Prediction method matched with coal blend vitrinite reflectance distribution and application of predication method

A technology of vitrinite reflectance and prediction method, applied in the field of coal coking, can solve the problems of misleading coal blending, not considering vitrinite content, large difference, etc.

Active Publication Date: 2014-10-08

INST OF RES OF IRON & STEEL JIANGSU PROVINCE

View PDF4 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

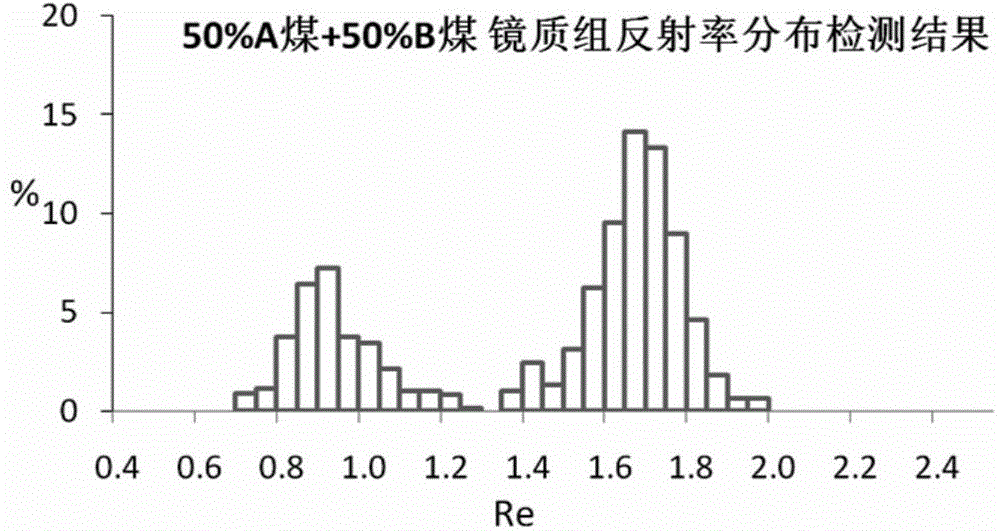

The existing calculation method of blending coal reflectance distribution adopts the method of simple summation, and calculates the blending coal vitrinite reflectance distribution according to the proportion of blending coal and the distribution of vitrinite reflectance, but this method does not consider the distribution of each blending coal The content of vitrinite is different. For example, Changguang Gas Feifei Coal has a vitrinite content of about 16%, while Ai Weiergou Coke and Feimei Coal have a vitrinite content of about 90%. Therefore, the combined coal vitrinite content calculated by simply adding There is a huge difference between the group reflectance distribution and the actual test results, which is misleading for the guidance of coal blending

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0025] 1 The present invention cooperates with coal vitrinite reflectance distribution prediction method implementation case 1, and the specific steps are:

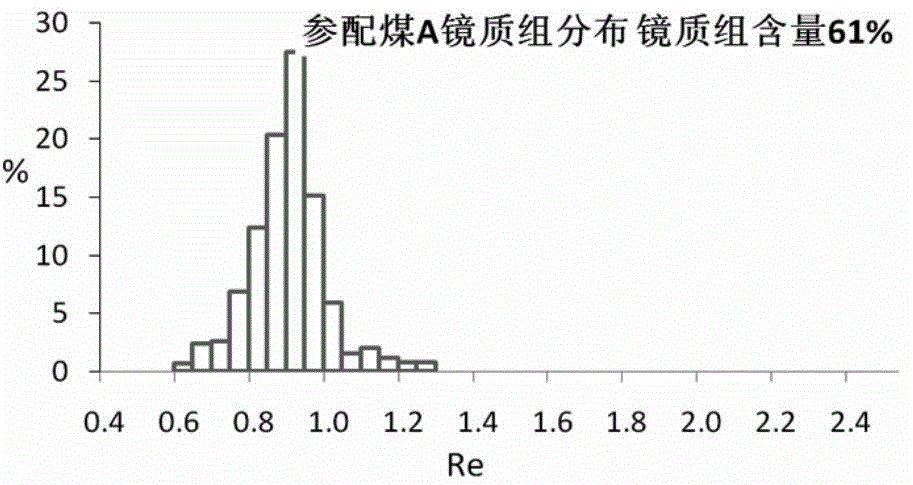

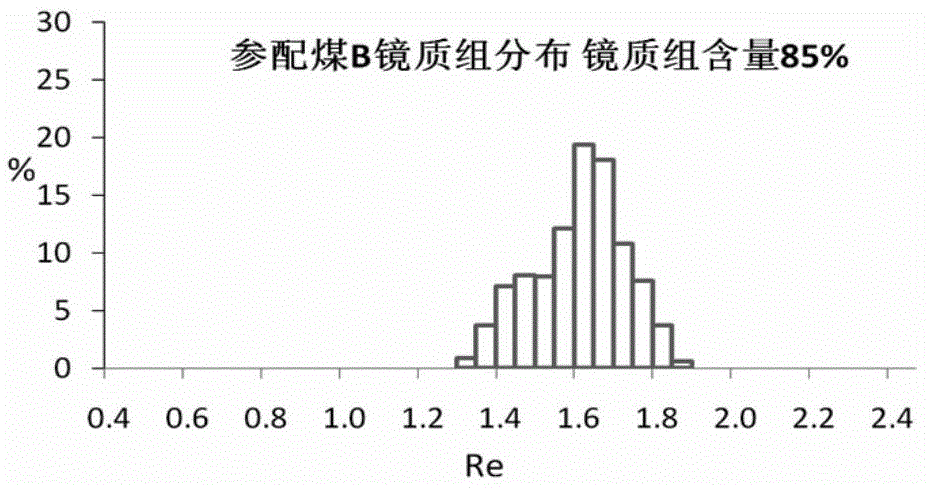

[0026] (1) Detect the vitrinite reflectance distribution and vitrinite content of blending coal A and blending coal B;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| cohesion index | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to the field of coking, and particularly relates to a method for predicting the vitrinite reflectance distribution of coal blend according to coal blend ratio, vitrinite content and reflectance distribution, and a method for guiding coal blend by combining a mobility change function and a G value. The method comprises the following steps: by adopting a coal petrography analysis system, detecting the vitrinite reflectance distribution and vitrinite content of coal blend, and calculating the vitrinite reflectance distribution and content of the coal blend according to the vitrinite content, the reflectance distribution and coal blend ratio of the coal blend; and through calculation, controlling the vitrinite reflectance distribution range, the mobility and the G value of the coal blend, thus further controlling the mass of coke. According to the method disclosed by the invention, the errors of simply adding and calculating the vitrinite reflectance distribution of the coal blend according to the coal blend ratio without the consideration of different contents of different single vitrinite in a traditional method are corrected, the vitrinite reflectance distribution of the coal blend can be accurately predicted, high-strength coke under relatively low caking index conditions can be blended by combining the mobility function and G value.

Description

technical field [0001] The invention relates to a method for predicting the reflectance distribution of blended coal vitrinite in the field of coal coking, and a method for guiding coal blending and controlling coke quality by combining the fluidity of blended coal and the G value. Background technique [0002] Coal lithofacies is gradually applied to the field of coking coal blending because of its important role in coal rank characteristics, coke microstructure, and cold and hot strength. The existing calculation method of blending coal reflectance distribution adopts the method of simple summation, and calculates the blending coal vitrinite reflectance distribution according to the proportion of blending coal and the distribution of vitrinite reflectance, but this method does not consider the distribution of each blending coal The content of vitrinite is different. For example, Changguang Gas Feifei Coal has a vitrinite content of about 16%, while Ai Weiergou Coke and Fei...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N33/22C10B57/04

Inventor 杜屏周俊兰吕青青

Owner INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com