Patents

Literature

96 results about "Coal petrography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal petrography multiphase different fluid three-axis crushing test unit and method

ActiveCN105510142ARealize the effects of fracturingEnables research on the effects of fracturingMaterial strength using tensile/compressive forcesTest comparisonData acquisition

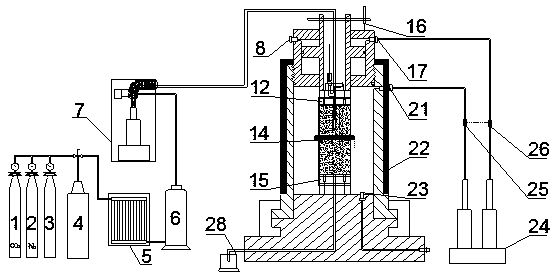

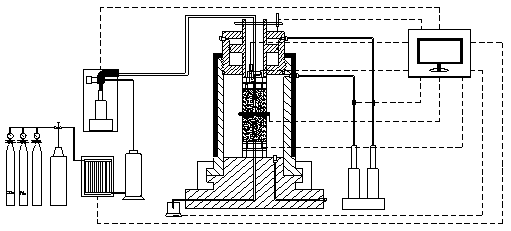

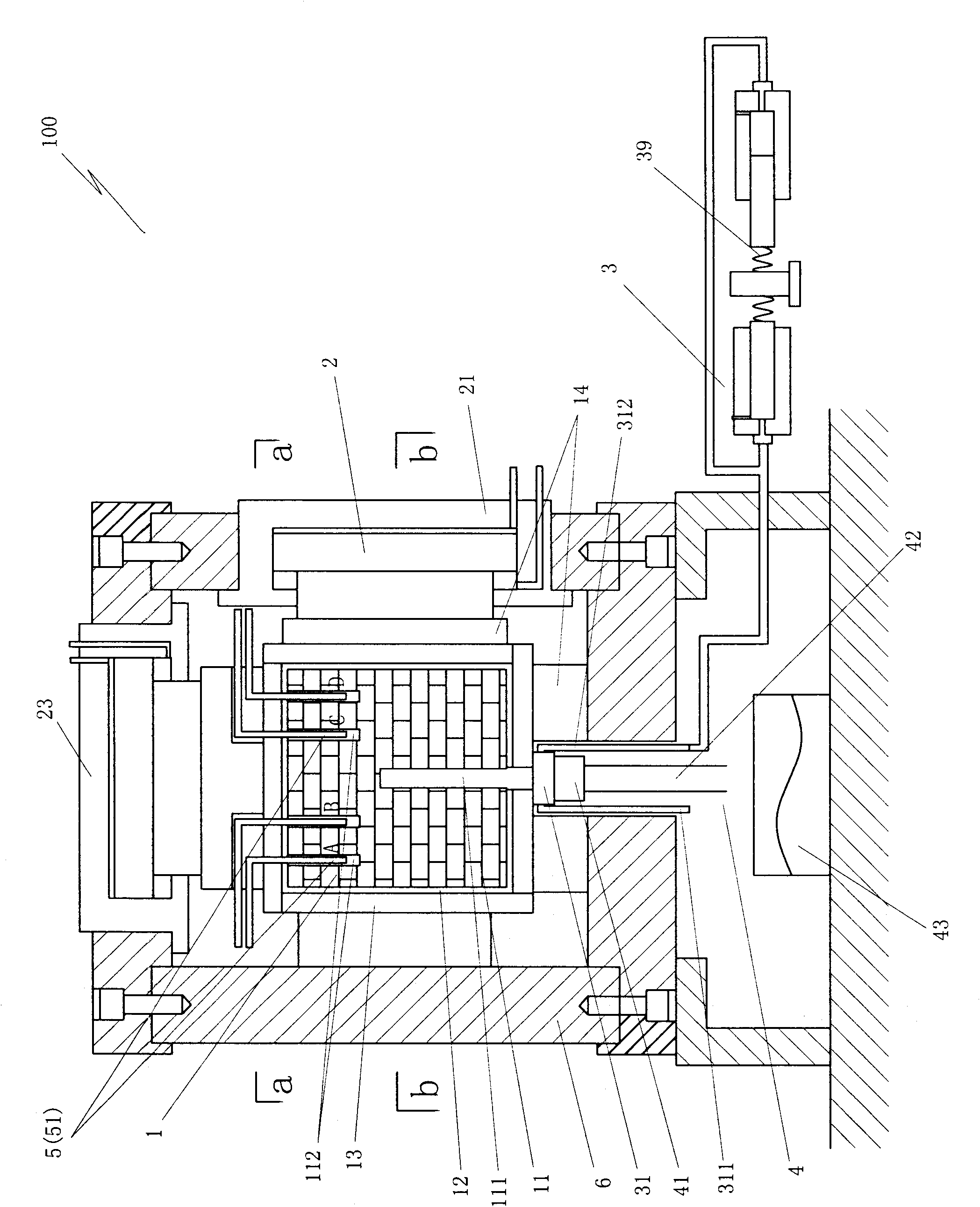

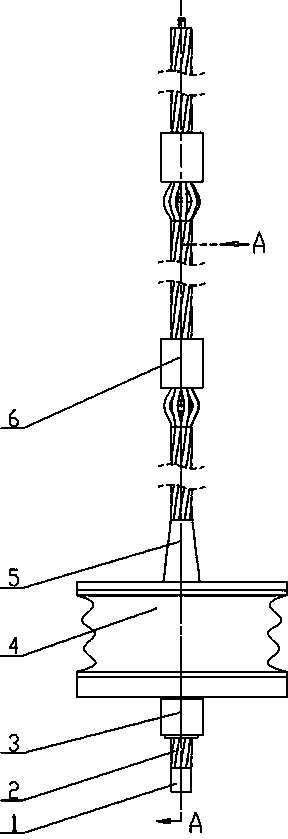

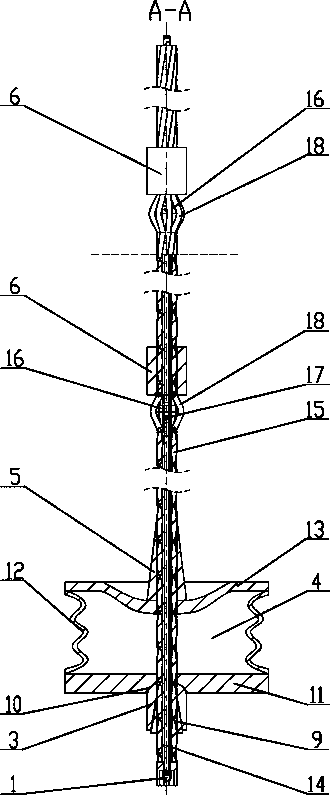

The invention discloses a coal petrography multiphase different fluid three-axis crushing test unit and method and belongs to the technical field of rock and rock mass mechanics and engineering. The unit is composed of a three-axis stress real-time loading system, a multiphase different fluid crushing system, a sealing system, a temperature control system, an acoustic emission monitoring system and a data acquisition system. Different fluid and multiphase crushing test comparison can be conducted on a coal petrography test piece, sensibility of parameters, such as fluid pressurization rate, fluid viscosity, fluid isothermal compressibility and fluid temperature, affecting crushing of the coal petrography test piece can be analyzed under multiple conditions, the change rule of the pressure and temperature of a crushing medium can be precisely recorded in a crushing experiment, acoustic emission events during test piece crushing can be recorded in real time through an assembled micro acoustic emission sensor, and multi-phase fluid seepage tests before and after crushing can also be conducted on the coal petrography test piece.

Owner:TAIYUAN UNIV OF TECH

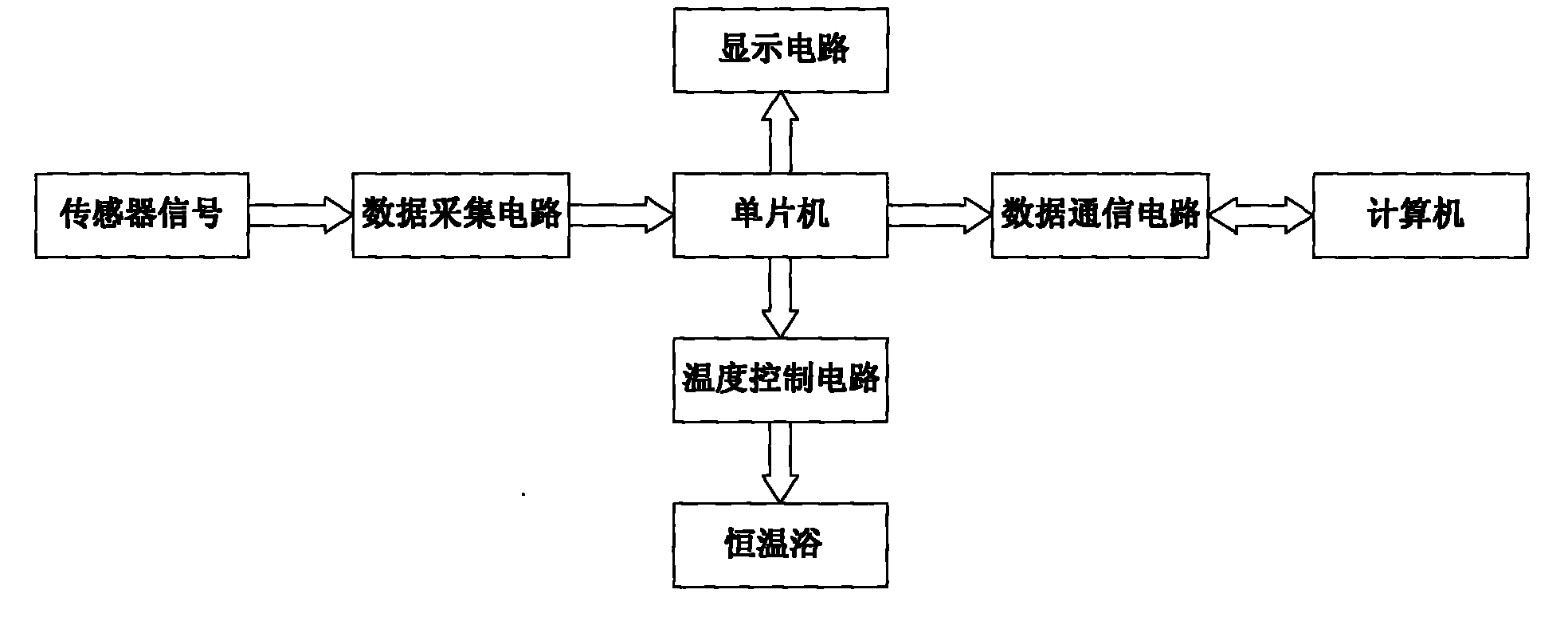

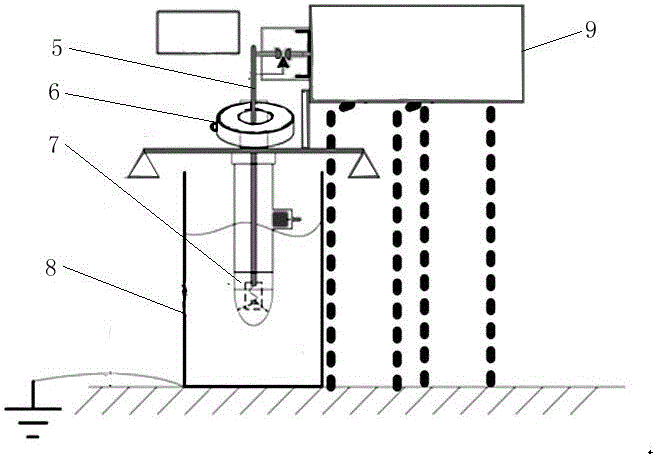

Method for simultaneously measuring high-pressure gas adsorption capacity and adsorption swell capacity of coal petrography and measuring equipment

InactiveCN101975718AEasy to measureQuick measurementMaterial analysisHigh resistanceSwelling capacity

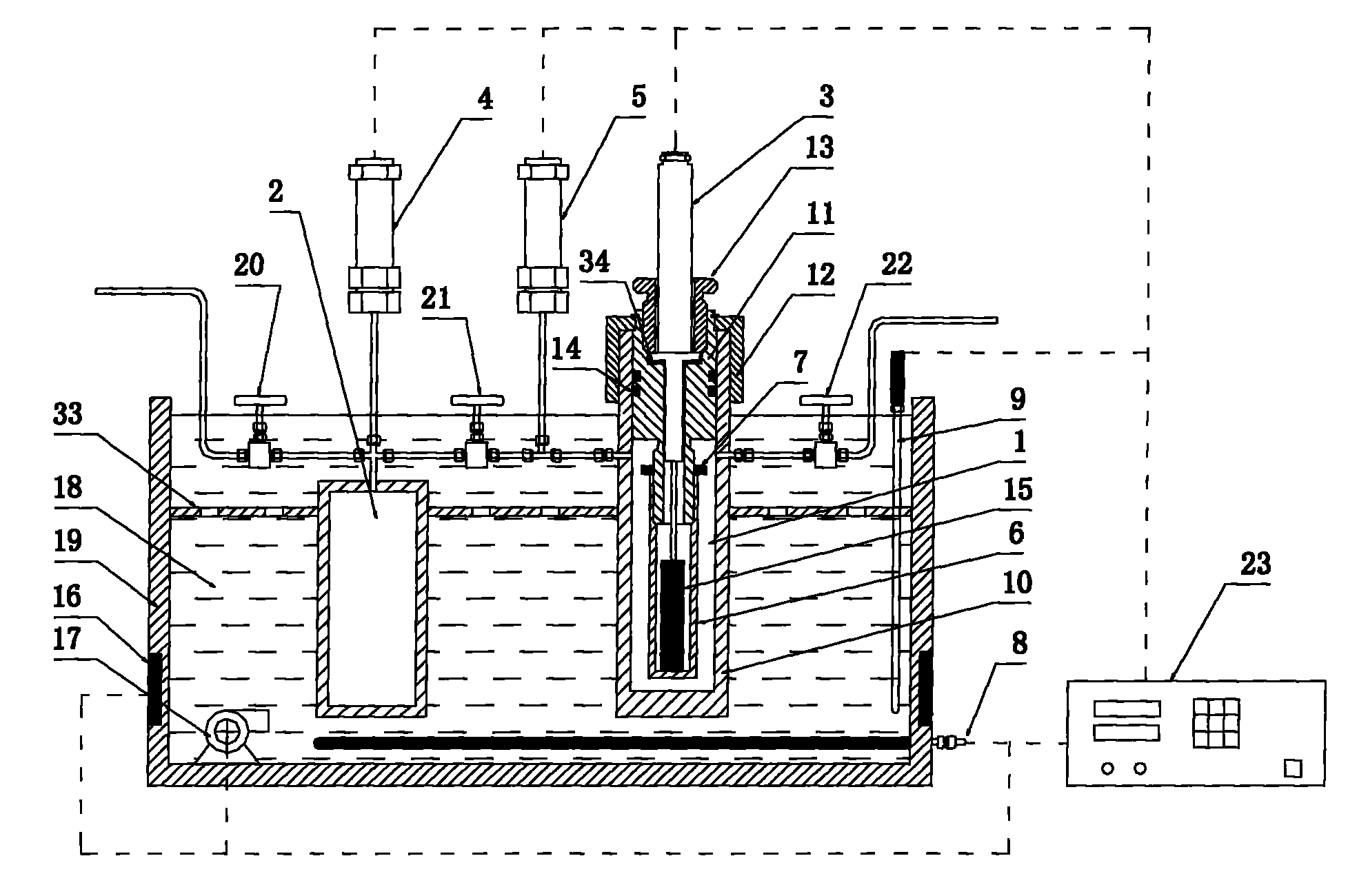

The invention provides a method for simultaneously measuring high-pressure gas absorption capacity and adsorption sell capacity of coal petrography and measuring equipment, which can simultaneously measure the adsorption capacity and adsorption swell capacity of the coal petrography in high-pressure gas at a pressure of 0-20MPa and a temperature of 0-80 DEG C. In the process of measurement, a measurement and control device is used for performing signal transformation and analog-to-digital conversion on electrical signals of a displacement sensor, a temperature-measuring hot resistor and a pressure transmitter; a computer is used for automatically receiving pressure, temperature and displacement signal data from the measurement and control device and recording and saving the received data; and a computer screen is used for displaying the pressure, temperature, adsorption capacity and swell capacity data timely in the process of measurement and the change law curves of the pressure, the temperature and the swell capacity with the change of time in real time. In the method of the invention, the measurement on the adsorption capacity and the adsorption swell capacity can be finished simultaneously, so that the method is simple and convenient and fast, and has the advantages of simple structure, reliable and safe high-pressure seal, easy operation, high measurement accuracy, high resistance to pressure and automatic measurement.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

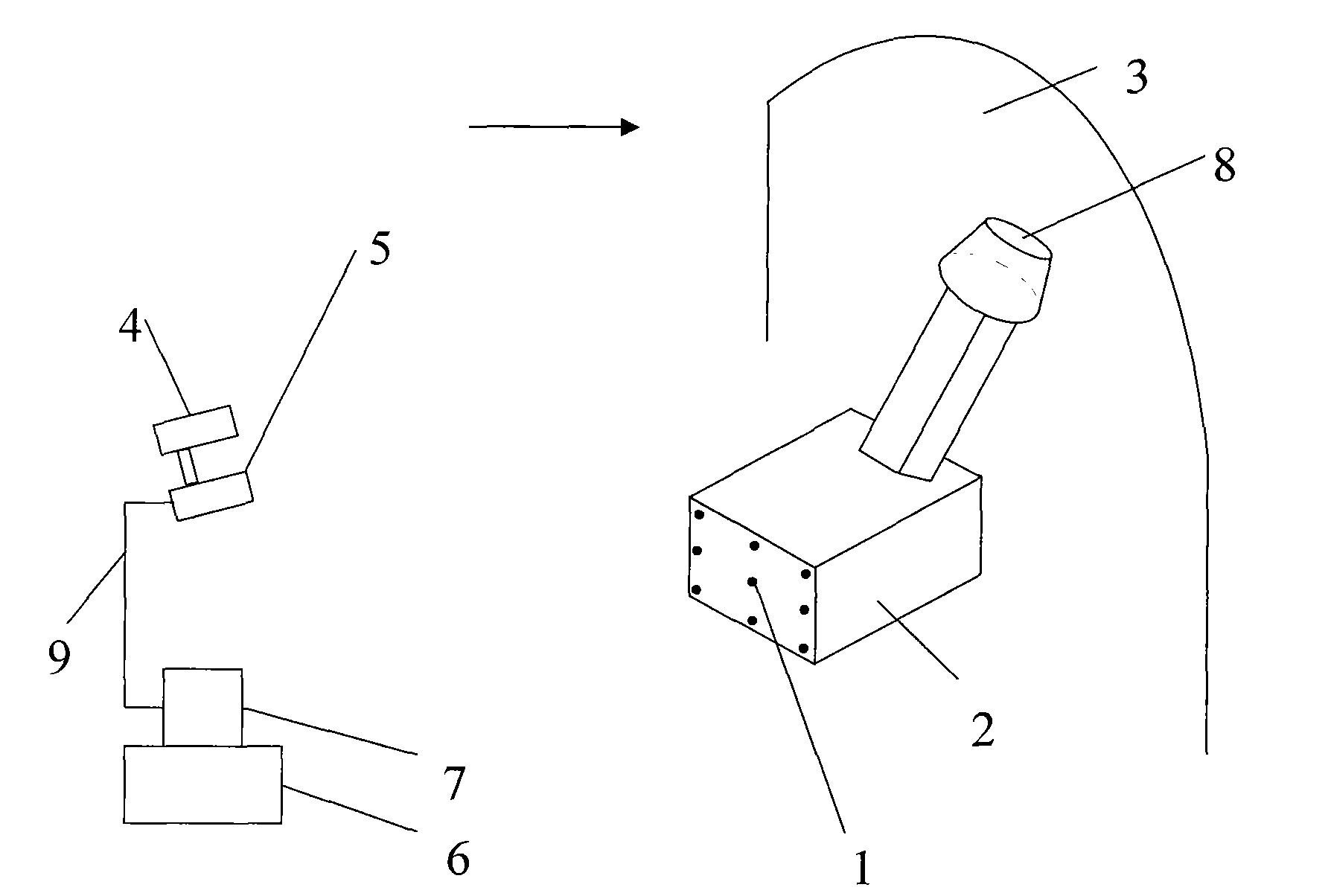

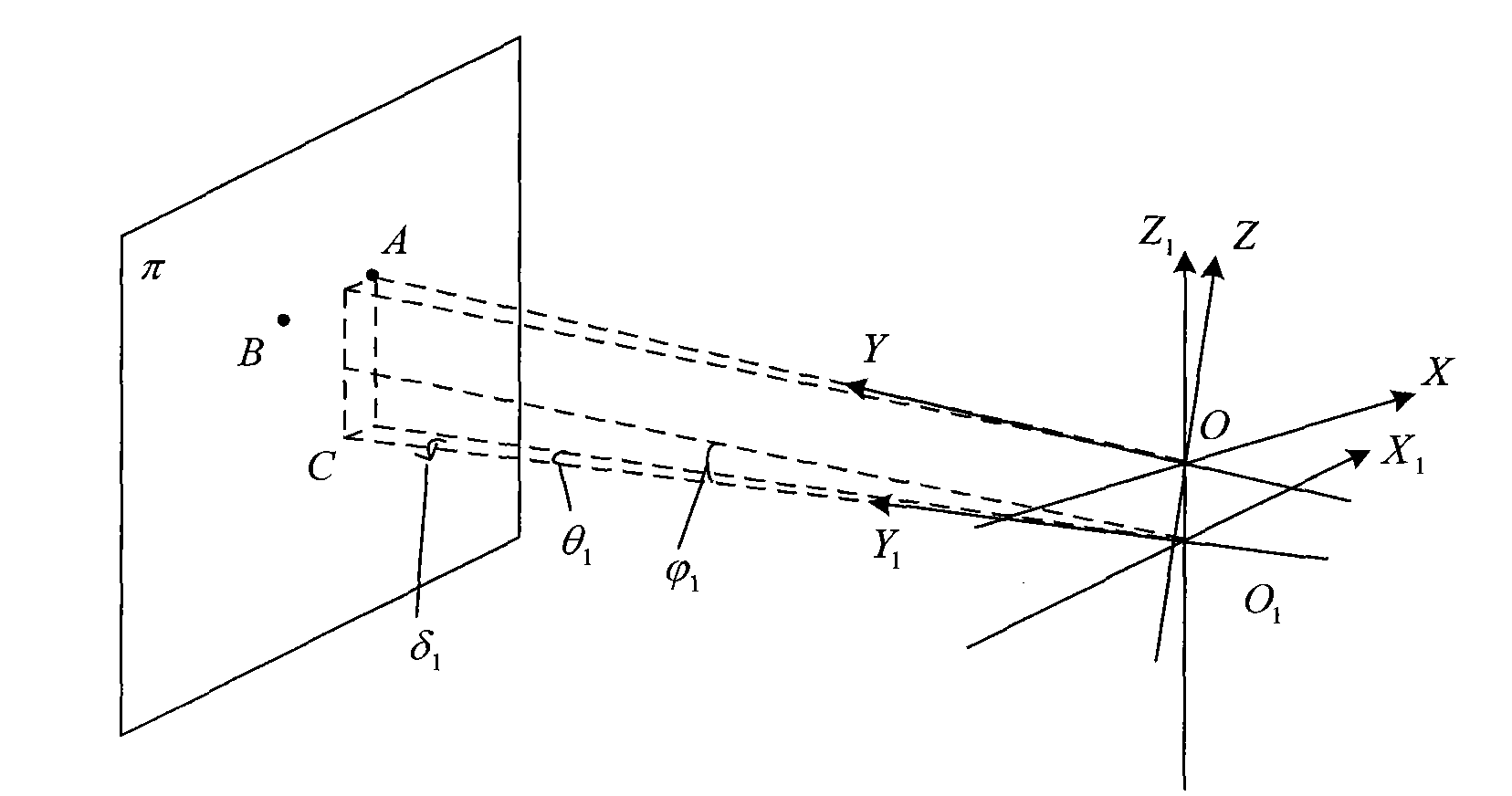

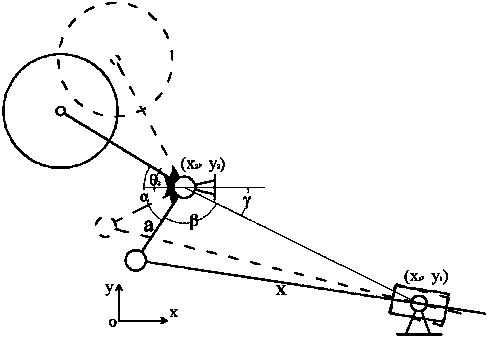

Method for automatically measuring special position of tunnel boring machine

ActiveCN101819036AIdeal mining pose measurement methodAdvancedAngle measurementView cameraTunnel boring machine

The invention relates to a method for automatically measuring the special position of a tunnel boring machine. According to the practical situation of the tunneling operation of the tunnel boring machine in a small underground space of a coal mine, an industrial view camera, an industrial computer, a laser orientation instrument and an image acquisition card are arranged on the back part of the tunnel boring machine. The position of the tunnel boring machine on a coal petrography cross section is measured and calculated, the most reasonable position of a machine body is determined, a command on an excavating operation is made and operators are far away from hazardous areas so as to reduce sudden accidents, enhance excavating safety and keep the tunnel boring machine on a best and most reasonable position and in a best and most reasonable state. A maximum cover angle is + / -60 degrees, a displacement detection deviation is less than 10 millimeters, the detection accuracy of a deflection angle is + / -12 gon, the detection accuracy of a pitch angle is + / -6 gon and the detection accuracy of a roll angle is + / -6 gon so as to improve excavating quality and efficiency. The method is advanced, reasonable and correct, is a very ideal method for measuring the excavation position of a coal extraction tunnel boring machine and can be used in tunnel excavation operation.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

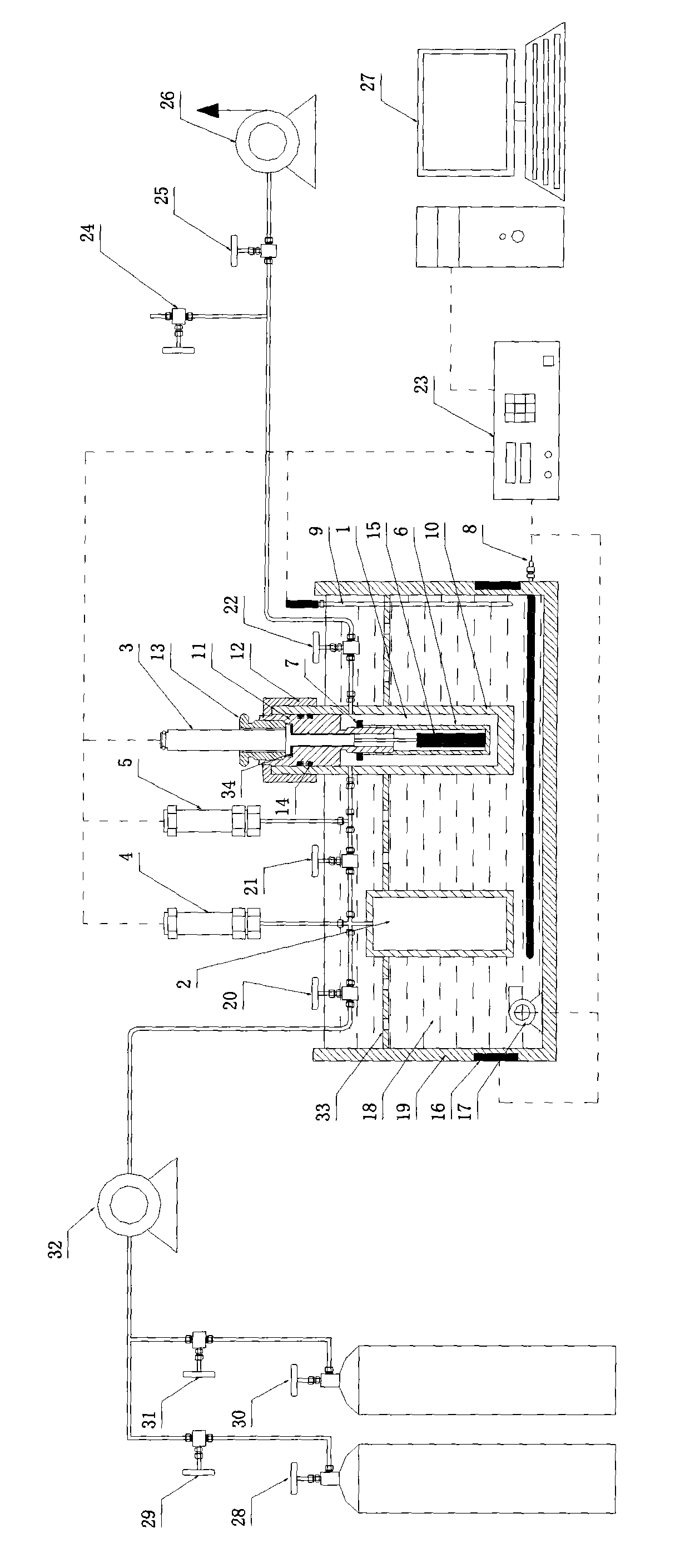

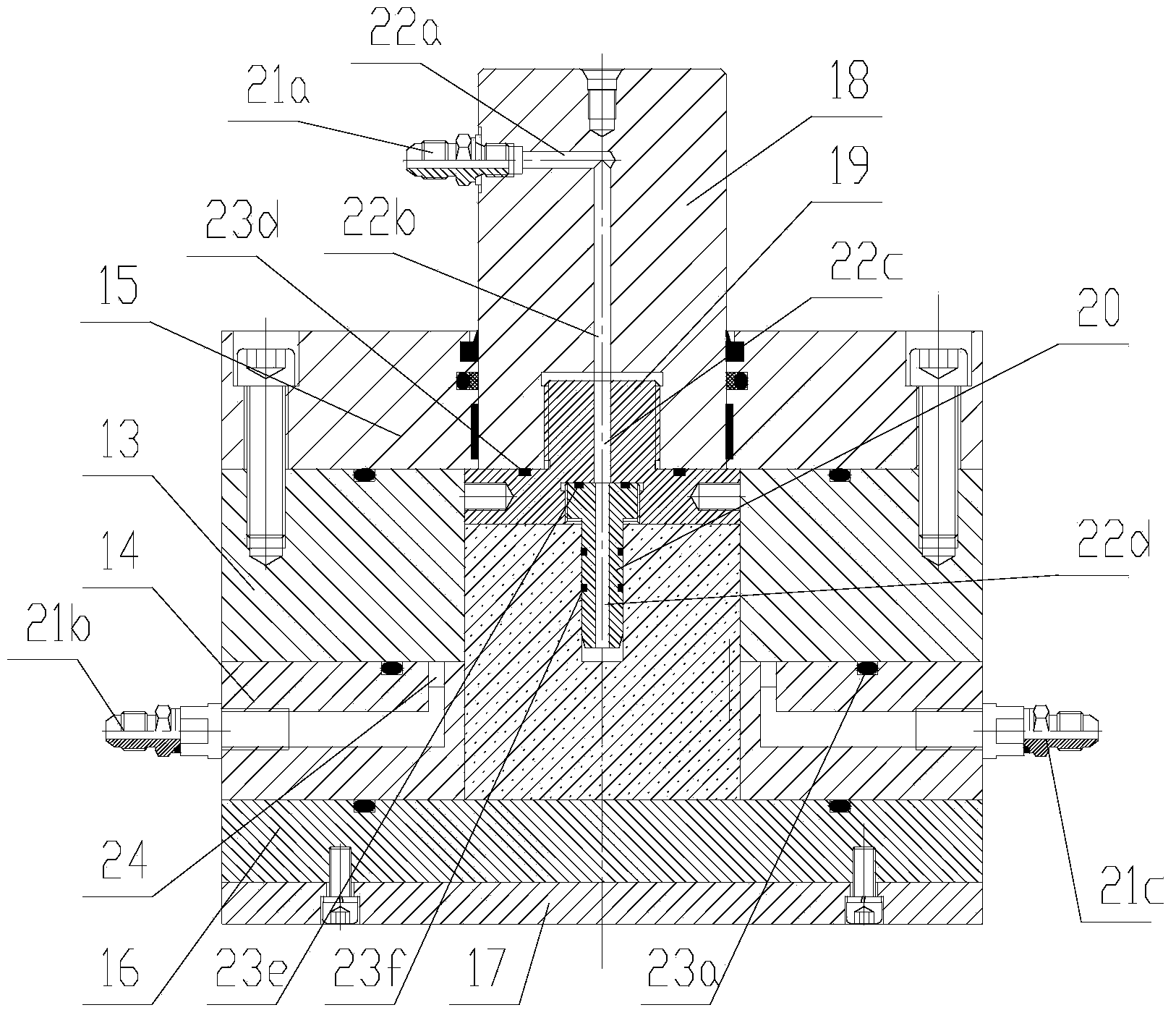

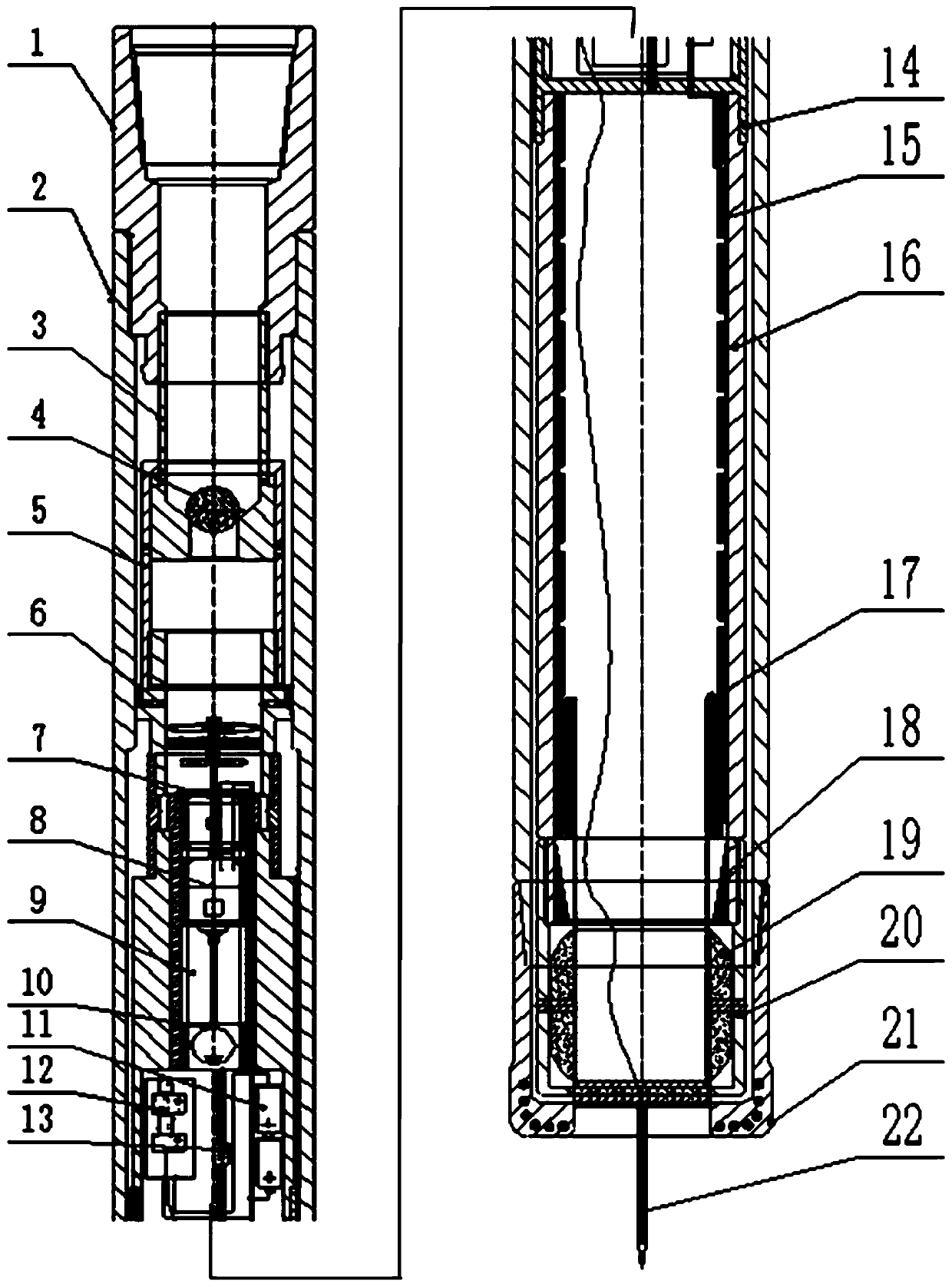

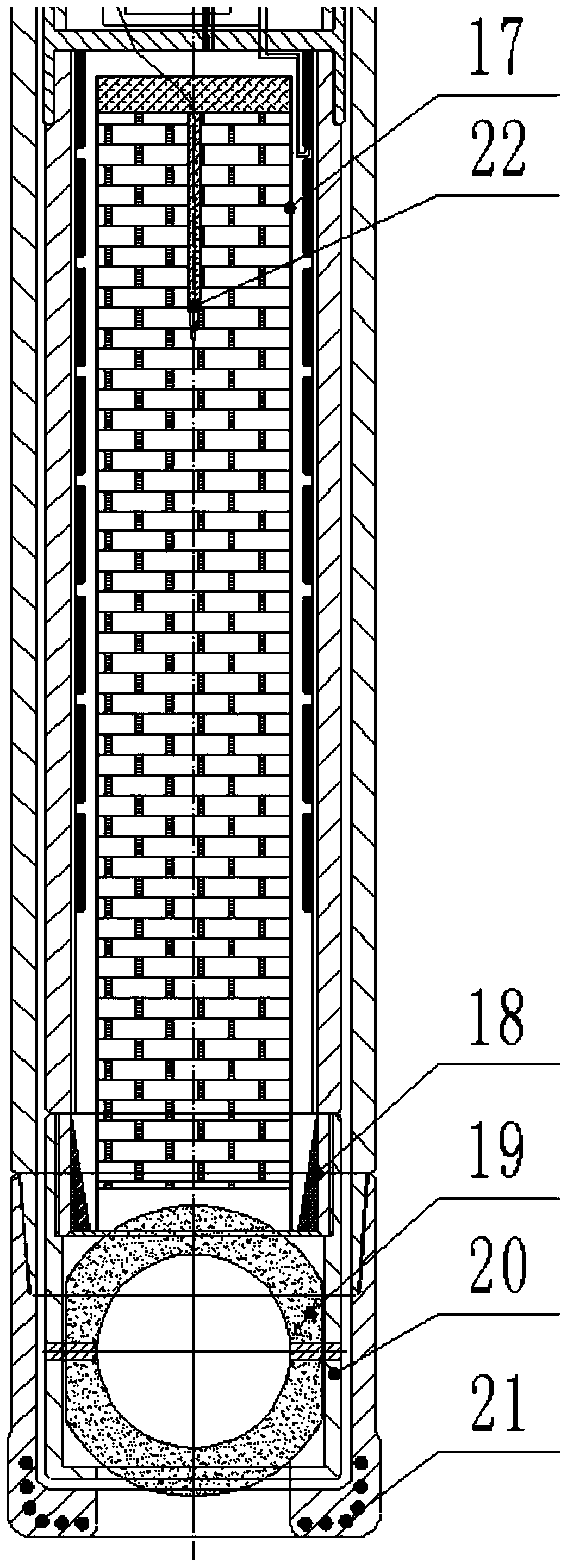

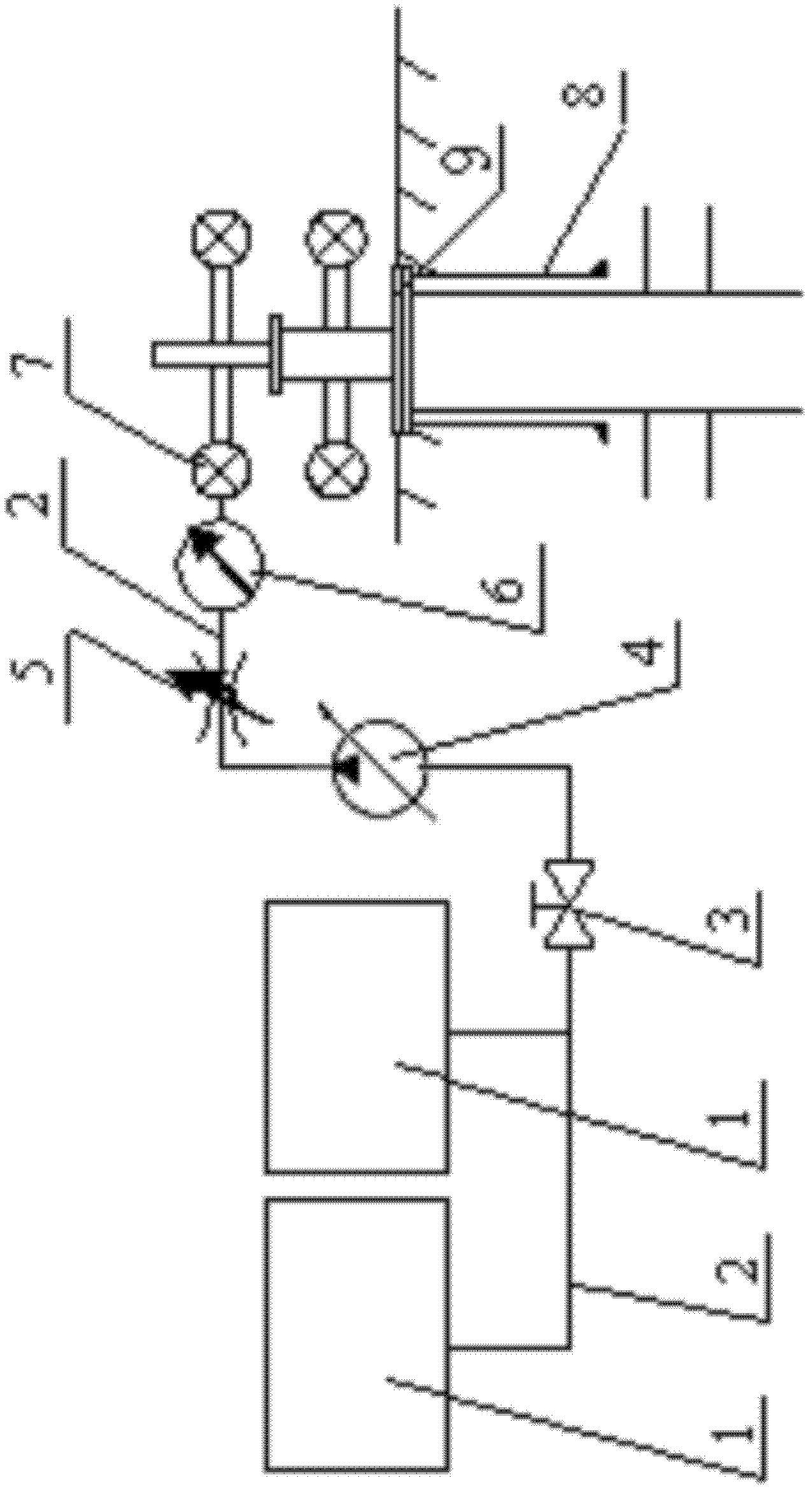

Supercritical carbon dioxide fracture-creepage-seepage test device for high-temperature high-pressure coal petrography

InactiveCN110057739AMonitor pressureRich researchPermeability/surface area analysisEngineeringHigh pressure

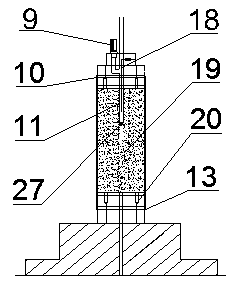

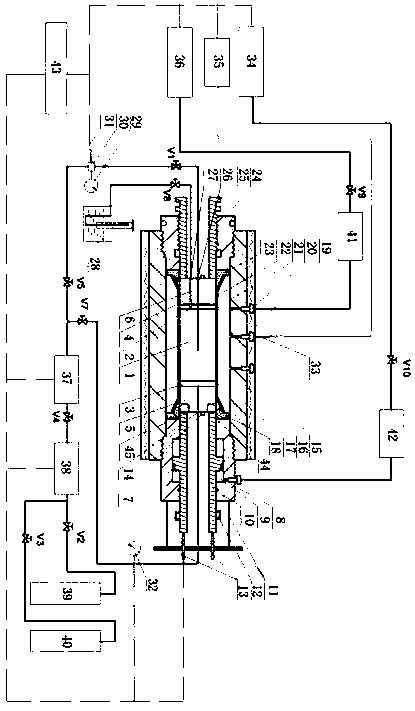

The invention discloses a supercritical carbon dioxide fracture-creepage-seepage test device for high-temperature high-pressure coal petrography. The device comprises a triaxial cell, a supercriticalcarbon dioxide generator system, an axle load and confining pressure loading system, an acoustic emission monitoring system, a temperature rise control system, a deformation-pressure monitoring systemand a permeability measuring system. The device is capable of realizing the supercritical carbon dioxide fluid fracture test of coal petrography under high temperature and high pressure, monitoring and recording the temperature and pressure changes of supercritical carbon dioxide and characteristics of fracture cracking and extension in the supercritical carbon dioxide fracture process in real time, monitoring and recording the axial and radial deformations of coal petrography samples in real time, directly and effectively measuring the DH4 permeability of the coal petrography before and after the fracture without unloading the coal petrography sample stress, and measuring the CH4 permeability of the coal petrography after the fracture under the action of creepage. The measurement methodis high in precision, intuitional and high in automation degree, and the device is simple in structure.

Owner:TAIYUAN UNIV OF TECH

Multi-parameter aggregative indicator forecasting method of coal petrography dynamic disaster

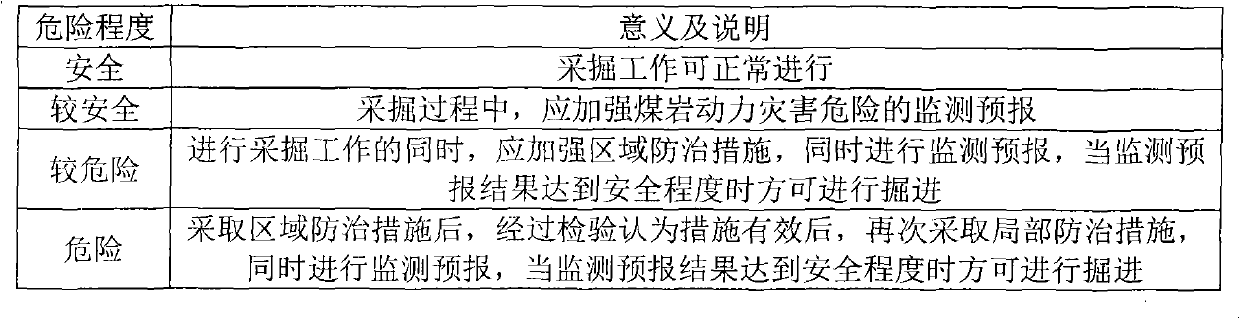

A multi-parameter aggregative indicator forecasting method of a coal petrography dynamic disaster is suitable for forecasting coal petrography dynamic disasters such as outburst of coal and gas and rock bust of coal and gas in a coal mine excavating process. When various index prediction methods are coupled in the same monitoring system, problems such as how to select importance degrees of various indicators and how to determine a critical value of the various indicators are produced. According to amplitude values of four indicators including electromagnetic radiation, slight shock, acoustic emission and gas density, an average value of the amplitude values in a normal level and the maximum value of the amplitude values of the four indicators when the coal petrography dynamic disasters happen at any moment, the multi-parameter aggregative indicator forecasting method of the coal petrography dynamic disaster determines a single indicator hazard index of the four indicators at the moment. The value of single index hazard index determines single index weights of the four indicators, and therefore an aggregative indicator hazard index of the four indicators is calculated, and finally a danger class of the coal petrography dynamic disaster which happens in an excavating roadway is determined according to the value of the aggregative indicator hazard index. The multi-parameter aggregative indicator forecasting method of the coal petrography dynamic disaster provides a critical value determination method and an early warning standard for the research and development of a multi-parameter monitoring system of the coal petrography dynamic disaster.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

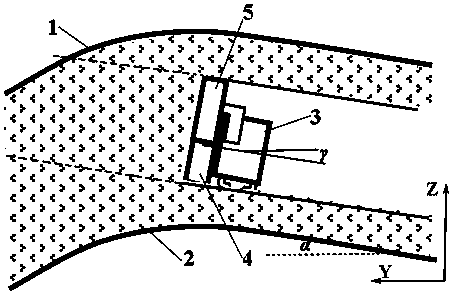

Sensor fixing test rack for uniaxial compression sound emission test of coal petrography and application method of same

InactiveCN103412054AReduce lossGuaranteed reuseMaterial analysis using acoustic emission techniquesUniaxial compressionEngineering

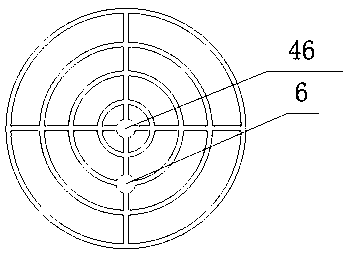

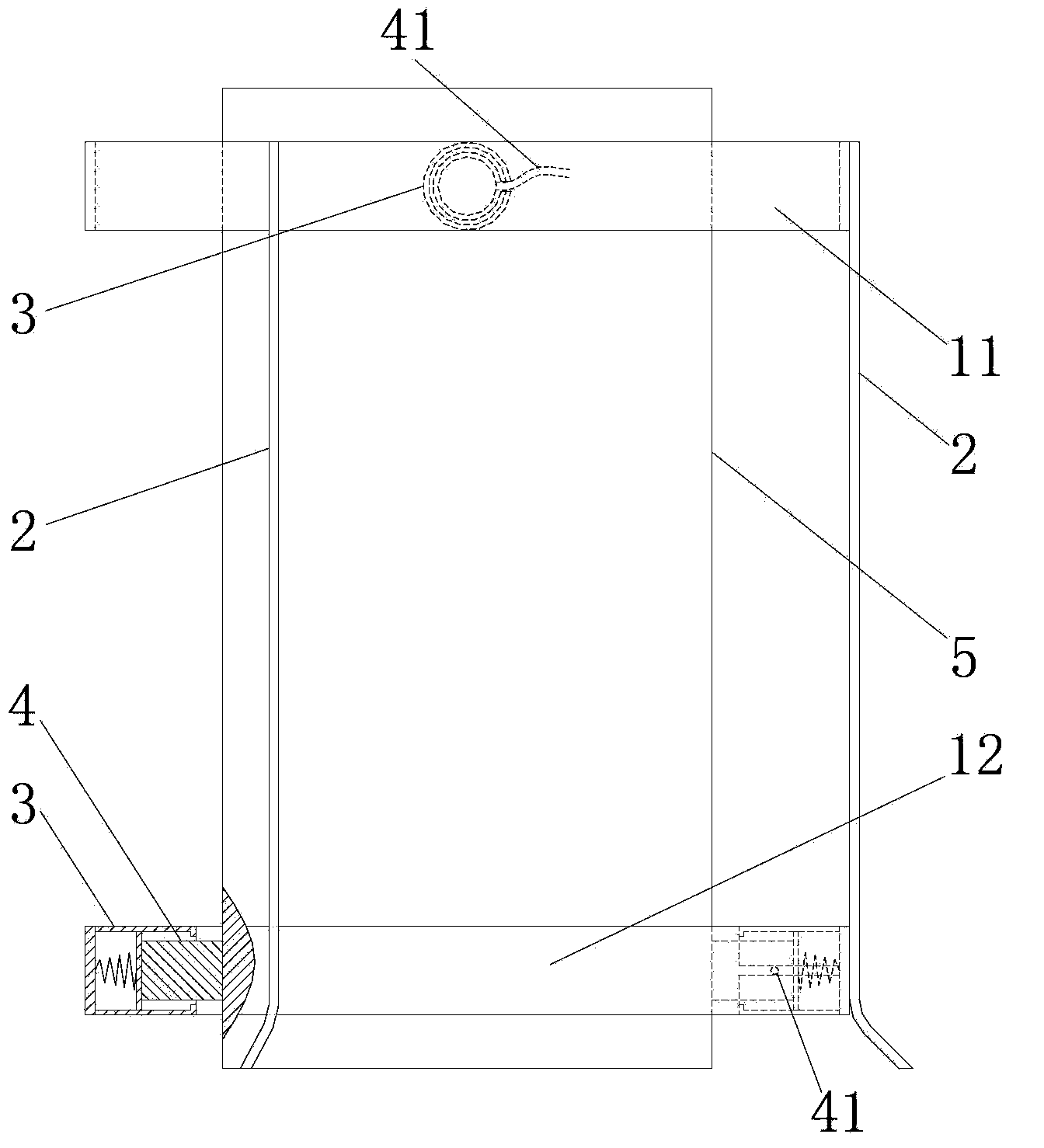

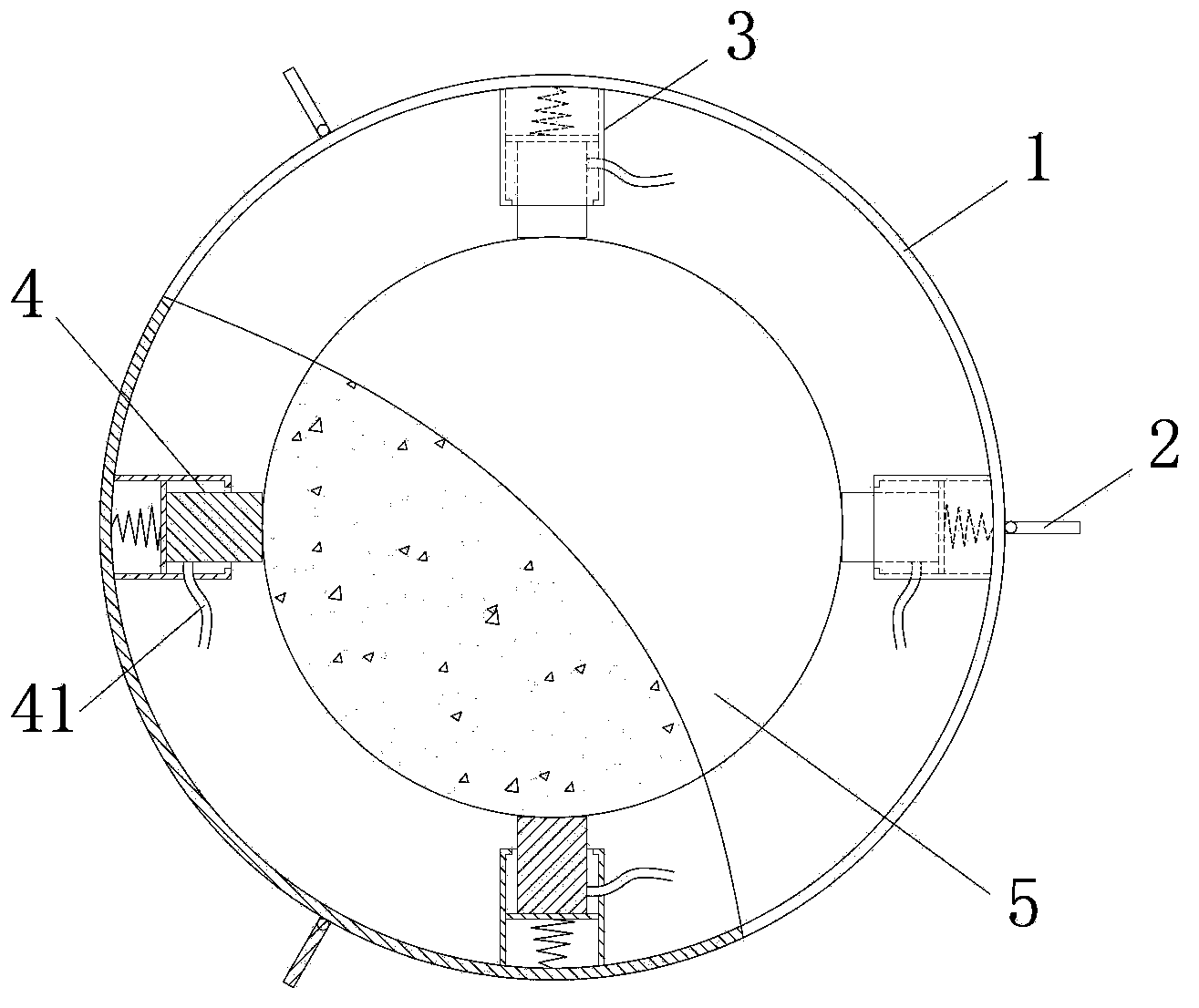

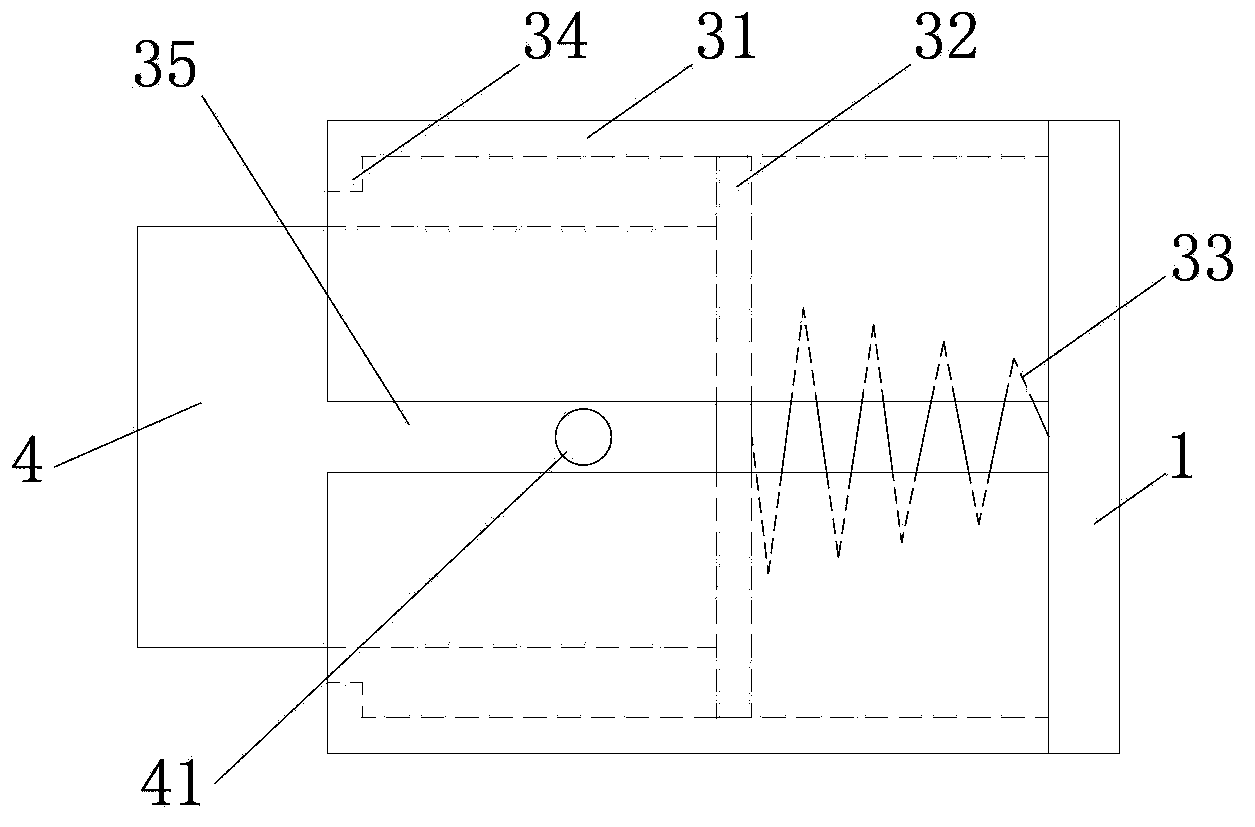

The invention discloses a sensor fixing test rack for a uniaxial compression sound emission test of coal petrography and an application method of the sensor fixing test rack. The test rack comprises a round rack in which a coal petrography sample is arranged, and three foot stools distributed at 120 degrees and used for fixing the round rack, wherein clinging devices used for fixing sound emission sensors in contact with the coal petrography sample are arranged on the round rack; the round rack comprises an upper round rack and a lower round rack which are respectively fixed with the upper parts and the lower parts of the three foot stools; the plurality of clinging devices are respectively fixed on the upper round rack and the lower round rack. When in use, the sensor fixing test rack is placed on a uniaxial compression tester; a coupling agent is uniformly applied on the surfaces of the signal acquisition ends of the sound emission sensors; after the sound emission sensors are mounted, the coal petrography sample is placed, and then the uniaxial compression sound emission test can be performed. The sensor fixing test rack solves the problems that at present, when the uniaxial compression sound emission test is performed in a laboratory, the spatial position of the sensors can not be fixed accurately, the sensors drop in the testing process, and high labor intensity is caused by repeated disassembly and assembly of the sensors.

Owner:CHINA UNIV OF MINING & TECH

Method for identifying coal petrography interface of thin coal layer and automatically heightening expansion cylinder

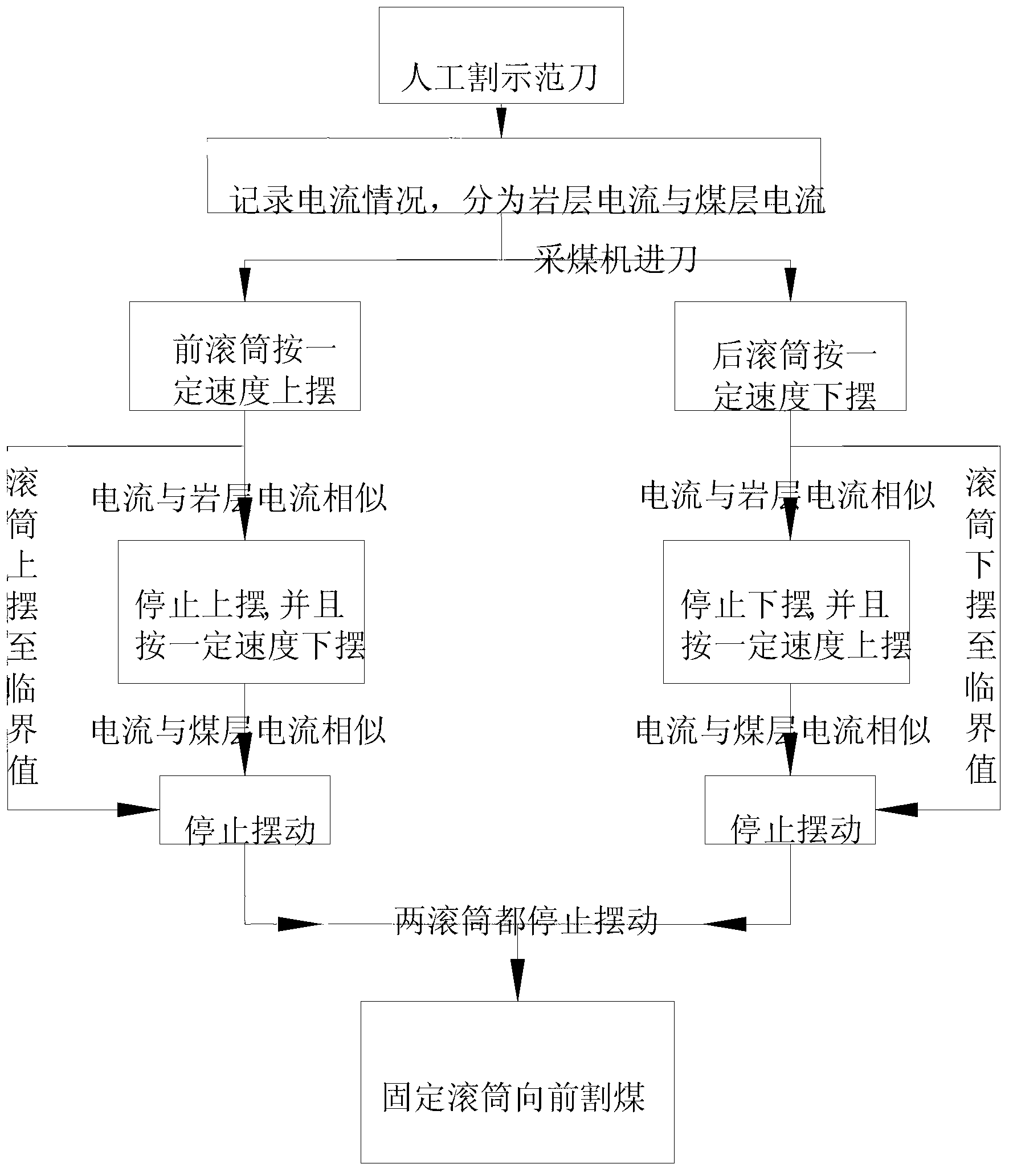

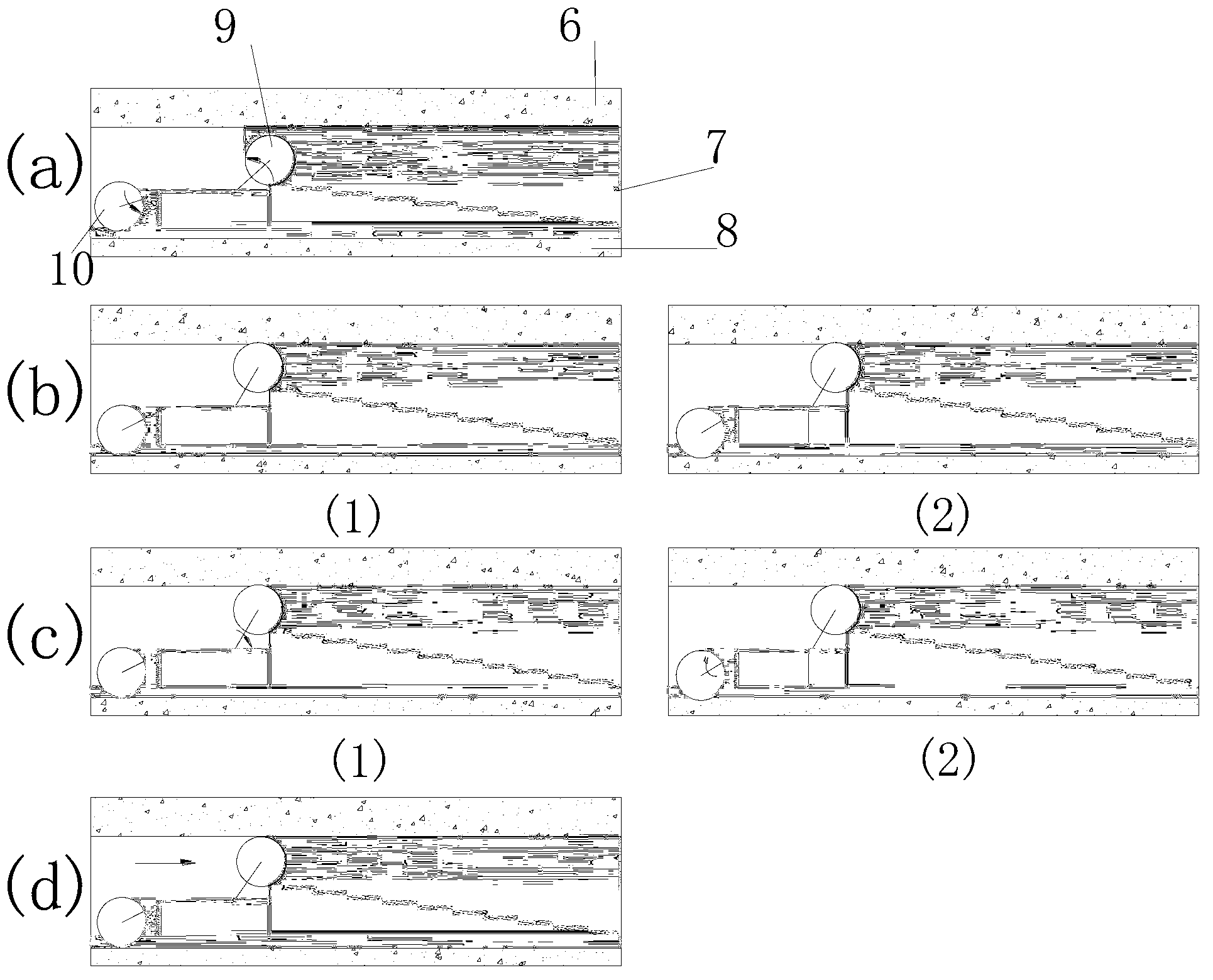

ActiveCN103216233ARealize unmanned operationPromote recoverySlitting machinesCurrent limitingPower flow

The invention provides a method for identifying a coal petrography interface of a thin coal layer and automatically heightening an expansion cylinder. A current sensor is arranged on a slicing motor of a coal cutter. The method comprises the following step of: (1) firstly cutting for once to be taken as demonstration cutting by the slicing motor of the coal cutter, and recording the respective current value condition when the coal seam and the rock stratum are cut by the coal cutter, wherein the current value is taken as a coal seam / rock stratum current limiting value; (2) enabling a rocker arm of a front expansion cylinder to upwards swing automatically after the coal cutter is used for cutting, and enabling a back expansion cylinder of the coal cutter to downwards swing, identifying the coal petrography layer by detecting a current fluctuation range, and automatically adjusting the mining height according to the different current limiting values of the coal seam and the rock stratum; and (3) judging by the means that the current data generated when the coal petrography is cut by the coal cutter and recoded in the process of coal cutting by the demonstration cutting are taken as the standard value. Under the condition that the coal petrography interface is identified, the coal cutter can be used for automatically adjusting the mining height according to the thickness of the coal, so that the recovery ratio can be improved.

Owner:CHINA UNIV OF MINING & TECH

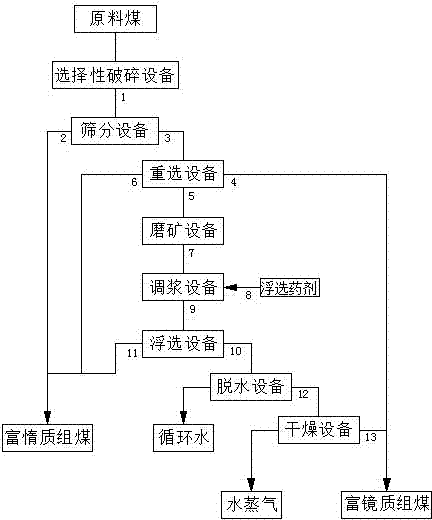

Deep preparation technology of coal for direct coal liquefacation

The invention discloses a deep preparation technology of coal for direct coal liquefacation. Feed coal is selectively crushed and then is sieved with a 0.5 mm particle size to grade; products passing through the sieving are separated through gravity concentration equipment, so as to obtain gravity treated cleaned coal, gravity treated middlings and gravity treated tailings; the gravity treated middlings is ground and fed into size mixing equipment; flotation reagent is added to the size mixing equipment, size mixing is performed, and then products are pumped into flotation equipment to perform separation, so as to obtain flotation cleaned coal and flotation tailings; the flotation cleaned coal is filtered and dried and then mixed with the gravity treated cleaned coal to form rich-vitrinite coal which is served as coal for direct coal liquefacation; and the products of the feed coal not passing through the sieving after crushing and sieving, the gravity treated tailings and the flotation tailings are mixed into rich-inertinite coal which can be served as high-quality steam coal, coal for gasification and the like. The technology is based on coal petrography maceral, adopts the differences in terms of densities and surface natures of different coal petrography maceral, and adopts the method of the combination of gravity concentration and flotation, so as to realize the large-scale separation and enrichment of coal maceral, increase the hydrogen-to-carbon ratio of coal for liquefacation, greatly improve the oil yield of direct liquefacation of coal, and obviously increase the economic benefit of direct liquefacation of coal.

Owner:CHINA UNIV OF MINING & TECH

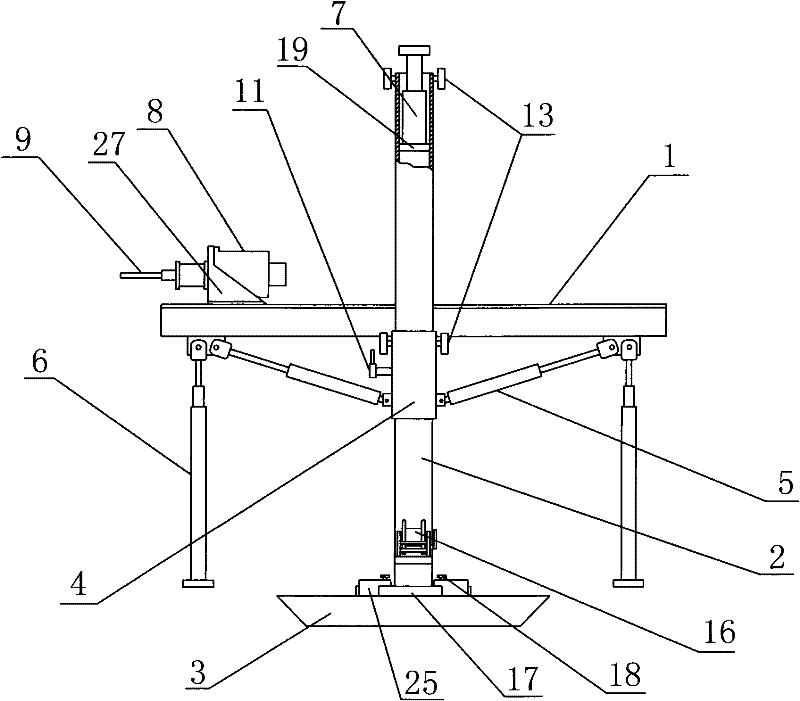

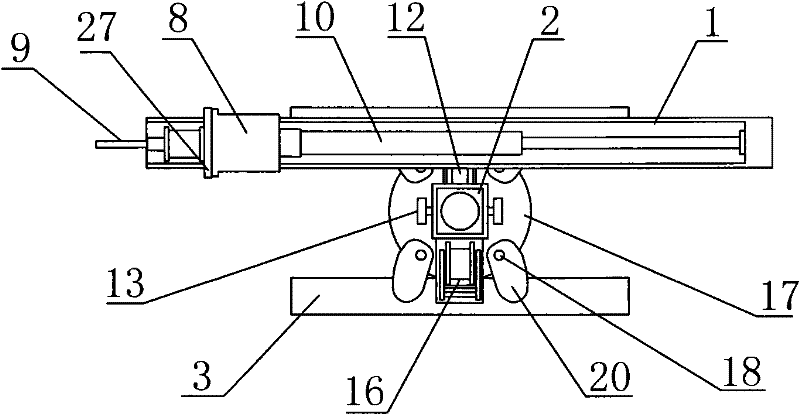

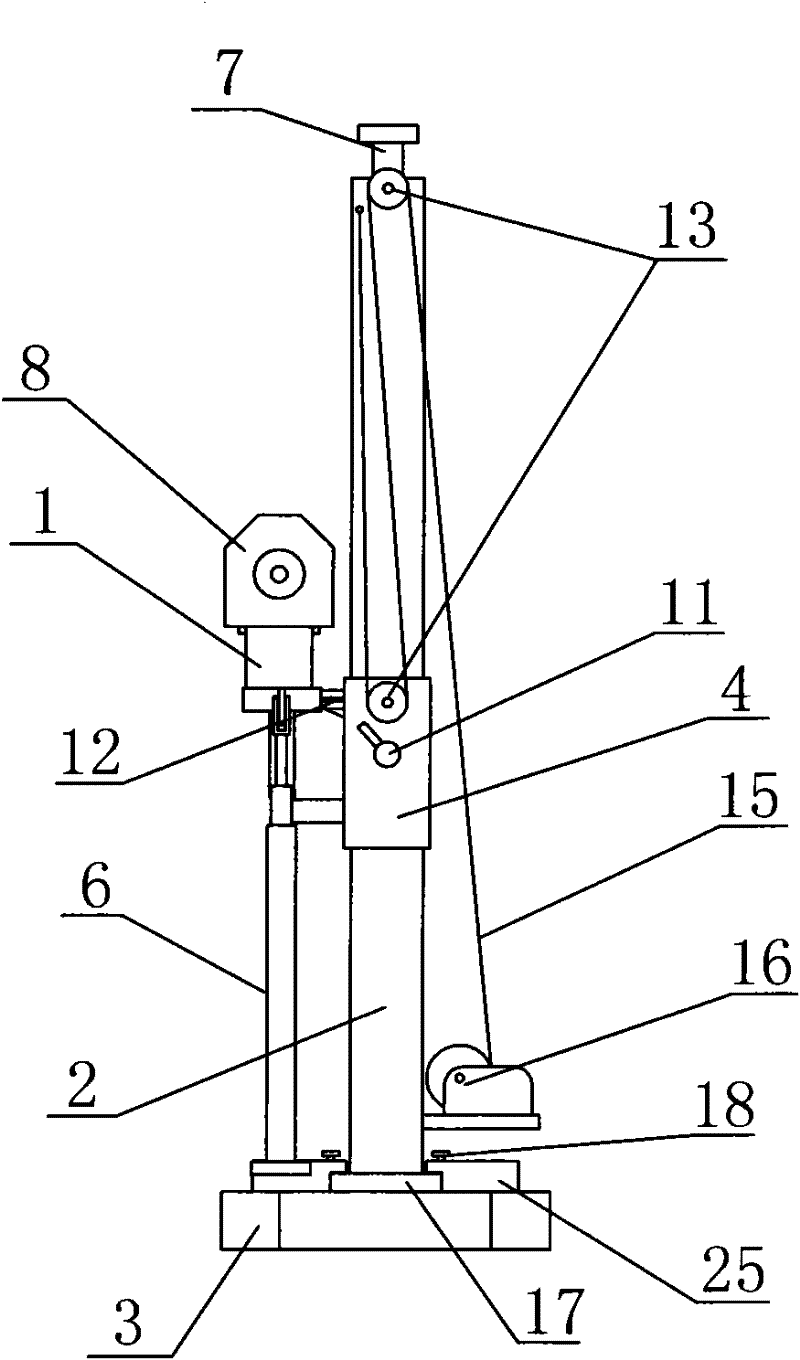

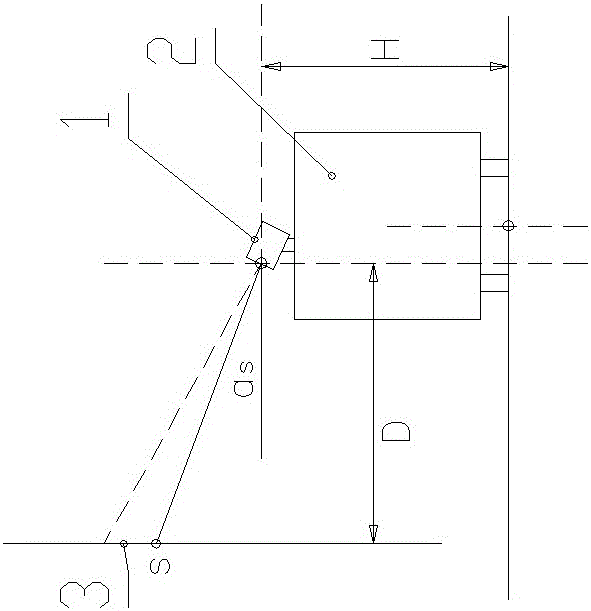

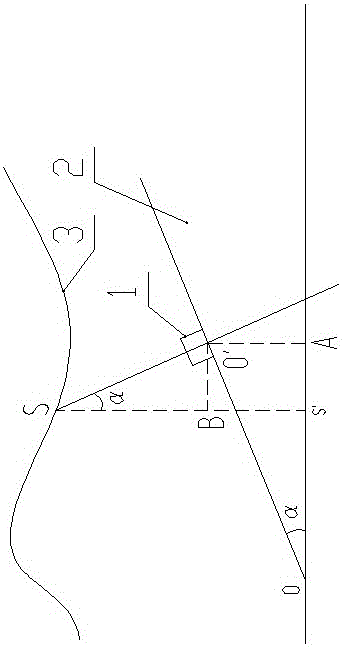

Multi-angle coal petrography drilling machine

The invention discloses a multi-angle coal petrography drilling machine relating to a drilling machine used for pumping gas under a coal mine. The multi-angle coal petrography drilling machine mainly comprises a horizontal guide rail, a lifting guide rail, a base, a drill rod and a motor, wherein the horizontal guide rail is connected with the lifting guide rail by a sliding sleeve arranged on the lifting guide rail, the sliding sleeve is symmetrically provided with two obliquely stretching supporting arms connected with the horizontal guide rail, two ends of the horizontal guide rail are provided with downward stretching supporting arms which are vertically downward, a drill rod driving seat is arranged in a track groove of the horizontal guide rail, and a thrust cylinder is also arranged in the track groove of the horizontal guide rail. The machine simplifies the structure of the drilling machine, and saves cost; and the drilling machine has a small volume, is convenient to use in a narrow mine, and can realize the drilling operation at various angles under the condition that the position of the drilling machine is not moved.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD

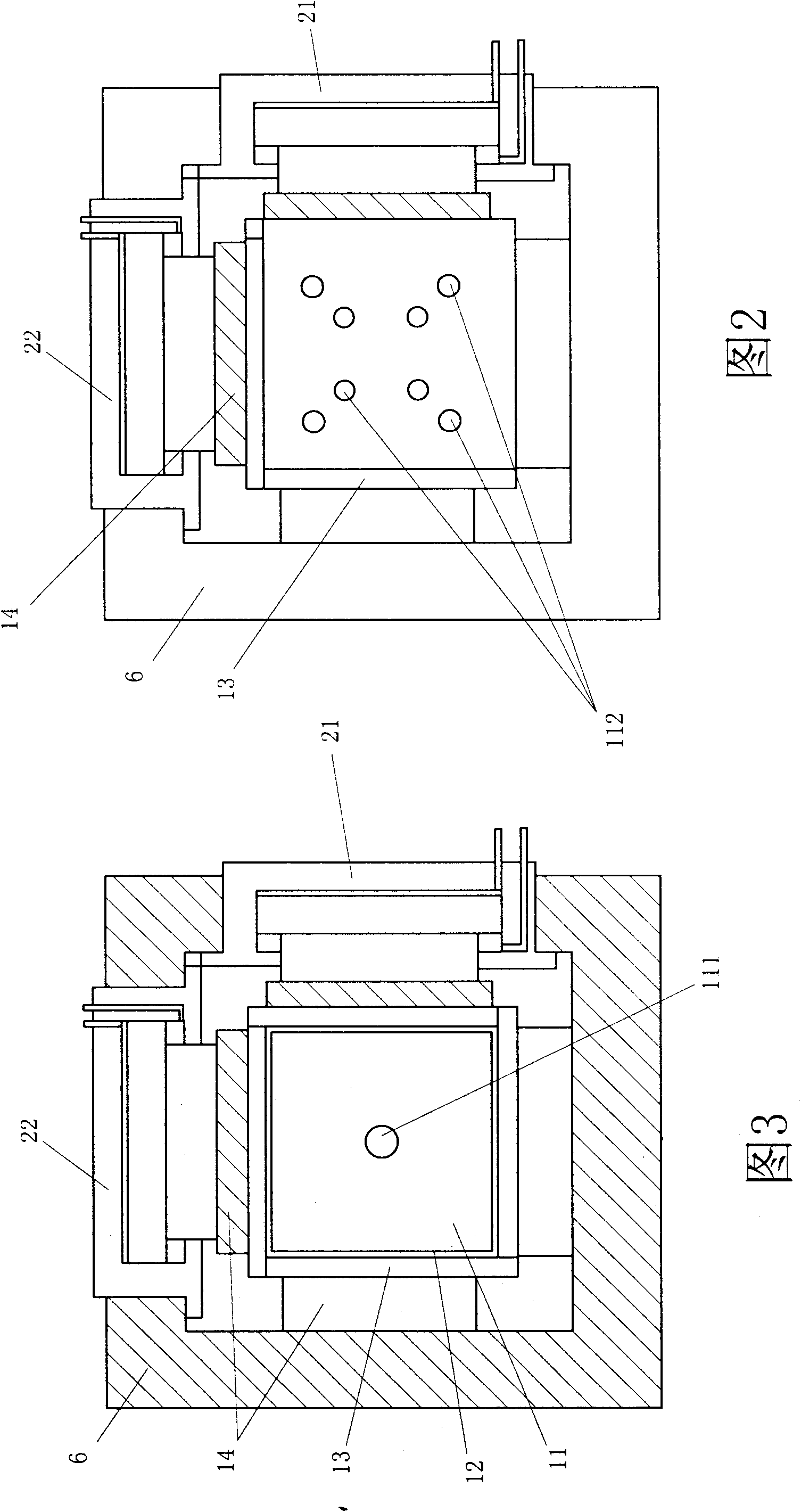

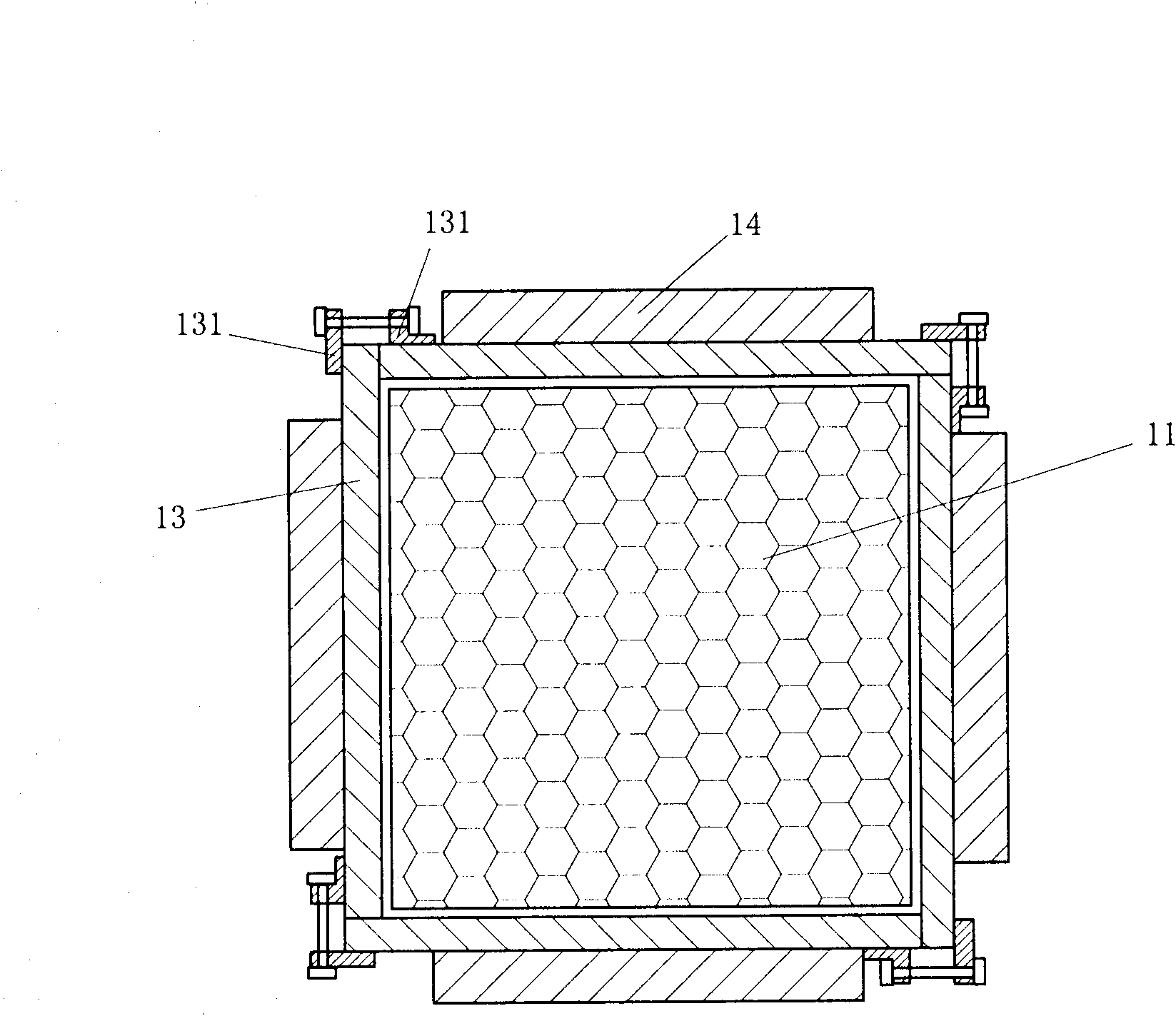

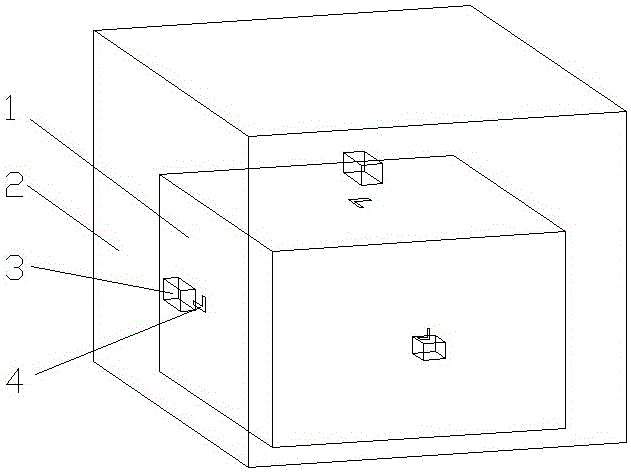

Experimental apparatus for evaluating coalbed methane cave well completion

The invention provides an experimental apparatus for evaluating coalbed methane cave well completion. The device comprises a cube coal petrography model arranged in a frame, wherein the bottom surface of the coal petrography model is provided with a wellbore hole simulator extending upwards, the top surface of the coal petrography model is provided with a plurality of pressure taps extending downwards, a seal rubber cover is arranged outside the coal petrography model, press plates are fixed on the six side faces which are at the outer side of the rubber cover and correspond to the coal petrography model, through holes are respectively arranged at on the press plates at the upper side and the lower side and at the parts of the rubber cover, which correspond to the wellbore hole simulator and the pressure taps, and each pressure tap is internally provided with a pressure test pipe with a pressure sensor; three server pressuring oil cylinders are arranged in three directions in an outer space of the coal petrography model; and a communicating vessel is arranged on the press plate at the lower side in a sealing way and is communicated with the wellbore hole simulator, the upper part of the communicating vessel is provided with a gas inlet pipe, a water inlet pipe and a pressure test pipe with the pressure sensor, the lower part of the communicating vessel is provided with an electric ball vale, the lower end of the electric ball vale is connected with a pressure release pipe, and the bottom end of the pressure release pipe is correspondingly provided with a pulverized coal collecting water tank.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

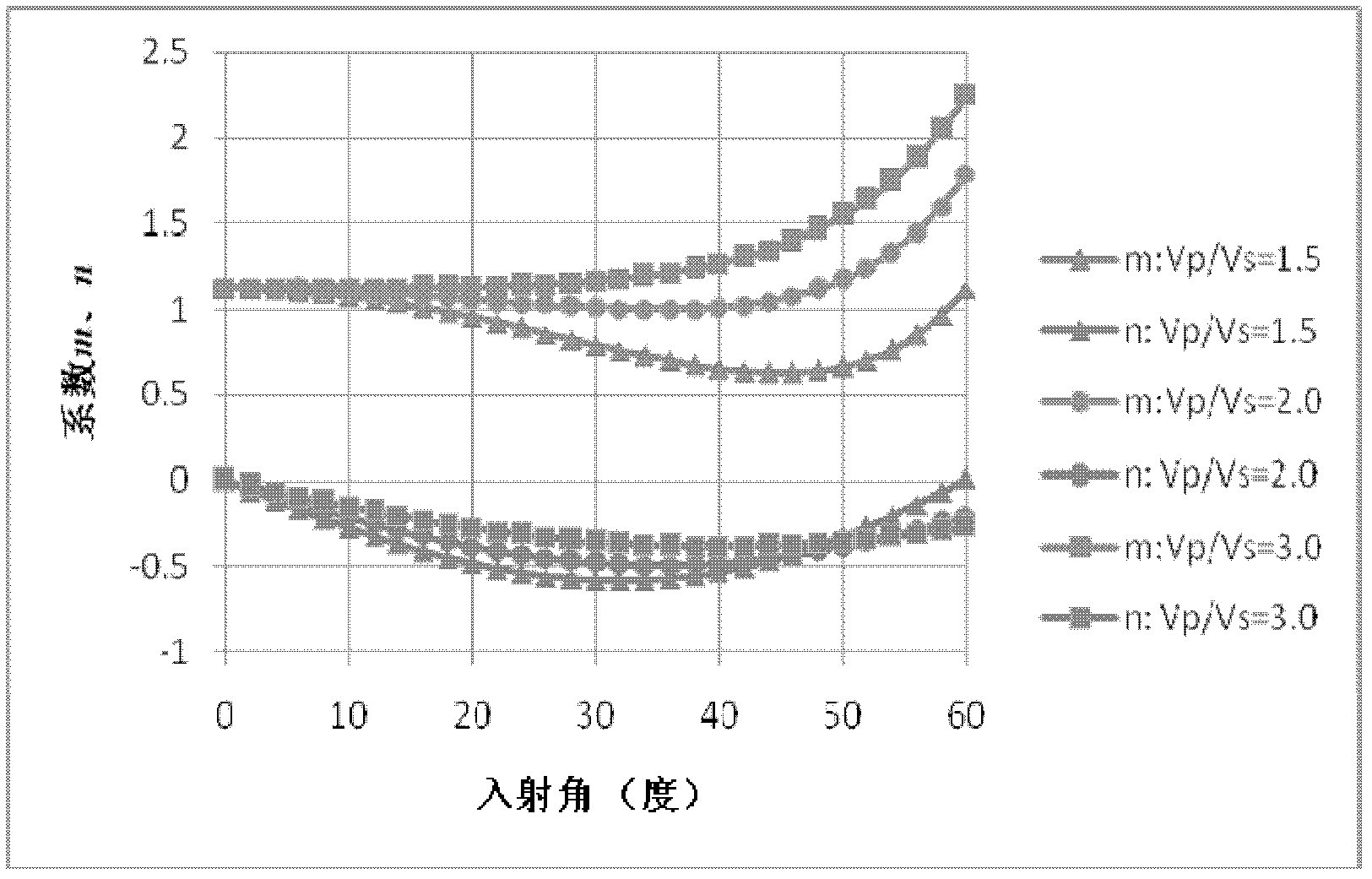

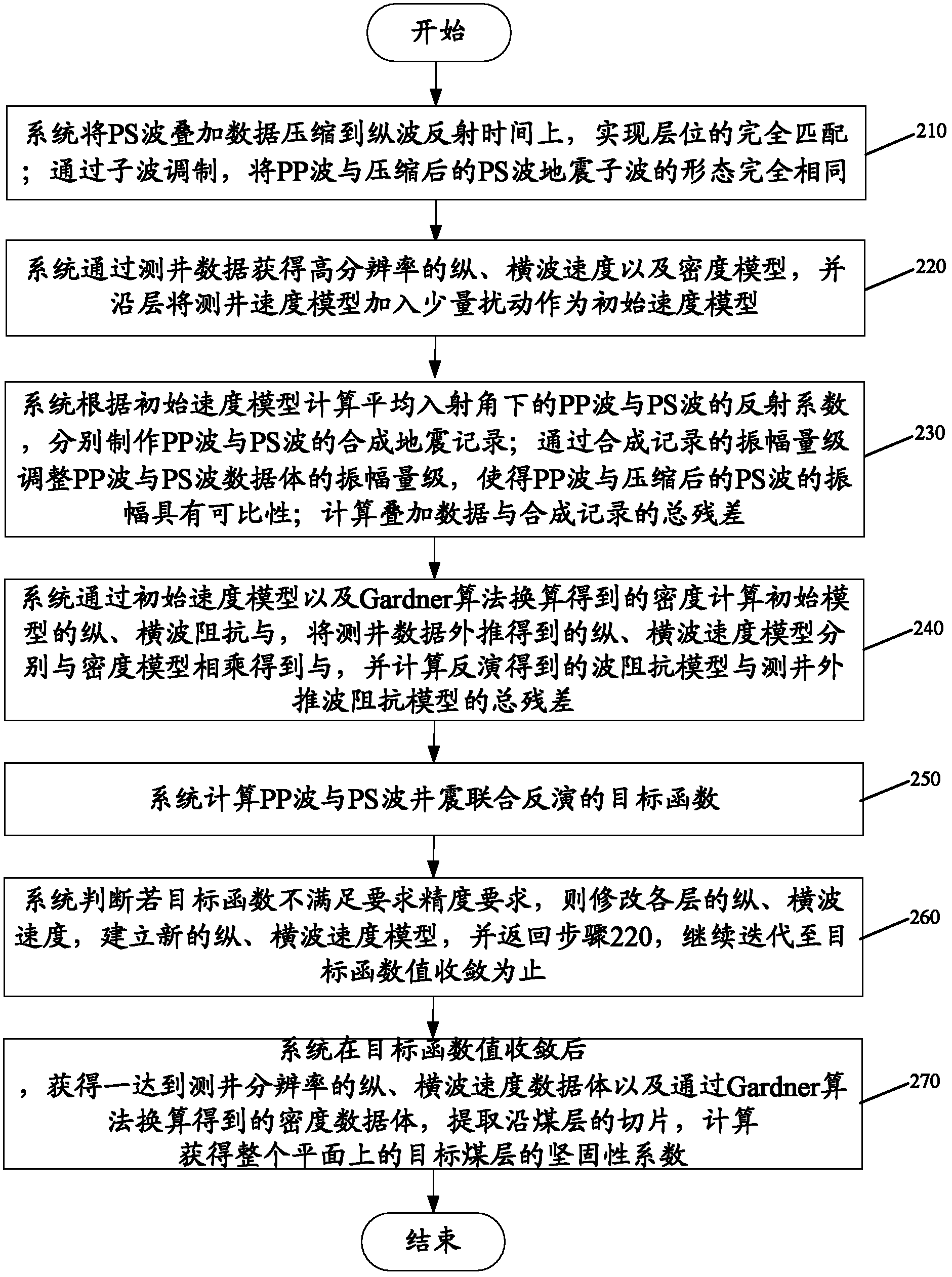

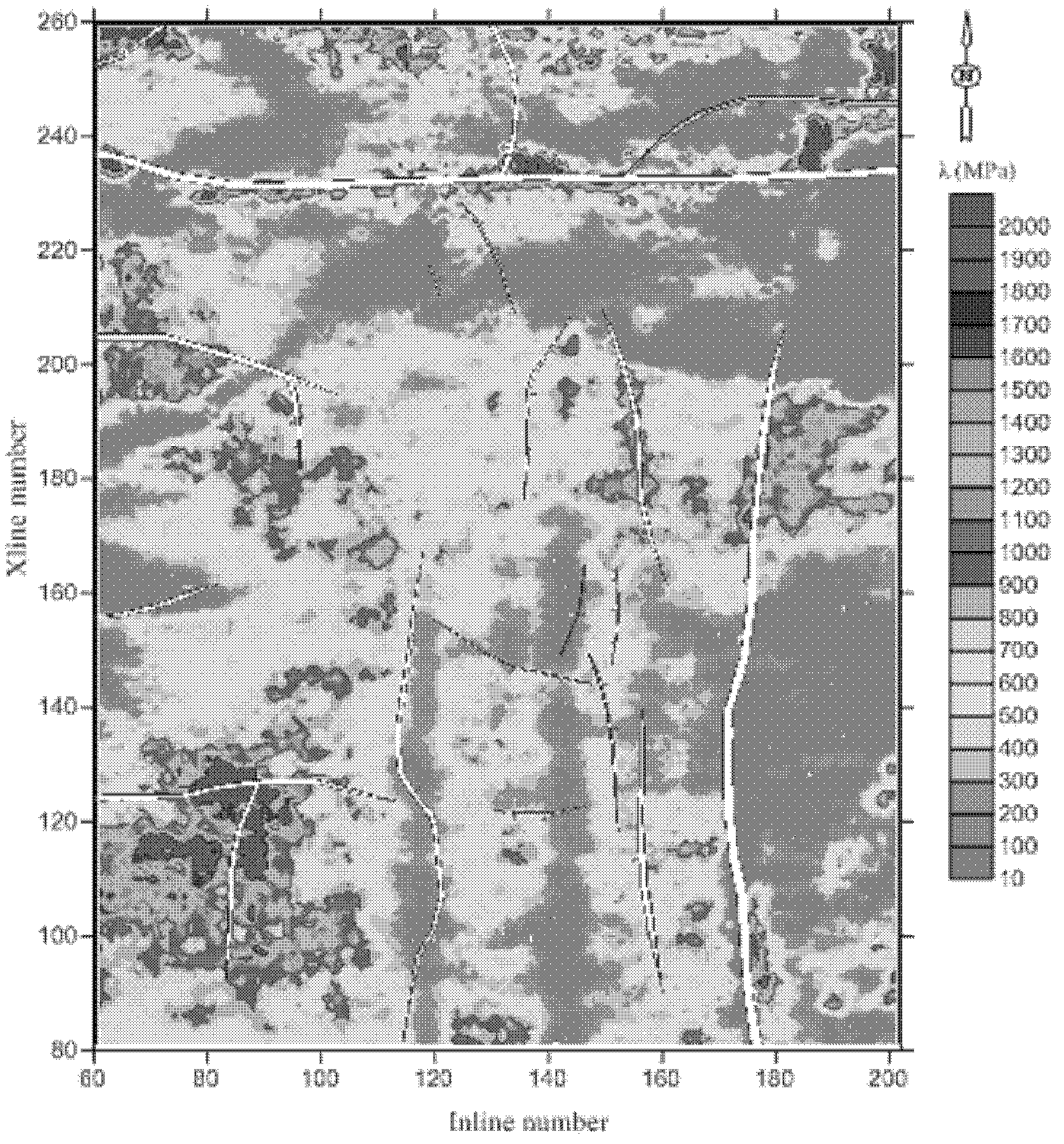

Detection method for coal petrography intensity based on multi-wave seismic data

ActiveCN102359924AEnsure safe productionSeismic signal processingSpecific gravity measurementImage resolutionDensity model

The invention relates to a detection method for the coal petrography intensity based on multi-wave seismic data, which comprises the following steps that: A, vertical and transverse wave speed models and density models are obtained through multi-wave seismic data and logging data, and initial speed models are built through logging speed models; B, synthetic seismic records are generated, and the total residual error of overlapped data and the synthetic seismic records is obtained through calculation; C, the total residual error of a wave impedance model and a logging external push wave impedance model is obtained through calculation; D, the objective function value is calculated, the vertical and transverse wave speed of each layer is modified when the value is judged not to meet the precision requirement, a new vertical and transverse wave speed model is built, the operation returns to the step A, and the continuous iteration is carried out until the objective function value convergence; and E, after the objective function value convergence, the vertical and transverse wave speed data reaching the logging resolution and the density data obtained through calculation are obtained, slices along a coal bed are extracted, and the firmness factor of the objective coal bed on the whole plane can be obtained through calculation. The problem of judgment of coal and gas projection possibility in the coal bed is solved.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

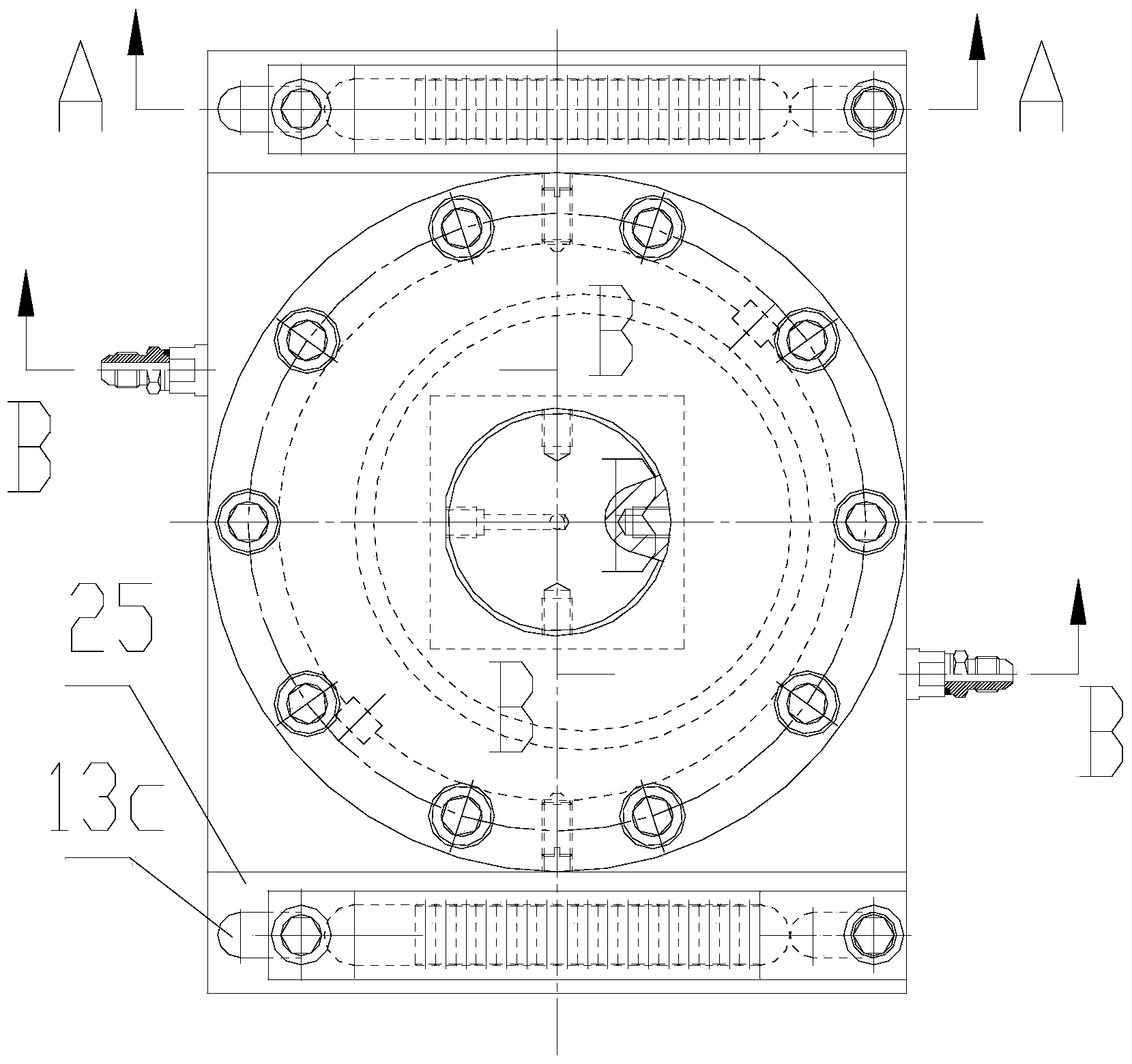

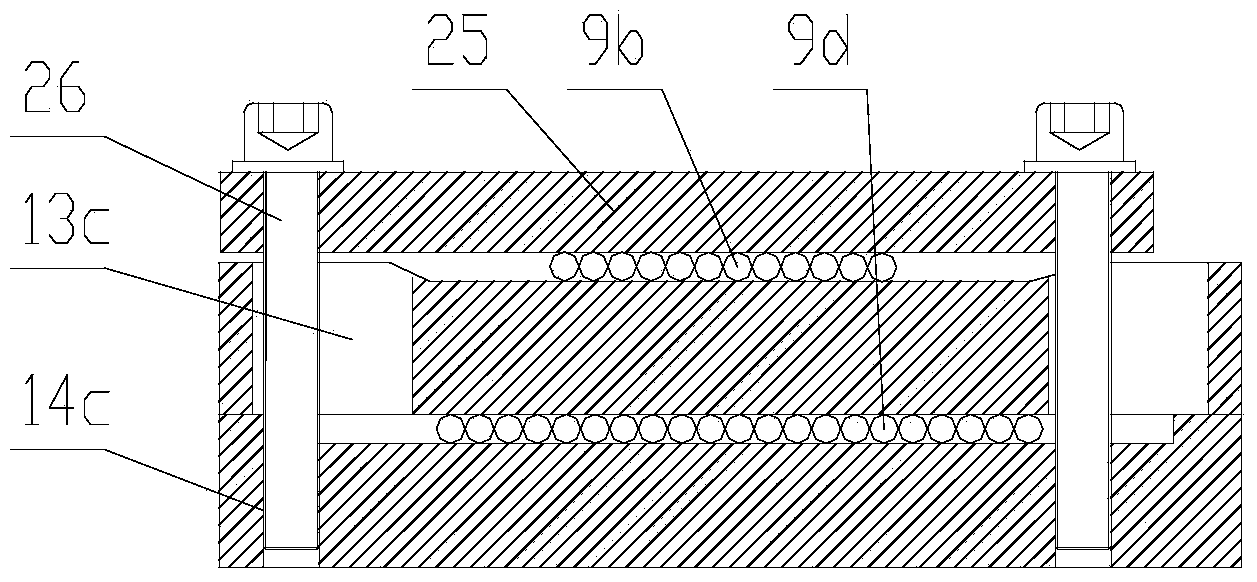

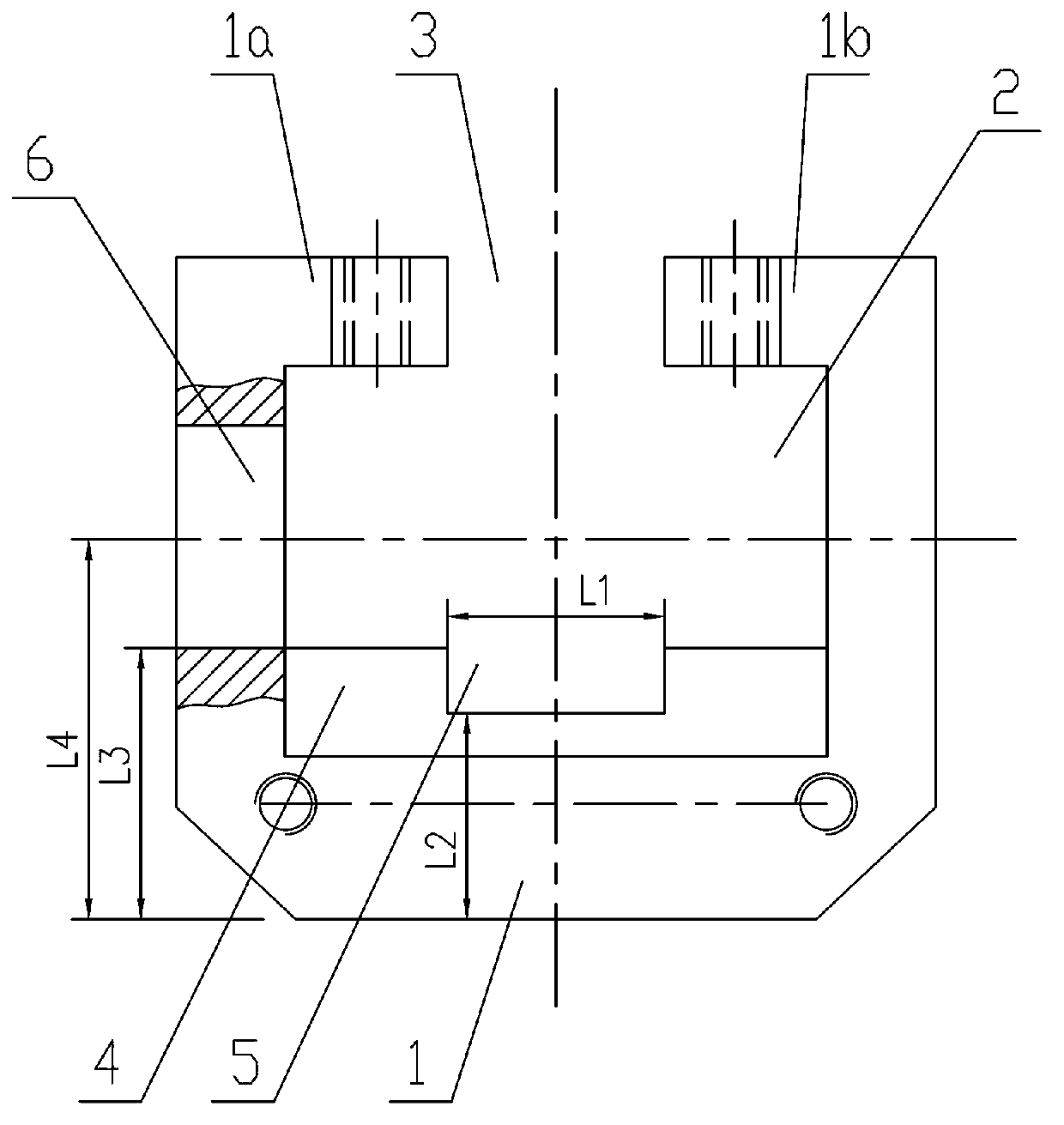

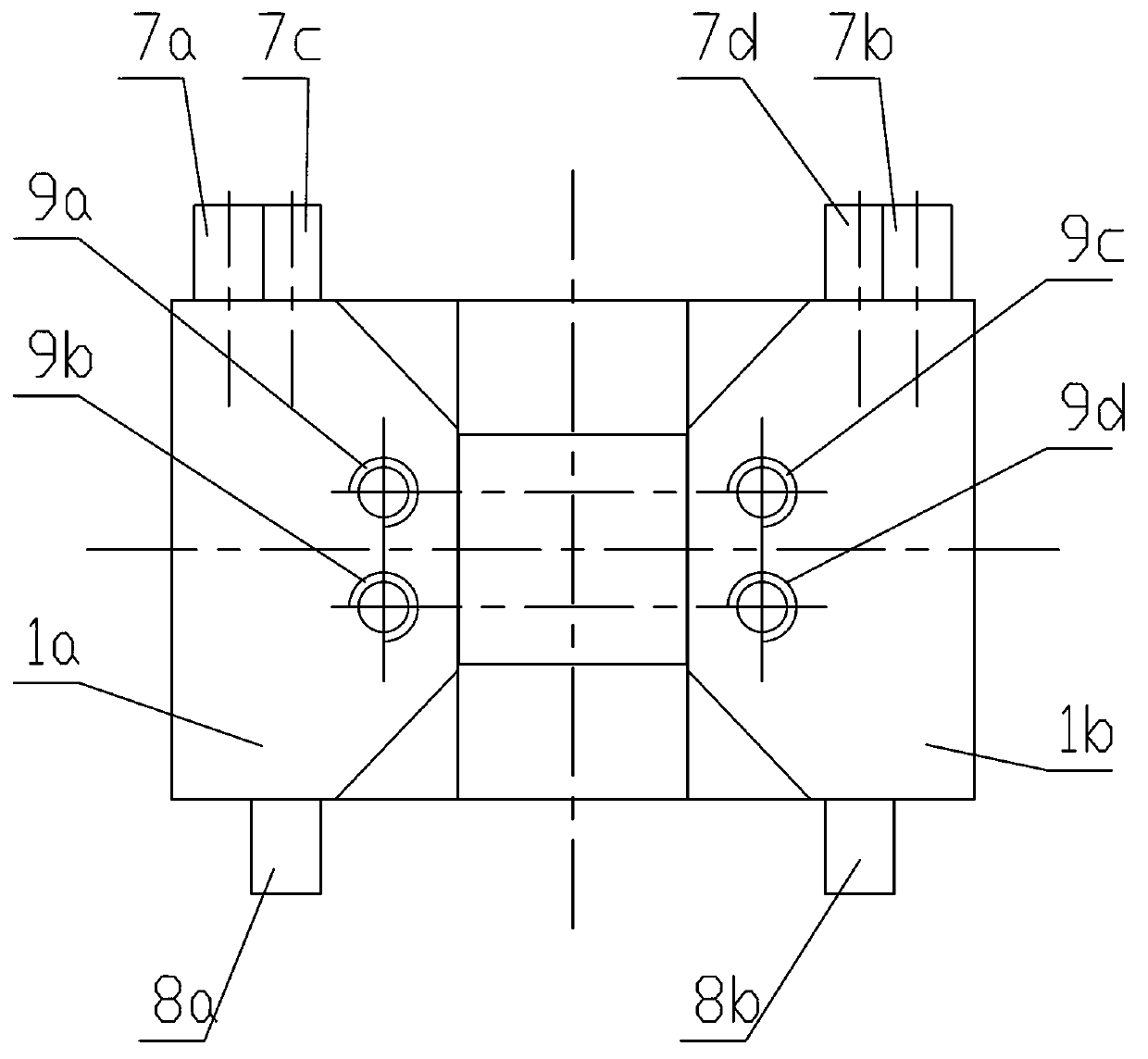

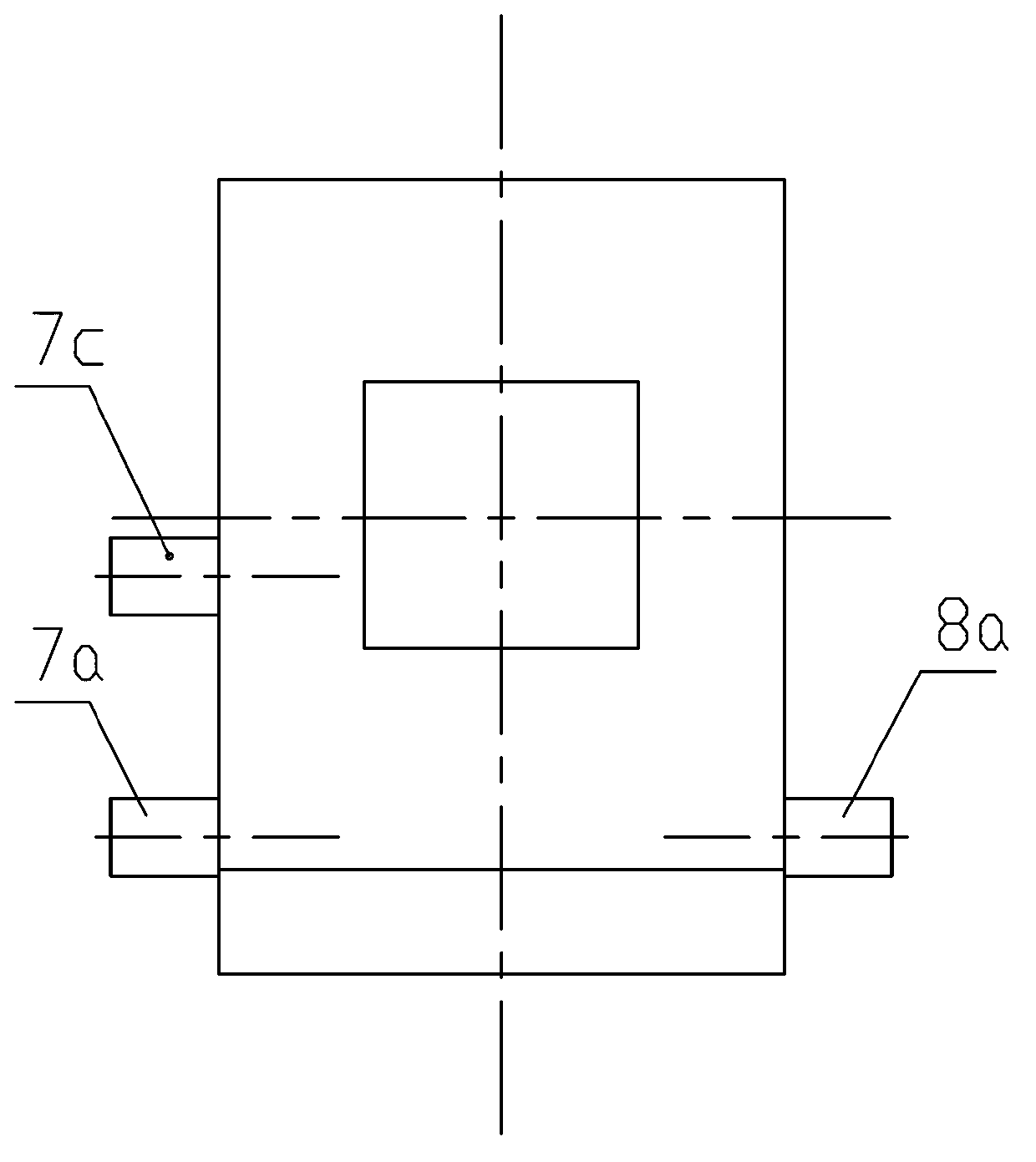

Fluid-solid coupling coal petrography shear-seepage test shearing and sliding combined shearing box

InactiveCN103760040AImprove test accuracyEasy to collectMaterial strength using steady shearing forcesPermeability/surface area analysisEngineeringFluid solid coupling

The invention discloses a fluid-solid coupling coal petrography shear-seepage test shearing and sliding combined shearing box which comprises an upper box body and a lower box body which are fixedly connected with each other, wherein cavities for containing test pieces are formed in the upper box body and the lower box body; a first flange and a second flange are respectively arranged on the front side and the rear side of the upper box body; a third flange and a fourth flange are respectively arranged on the front side and the rear side of the lower box body; a second rolling way and a second rolling way are respectively arranged on two sides of the first flange and the two sides of the second flange of the upper box body; clamping plates are arranged on the second rolling way and the third rolling way; a fourth rolling way and a fifth rolling way are respectively arranged on the inner sides of the third flange and the fourth flange of the lower box body; four threaded holes are rectangularly formed in the lower box body; waist-shaped through holes are formed in positions, which correspond to the threaded holes, on the upper box body; bolts penetrate through the clamping plates and the waist-shaped through holes and are matched with the threaded holes. The fluid-solid coupling coal petrography shear-seepage test shearing and sliding combined shearing box can simulate a real actual working condition, so that the test precision can be improved.

Owner:CHONGQING UNIV

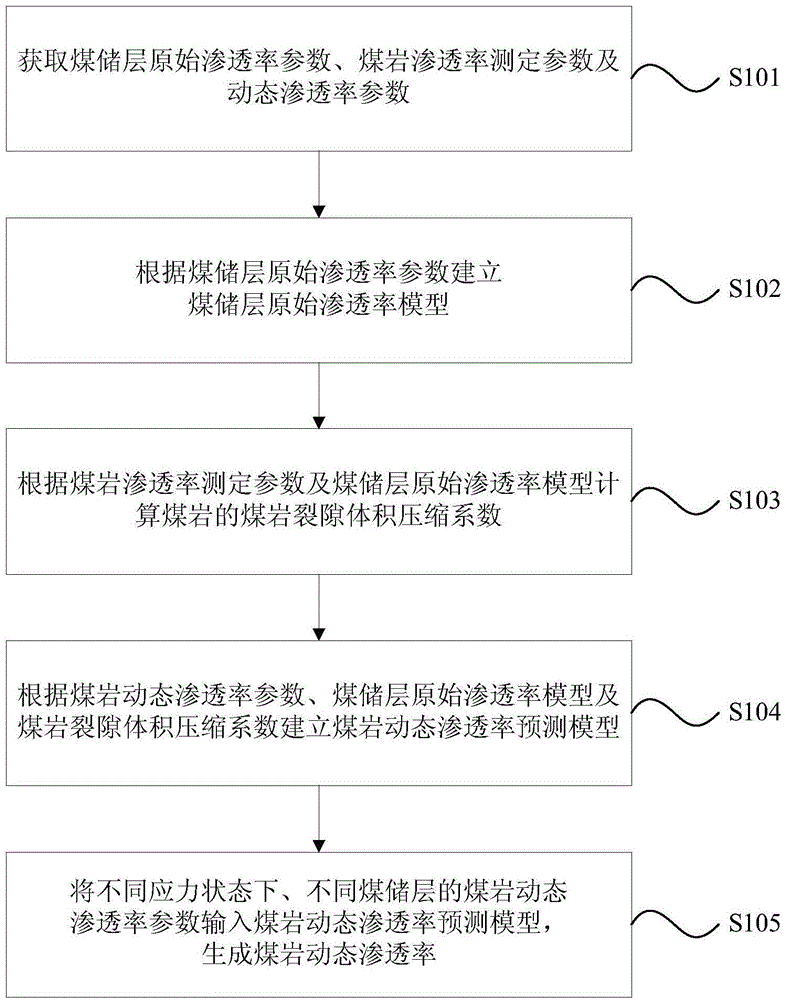

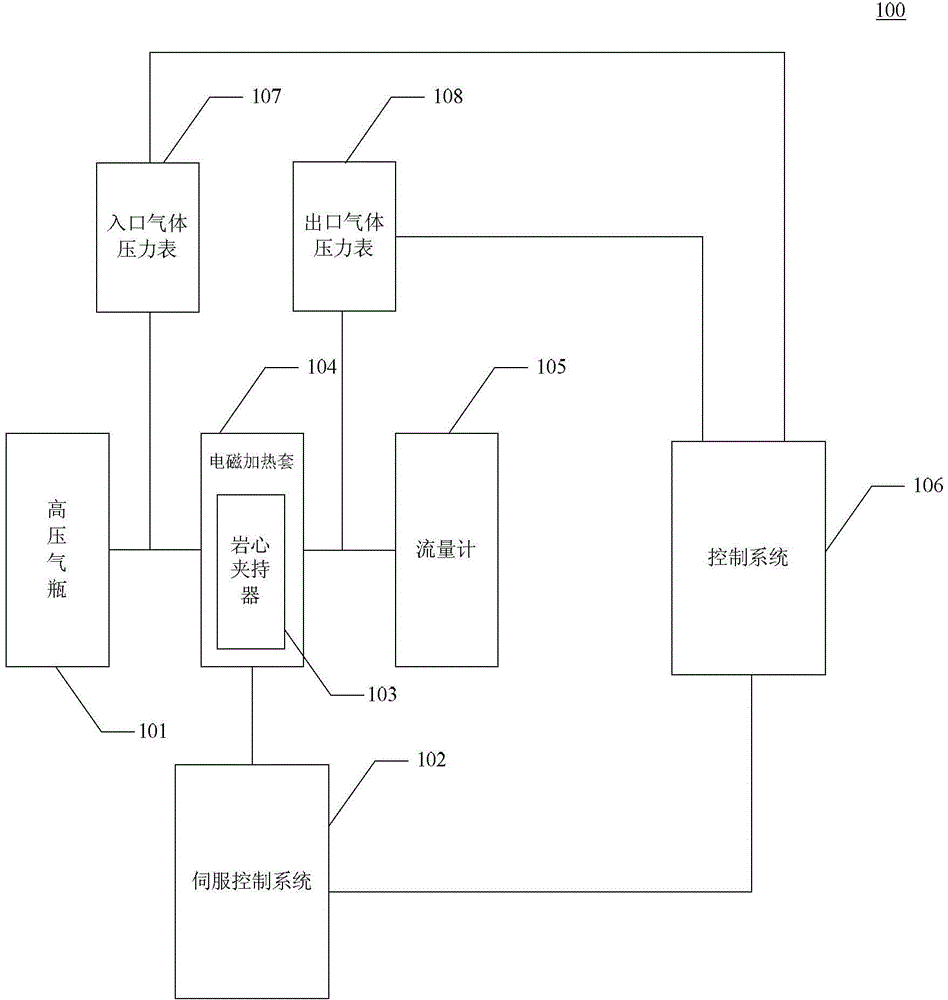

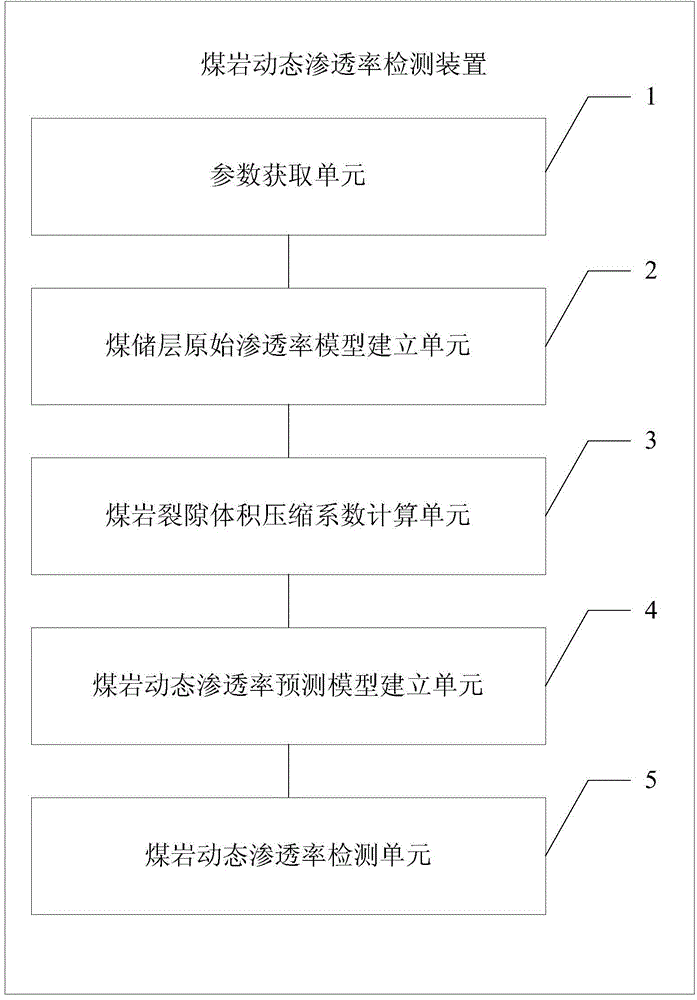

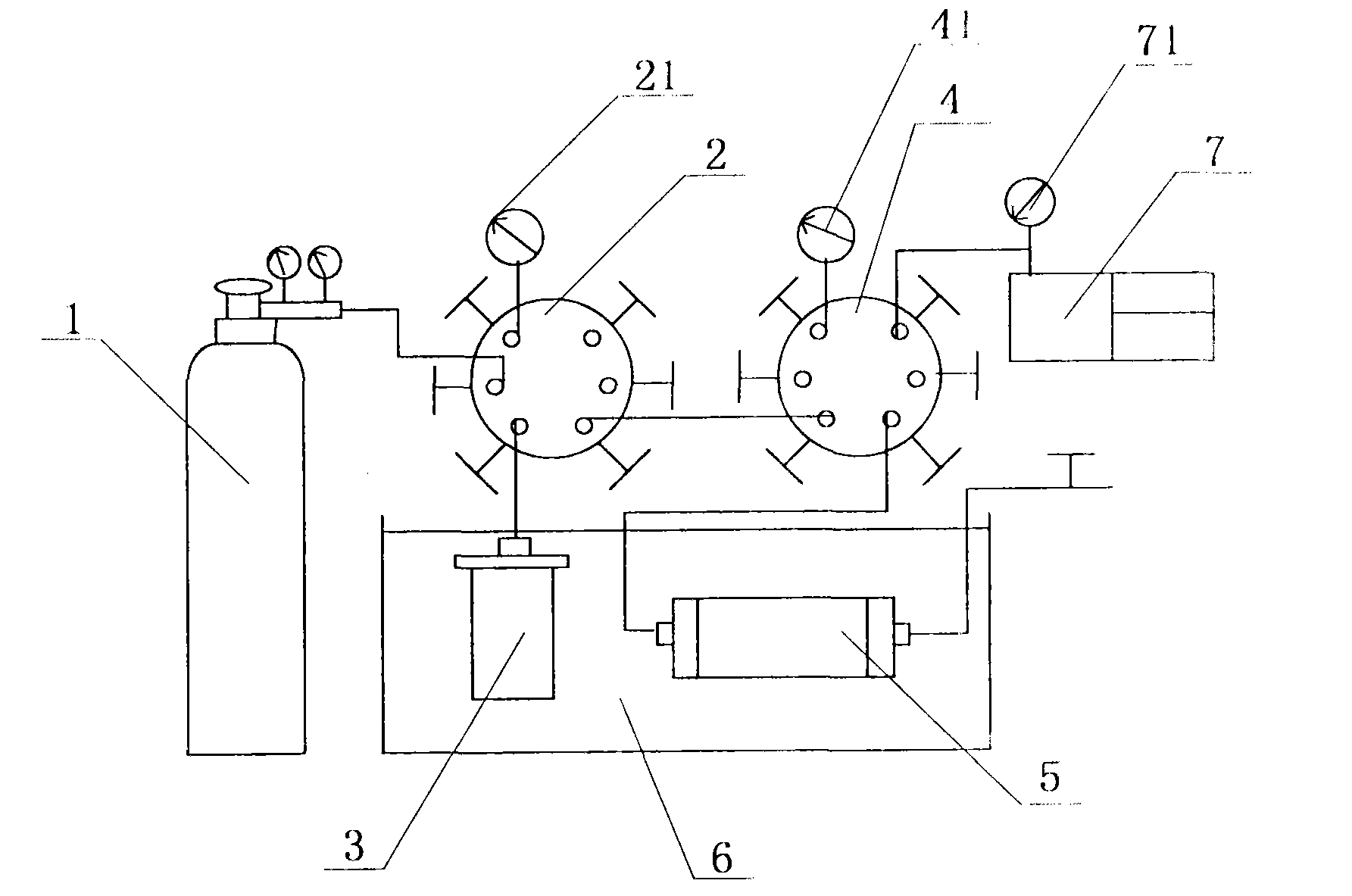

Method and device for detecting dynamic permeability of coal petrography

ActiveCN104535472AReliable reservoir physical parametersImprove accuracyPermeability/surface area analysisStress conditionsPermeability measurements

The invention provides a method and a device for detecting the dynamic permeability of coal petrography. The method comprises the following steps: acquiring the original permeability parameters of a coal reservoir, the coal petrography permeability measurement parameters and dynamic permeability parameters; establishing a coal reservoir original permeability model according to the original permeability parameters of the coal reservoir; calculating the coal petrography fracture volume compression coefficient of the coal petrography according to the coal and rock permeability measurement parameters and the coal reservoir original permeability model; establishing a coal petrography dynamic permeability prediction model according to the coal petrography dynamic permeability parameters, the coal reservoir original permeability model and the coal a petrography fracture volume compression coefficient; and inputting the coal petrography dynamic permeability parameters of different coal reservoirs under different stress conditions into the coal petrography dynamic permeability prediction model, and generating the coal petrography dynamic permeability. According to the method disclosed by the invention, reliable reservoir physical property parameters are provided for dynamic detection of coal-bed gas well production and parameter optimization of target well sections of a complex structural well, so that the accuracy of detecting the coal petrography dynamic permeability can be improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

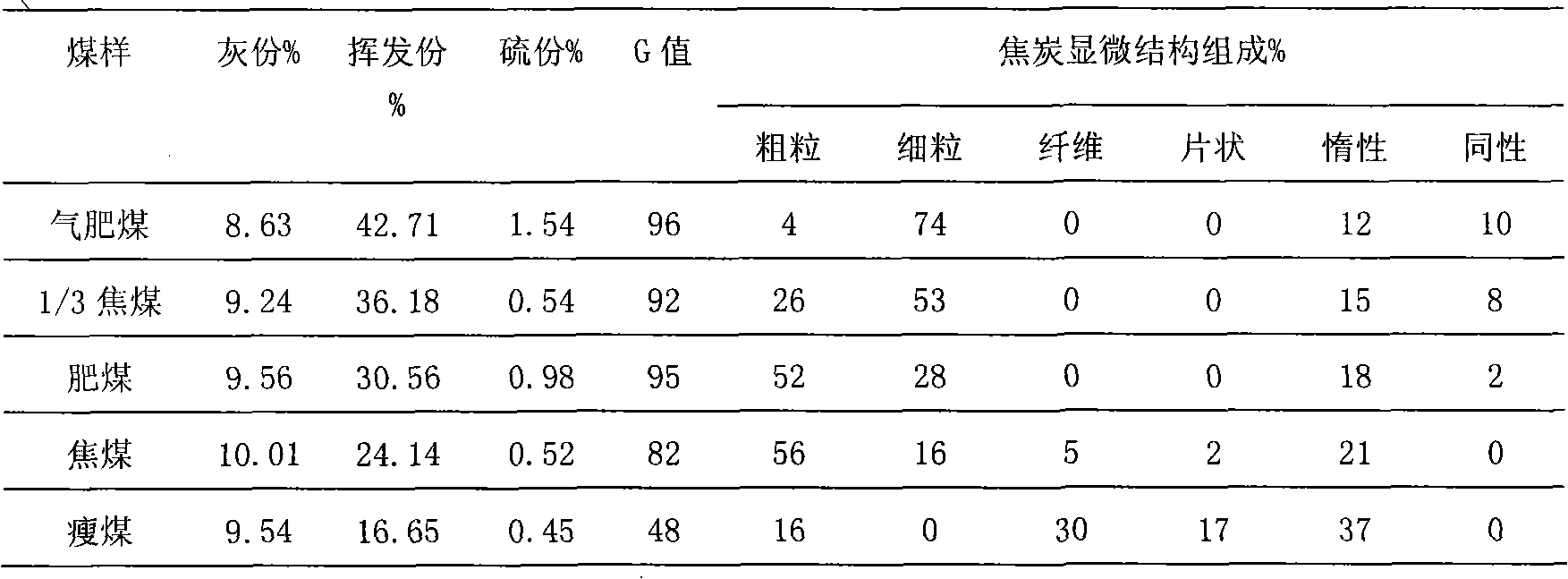

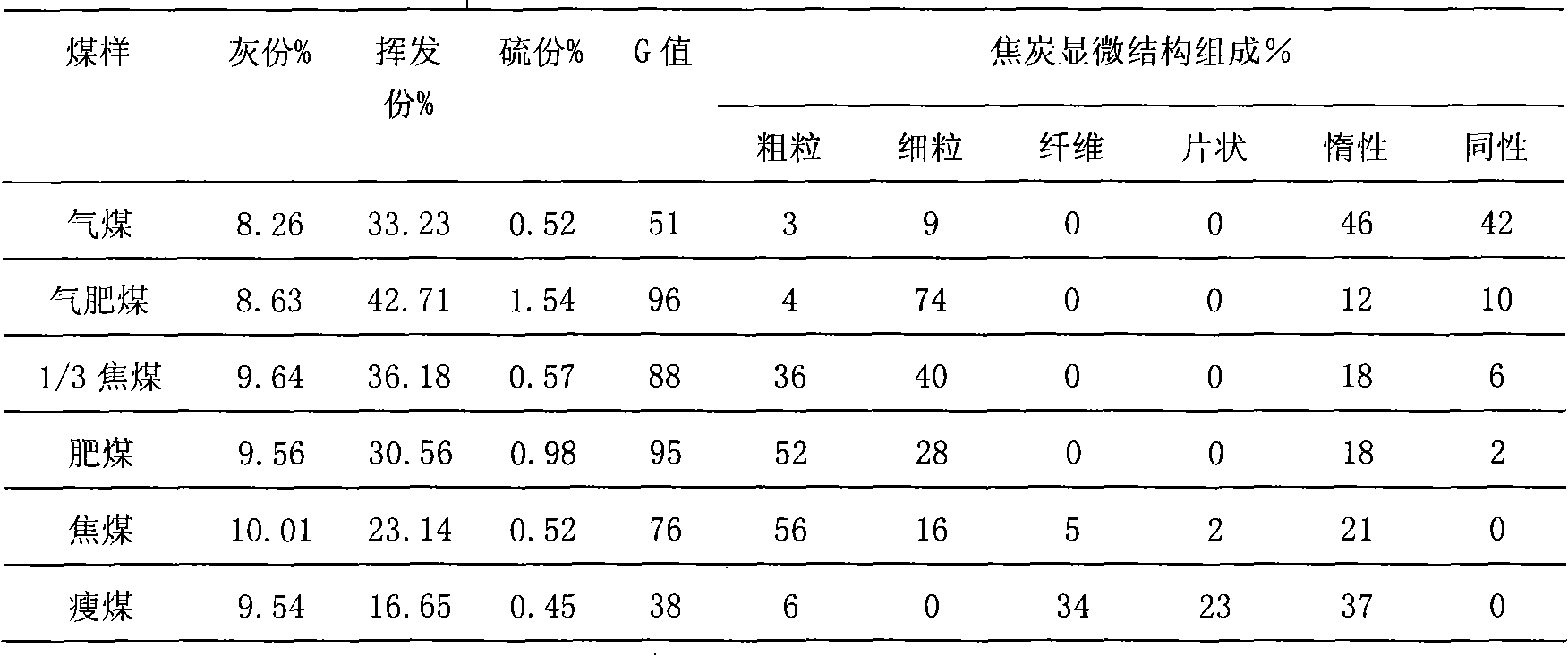

Method for anthracology coal blending

InactiveCN101294948AImproved coal blending qualityQuality improvementCoke ovensFuel testingEngineeringAnthracology

Owner:武汉钢铁有限公司

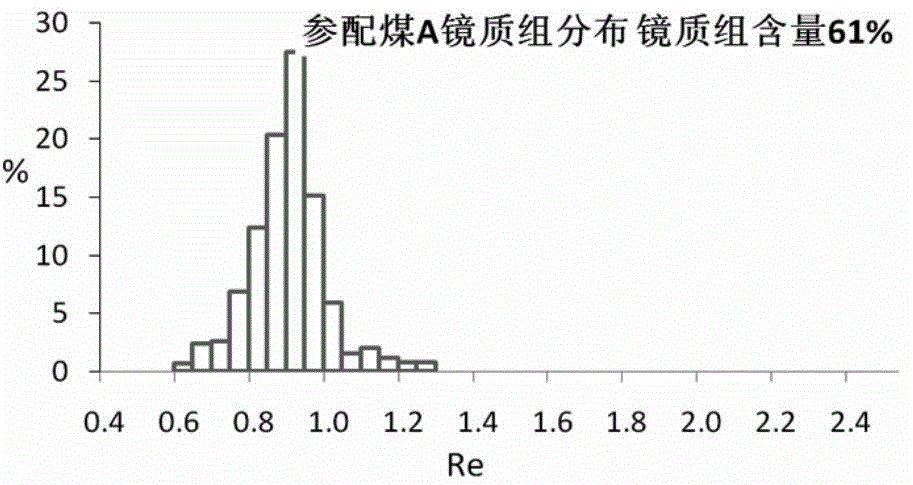

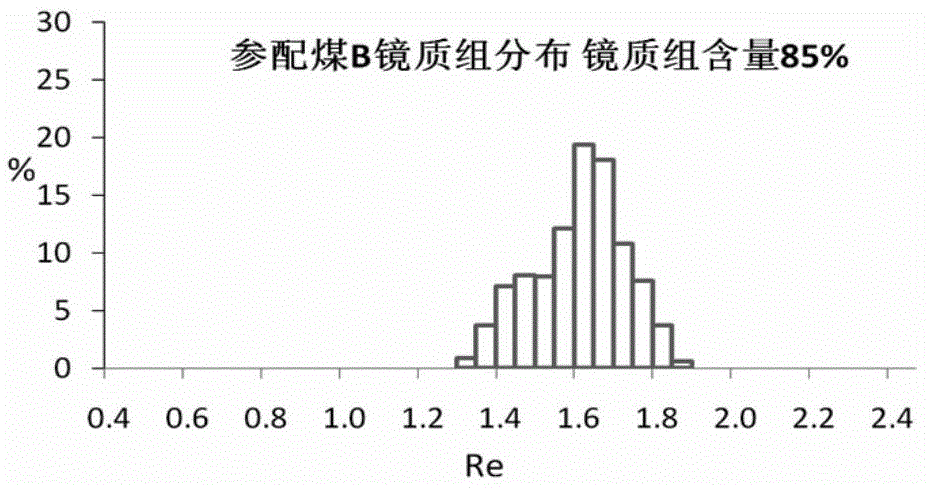

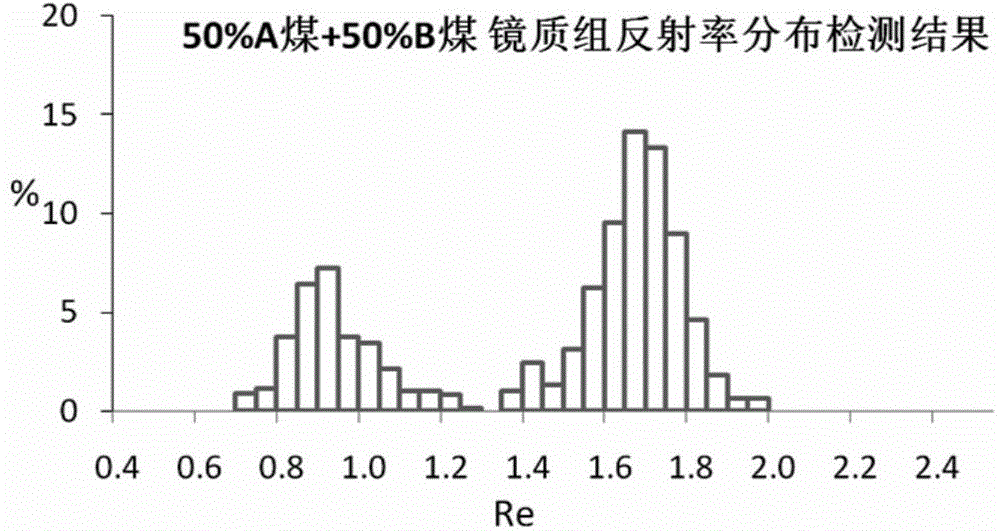

Prediction method matched with coal blend vitrinite reflectance distribution and application of predication method

The invention relates to the field of coking, and particularly relates to a method for predicting the vitrinite reflectance distribution of coal blend according to coal blend ratio, vitrinite content and reflectance distribution, and a method for guiding coal blend by combining a mobility change function and a G value. The method comprises the following steps: by adopting a coal petrography analysis system, detecting the vitrinite reflectance distribution and vitrinite content of coal blend, and calculating the vitrinite reflectance distribution and content of the coal blend according to the vitrinite content, the reflectance distribution and coal blend ratio of the coal blend; and through calculation, controlling the vitrinite reflectance distribution range, the mobility and the G value of the coal blend, thus further controlling the mass of coke. According to the method disclosed by the invention, the errors of simply adding and calculating the vitrinite reflectance distribution of the coal blend according to the coal blend ratio without the consideration of different contents of different single vitrinite in a traditional method are corrected, the vitrinite reflectance distribution of the coal blend can be accurately predicted, high-strength coke under relatively low caking index conditions can be blended by combining the mobility function and G value.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

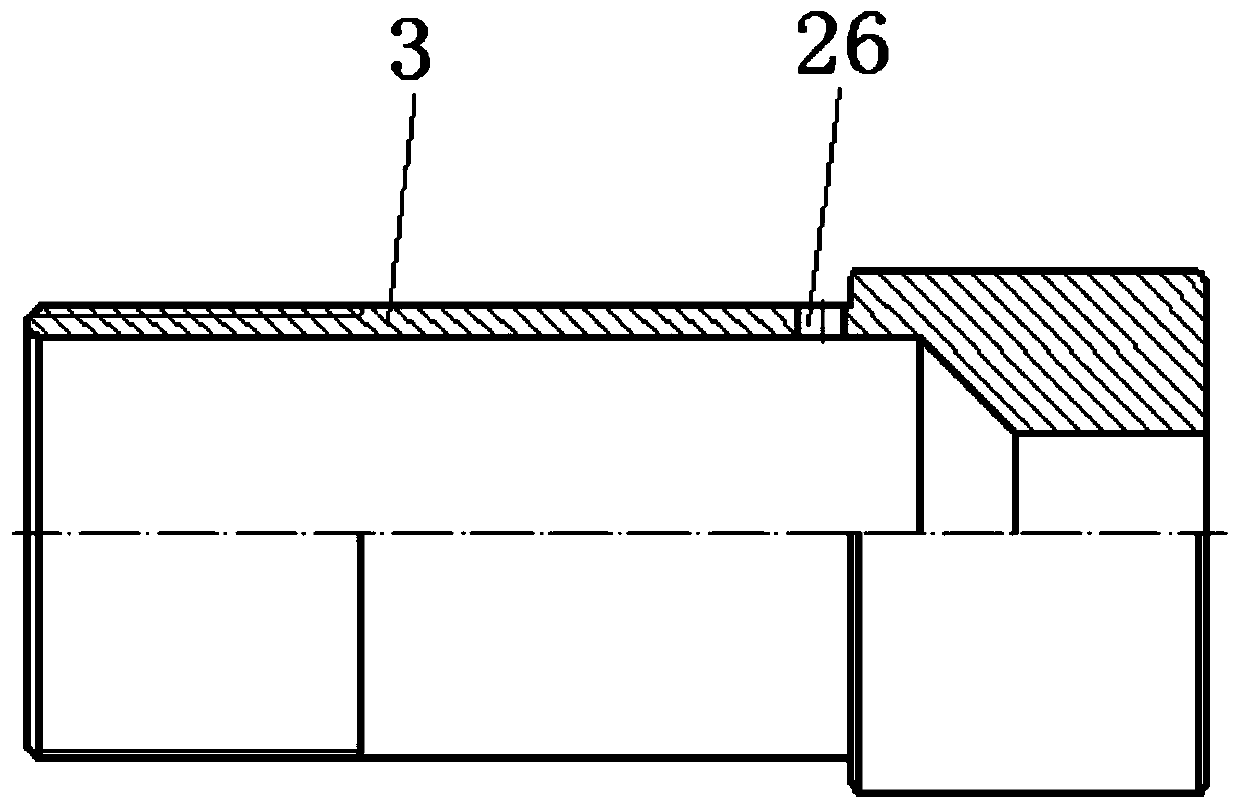

In-situ coal petrography heat-insulation pressure-maintaining coring device and application method

The invention relates to the technical field of coal bed gas well-drilling coring, in particular to an in-situ coal petrography heat-insulation pressure-maintaining coring device and an application method. The device comprises an upper connector, an outer barrel and a coring drill bit, wherein the lower end of the upper connector is connected with the outer barrel; the lower end of the outer barrel is connected with the coring drill bit; a connecting sleeve is connected to the inner wall of the lower end of the upper connector; a pressure ball seat matched and sealed with a starting ball is designed at the lower end of the connecting sleeve; a communicating hole I is formed in the connecting sleeve at the upper end of the pressure ball seat; a differential sliding sleeve is connected ontothe pressure ball seat in a hanging way and shields the communicating hole I; and a communicating hole II is formed in the differential sliding sleeve. According to the in-situ coal petrography heat-insulation pressure-maintaining coring device and the application method provided by the invention, a taken-out coal petrography sample maximally maintains temperature and pressure of an original stratum, a tough pressure film is adopted to cover an original coal core entering the barrel so as to prevent the coal core from being polluted by extraneous fluids such as a drilling fluid, high-pressurehydraulic oil is isolated in the follow-up pressure-maintaining stage, original physical and chemical characteristics of the coal core are further maximally protected, and a high-quality truth-preserving coal core sample is ensured to be acquired.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

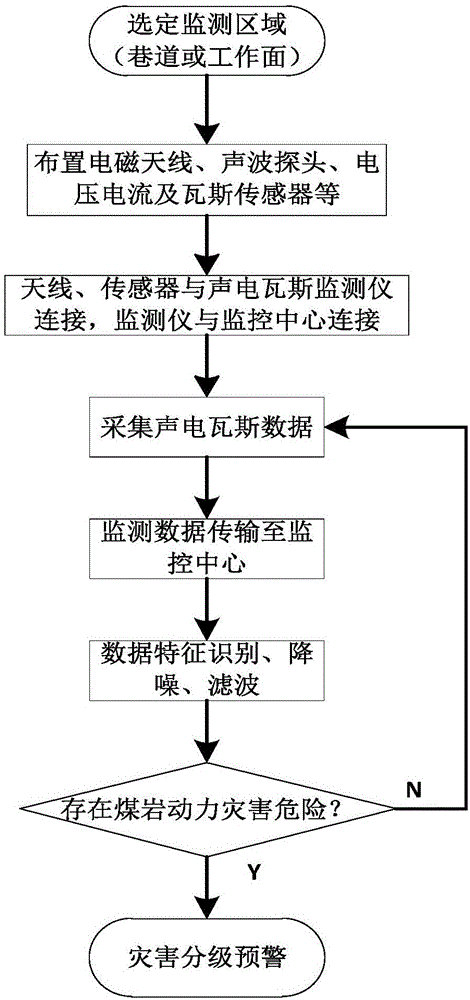

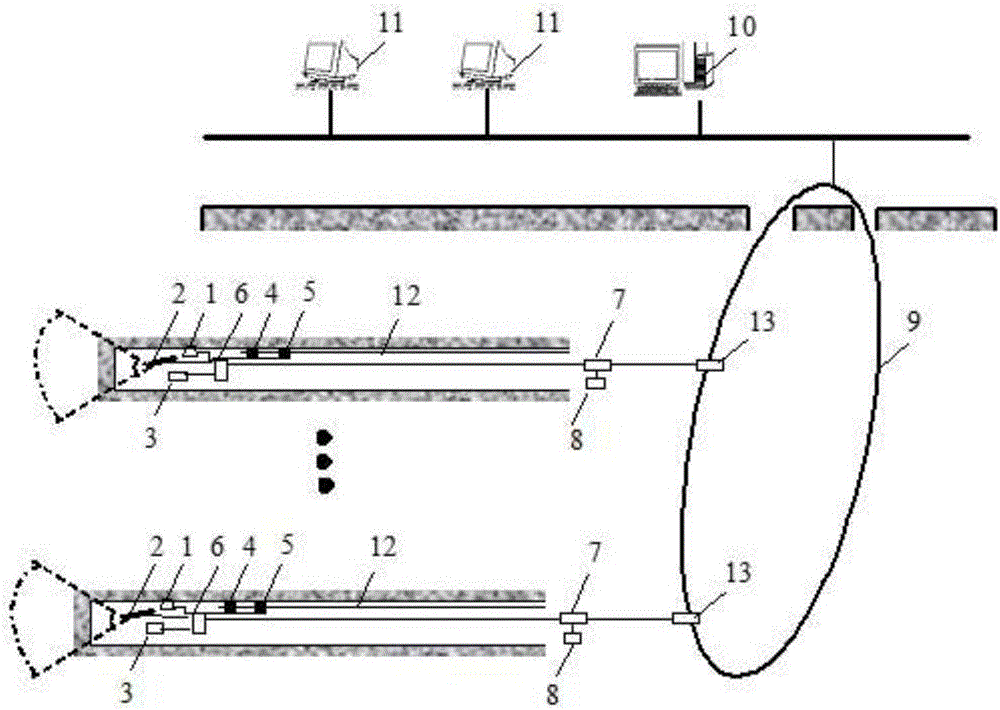

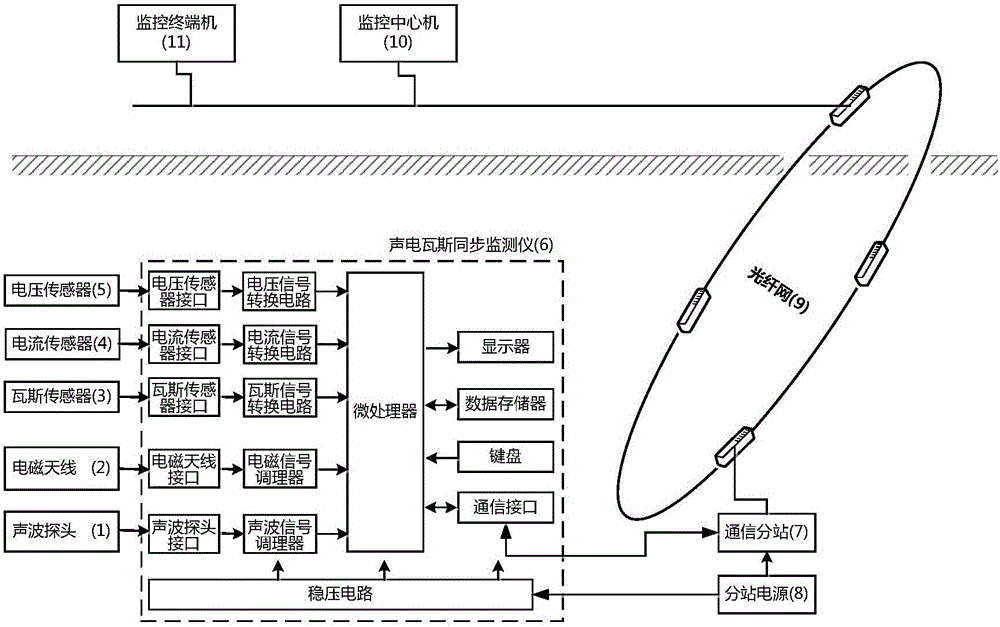

System and method for acoustic-electric gas real-time automatic monitoring of coal petrography dynamic disasters

ActiveCN106761931AWarning dangerRealize integrated automatic monitoringMining devicesFrequency spectrumEngineering

The invention relates to a system and method for acoustic-electric gas real-time automatic monitoring of coal petrography dynamic disasters and belongs to the field of mine safety and monitoring. The system is composed of a sonic probe, an electromagnetic antenna, a gas sensor, a current sensor, a voltage sensor, an acoustic-electric gas real-time monitor, a communication substation, a substation power supply and a monitoring center machine and the like. The system receives sound waves and electromagnetic radiation and gas signals through the acoustic-electric gas real-time monitor, the voltage sensor can be connected to monitor power cable power-on conditions, and the current sensor is connected to monitor working conditions of an electromechanical device; through abrupt change conditions of the sound waves and electromagnetic radiation and gas signals and acoustic-electric spectrum characteristics, probe and antenna movement and excavation activity conditions are recognized by combination with current and voltage signal changes; and early warning on abnormal areas in front of a working face and coal petrography dynamic disaster danger is performed through effective sound wave and electromagnetic signal changes and combination with gas signal change characteristics. The system can be applied to abnormal area monitoring in front of the working face and coal and gas outburst and rock burst monitoring and early warning.

Owner:CHINA UNIV OF MINING & TECH

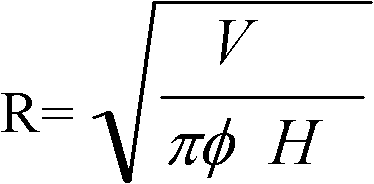

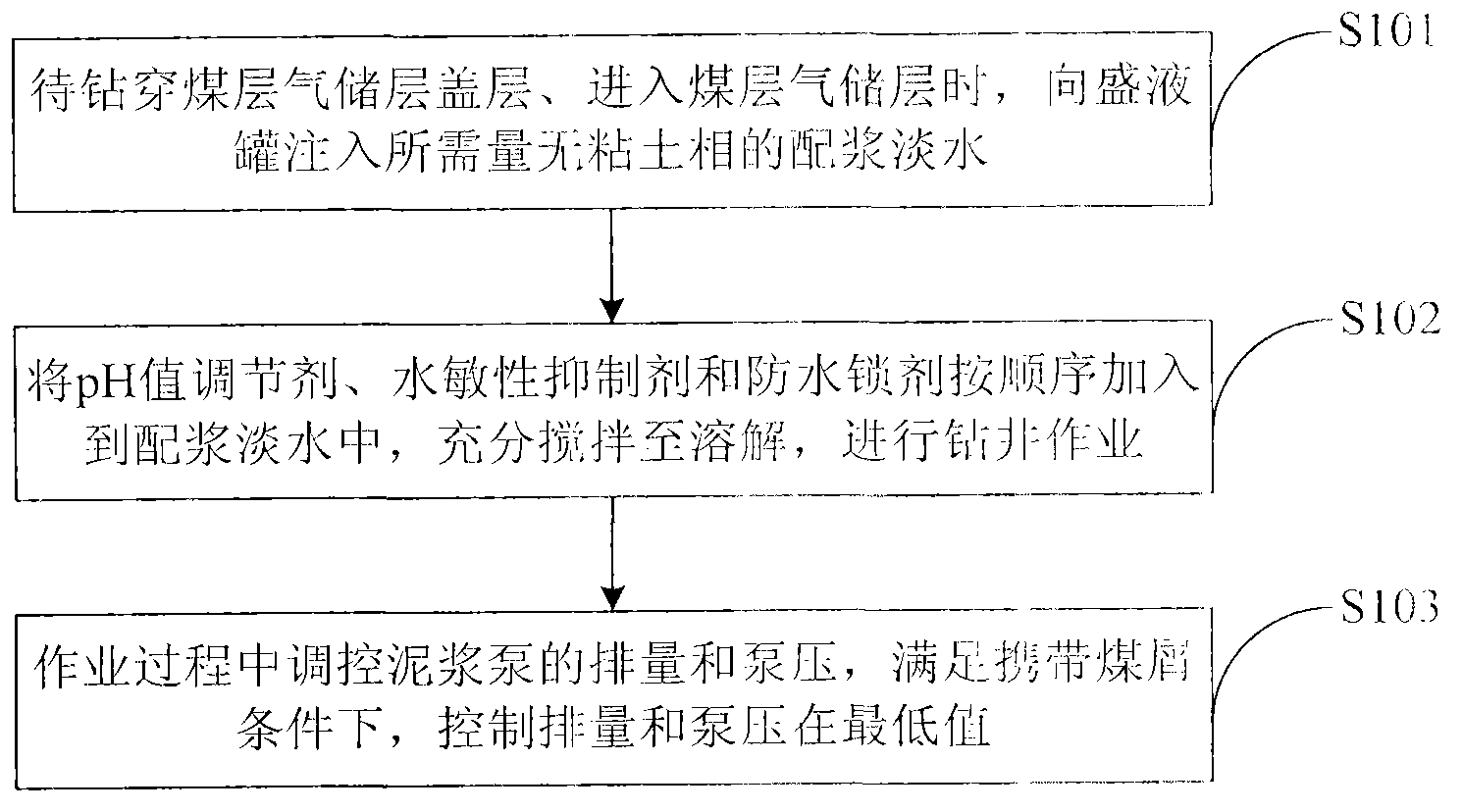

Pressure control injection yield increase method for coalbed methane well

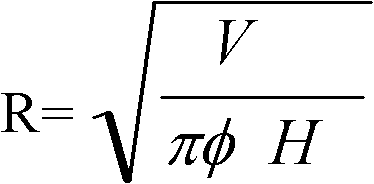

The invention relates to a pressure control injection yield increase method for a coalbed methane well. The radius affected by the pressure of a created fracture after thehydraulic fracture according to the gas production rate, the coal seam thickness and the gas content per ton after the fracture of the coal petrography; the injection solution amount for yield increase is determined; a sleeve can be injected when the sand wash of the borehole operation is 10m far from a coal seam; two bottles of fracturing fluids are connected into an inlet of a plunger pump in parallel; the outlet of the plunger pump is connected with a sleeve valve of a gas collection tree, and a well mouth is provided with a pressure meter; and the accumulated water yield during the production period of a construction well is injected into the coal seam with the maximum pump discharge for filling the volume of the recover part, fluids can be injected by controlling the pressure, 5-20 Mpa injection amount of the fluids is injected in small pump discharge and steady pressure ways according to different pressures, the injection can be stopped when the stratum is saturated and the fluids can not be injected. The well mouth is pressure free in 3-5 days; and when the stratum is saturated and the pressure is not decreased to 5Mpa during the fifth-seventh day, the construction of the well can be finished. The invention has the beneficial effects that the method is suitable for the growth feature of the coal petrography of high order coal, the fracture conductivity is improved, and the generation of coal dust can be controlled.

Owner:PETROCHINA CO LTD

Micro-seismic identification method based on coal petrography impact instability mode

ActiveCN106154307AHigh precisionImprove applicabilityEarthquake measurementSeismic signal processingMicrotremorDecomposition

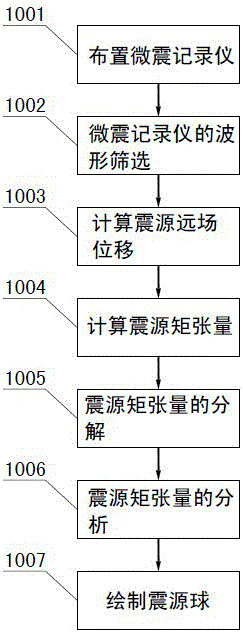

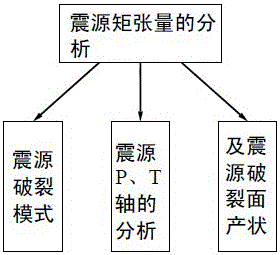

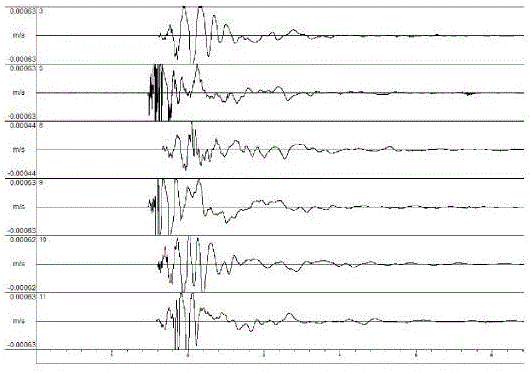

The invention, which belongs to the technical field of the micro-seismic characteristic analysis of the impact rock pressure, provides a micro-seismic identification method based on a coal petrography impact instability mode. The method comprises: step 1001, a plurality of microseismographs are arranged at different positions at a same stope to carry out micro-seismic monitoring and each microseismograph forms a micro-seismic signal record; step 1002, a plurality of micro-seismic waveforms are screened among the micro-seismic records monitored by the microseismographs; step 1003, on the basis of a focus far-field displacement calculation step, a focus far-field displacement value of each micro-seismic waveform is calculated; step 1004, calculation is carried out to obtain a focus moment tensor; step 1005, the focus moment tensor obtained by calculation at the step 1004 is decomposed; and step 1006, the focus moment tensor after decomposition at the step 1005 is analyzed to obtain a focus fracture mode, focus P and T axes, and focus fracture plane occurrence.

Owner:CHINA UNIV OF MINING & TECH

Test piece of coal seam simulation experiment using shock waves to increase permeability and experiment method based on test piece

InactiveCN106053169ALarge scaleEasy to manufactureAnalysing solids using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationShock waveBrick

The invention belongs to the technical field of coal seam physical simulation experiments and particularly relates to a test piece of a coal seam simulation experiment using shock waves to increase permeability and an experiment method based on the test piece. The quantitative relation between fluctuation parameters and the coal petrography cracking effect and permeability variation feature is built through the physical simulation experiment. The test piece comprises a shell, strain bricks and coal sample strain gauges, wherein the shell is a bottom-free rectangular shell, one strain brick is fixed in the middle of each of the faces, except the bottom, on the inner side of the shell, a coal sample is fixed in the shell, and two vertical coal sample strain gauges are fixed in the middle of each of the faces, except the bottom, of the coal sample, every two coal sample strain gauges are respectively fixed in the vertical direction and the horizontal direction, and each strain brick presses on the surfaces of the corresponding two coal sample strain gauges. The test piece has the advantages that the test piece is large in dimension, deformation features can be conveniently recorded during the experiment process, the crack development conditions can be statistically recorded during the experiment process, and cement mortar on the outer surface of the coal sample can simulate surrounding rock.

Owner:SHANXI DATONG UNIV

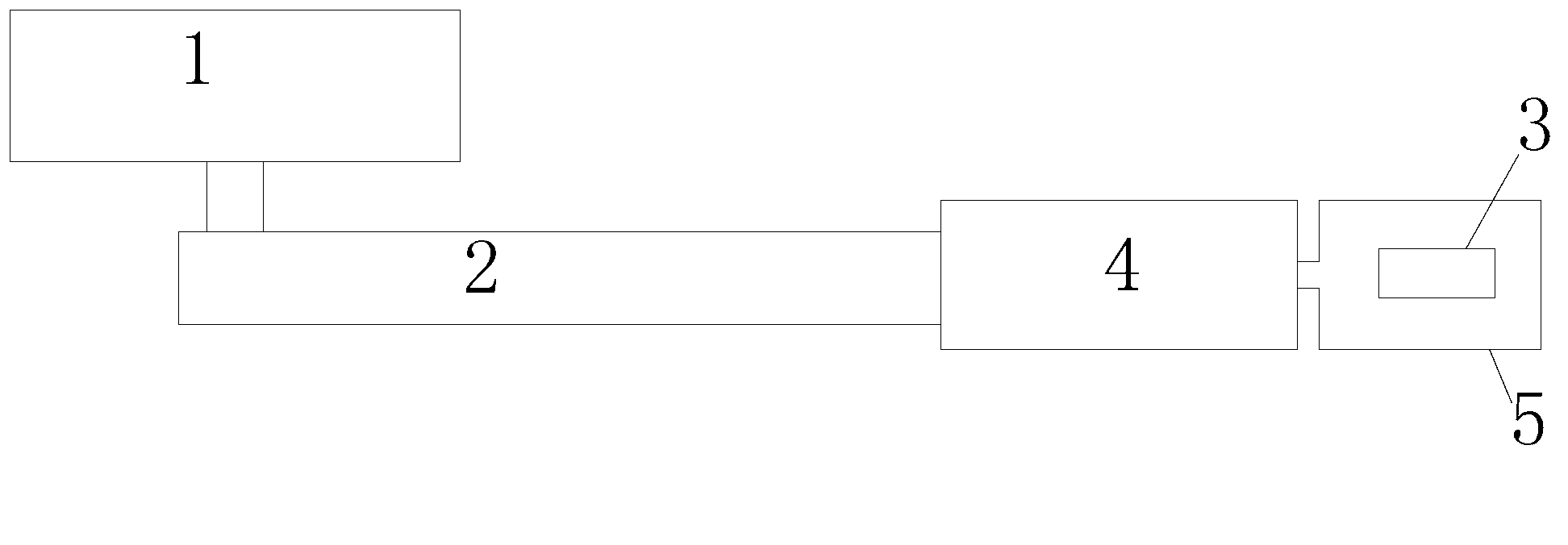

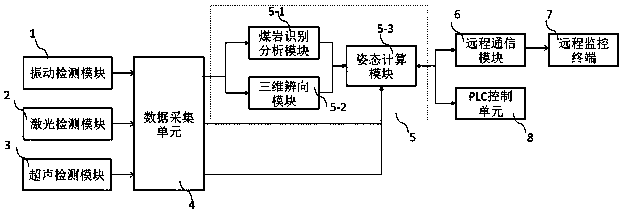

Adjusting system for tunneling posture of coal mining machine

ActiveCN108119140AAvoid failureReal-time adjustment of tunneling postureSlitting machinesProgrammable logic controllerComputer module

The invention discloses an adjusting system for tunneling posture of a coal mining machine. The adjusting system comprises a vibration detecting module, a laser detecting module, an ultrasonic detecting module, a data acquisition unit, an industrial control computer and a remote communication module, wherein the vibration detecting module is used for obtaining the conditions of a coal seam and tunneling vibration; the laser detecting module is used for obtaining an inclined angle of the coal seam; the ultrasonic detecting module is used for obtaining the tunneling attitude of the coal mining machine; the data acquisition unit is used for acquiring sensor signals obtained by the vibration detecting module, the laser detecting module and the ultrasonic detecting module and transmitting the sensor signals to the industrial control computer; the industrial control computer is provided with a coal petrography identification analysis module, a three-dimensional direction seeking module and an posture computing module; a PLC (Programmable Logic Controller) control unit is connected with the industrial control computer and is used for adjusting the tunneling posture of the coal mining machine; the remote communication module is connected with the industrial control computer and is used for transmitting coal petrography identification information obtained by calculation of the coal petrography identification analysis module and tunneling posture data, obtained by the posture computing module, of the coal mining machine in the industrial control computer to a remote monitoring terminal. The adjusting system disclosed by the invention provides more detailed information for the tunneling posture adjustment of the coal mining machine so as to better avoid the faults of the coal mining machine.

Owner:SHANDONG TECHGONG GEOTECHN ENG EQUIP CO LTD

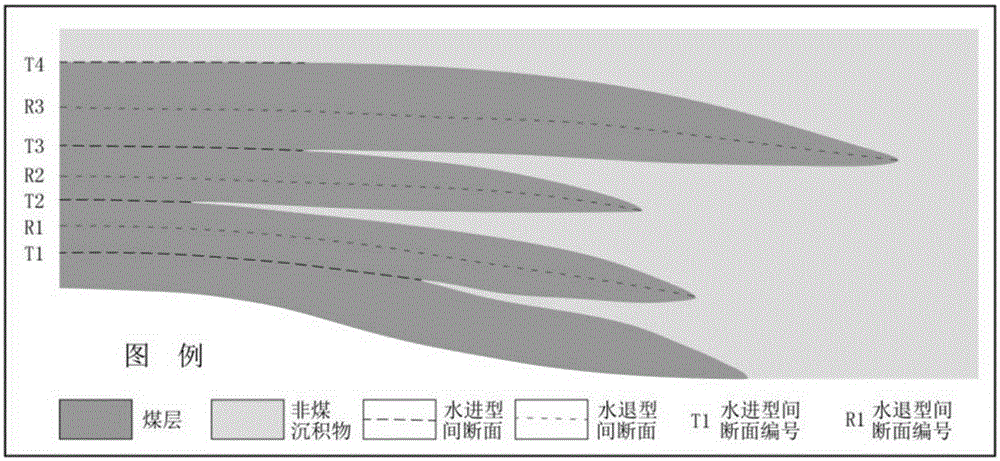

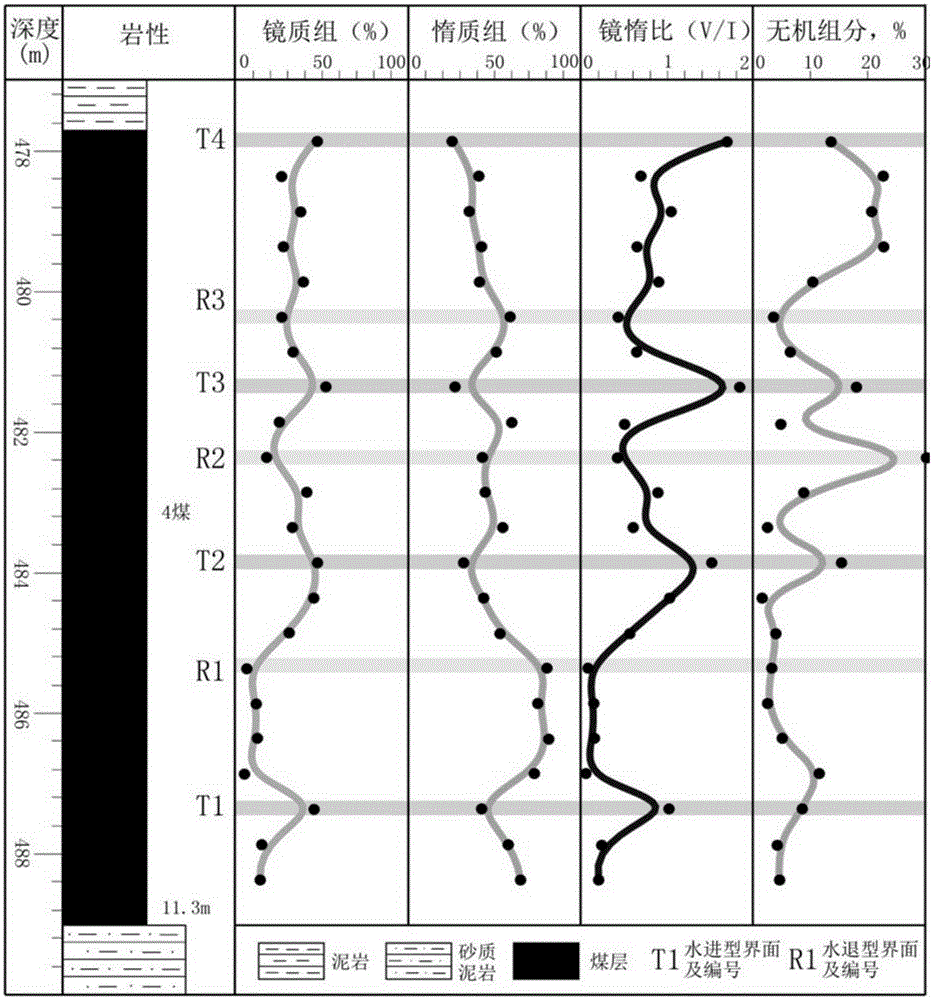

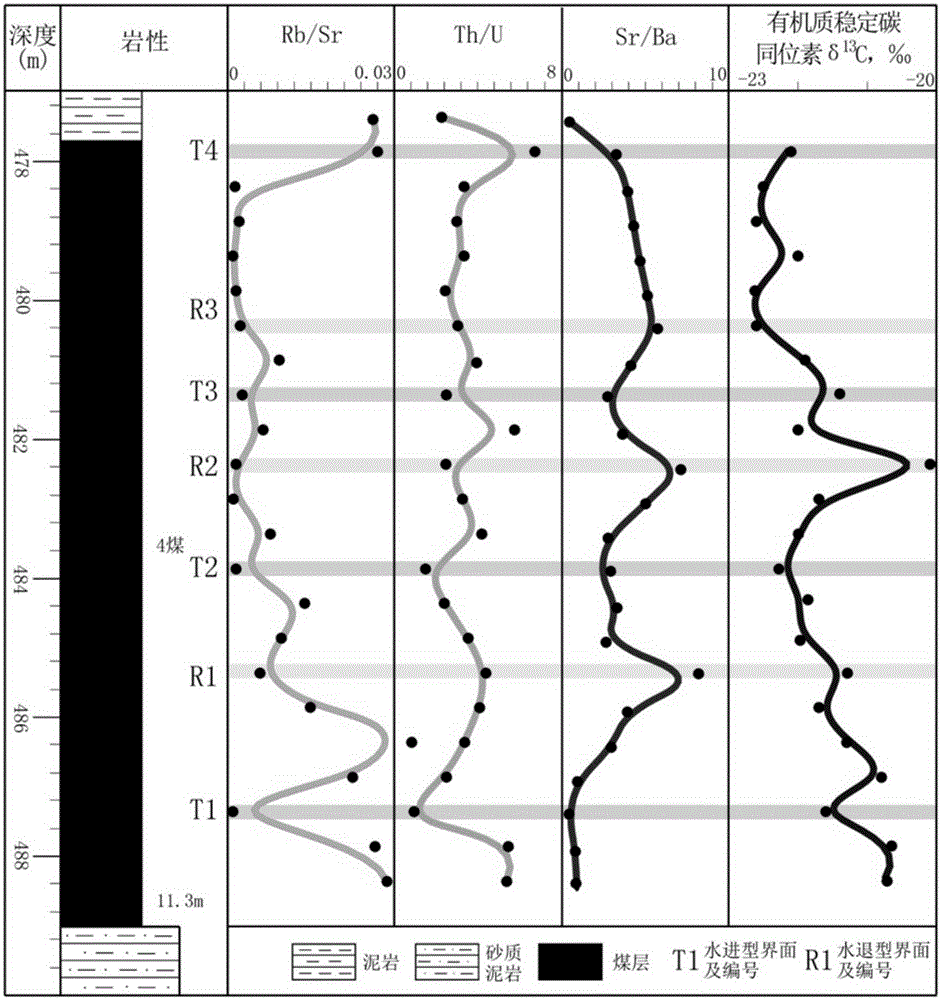

Method for comprehensively recognizing sedimentation hiatal surfaces in ultra-thick seam

InactiveCN105201492AHigh precisionStrong reliabilityBorehole/well accessoriesGrowth controlRoot cause

The invention discloses a method for comprehensively recognizing sedimentation hiatal surfaces in an ultra-thick seam. The sedimentation hiatal surfaces in the ultra-thick seam are comprehensively recognized according to five parameters acquired through coal petrography and coal quality analysis, microelement analysis, organic matter stable carbon isotope analysis, one-dimensional continuous wavelet transformation of log data and Milankovitch cycle analysis of the log data; growth control factors of the sedimentation hiatal surfaces are explained from the origin essentially through recognition of Milankovitch cycles in the ultra-thick seam, the root cause of growth of the sedimentation hiatal surfaces is found out, and the accuracy and the credibility of the sedimentation hiatal surfaces are greatly improved. Besides, weight scoring is performed according to sensitivity of different recognition methods, the recognized sedimentation hiatal surfaces are correspondingly assigned, the scores obtained with all the methods are added up, and the reliability of the sedimentation hiatal surfaces is described quantitatively. The recognition method is convenient and flexible and has better practicability.

Owner:SHANDONG UNIV OF SCI & TECH

Microscopic cracking evolution process test equipment for bifacial shearing of coal petrography

InactiveCN103105338AReliable test methodEasy to installMaterial strength using steady shearing forcesEngineeringProcessing cost

The invention discloses microscopic cracking evolution process test equipment for bifacial shearing of coal petrography. The test equipment comprises a body, wherein the body is provided with a test piece cavity which is internally provided with a support; the top wall of the body is of a split structure and comprises a left top wall and a right top wall which are symmetrical in structure and are arranged at an interval to form a pressure head installation port; the front and rear ends of the body are provided with openings; a groove is formed in the part, which is over against the pressure head installation port, of the support; the left side wall of the body is provided with a guide hole; the front and rear parts of the left top wall are symmetrically provided with a first fastening bolt hole and a second fastening bolt hole which are communicated with each other; and the right top wall is provided with a third fastening bolt hole and a fourth fastening bolt hole which are symmetrical with the first fastening bolt hole and the second fastening bolt hole. The test equipment provided by the invention has the characteristics of wide adaptability, simple structure, low processing cost, high reliability, convenience in operation and the like.

Owner:CHONGQING UNIV

Method for detecting coal field fire district distribution range

InactiveCN102508309AAvoid defectsImprove targetingElectric/magnetic detection for well-loggingDetection using electromagnetic wavesHigh concentrationElectromagnetic field

The invention provides a method for detecting a coal field fire district distribution range, which is applicable to detection of coal field fire distribution ranges and development degree. According to the characteristic that coal field fire often happens in a coal petrography scattering area, a geological radar and a transient electromagnetic instrument detect electromagnetic wave amplitudes and secondary induction electromagnetic fields in a detection area, and a distribution range of the coal petrography scattering area in the detection area is defined. Gas measurement drill hole is constructed in the defined coal petrography scattering area in the detection area, gas in the drill hole is sampled, and compositions and concentrations of carbon monoxide, acetylene and ethylene in a gas sample is analyzed. A gas concentration distribution contour map is developed according to analysis results of the gas sample, the area with low concentration is the edge of the fire district, and the area with high concentration is the area with serious fire district development degree. By means of pre-detection of the coal petrography scattering area, pertinence of the fire district detection drill hole is improved, construction amount of the detection drill hole is reduced, and detection cost is saved. The method for detecting the coal field fire district distribution range is simple and high in detection accuracy, and has wide practical applicability in the field of detection of the coal field fire district.

Owner:CHINA UNIV OF MINING & TECH +1

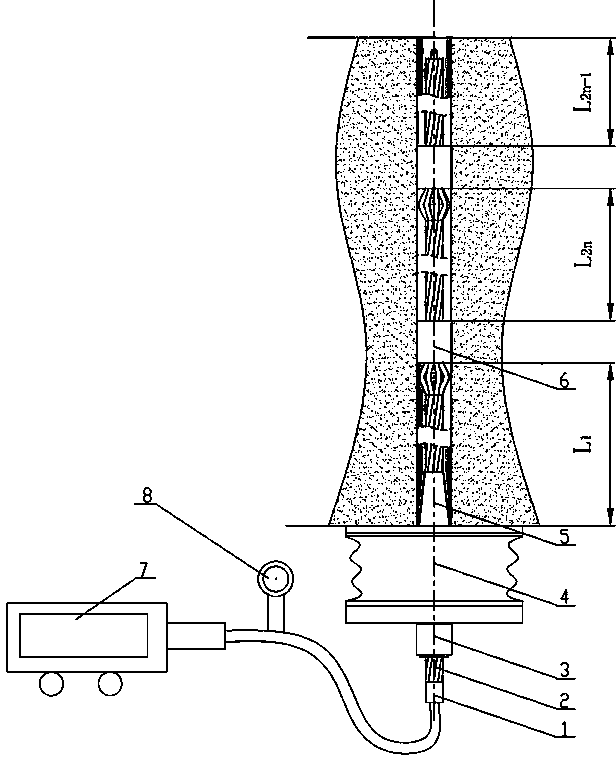

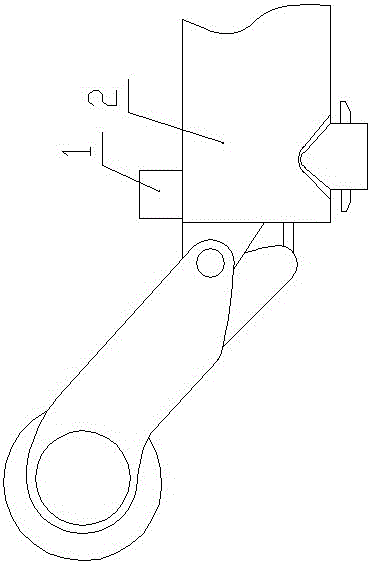

Impact-resistant interval grouting anchor cable and use method thereof

ActiveCN103590845AAlleviate the impact of the momentAvoid High Shear Stress StatesAnchoring boltsSupporting systemHigh stress

The invention discloses an impact-resistant interval grouting anchor cable and a use method of the impact-resistant interval grouting anchor cable. The impact-resistant interval grouting anchor cable comprises a one-way grouting valve, a hollow grouting stranded steel wire, an arc-shaped anchor ring, a sliding pressure yielding retraction ring, a tapered grout blocking plug and a subsection sealing plug, the sliding pressure yielding retraction ring is arranged between the arc-shaped anchor ring and the tapered grout blocking plug, grout discharge valves are arranged on a flexible grouting pipe in the hollow grouting stranded steel wire at certain-length intervals, the subsection sealing plug is arranged at the front end of an expansion area of the stranded steel wire, and interval grouting is achieved. The using method comprises the steps that a grouting section L2n-1 and a non-grouting section L2n are arranged according to coal petrography mechanical parameters of a construction location, initial resin anchoring is carried out on the interval grouting anchor cable, the interval grouting anchor cable is tensioned and pre-tightened, grouting materials are prepared, and a grouting pump is used for achieving the interval grouting on the grouting anchor cable. According to the condition of surrounding rock, the grouting section and the non-grouting section are arranged, the force bearing condition of a supporting system is scientifically improved, the instant high stress state, caused by the intense deformation of the surrounding rock, of the stranded steel wire of the anchoring section is relieved, and an anchor cable support is prevented from losing efficacy.

Owner:HENAN POLYTECHNIC UNIV

Coal petrography interface identification and positioning method based on machine visual sense

InactiveCN105913445AReflect the real situationPromote recoveryImage enhancementImage analysisAttitude controlCoal dust

The present invention provides a coal petrography interface identification and positioning method based on machine visual sense. The method comprises the following steps: (1) installing a camera at the body of a coal cutter through a rapid coupling mechanism, employing the camera to collect the coal mining surface and obtain pictures of the coal mining surface, converting the original image extracted in the camera collection information to a gray image through image preprocessing, and then performing image enhancement, gray stretching and median filtering of the gray image; and (2) processing the influence on the gray image caused by the light reflection, the coal dust and the band, and finally obtaining a whole coal rock interface curve picture. The coal petrography interface identification and positioning method based on a machine visual sense improves the coal recovery ratio, avoids the device damaging even accident initiation caused by cutting to the top plate by using the roller pick of the coal cutter so as to provide reliable basis for the attitude control of the coal cutter, enhance the coal mining automation level for underground coal mine and improve the coal mining work benefit.

Owner:HENAN POLYTECHNIC UNIV

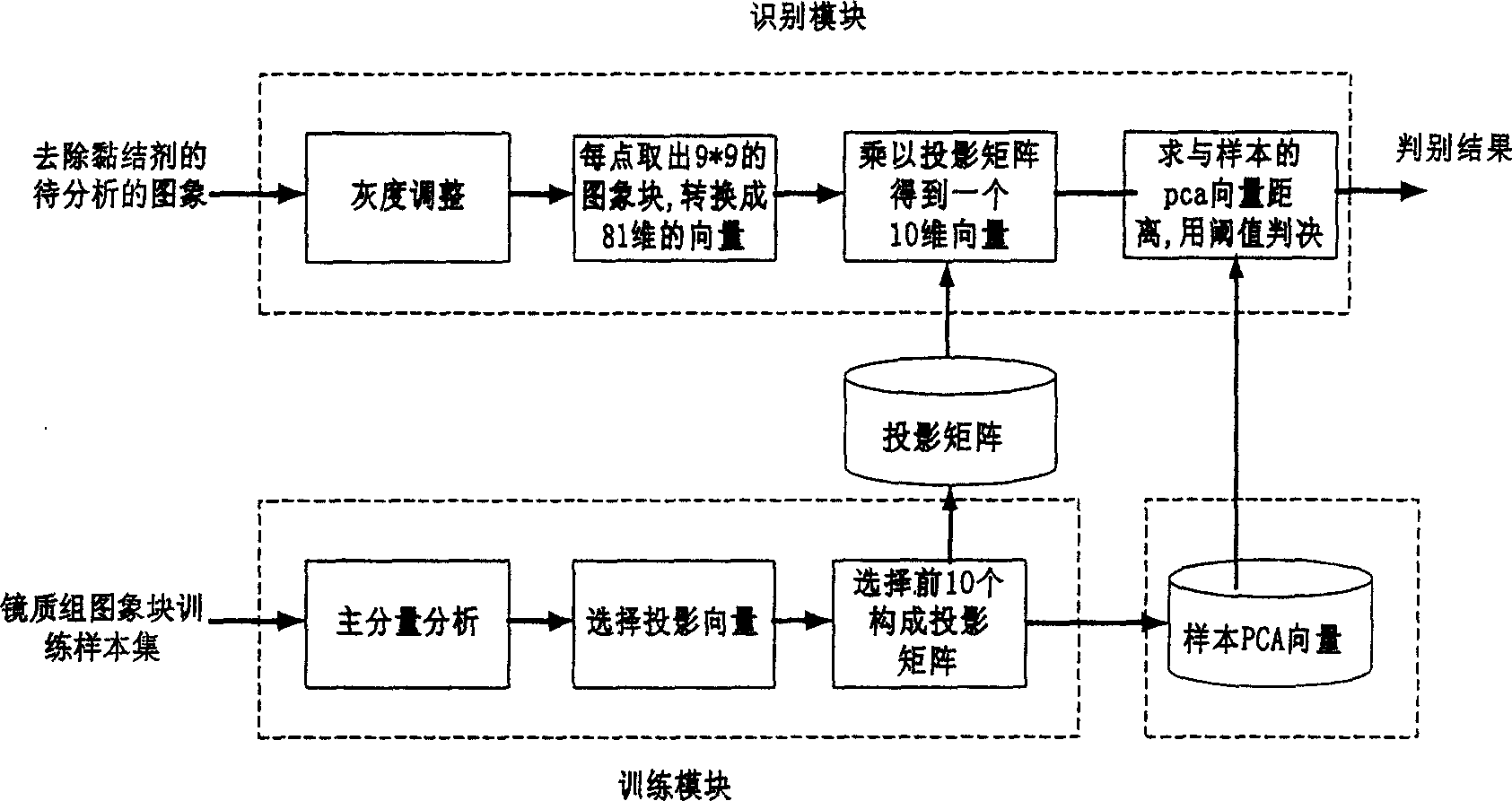

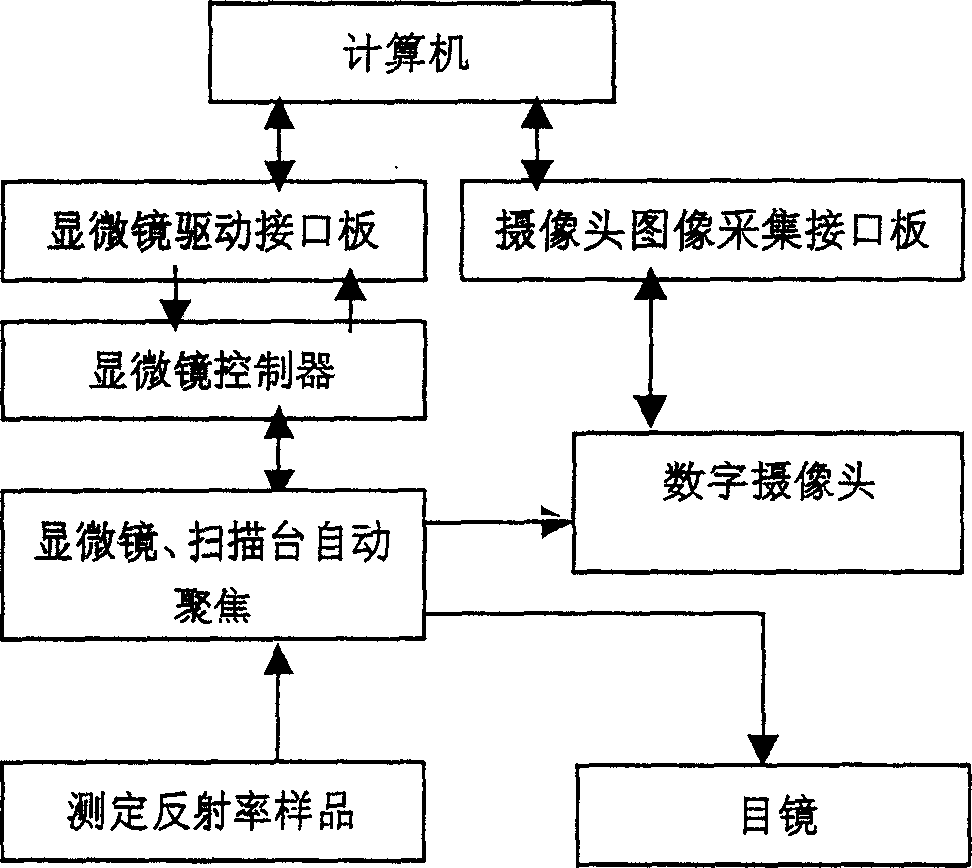

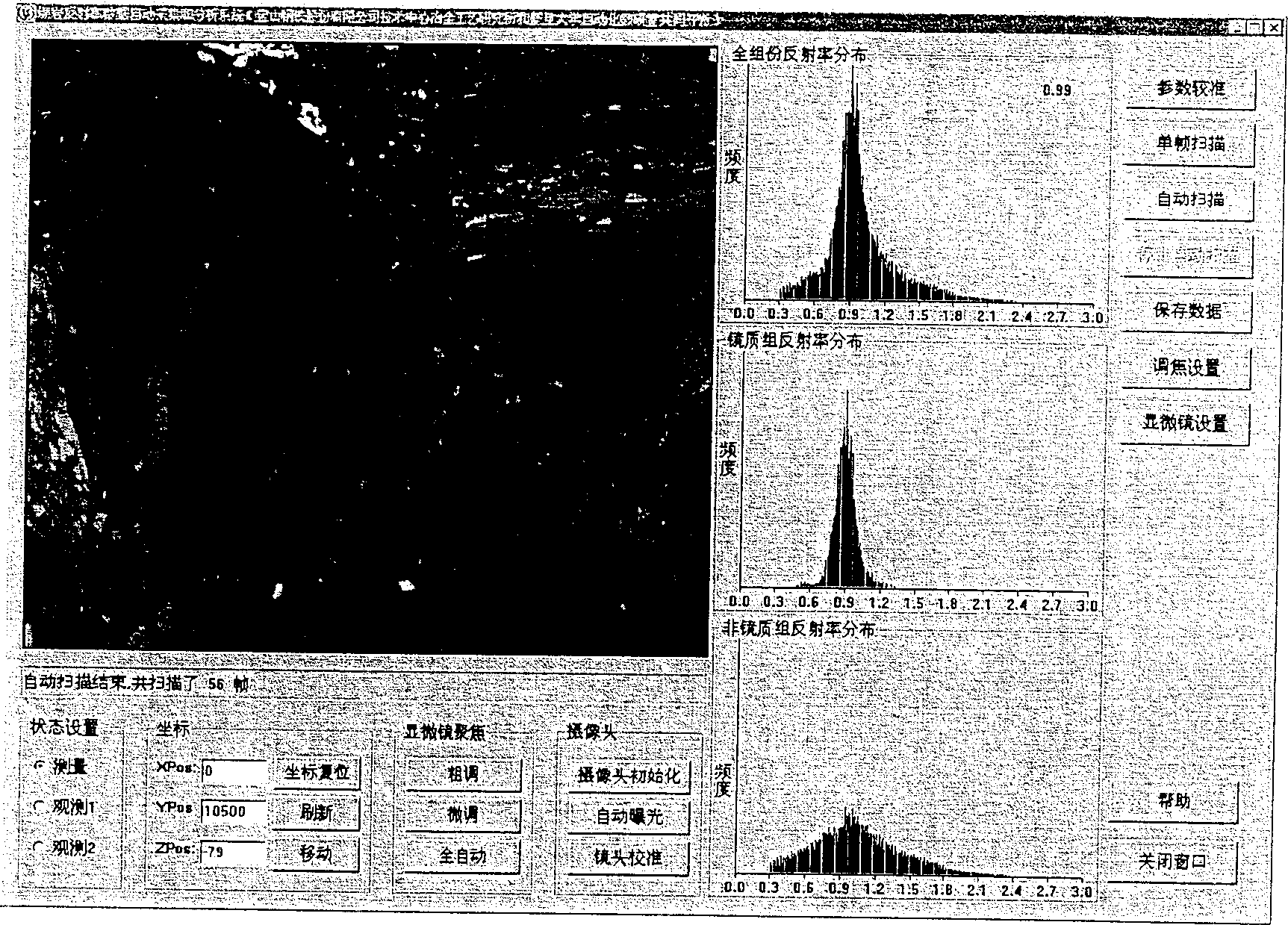

Coal petrography reflection rate digital automatic determination method

InactiveCN1493869AHigh speedAccurate reflectivityScattering properties measurementsComputer scienceCoal

A digitalized method for automatically measuring the reflectivity of coal rock features that a digital camera head is used to measure the reflectivity of coal rock and the image analyzing technique is used to divide the microscopic components of coal rock. Its advantages are high precision and high automation level.

Owner:BAOSHAN IRON & STEEL CO LTD

Drilling fluid capable of protecting coal bed methane reservoir

InactiveCN103194189AEffective protectionAvoid damageDrilling compositionMaterial analysisClay mineralsAdditive ingredient

The invention discloses a drilling fluid capable of protecting a coal bed methane reservoir. The drilling fluid comprises the following ingredients in percentage by weight: 100 parts of fresh water, 0.1-0.3 part of pH value modifier, 0.5-10 parts of water-sensitivity inhibitor, and 0.1-1 part of waterproof blocking agent. For the drilling fluid, the density is 1.01-1.08g / cm<3>, the pH value ranges 8 to 10, the expansion rate reduction ratio is greater than or equal to 60%, the contact angle reduction rate is greater than or equal to 50%, the hygroscopic-state recovery rate of the core permeability is greater than or equal to 85%, the dry-state recovery rate is greater than or equal to 95%, the coal powder landberra volume reduction rate is greater than or equal to 15%, clay-free phase does not exist, the damage to the coal bed methane reservoir caused by same-phase invasion can be furthest reduced, the hydration of the clay mineral in coal petrography can be effectively prevented, water blocking is reduced, the coal bed methane can be forced to be desorbed from the surface of the coal petrography, the coal bed methane reservoir can be effectively protected, the stability of the coal bed well wall can be retained, the practicability is strong, and the stronger popularization and application values can be achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

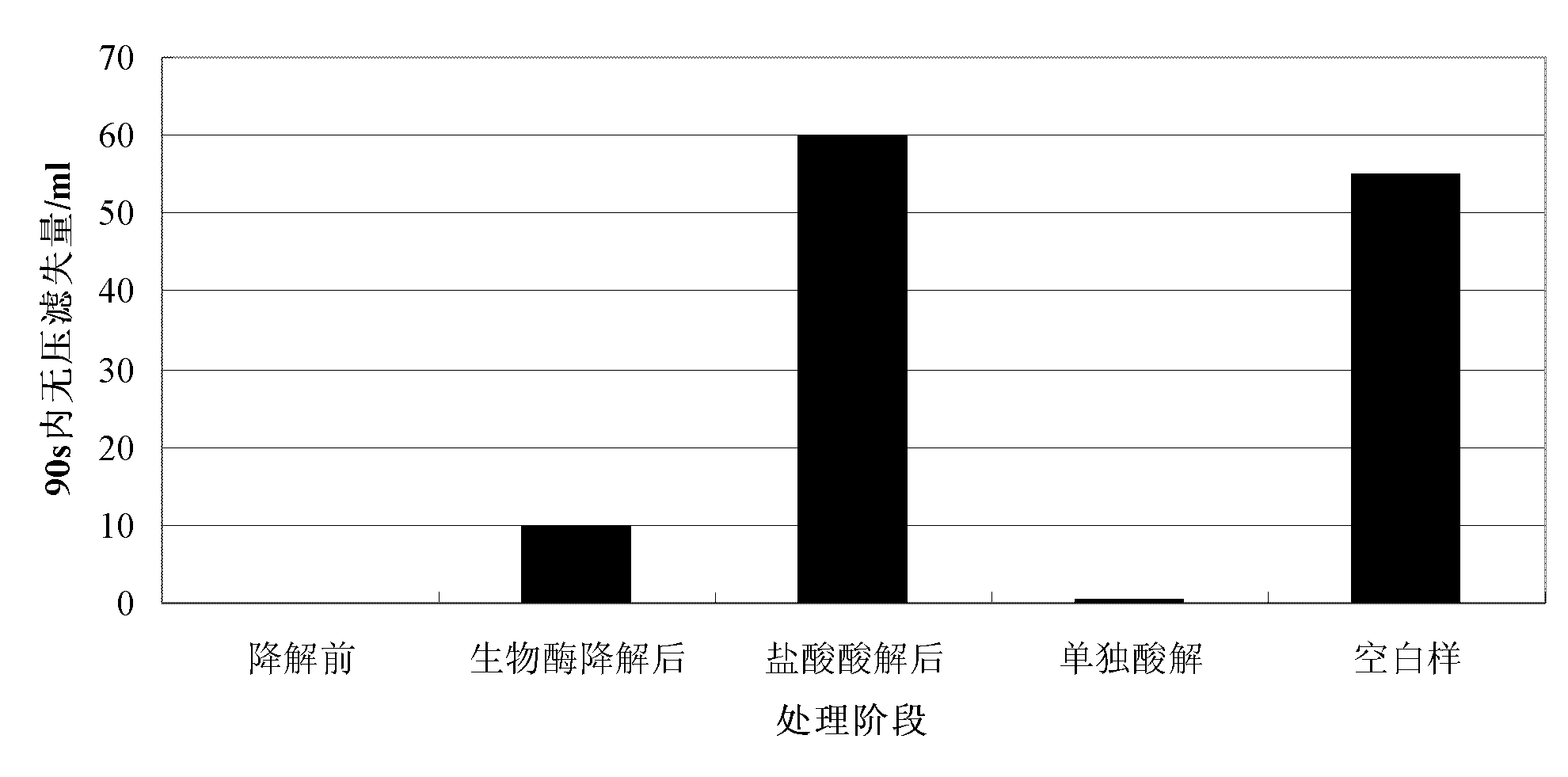

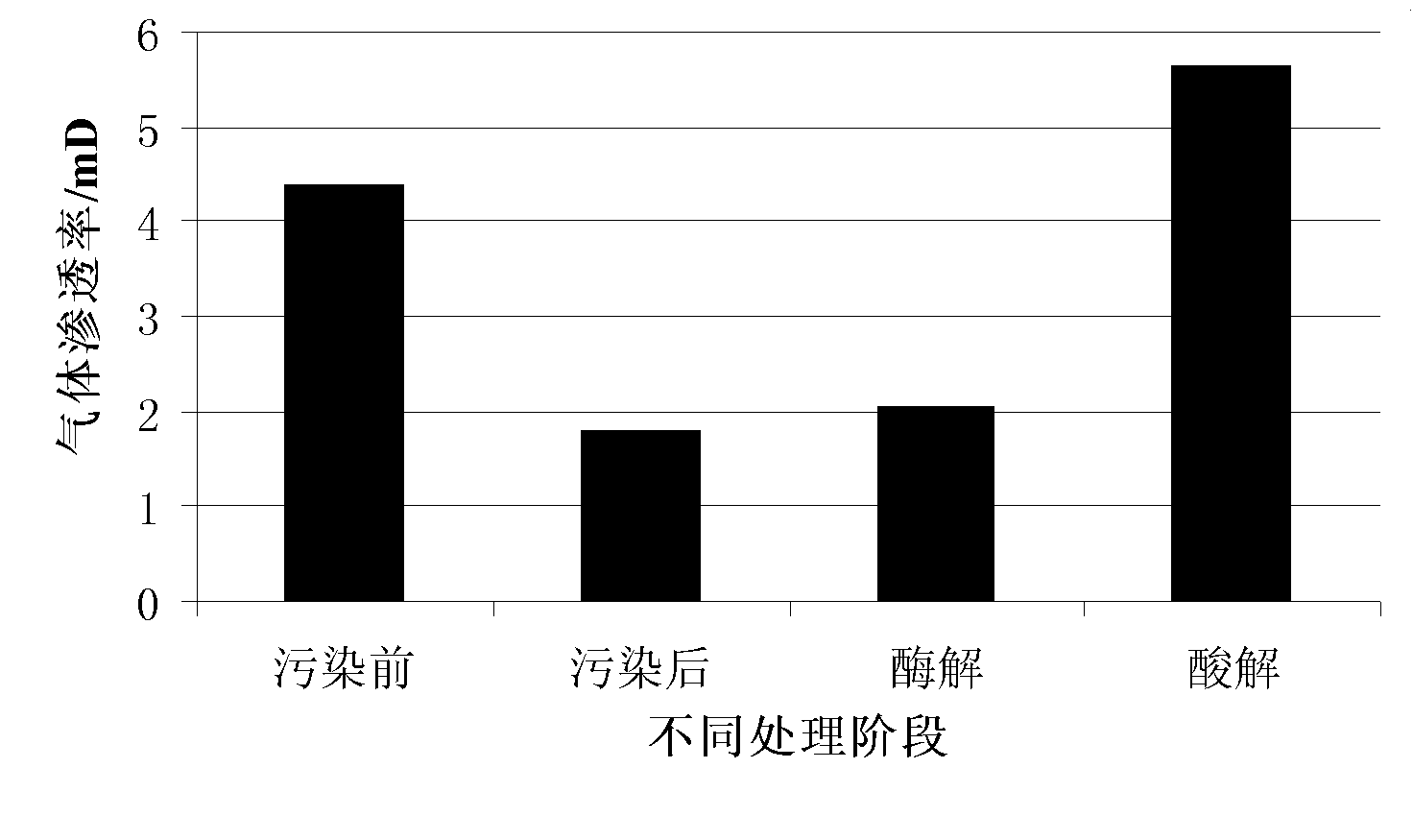

Degradable drilling fluid used for drilling in soft coal seam

The present invention relates to a drilling fluid used for ground coalbed methane drill or underground gas drainage, especially is suitable for drilling in the soft coal seam. The degradable drilling fluid used for the soft coal seam is characterized in that the fluid is composed by mixing water, a biodegradable polymer, slurry clay, a filtrate loss reducer, a bridging agent, a pH modifier and a gel breaker; by referring the amount of computation per 100 ml of water 0.5-0.75 g of degradable polymers, 0-2 g of slurry clay, 0.5-2 g of the loss reducer, 1-2 g of the bridging agent and 0.01-0.1 g of the gel breaker, the addition amount of the pH regulator satisfies the drilling fluid pH value to 7. The fluid of the invention has the advantages of good rheology and filtrate loss performance, the drilling fluid can meet the requirements of cuttin carrying of the soft coal seam drilling rock debris and wellbore stability; the gel breaker degradation and dilute hydrochloric acid double acidification can effectively remove the damage of degradable drilling fluid onto coalbed methane reservoir, and restore or even improve the gas permeability of coal petrography.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

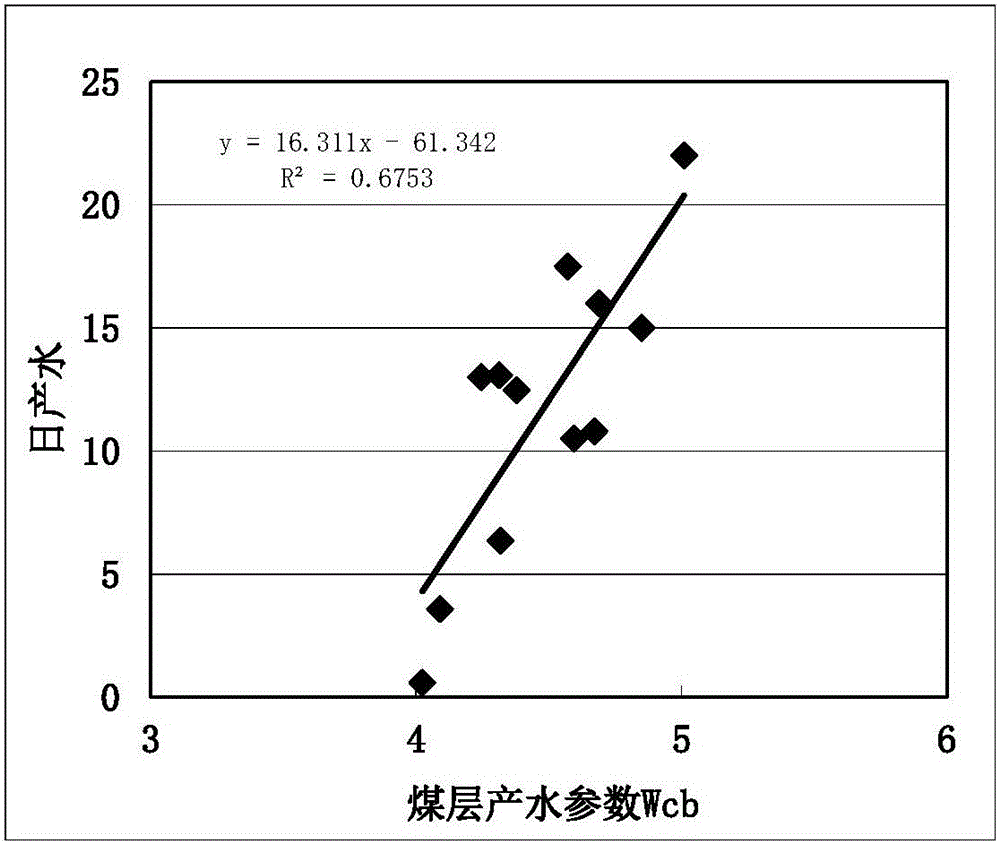

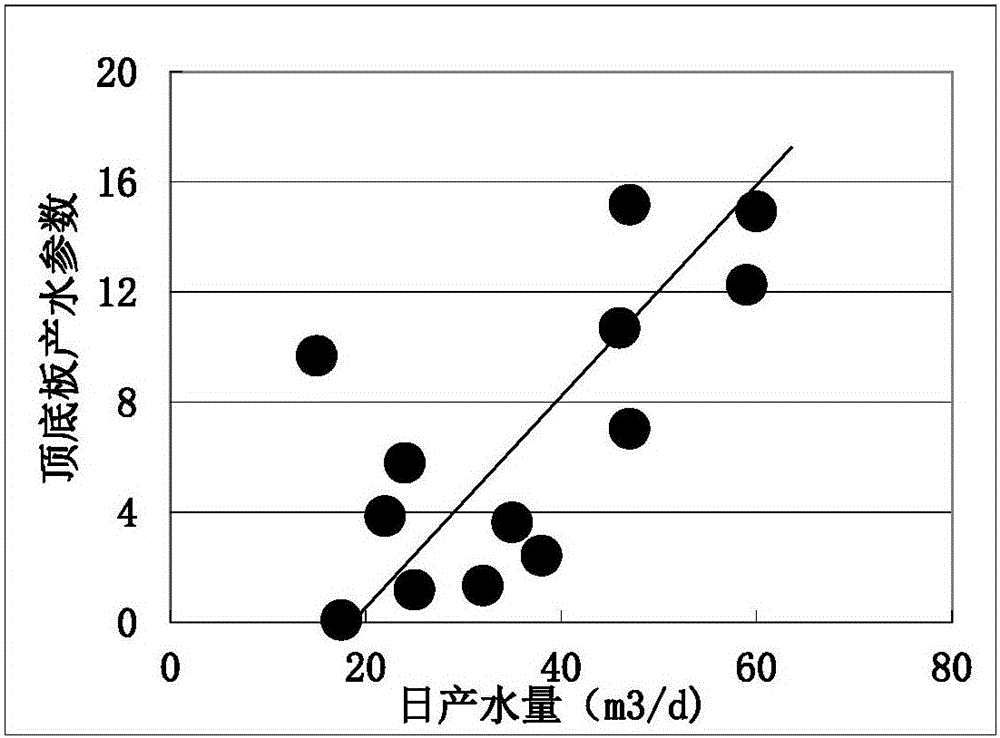

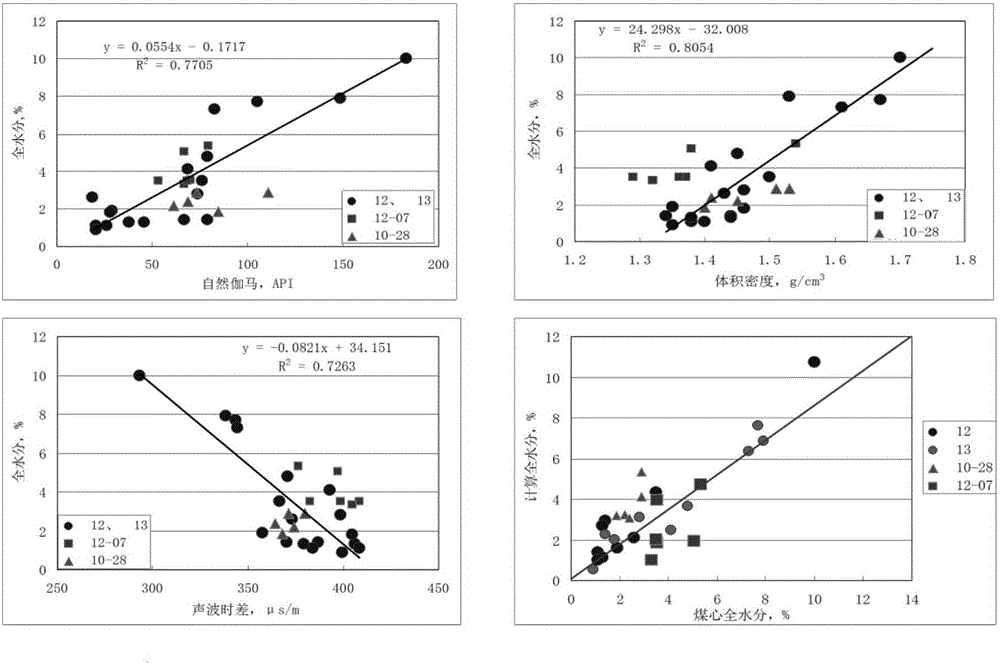

Method for predicting water content and water yield of coal seam

The invention discloses a method for predicting a water content and a water yield of a coal seam. The method comprises: (1), calculating a water yield parameter and a water yield of a pure coal seam; (2), constructing an integrated evaluation parameter of water yields of stand stones at a top bed and a bottom bed; (3), calculating a water yield of coal seam drainage; (4), calculating total moisture of the coal seam; (5), calculating a water content of the coal seam; and (6) calculating water contents of the stand stones at the top bed and the bottom bed of the coal seam. According to the invention, a relationship between the water yield and the logging value at the initial stage of the coal seam draining is analyzed and a method for predicting the water yield of the draining of the pure coal seam by using logging data is established; under the circumstance that water-contained sandstones exist in a short-distance range of the coal seam, a water yield calculation model of joint water yields of the coal seam and the water-contained sandstones is provided; on the basis of the coal petrography experiment, a method for calculating the water content of the coal seam by using logging data is established and a total water content of the sandstone layer of the top bed is provided; and with the water content and the water yield of movable water, the water yield cycle of the draining process can be predicted preliminarily.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com