Method for automatically measuring special position of tunnel boring machine

A technology of automatic measurement and roadheading machine, which is applied in the directions of measuring device, angle measurement, surveying and navigation, etc., and can solve the problems of limiting the scope of application and not measuring the posture of the heading machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0137] The present invention will be further described below in conjunction with accompanying drawing:

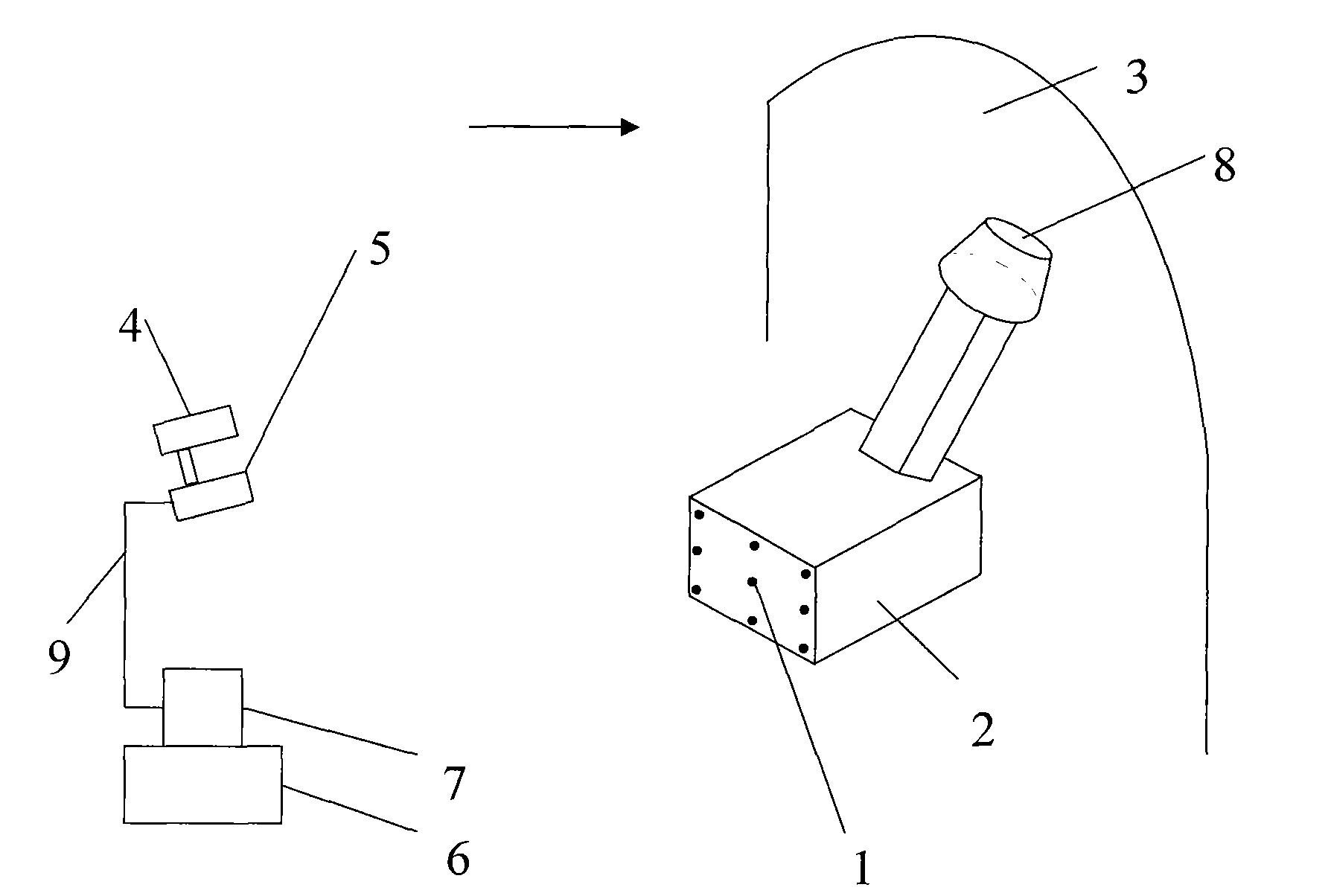

[0138] figure 1 Shown is the location map of measuring instruments, roadheaders, and coal and rock sections. The location, coverage angle, direction, and height of each part must be reasonable and correct, and the wires of each instrument must be firmly connected.

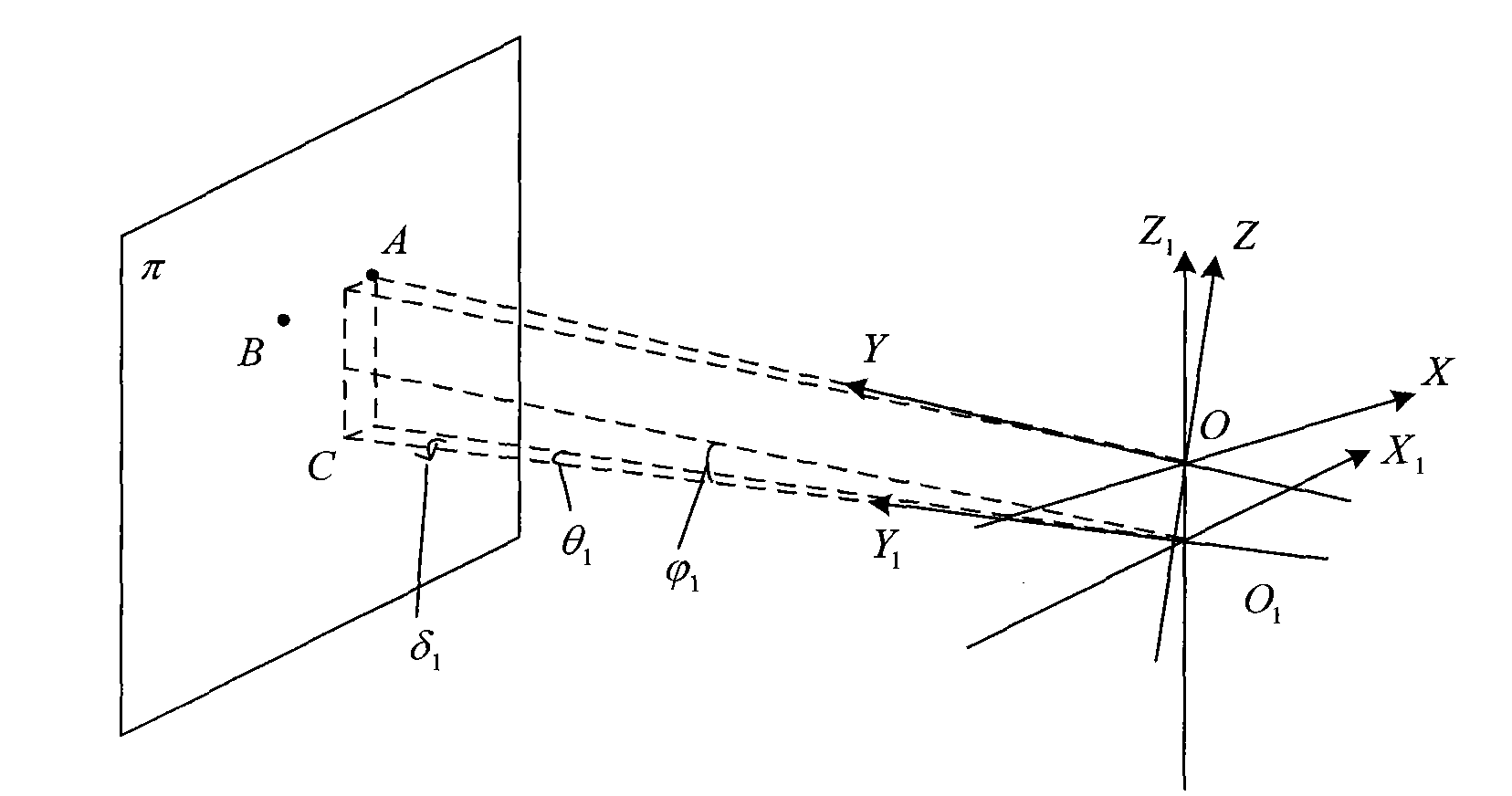

[0139] figure 2 Shown is the industrial camera, laser pointing device, datum plane, and datum point positions. It can be seen from the figure that the π plane is the datum plane, and points A and B are the datum points.

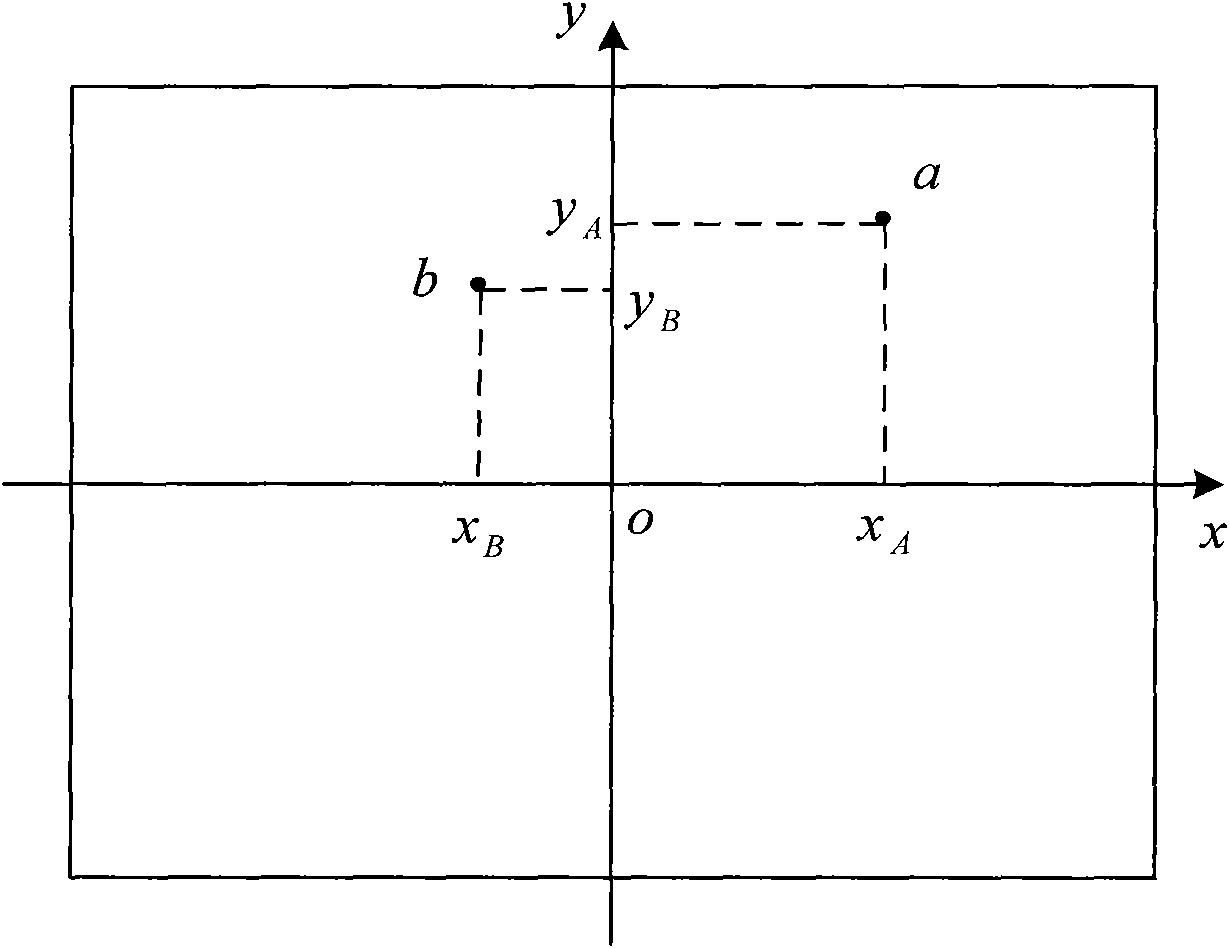

[0140] image 3 Shown is a schematic diagram of the measurement plane, and the measurement planes are all on the X, Y, and O coordinate axes.

[0141] Figure 4 As shown, it is the principle diagram of space pose calculation. It can be seen in the figure that the required roadway orientation is determined by the beam of the laser pointing device, and the world coordinate system OXYZ is est...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com