Positioning method based on automatic lifting hook system

A positioning method and hook technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of inaccurate positioning, interference with the location and capture operation of the sling, and achieve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

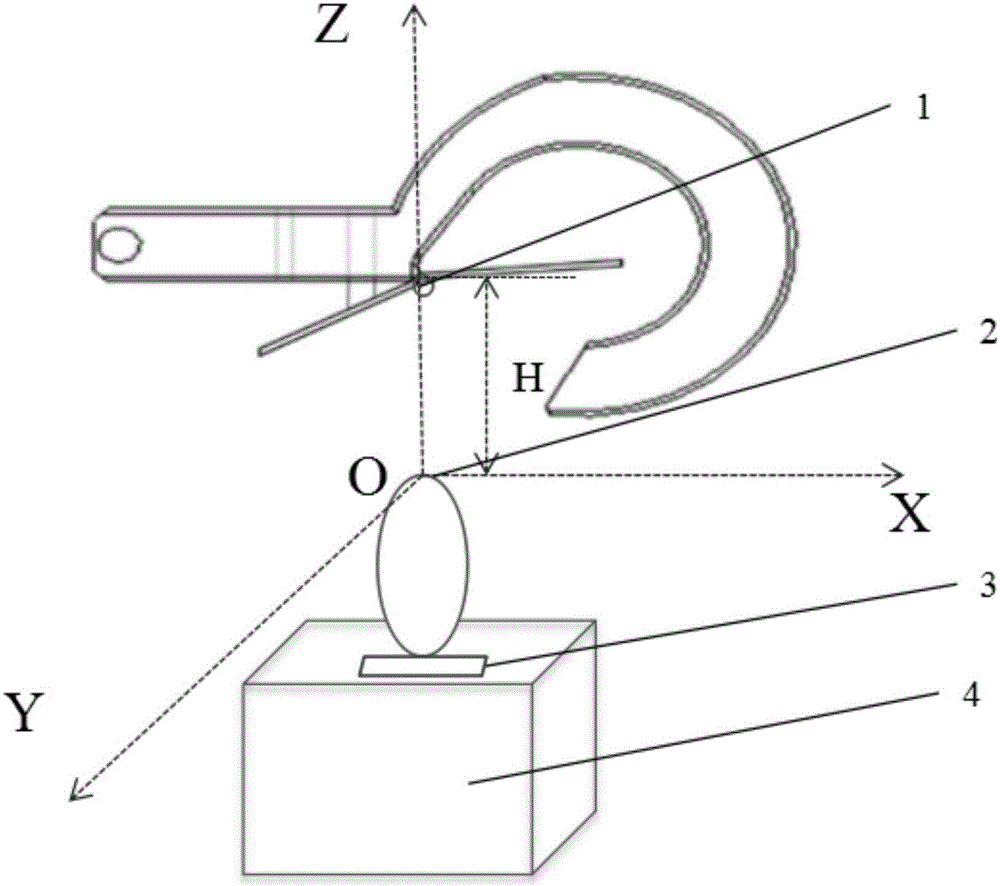

[0030] 1. The principle design of the automatic hook system positioning method involved in the present invention is as follows: figure 1 shown. Its goal is to achieve precise positioning between hook positioning point 1 and load positioning point 2. The combination of the hook positioning point and the lifting ring positioning point determines the relative position of the load and the hook, and the visual positioning results meet a certain accuracy, otherwise the automatic hook system cannot work normally.

[0031] Design the automatic hook system positioning hardware platform:

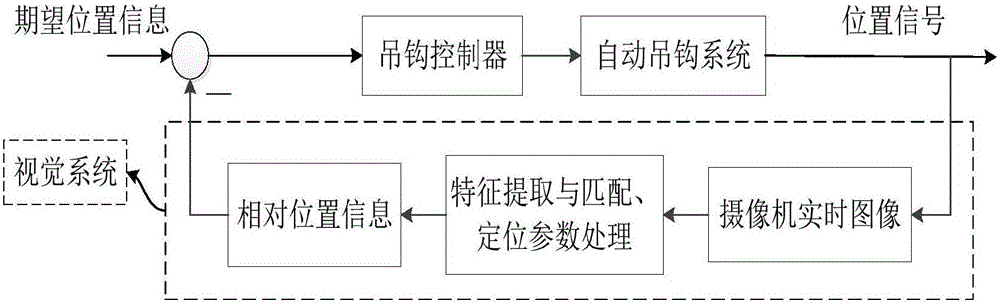

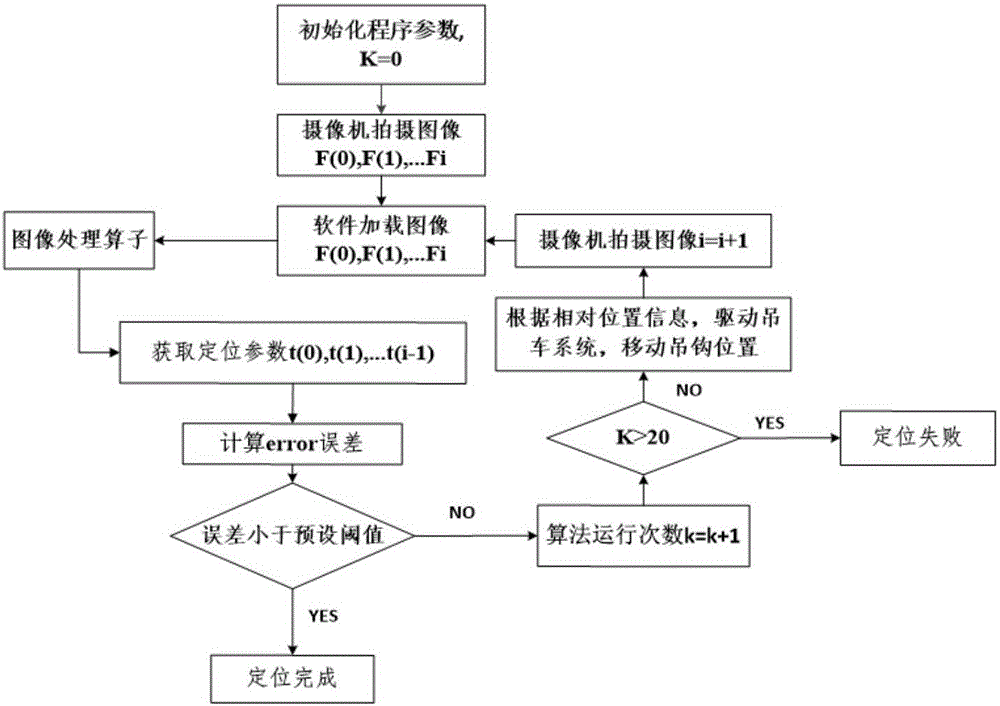

[0032] Based on the positioning method combining ultrasonic ranging and machine vision, the automatic hook system positioning method is adopted to realize the precise positioning of hook positioning point 1 and load positioning point 2. The installation position of the connection circuit composed of the ultrasonic sensor and the main controller of the hook is located at the anchor point of the hook,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com