Multi-angle coal petrography drilling machine

A multi-angle, coal-rock technology, used in drilling equipment, earth-moving drilling, drilling equipment and methods, etc., can solve the problems of inconvenient adjustment of the drilling direction, large size and bulkiness of the drilling rig, saving manufacturing materials and simplifying the drilling rig. Structure, the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

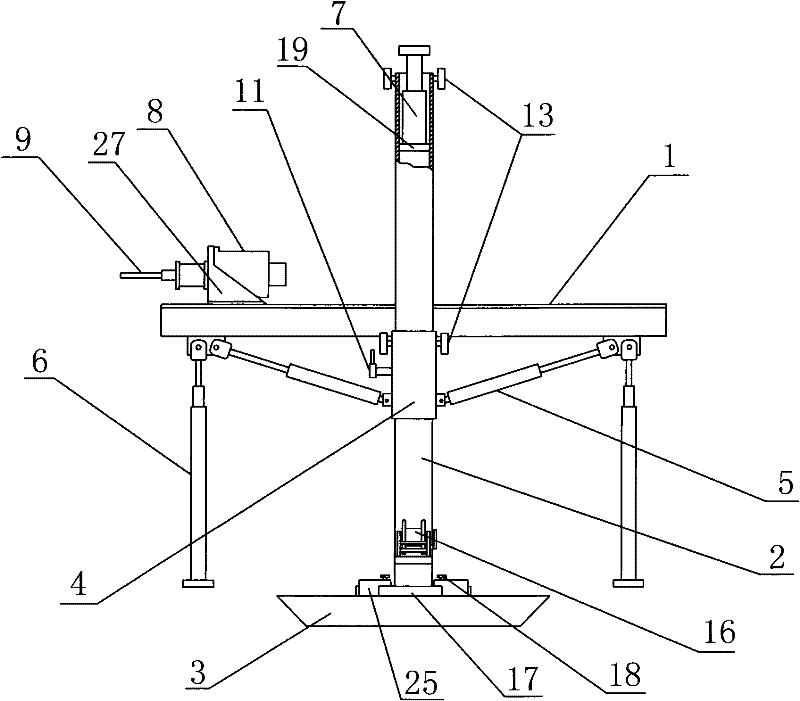

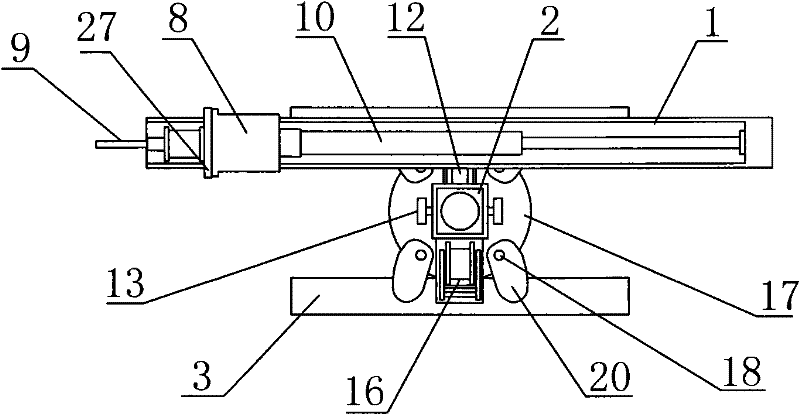

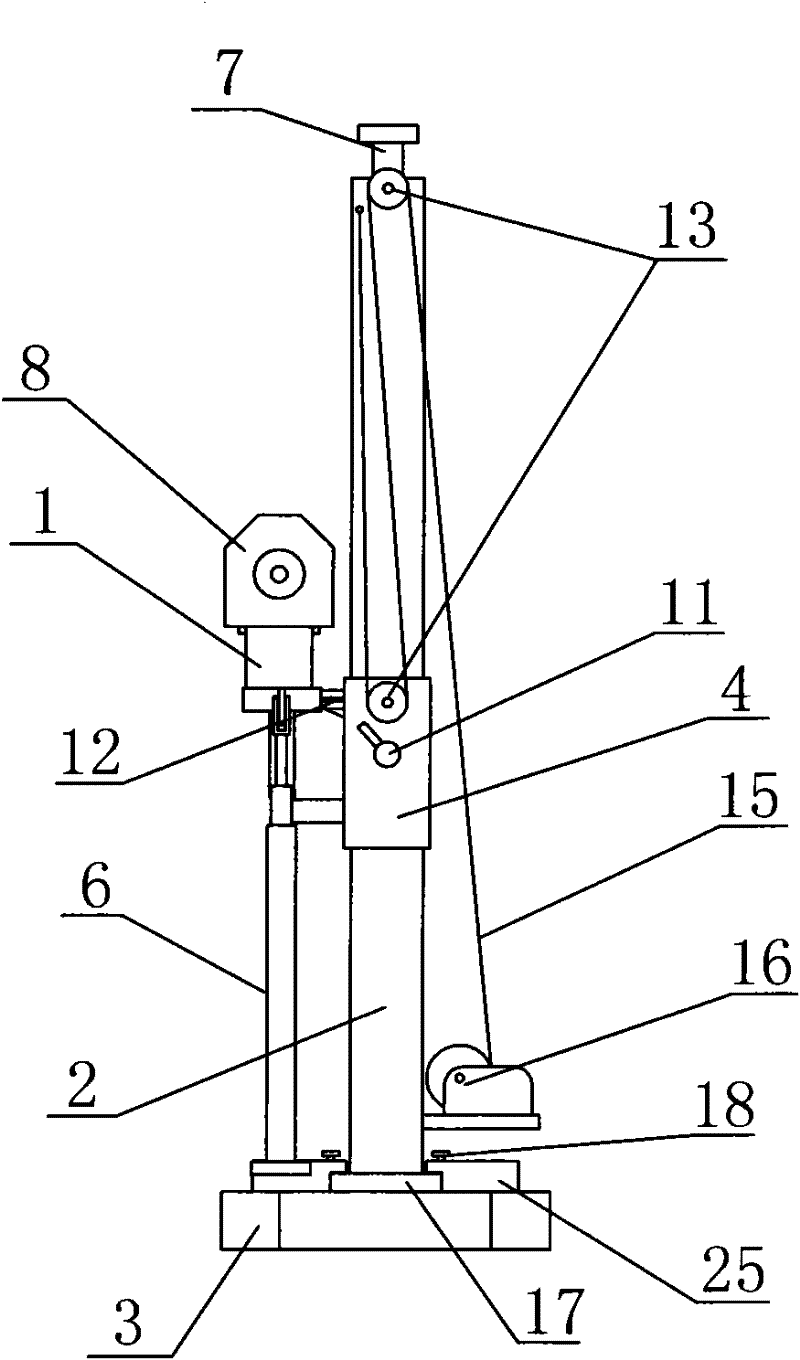

[0018] As shown in the figure, a multi-angle coal rock drilling rig is provided with a motor 8 in the track groove of the horizontal guide rail 1, and the motor 8 is connected with a propulsion cylinder 10 in the track groove of the horizontal guide rail 1. Drill rod 9 is connected with motor 8 . Motor 8 is a variable speed motor, which can be driven by electricity or hydraulic pressure. The center of the drill rod 9 is provided with a through hole 26 through which high-pressure water or air can be introduced for cooling or powder discharge during the drilling process. The drilling machine also includes a lifting guide rail 2, and the lifting guide rail 2 and the horizontal guide rail 1 are arranged in a cross. A sliding sleeve 4 is provided on the lifting guide rail 2 . The horizontal guide rail 1 is arranged on one side of the sliding sleeve 4 , and its middle is connected with the sliding sleeve 4 through a rotating shaft 12 . Two oblique telescopic support arms 5 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com