In-situ coal petrography heat-insulation pressure-maintaining coring device and application method

A coal rock and coring technology, which is applied in the field of in-situ coal rock heat preservation and pressure preservation coring device, can solve the problem that the original formation temperature and pressure cannot be maintained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

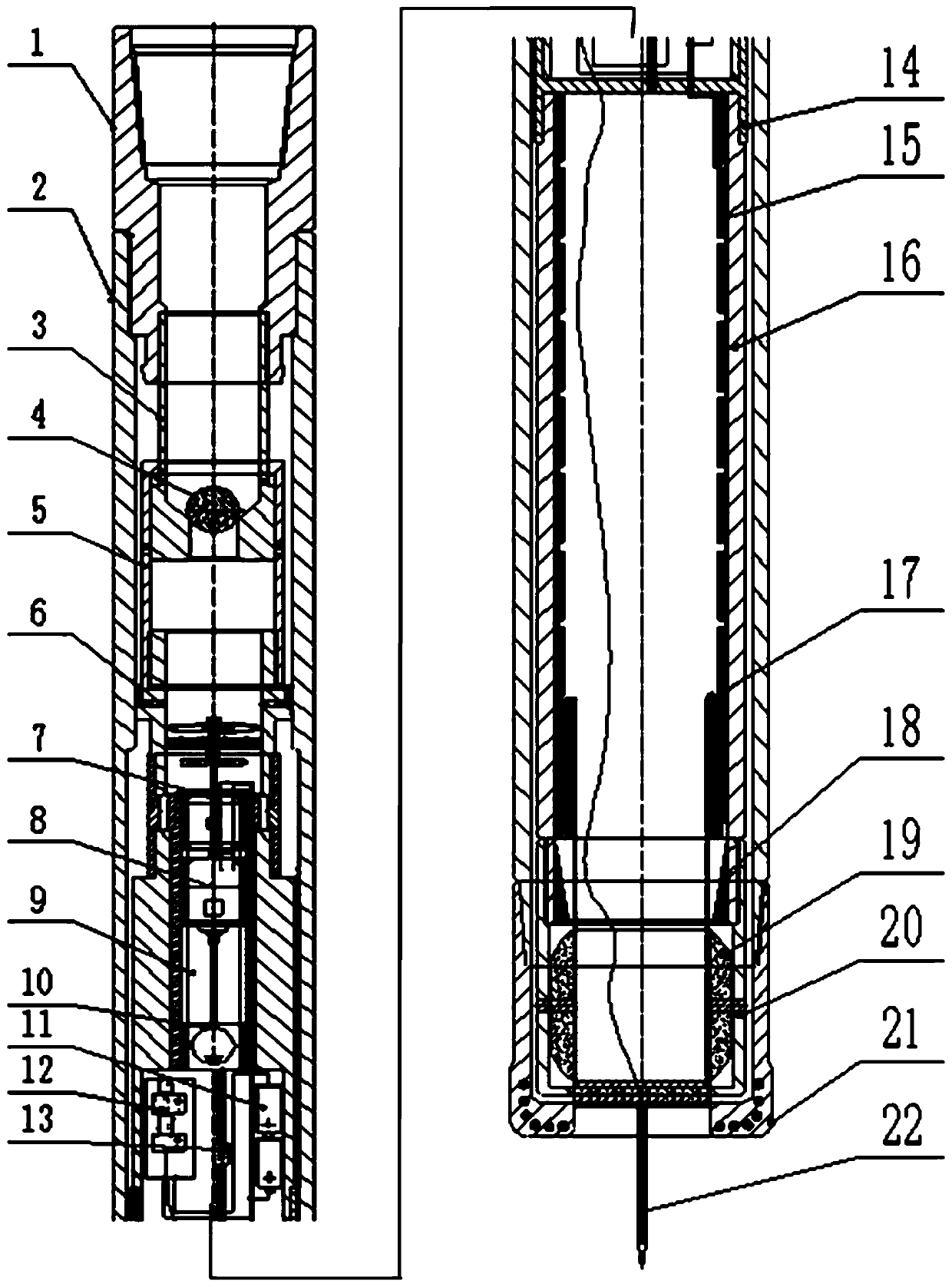

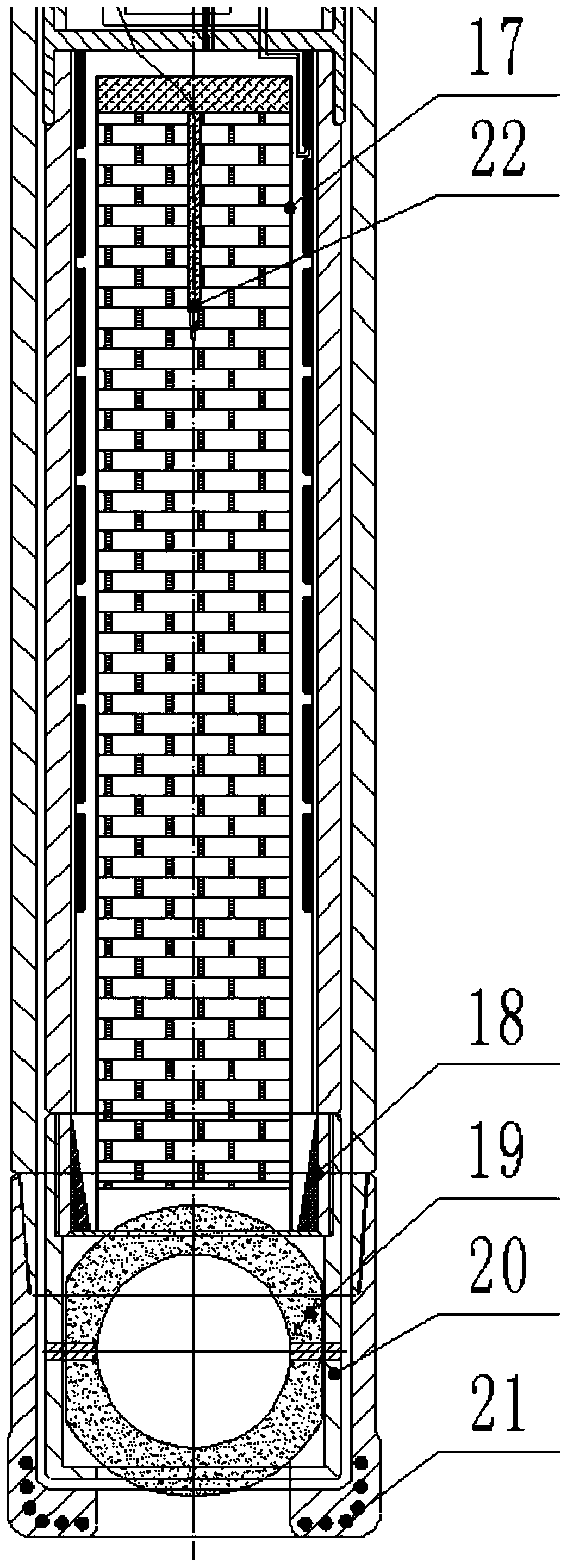

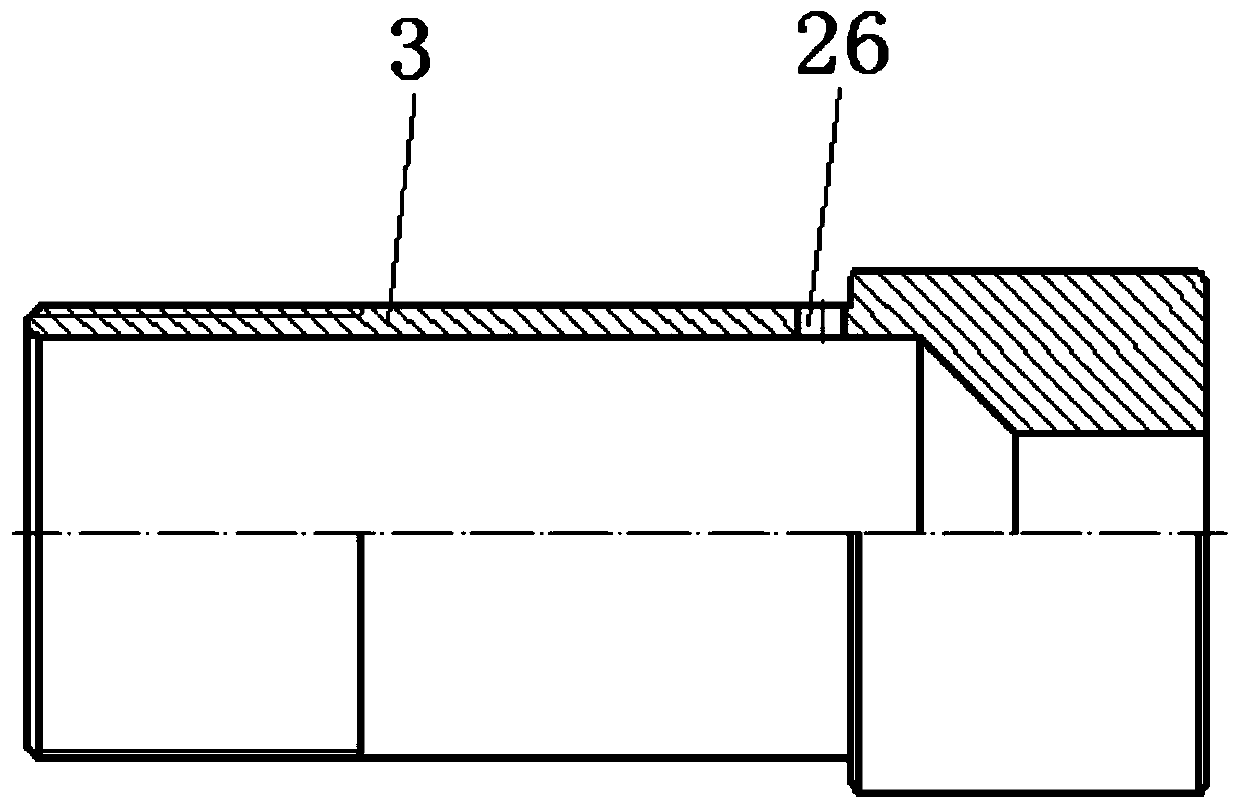

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, an in-situ coal and rock heat preservation and pressure maintaining coring device includes an upper joint 1, an outer cylinder 2 and a coring bit 21, the lower end of the upper joint 1 is connected to the outer cylinder 2, and the lower end of the outer cylinder 2 is connected to the core bit 21; The inner wall of the lower end of the joint 1 is connected to the connecting sleeve 3, and the lower end of the connecting sleeve 3 is designed as a pressure ball seat that matches and seals with the starting ball 4. The connecting sleeve 3 at the upper end of the pressure ball seat has a communication hole I26, and the differential sliding sleeve 5 is hooked on the The pressure ball seat blocks the communication hole I26, and the differential sliding sleeve 5 has a communication hole II27. The differential sliding sleeve 5 can move up along the connecting sleeve 3 and make t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com