Method for identifying coal petrography interface of thin coal layer and automatically heightening expansion cylinder

A thin coal seam, automatic adjustment technology, applied in the direction of earthwork drilling, slitting machinery, etc., to achieve the effect of unmanned operation, improved recovery rate, and high-efficiency coal cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

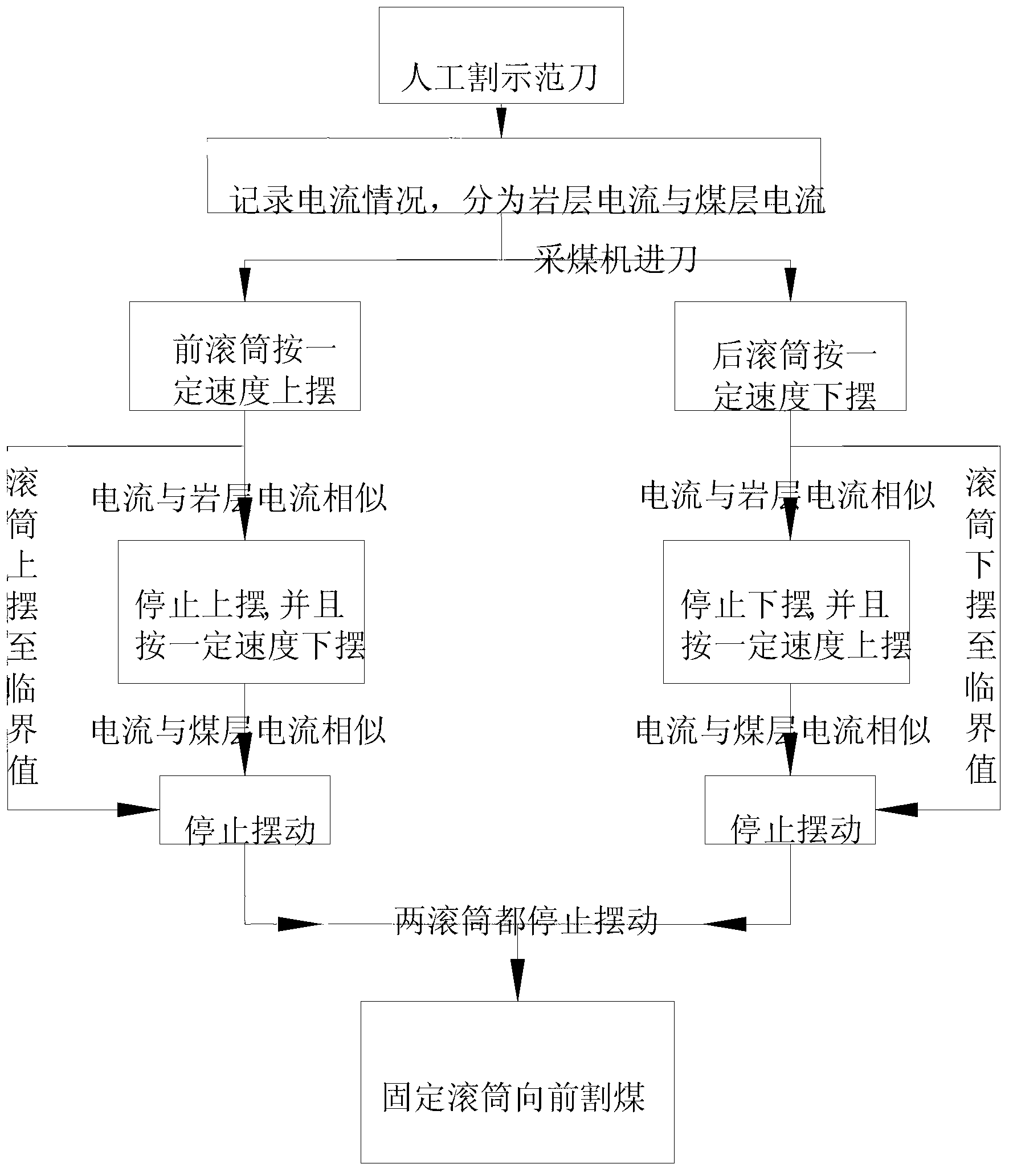

[0021] Embodiment 1: the specific method steps are as follows:

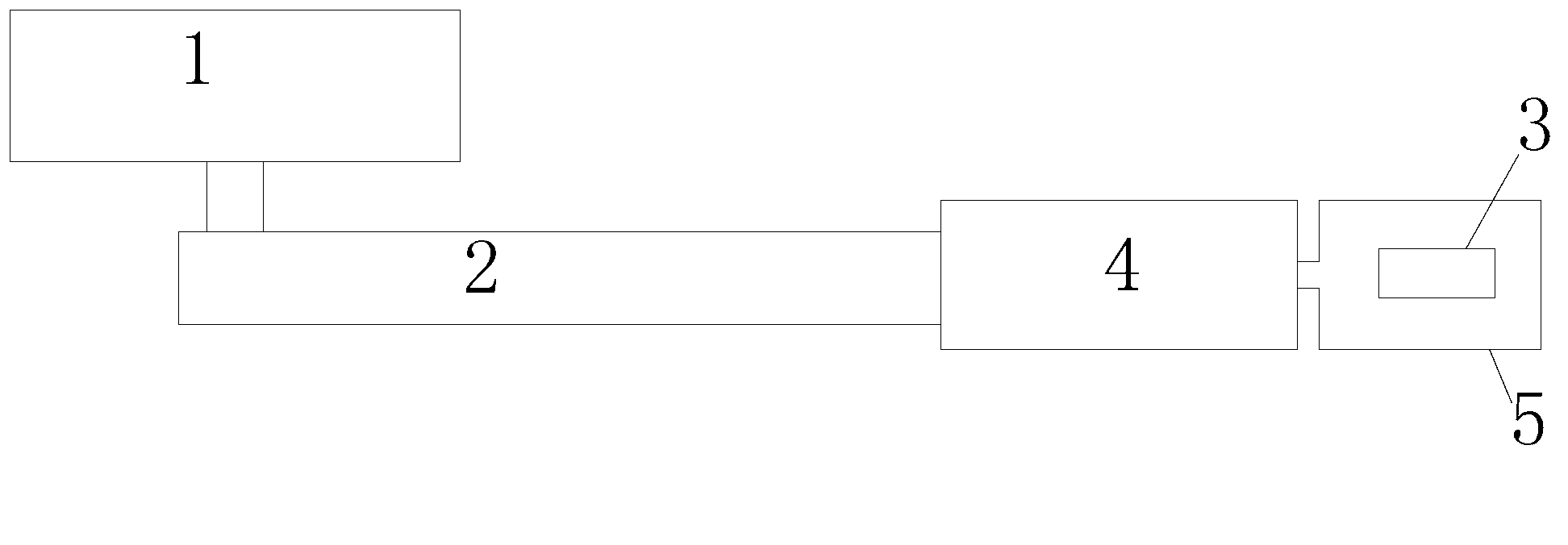

[0022] a. It is applied to the coal seam automatic fully mechanized mining face and requires a large difference in the hardness of coal and rock, such as image 3 As shown, a current sensor 3 is installed on the cutting motor 5;

[0023] b. Cut a knife with the coal shearer as a demonstration knife, record the respective current conditions after cutting the coal seam and rock formation, and record the current limit;

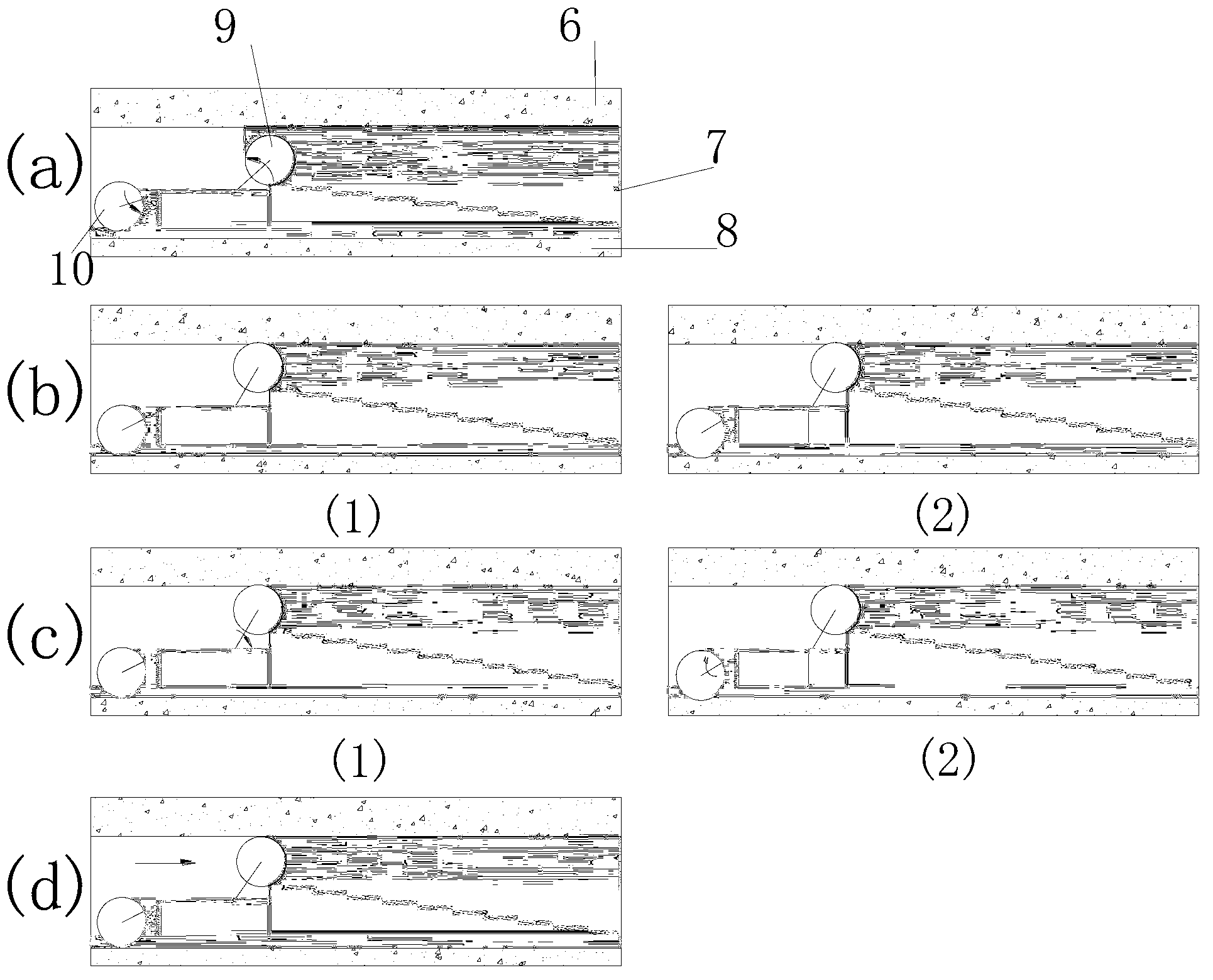

[0024] c. If figure 2 The rocker arm 3 of the front drum 9 swings up automatically after the shearer feeds in as shown in a, and the swing speed is set at 0.2 degrees per second;

[0025] d. When the monitored current becomes significantly larger, with obvious fluctuations, and the size is within the current range of the demonstration knife cutting to the roof rock layer 6, it is considered that the rock has been cut such as figure 2 as shown in b(1);

[0026] e. If figure 2 The rocker arm 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com