Aerated Concrete Block Horizontal Deep Hole Group Drilling Machine

A technology of aerated concrete and blocks, which is applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of aerated concrete block drilling, easy breakage, etc., achieve high drilling efficiency, ensure drilling The effect of hole accuracy and efficiency, easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

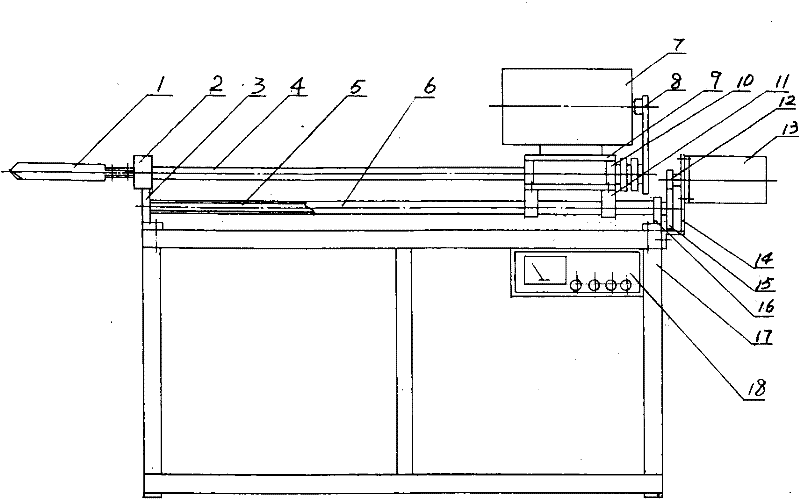

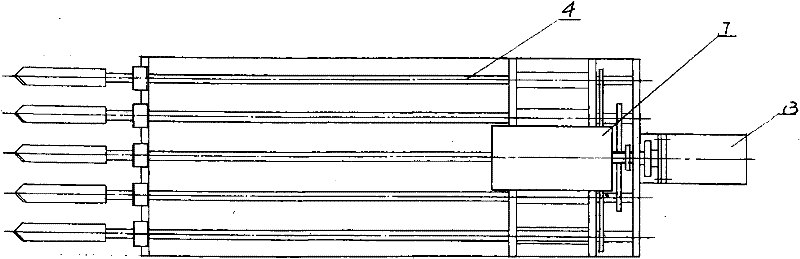

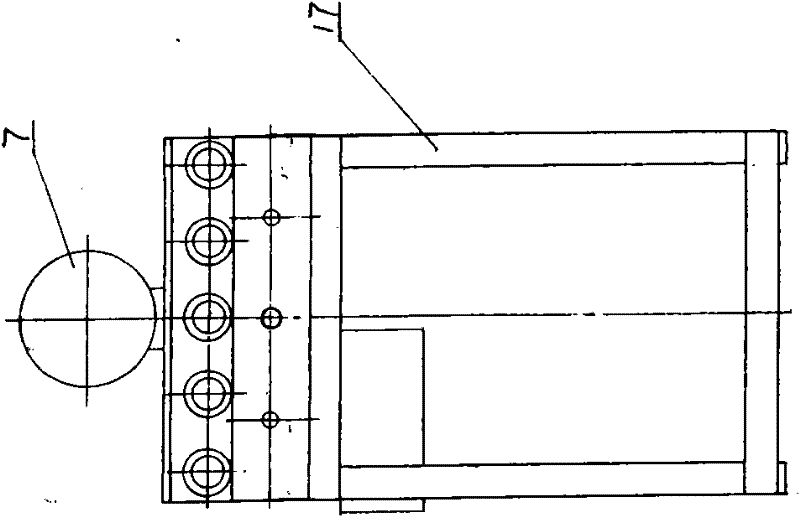

[0010] See attached figure 1 ~ attached image 3 Shown:

[0011] This embodiment consists of a twist drill bit 1, a composite bearing 2, a guide rod bracket 3, a drill rod 4, a screw rod 5, a guide rod 6, a drilling motor 7, a transmission system 8, a motor base 9, a movable drill stand 10, and a linear slider 11 , small gear 12, automatic advance and retreat knife motor 13, motor support 14, large gear 15, screw support 16, frame 17, electrical control box 18 are combined, the twist drill bit 1 is connected with the drill pipe 4, and the composite bearing 2 Under the support and guidance, it can move forward and backward. The composite bearing 2 is connected with the guide rod bracket 3 and installed on the left side of the frame 17. The rear part of the drill pipe 4 is connected to the movable drill frame 10 and moves together with the movable drill frame 10. , the drilling motor 7 is connected to the movable drill frame 10 with the motor base 9, and the movable drill fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com