloses a fixture for conducting rough machining on water plugging holes of an engine cylinder block. An engine cylinder block to be machined is placed on a supporting plate. The engine cylinder block can conduct slippage on a base along with the supporting plate, so that feeding and discharging of a cylinder block piece are facilitated. When machining is conducted, a clamping device clamps the engine cylinder block to the supporting plate, meanwhile a locking portion locks the supporting plate and the base, it is guaranteed that in the drilling process of a drill bit is guaranteed, the cylinder block cannot waggle, and drilling deviation is avoided. A guide device plays a guide function on the drill bit of a radial drilling machine, and drilling accuracy is guaranteed.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

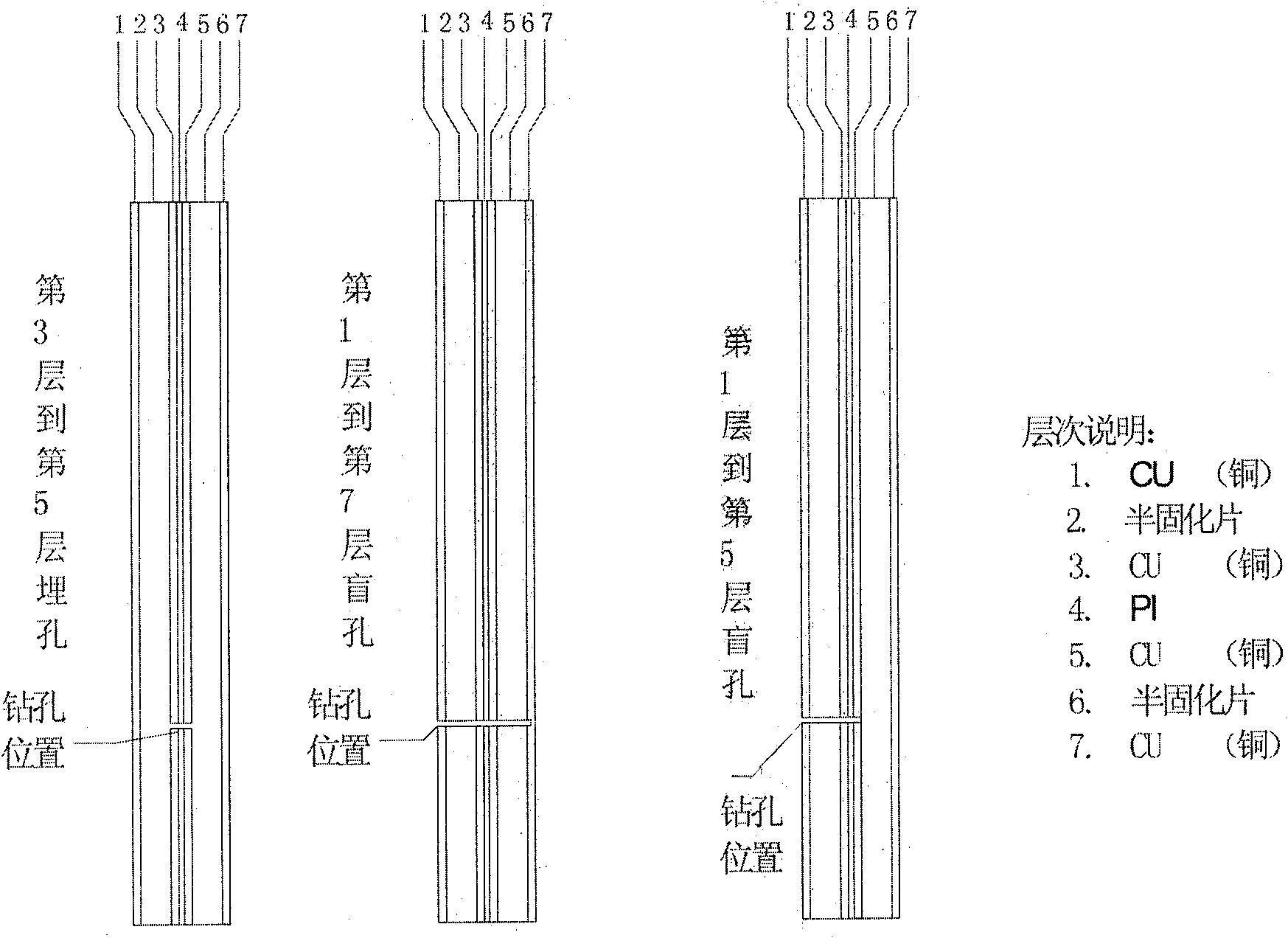

Flex-rigid integrated circuit (IC) package substrate and manufacturing method thereof

ActiveCN101656235AImprovement of Blind Drilling YieldThe overall thickness is thinSemiconductor/solid-state device detailsSolid-state devicesWire widthUltraviolet

The invention relates to a flex-rigid integrated circuit (IC) package substrate and a manufacturing method thereof. Aiming at improving the product quality and the product performance of the multi-layer integrated circuit package substrate, the invention adopts a high-Tg nonflowing PP sheet and pure copper foil materials and the newest wire bonding surface treatment technology and the automatic alignment and parallel exposure technology so that the minimum wire width / wire pitch of the substrate reaches 30 microns / 30 microns, the pitch reaches 60 microns, the total thickness of four layers of flex-rigid substrates is less than or equal to 240 microns and the thickness tolerance is controlled within + / -5 microns. By adopting a method for combining ultraviolet with CO2 laser and a copper foiletching alignment technology, the invention can effectively avoid the problem of ensuring the drilling accuracy of blind holes by controlling the uniformity of the product thickness and improve the yield of blind buried drilling holes at 1 to 3 layers and 1 to 4 layers of four-order flex-rigid substrate products with the thickness of 240 microns by more than 30 percent.

Owner:XIAMEN INNOV INFORMATION TECH

Gear Drilling Tooling

ActiveCN104070413BRapid positioningImprove drilling efficiencyPrecision positioning equipmentWork clamping meansIndustrial engineering

Owner:双环传动(重庆)精密科技有限责任公司

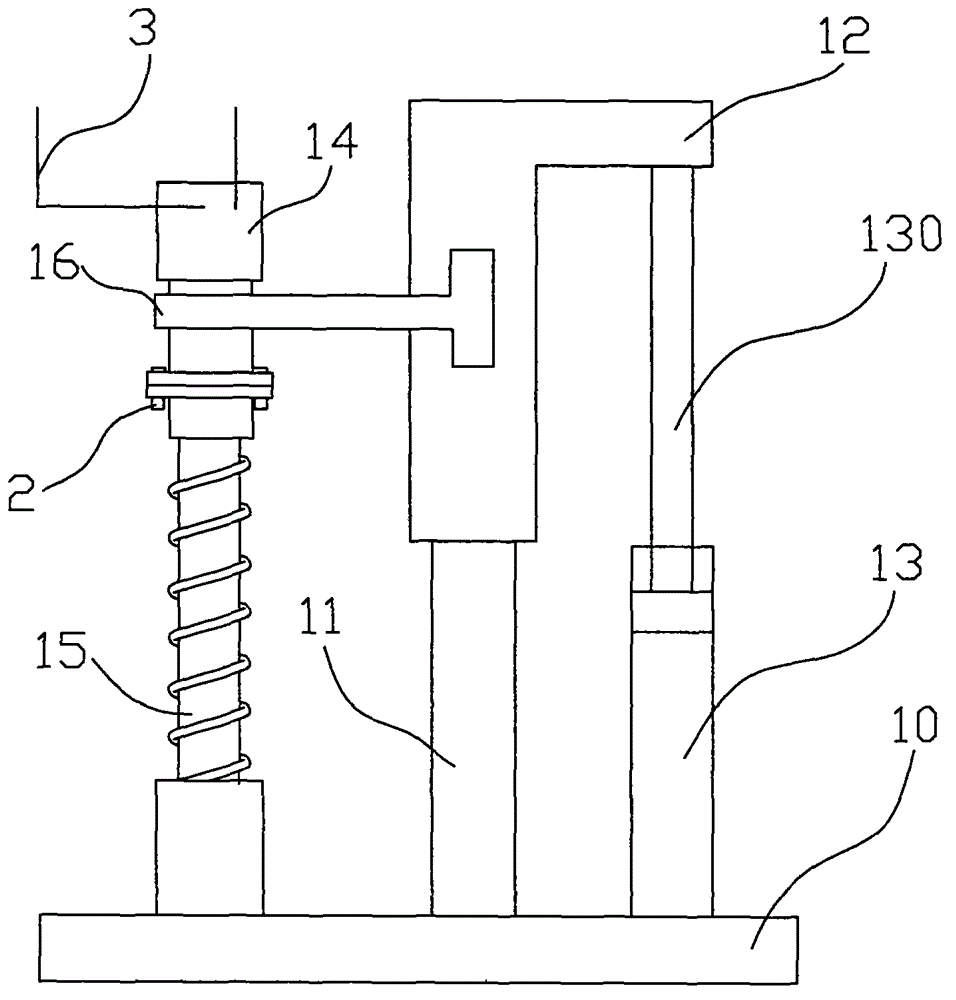

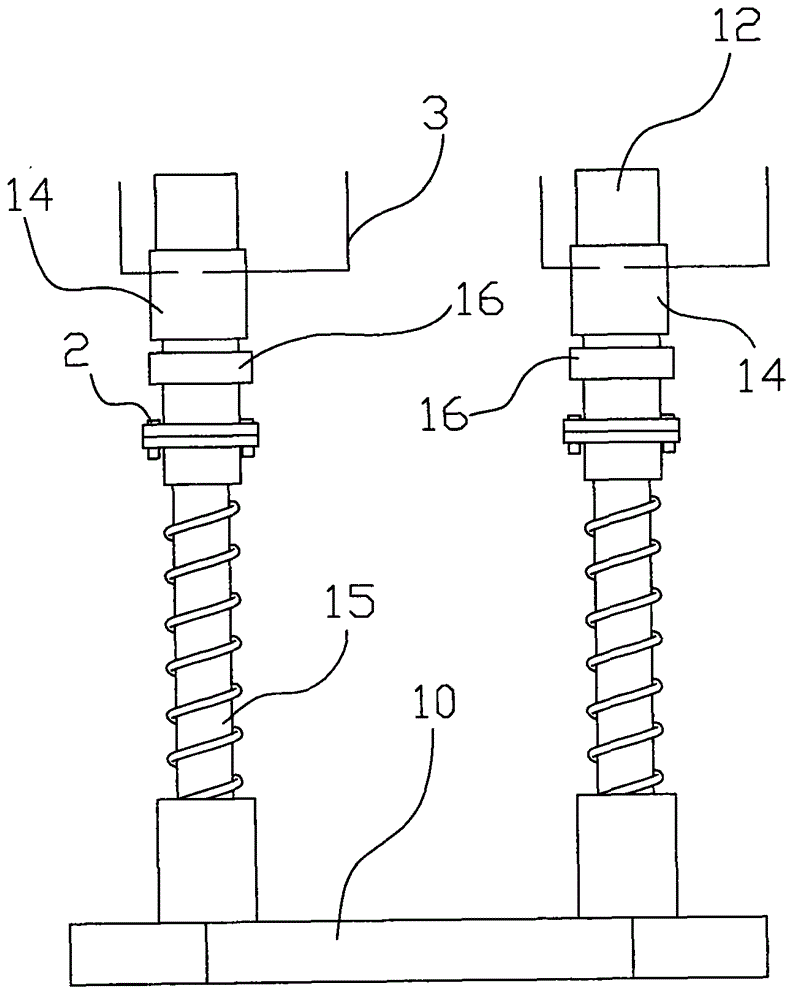

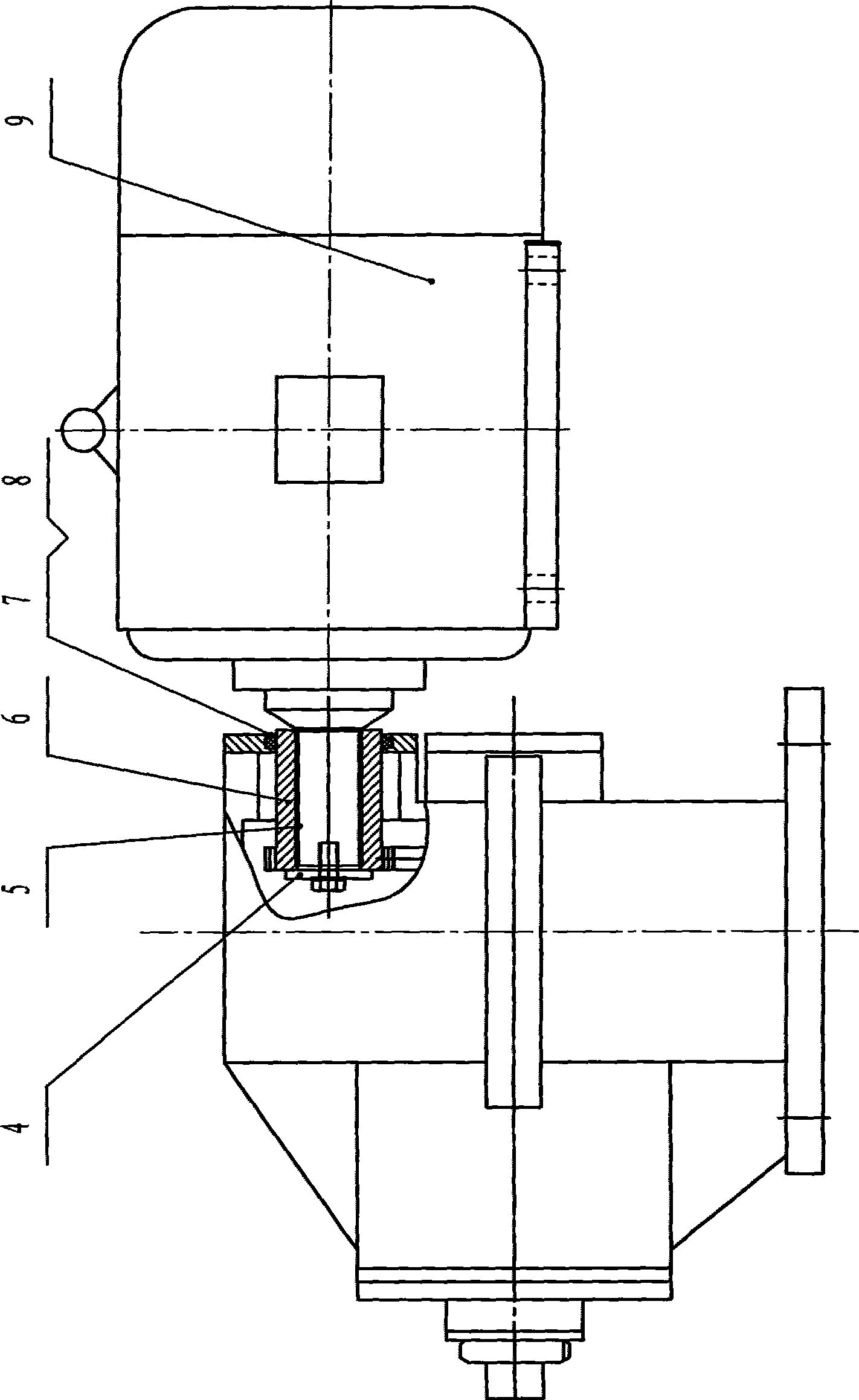

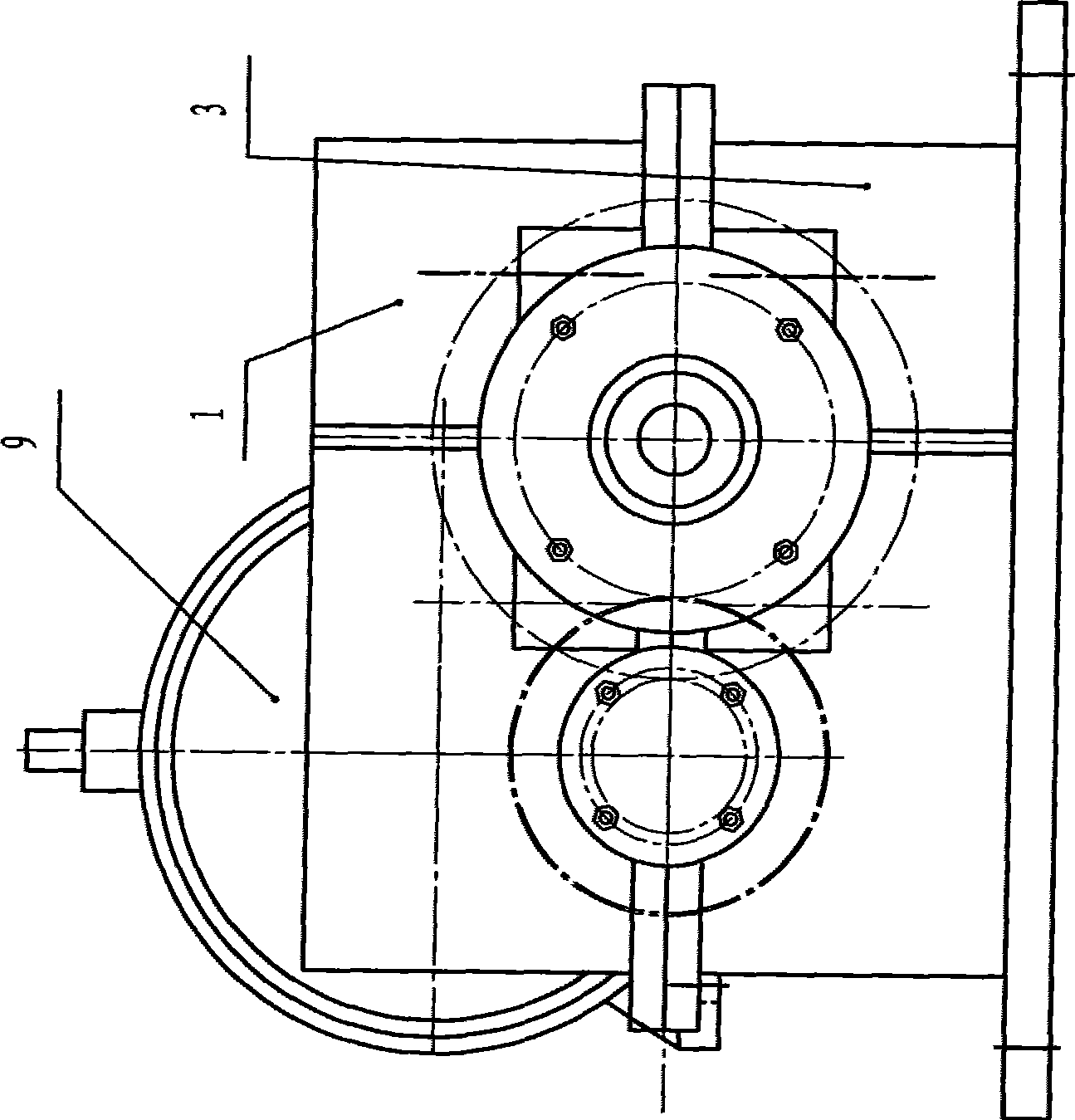

Double drilling rod drive apparatus and double drill rod mash gas outburst prevention drill

InactiveCN101509355AEnsure safetyInnovative designGearboxesDrilling rodsHydraulic cylinderGear wheel

The invention discloses a dual-drill stem transmission gear and a dual-drill stem gas outburst-preventing drill. The dual-drill stem transmission gear is provided with a transmission gear shaft in a box body; the box body is provided with a hollow external gear shaft therein; the external gear shaft and the box body are rotationally and hermetically connected; an internal gear shaft is sheathed and fixed with the internal hole of the dual-drill stem transmission gear by a bearing; a limiting mechanism is arranged between the internal hole and the internal gear shaft; the external gear shaft and the internal gear shaft are provided with transmission gears which are meshed with two transmission gears arranged on the transmission gear shaft; and the transmission gear shaft is connected with a power machine. The dual-drill stem gas outburst-preventing drill further comprises a machine frame, and an elevating positioning mechanism which are connected to a vertical support frame; the vertical support frame is provided with a sliding track; the sliding track is provided with a sliding plate; the sliding track and the sliding plate are in slip fit. The box body of the dual-drill stem transmission gear is arranged on the sliding plate; and a propeller hydraulic cylinder is arranged between the box body and the sliding plate. The invention has novel design, compact structure, high efficiency, excellent gas discharge effect, convenient usage, and excellent social and economic benefits.

Owner:王武涛

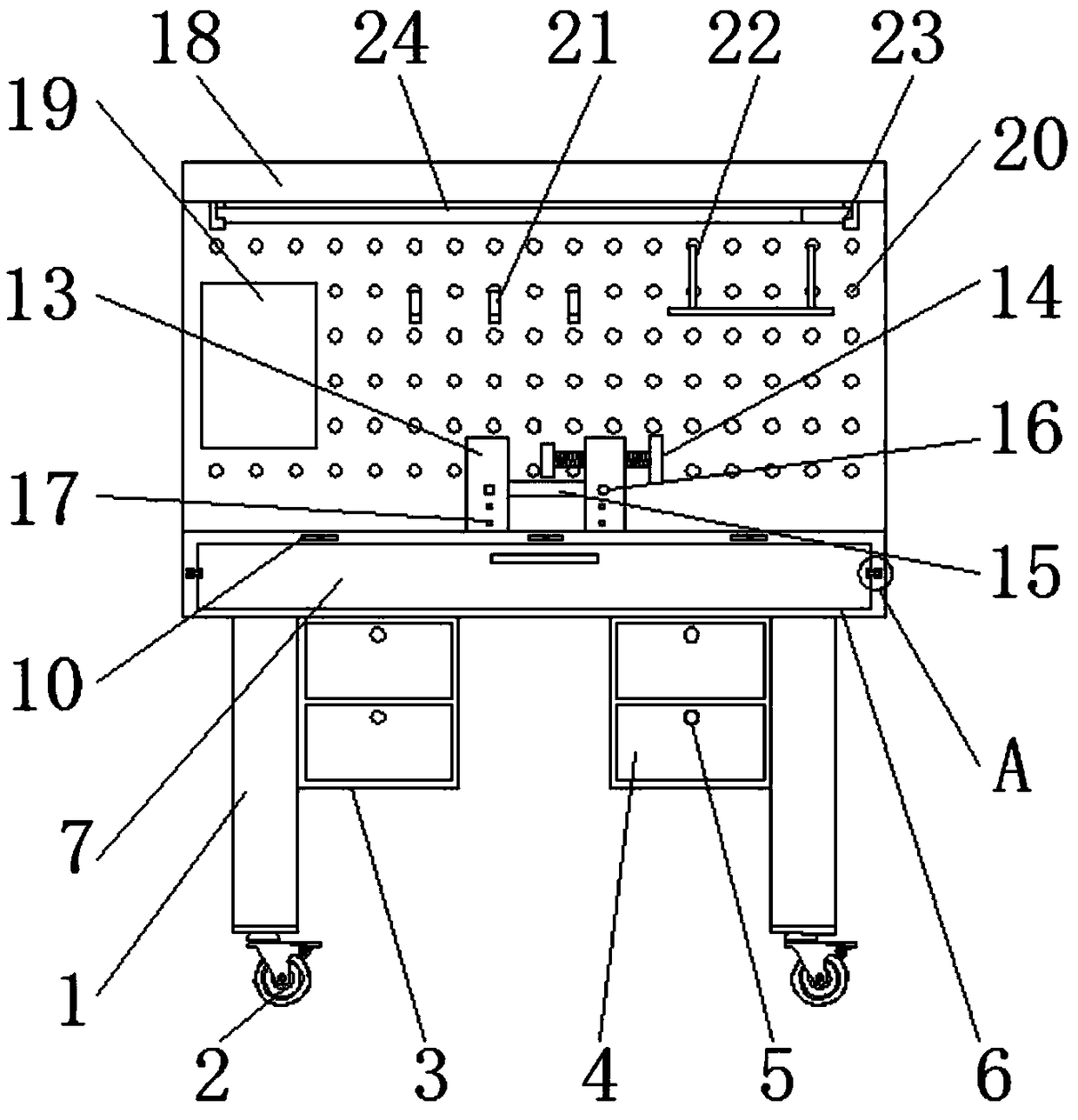

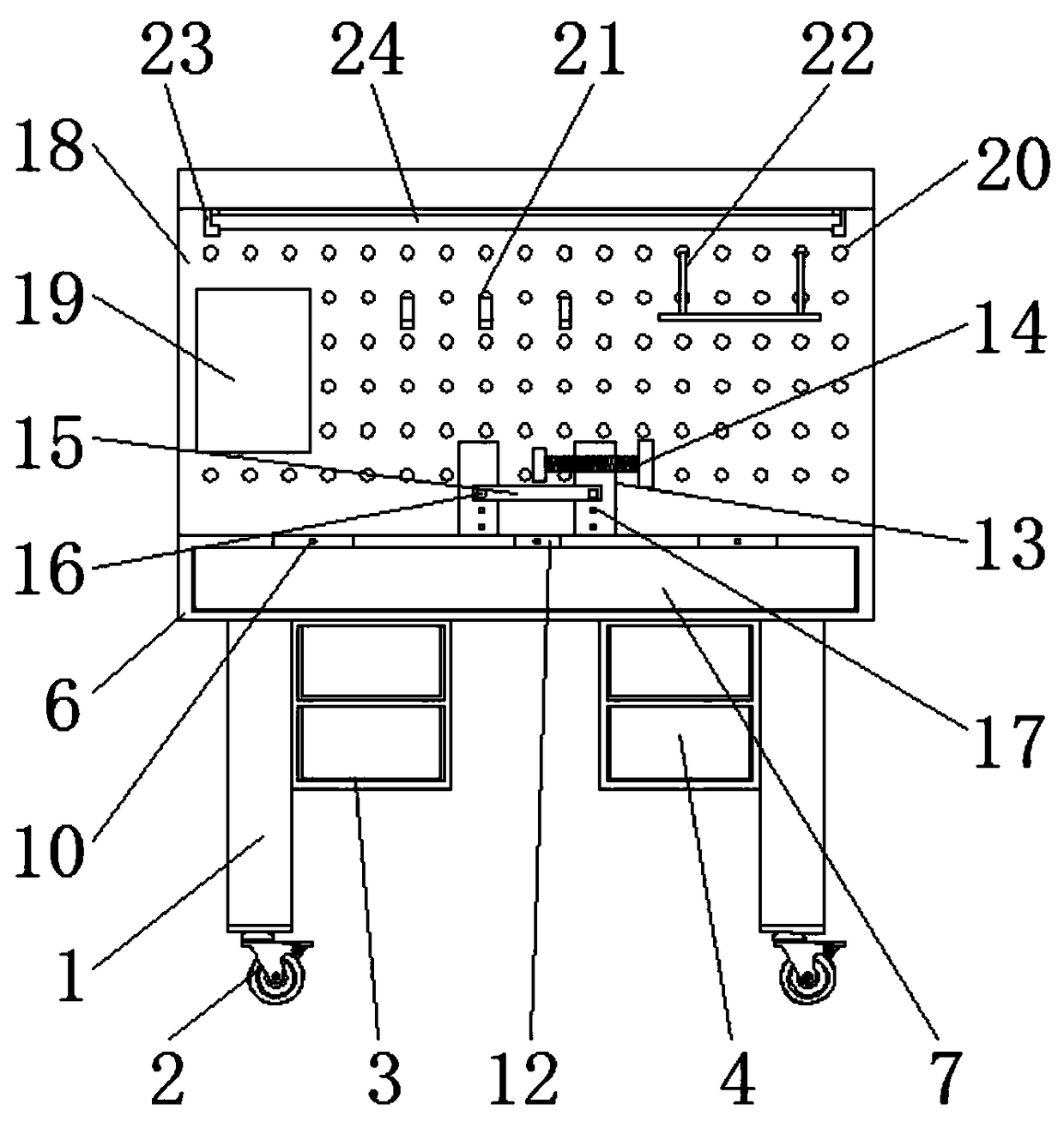

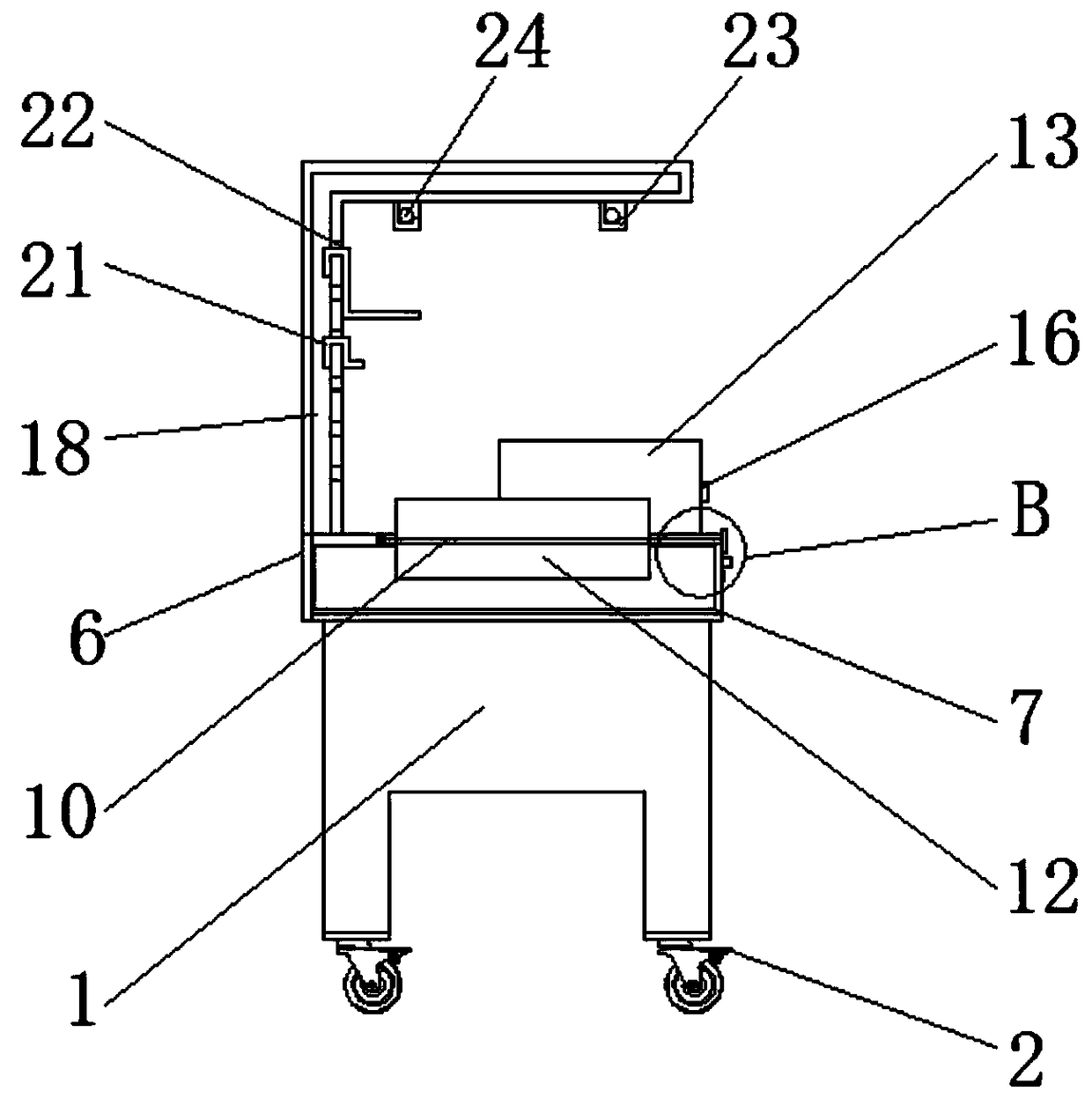

Hardware electromechanical drilling workbench convenient for collecting chippings

InactiveCN108746701AEasy to collectGuaranteed accuracyMaintainance and safety accessoriesBoring/drilling machinesSurface mountingEngineering

The invention discloses a hardware electromechanical drilling workbench convenient for collecting chippings. The hardware electromechanical drilling workbench comprises a support, a drawer, a first connecting rod and a storage plate, wherein a universal wheel is installed on the lower surface of the support, and a storage grid is fixed above the inner side of the support; the drawer is positionedinside the storage grid, and a lock opening is formed in the front surface of the drawer; a workbench plate is arranged on the upper surface of the support, and a chip placing groove is formed in theworkbench plate; the left side and the right side of the front surface of the workbench plate are correspondingly provided with a first connecting block, and the inner side of the first connecting block is connected with a first fixing block; the first connecting rod penetrates through the upper side of the workbench plate, and a turning plate is arranged on the outer side of the middle part of the first connecting rod. According to the hardware electromechanical drilling workbench convenient for collecting chippings, the scraps can be conveniently collected, the tidiness of the workbench canbe kept, the drilled objects can be clamped, the accuracy of drilling is guaranteed, the tool and the part can be conveniently stored, and the working efficiency is improved.

Owner:芜湖虹点帮网络科技有限公司

High-precision drilling tool

InactiveCN103100898APrevent movementGuaranteed drilling accuracyPositioning apparatusMetal-working holdersEngineering

Owner:WUXI HANGHU TECH

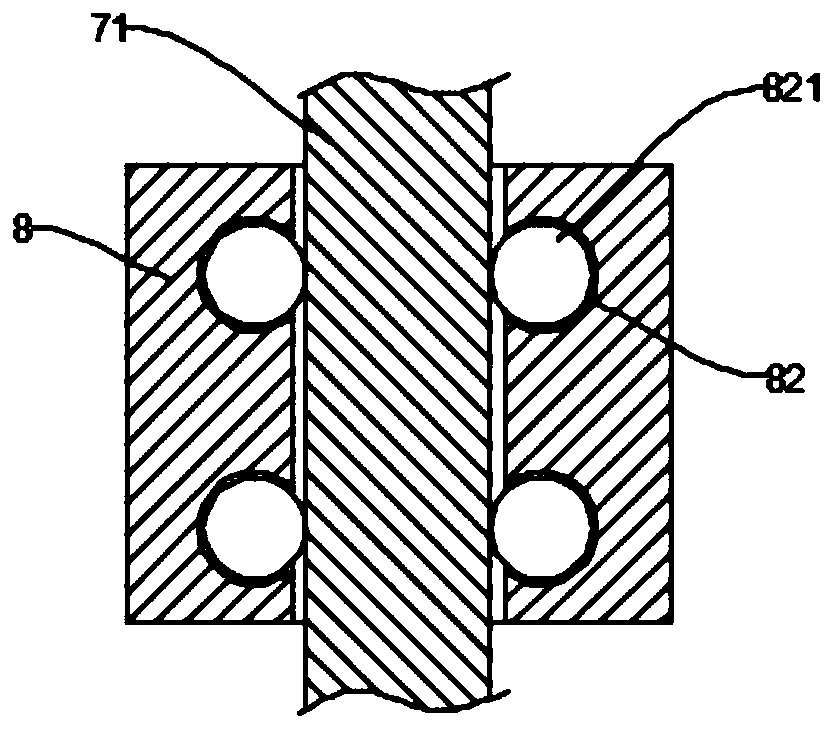

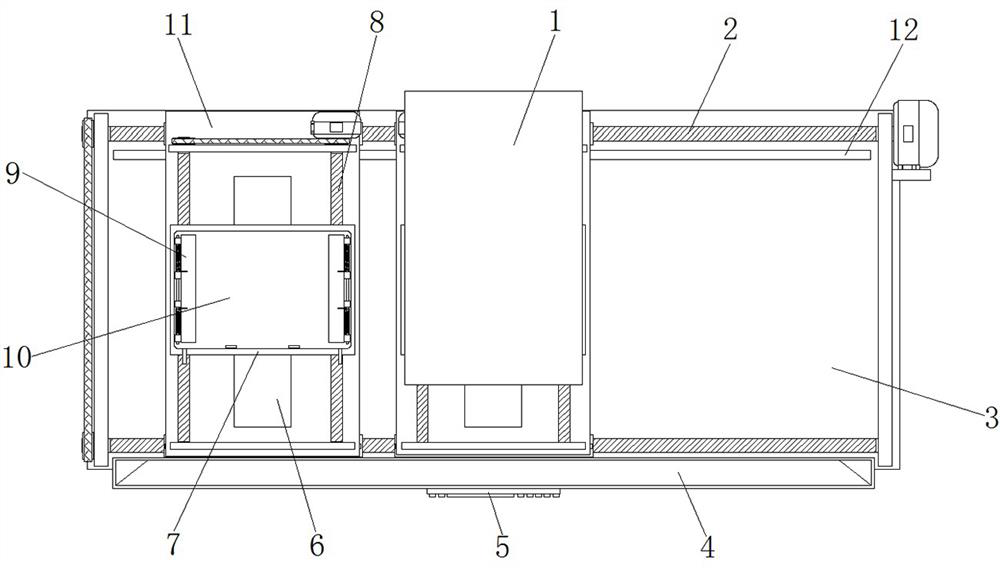

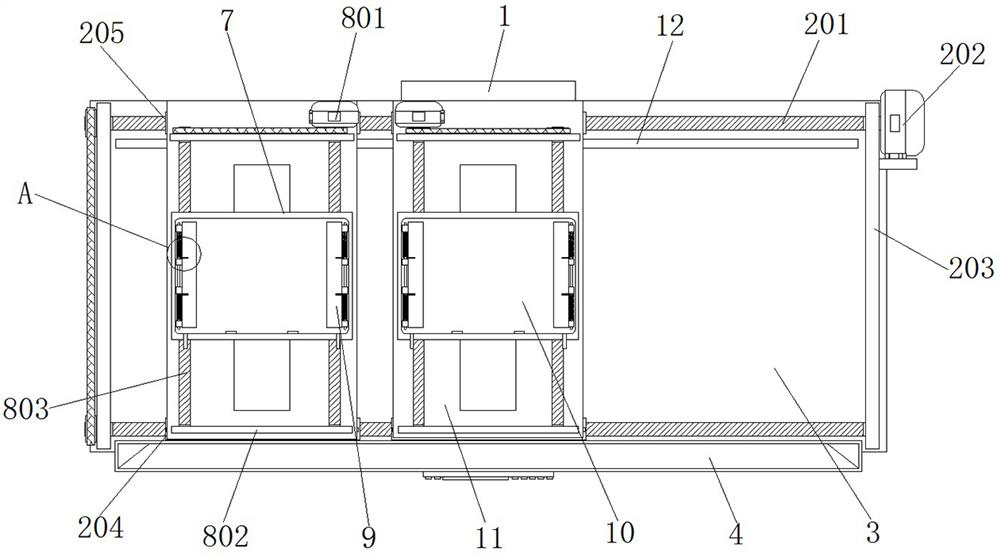

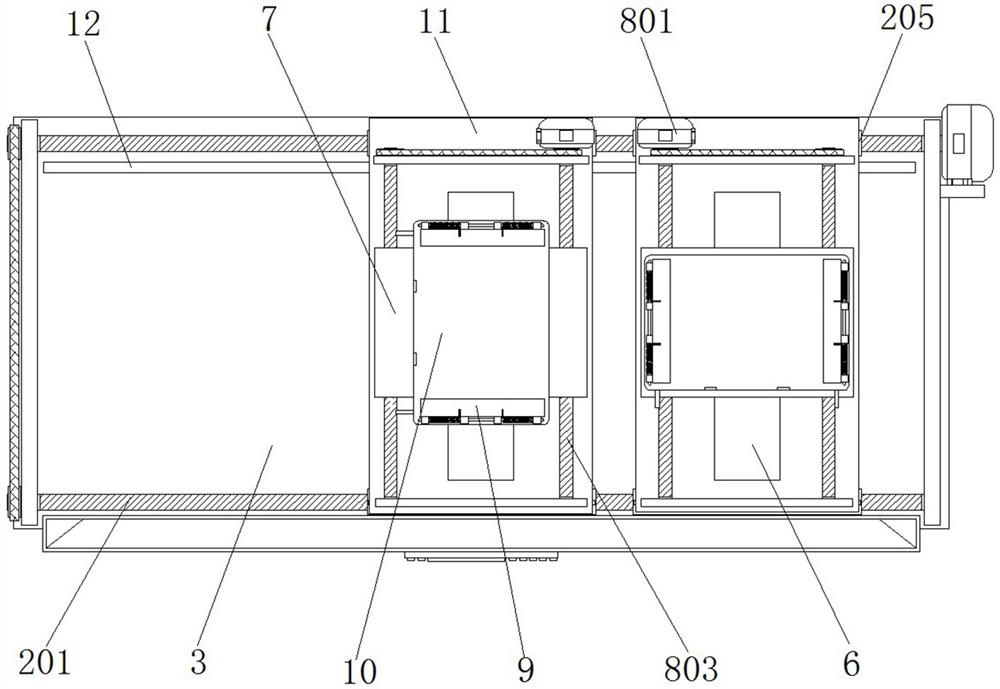

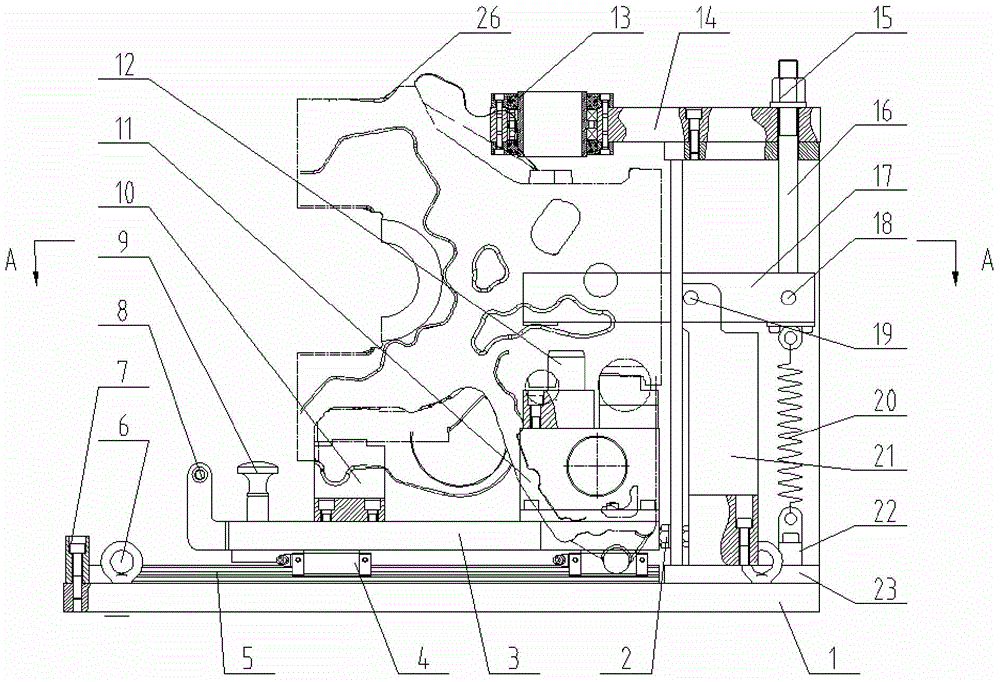

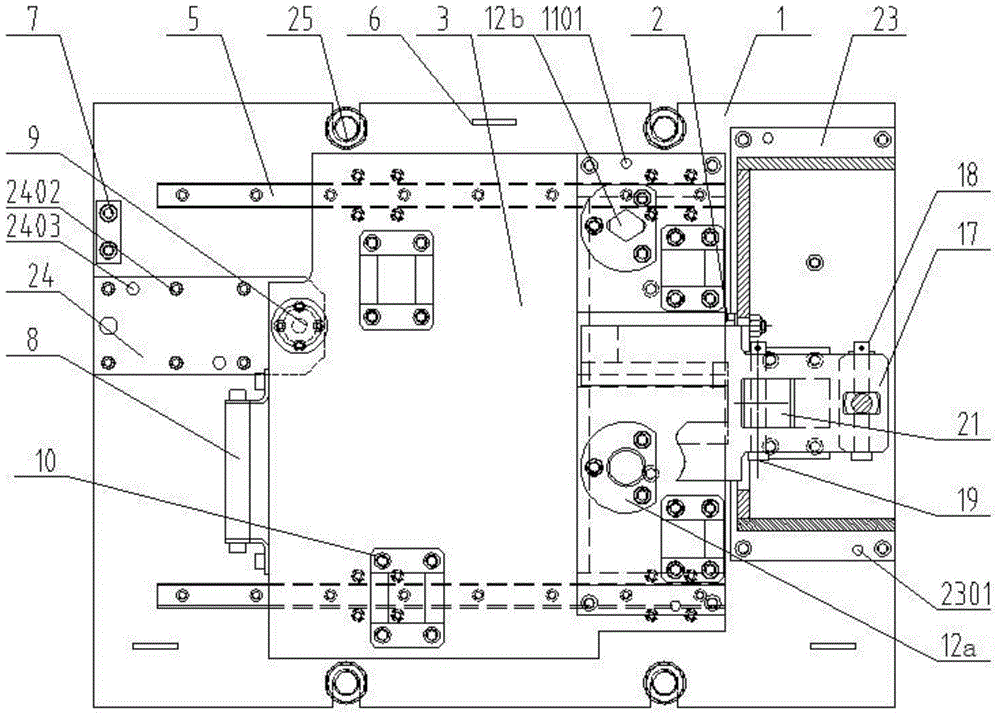

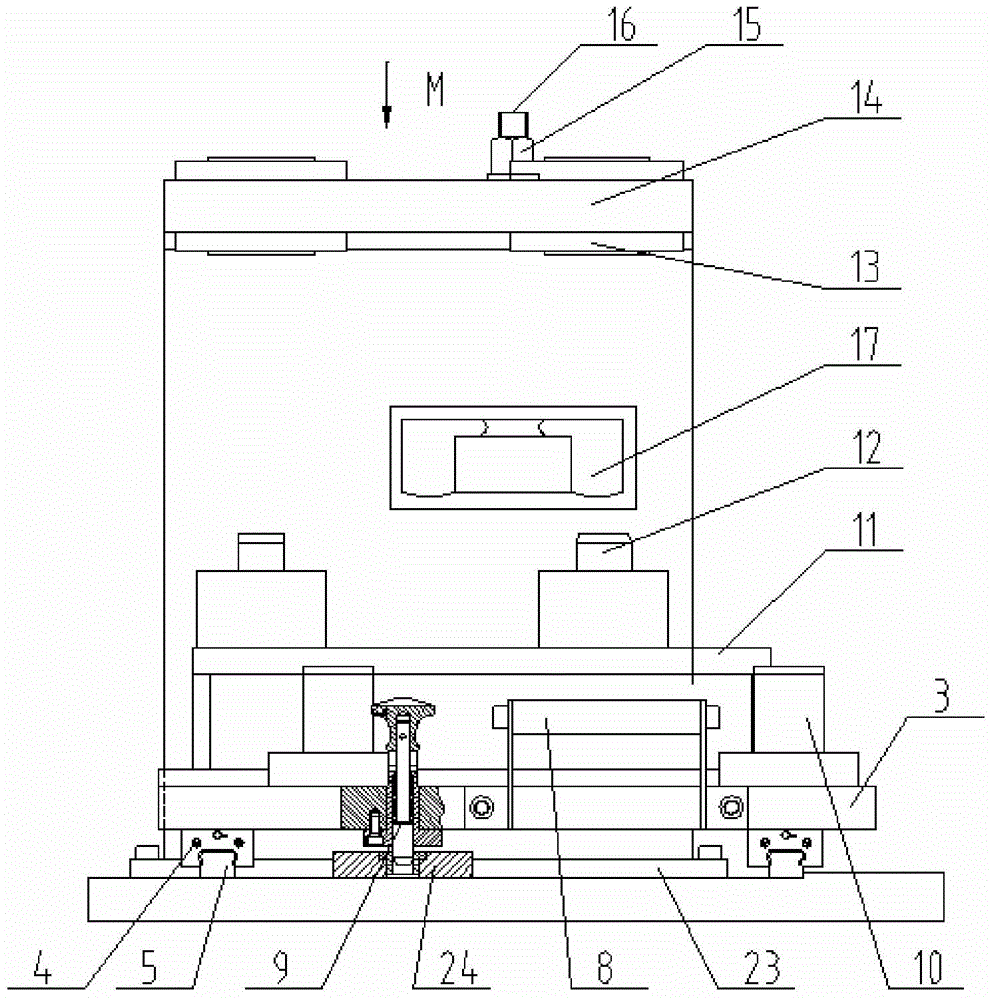

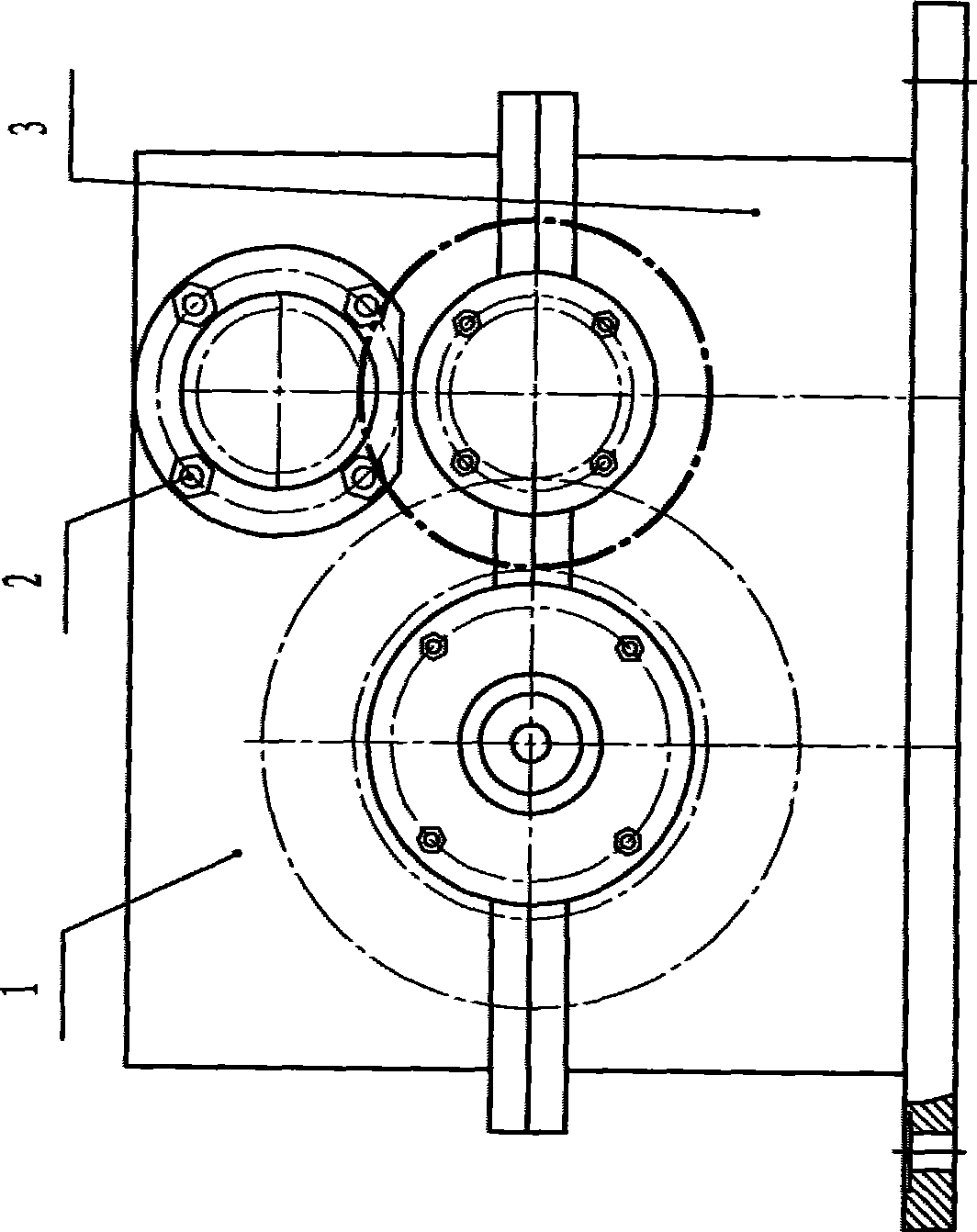

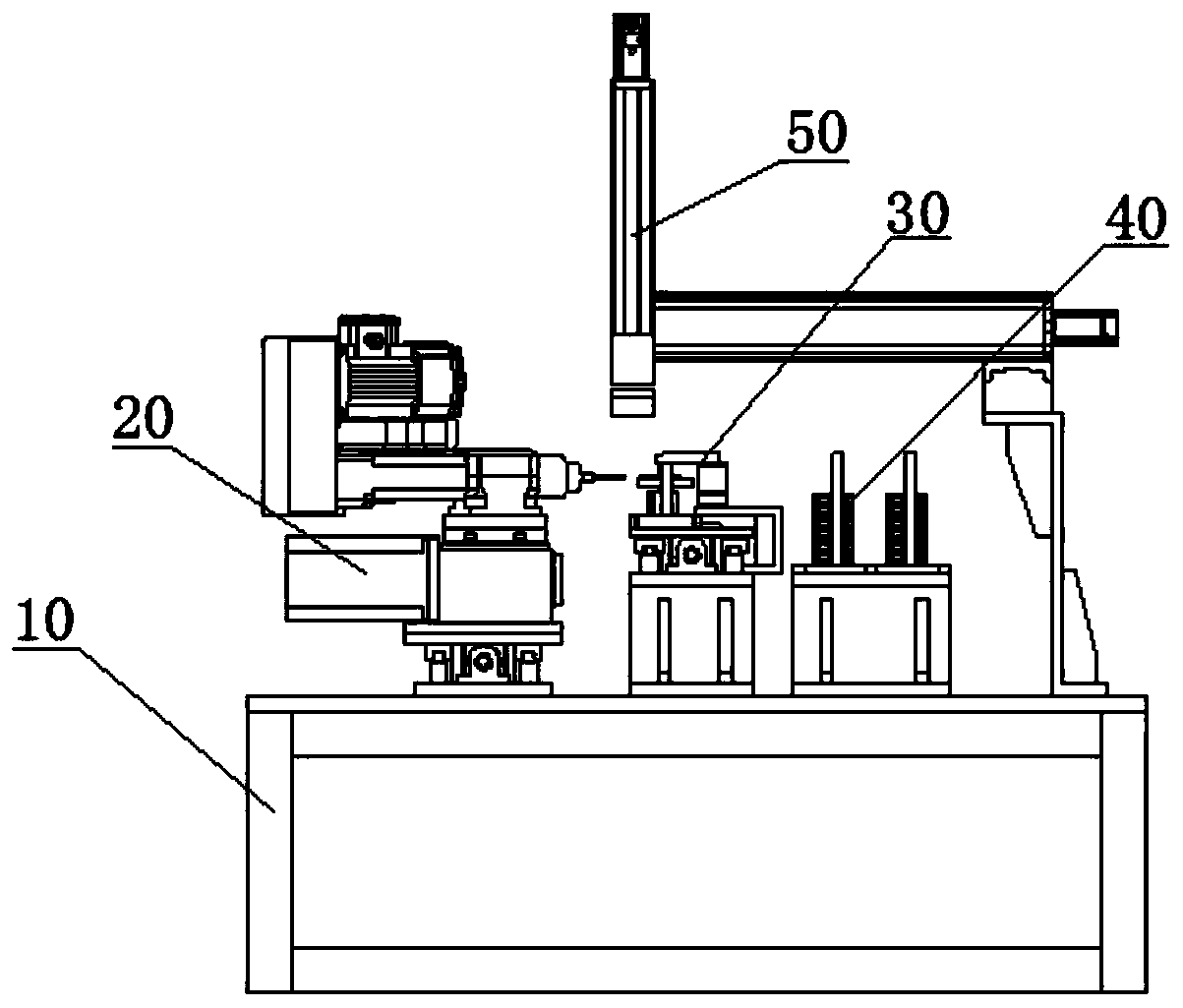

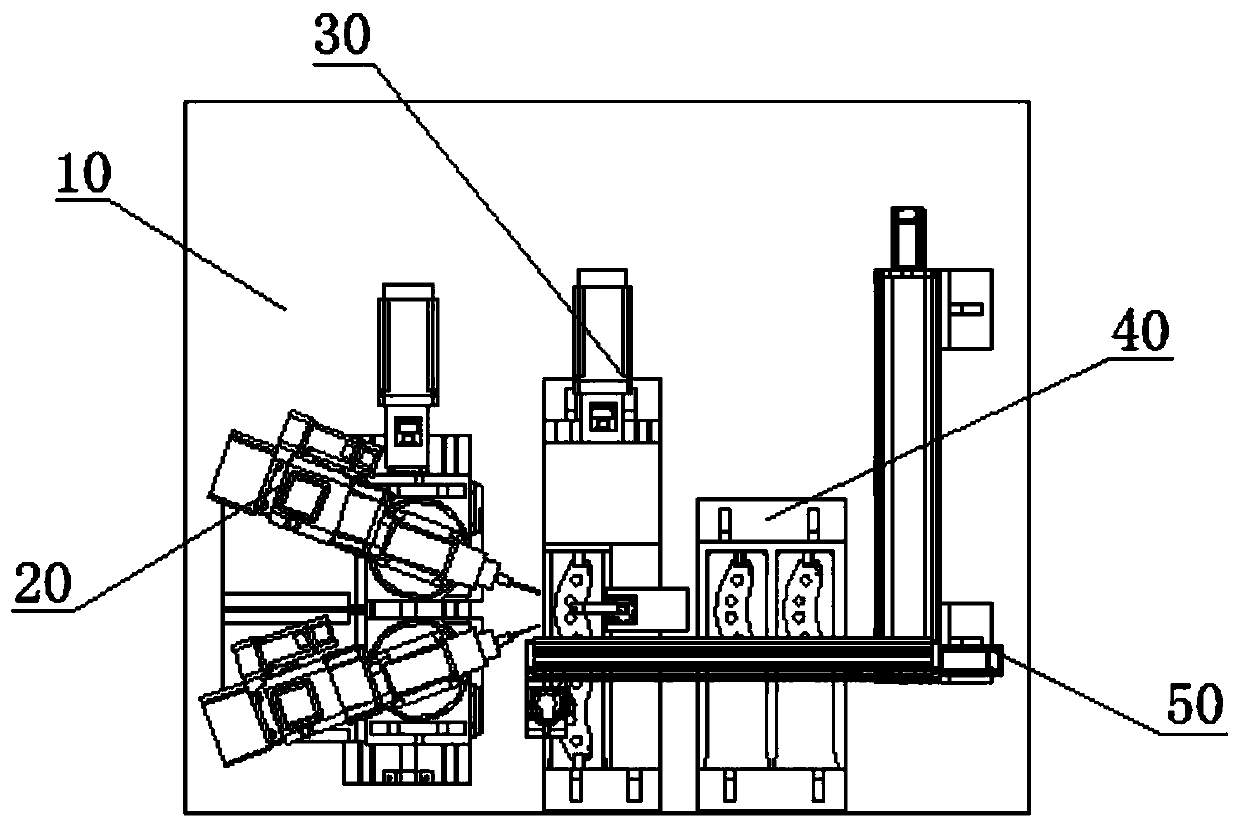

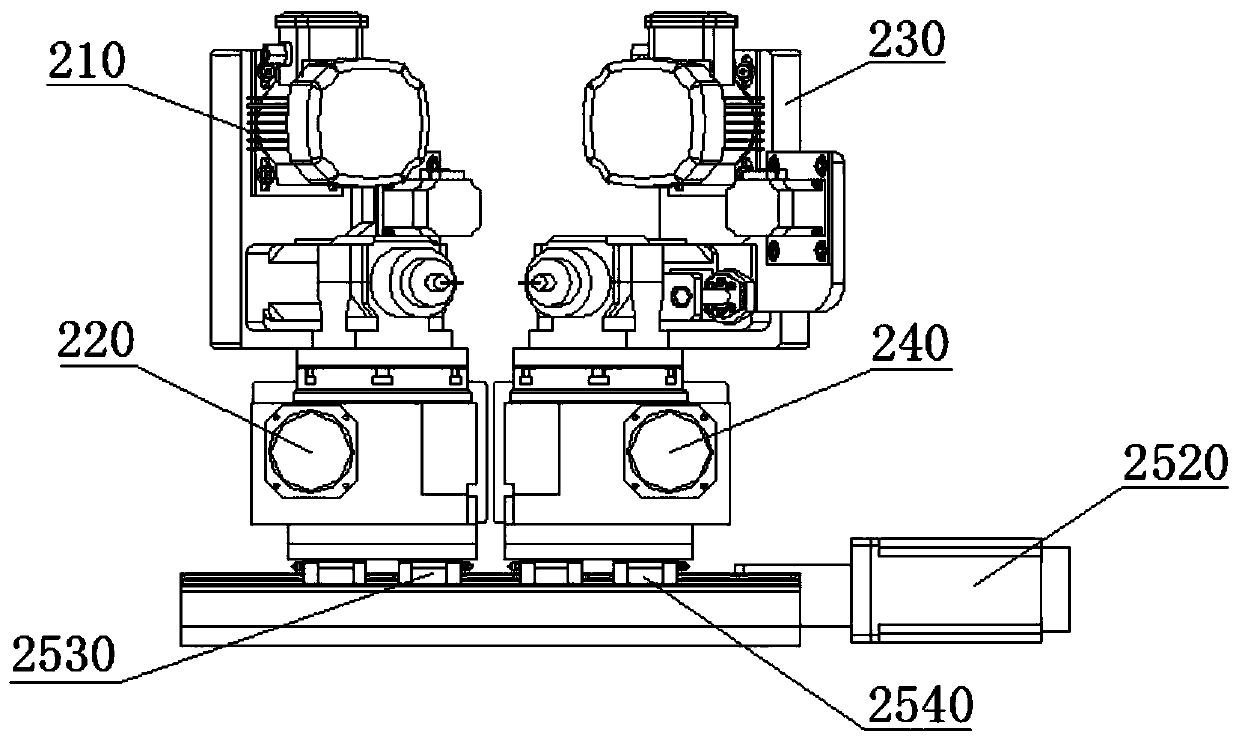

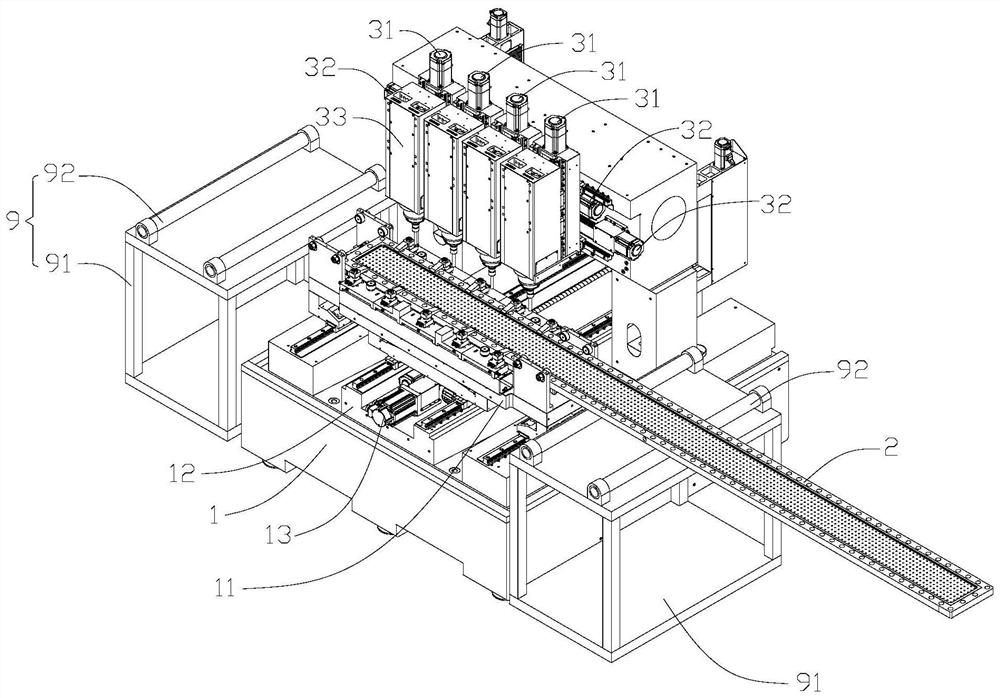

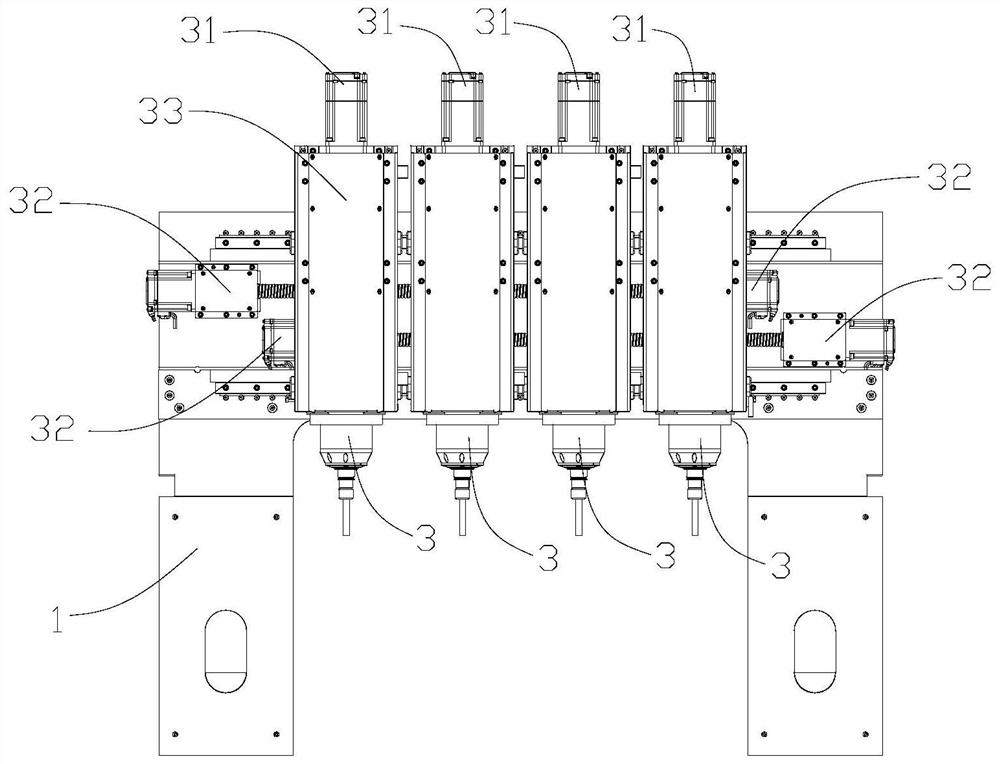

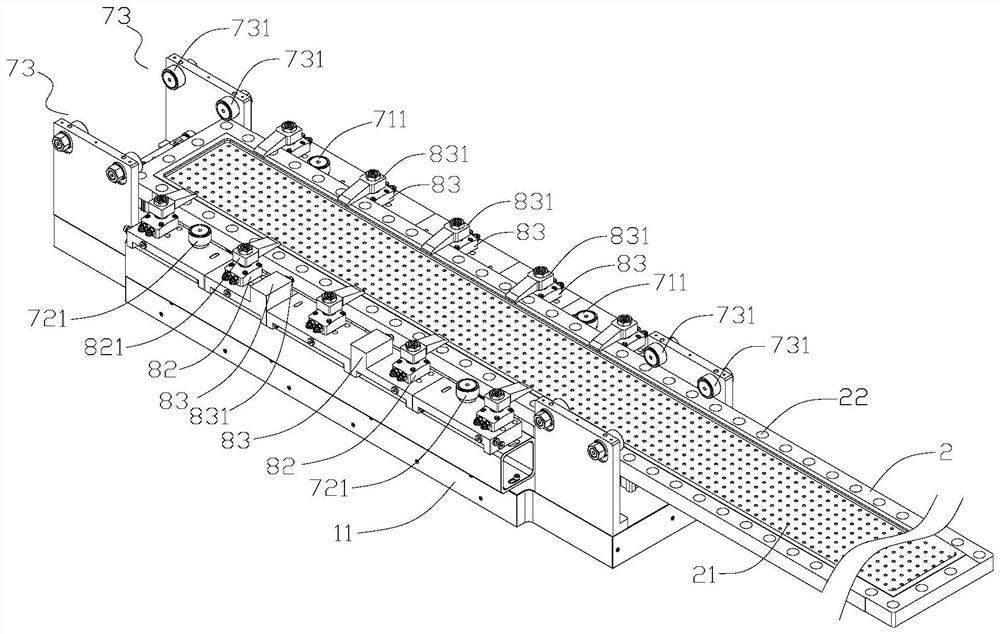

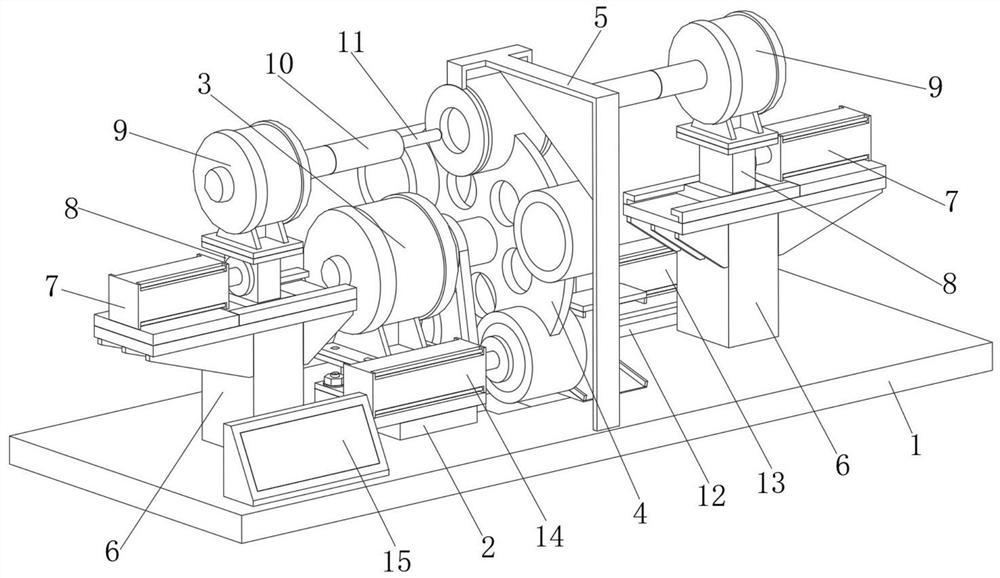

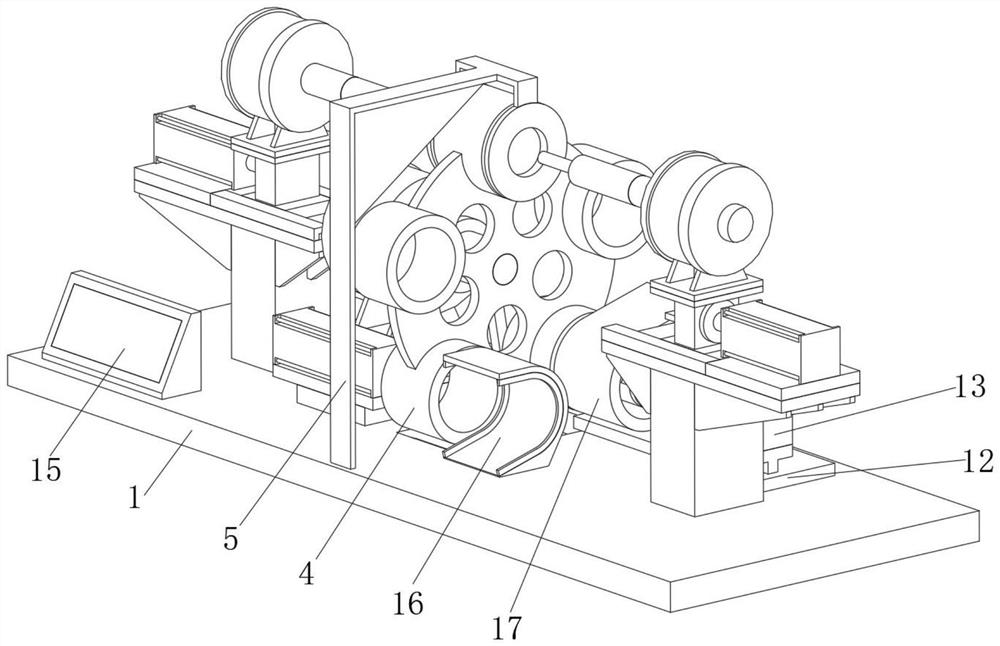

Full-automatic numerical control drilling machine for brake pad steel backing and power head assembly used in full-automatic numerical control drilling machine

InactiveCN110640181AReduce labor intensityImprove drilling efficiencyWork clamping meansLarge fixed membersNumerical controlRobot hand

The invention belongs to the technical field of numerical control drilling machines and relates to a full-automatic numerical control drilling machine for a brake pad steel backing and a power head assembly used in the full-automatic numerical control drilling machine. The full-automatic numerical control drilling machine comprises a rack assembly, a power head assembly, a station assembly, a binassembly, a three-axis positioning robot hand and an electric control system. Under the dispatching of the electric control system, the rack assembly, the power head assembly, the station assembly, the bin assembly and the three-axis positioning robot hand can be used for conducting high-precision and high-efficiency drilling on a top hole of an arc face of the brake pad steel backing automatically and continuously, and the obvious effects that the labor intensity is low and the application range is wide are achieved. By means of the full-automatic numerical control drilling machine for the brake pad steel backing and the power head assembly used in the full-automatic numerical control drilling machine, the linear distance between a front power head and a rear power head can be adjusted through a bidirectional screw rod module, the drilling angle of the front power head and the rear power head can also be adjusted correspondingly through a front electric indexing plate and a rear electric indexing plate, the parameter regulating range is wide, applicability is high, automatic drilling work of various types of brake pad steel discs on the current market can be completed, automatic machining of the top hole of the arc face of the brake pad steel backing is achieved, the market vacancy is filled up, and industry development is promoted.

Owner:宁国市铭昊智能装备有限公司

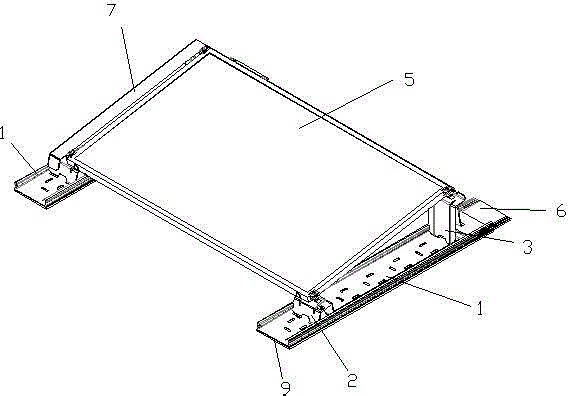

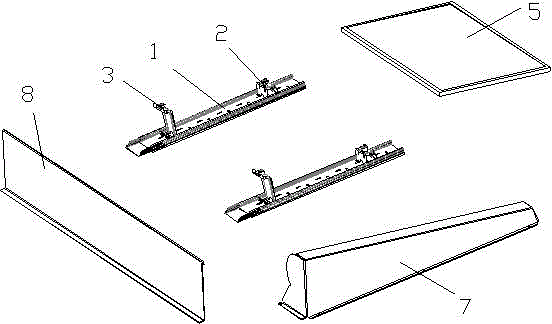

Non-penetration-type photovoltaic support

ActiveCN103986407AReduce load requirementsReduce windPhotovoltaic supportsPhotovoltaic energy generationEngineeringWind power

The invention discloses a non-penetration-type photovoltaic support which comprises a plurality of base plates, the front ends of the base plates are provided with front supporting bases, the rear ends of the base plates are provided with rear supporting bases, a photovoltaic module is fixed between every two adjacent base plates through pressing blocks arranged on the front supporting bases and the rear supporting bases, the rear sides of the photovoltaic modules are provided with back guide plates, and lateral backflow plates are arranged on the outer sides of the photovoltaic modules on the two sides of the photovoltaic support. The whole non-penetration-type photovoltaic support is designed by using the aerodynamics, the three sides of each photovoltaic module are all provided with the corresponding guide plates, air can be guided, wind power borne by whole equipment is reduced, the whole non-penetration-type photovoltaic support is designed independently, the non-penetration-type photovoltaic support can be used for modular production assembly, storage and transportation are greatly facilitated, net-shaped combination is used, no weights are needed for bottom stowage or only a small number of weights are needed for bottom stowage, and the cost is lowered; due to the fact that no bottom stowage and no fixation are needed, the weight is relatively low, and the bearing requirements for construction roofs can be lowered.

Owner:SUZHOU RADIANT PHOTOVOLTAIC TECH

Rotary type laser drilling positioning tool

ActiveCN109967901AGuaranteed drilling accuracySimple structureWelding/cutting auxillary devicesAuxillary welding devicesDrive motorLaser drilling

The invention discloses a rotary type laser drilling positioning tool, and mainly relates to the field of glass processing tools. The tool comprises a base, a supporting base, a locking mechanism anda workpiece positioning and fixing device, wherein a driving motor is arranged in the base; the supporting seat is rotationally connected with the base and is in transmission connection with the driving motor; the locking mechanism comprises an annular magnet fixed on the supporting seat and supports fixed to the top of the base, the center line of the annular magnet coincides with the center lineof the supporting base, electromagnets matched with the annular magnet are arranged at the top of the supports; and the workpiece positioning and fixing device is fixedly connected with the support seat. The tool can solve the requirement of glass annular drilling, and has the advantages of being simple in structure, convenient to operate, high in positioning precision and low in manufacturing cost.

Owner:JILIN TEACHERS INST OF ENG & TECH

Multi-spindle efficient drilling and milling machine tool and drilling method thereof

PendingCN113070505ASmall footprintLow costMeasurement/indication equipmentsMetal working apparatusMachine toolHole drilling method

The invention discloses a multi-spindle efficient drilling and milling machine tool. The multi-spindle efficient drilling and milling machine tool comprises a machine tool body, a workbench arranged on the machine tool body and used for placing a workpiece, a plurality of spindles arranged above the workbench and collinearly arranged in parallel in the length direction of the workpiece, a plurality of first driving assemblies respectively drive the spindles to move up and down in the height direction of the workpiece, and a plurality of second driving assemblies respectively drive the spindles to move left and right in the working length direction. According to the multi-spindle efficient drilling and milling machine tool, the spindles are driven by the independent first driving assemblies and the independent second driving assemblies correspondingly, so that the spindles can conduct machining at the same time, the center distance between the spindles can be conveniently adjusted, and therefore the multi-spindle efficient drilling and milling machine tool adapts to machining of workpieces with different hole distances, the machining efficiency is improved by multiple times, and the workpiece manufacturing period is shortened by multiple times. In addition, the invention further provides a drilling method applied to the multi-spindle efficient drilling and milling machine tool.

Owner:全准数控设备(苏州)有限公司

Drilling device for building construction

InactiveCN111761737AEnsure drilling qualityGuaranteed drilling accuracyWorking accessoriesStone-like material working toolsArchitectural engineeringSlide plate

The invention discloses a drilling device for building construction. The drilling device comprises a machine body, a drill bit and a handle are installed on the machine body, the drilling device further comprises a sleeve plate, the machine body is clamped in the sleeve plate in a sliding mode through sliding blocks, and supporting legs are vertically fixed to two sides of the sleeve plate; and asliding rail is horizontally fixed to the upper end of the machine body, a sliding plate is embedded in the sliding rail in a sliding mode, scale marks are arranged on the sliding plate, and an indicating strip matched with the scale marks is arranged on the upper end face of the sleeve plate. According to the drilling device for building construction, the machine body is vertically clamped in thesleeve plate in a sliding mode and supported on the wall face through the supporting legs on the sleeve plate, so that the drill bit is always perpendicular to the wall face in the drilling process,and then the drilling quality is guaranteed; and the sliding plate with the scale marks is arranged on the machine body, zero setting before drilling can be carried out according to the drill bits ofdifferent lengths, the drilling depth can be visually known according to the scales indicated by the indicating strip after zero setting is completed, thus the drilling precision is guaranteed, and the drilling device is suitable for the drilling requirements of different depths, and is convenient and rapid to operate.

Owner:许光福

Multi-station drilling machine capable of conveniently drilling two ends of column simultaneously

ActiveCN112338226AImprove continuityImprove drilling efficiencyMetal working apparatusBoring/drilling machinesControl engineeringElectric machinery

The invention discloses a multi-station drilling machine capable of conveniently drilling the two ends of column simultaneously. The multi-station drilling machine comprises a supporting table plate,a first supporting table is fixedly connected to the side, close to the front left portion, of the middle of the upper end of the supporting table plate, and a transposition motor is fixedly connectedto the rear portion of the upper end of the first supporting table; the output end of the transposition motor is fixedly connected with a material bearing mechanism in a penetrating and inserting mode, and the upper portion of the material bearing mechanism is movably connected with an L-shaped positioning mechanism; the lower end of the positioning mechanism is fixedly connected with the front side of the middle of the upper end of the supporting table plate, and a chip groove is formed in the middle of the upper end of the supporting table plate; and the chip groove is formed under the material bearing mechanism. According to the multi-station drilling machine capable of conveniently drilling the two ends of the column simultaneously, through rotation of a supporting disc, the five charging barrels are arranged on the supporting disc, drilling operation can be continuously conducted on the five columns, through drilling cutters on the left side and the right side of the material bearing barrel, the two end faces of the columns can be drilled at the same time, and the drilling efficiency is high.

Owner:中山开通塑胶五金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com