High-strength magnesium alloy and preparation method thereof

A magnesium alloy, high-strength technology, applied in the field of non-ferrous metal magnesium alloy preparation and application, can solve the problems of magnesium-aluminum alloy application limitation, inability to greatly improve the strength, toughness, corrosion resistance, low yield and other problems of magnesium-aluminum alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

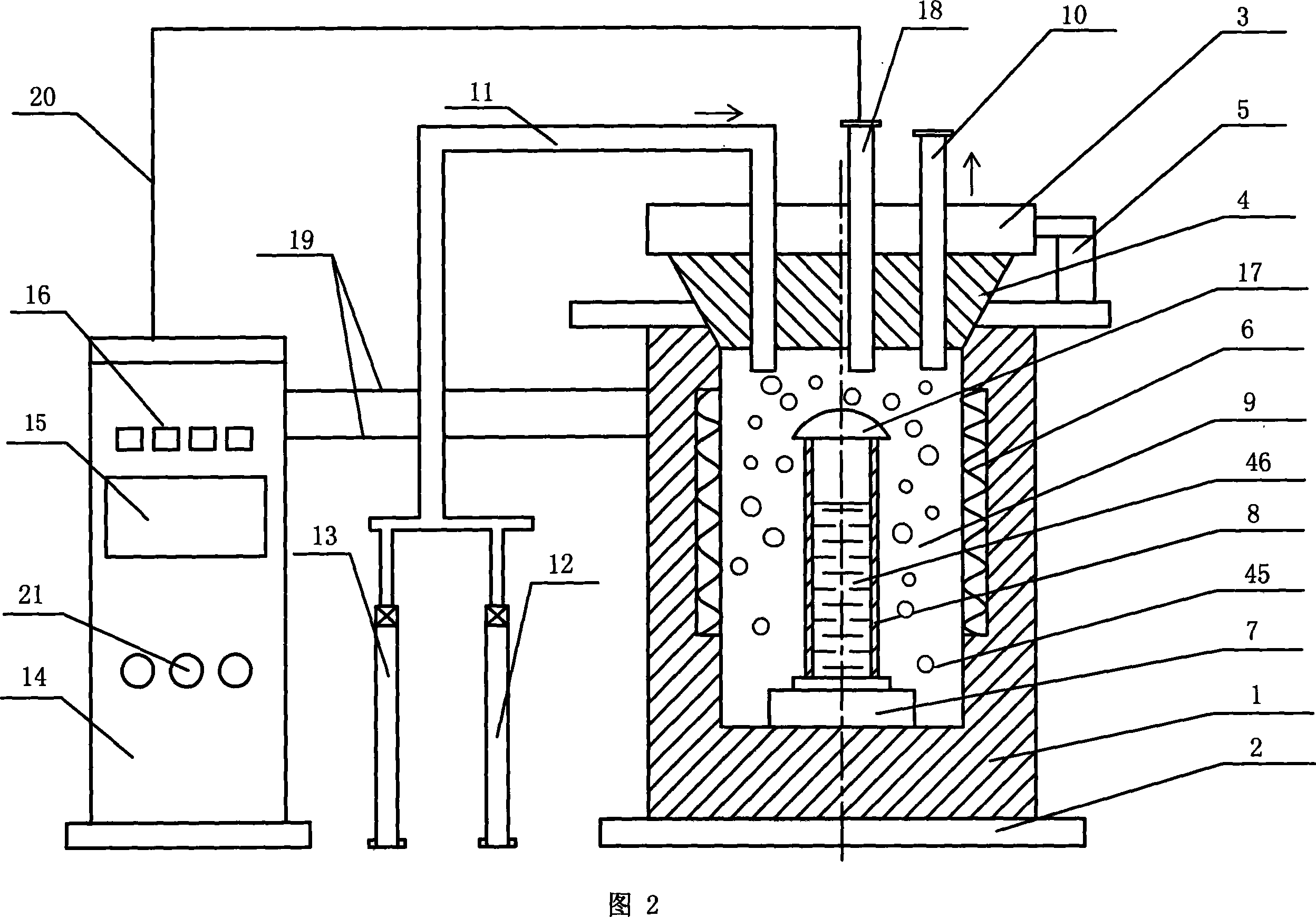

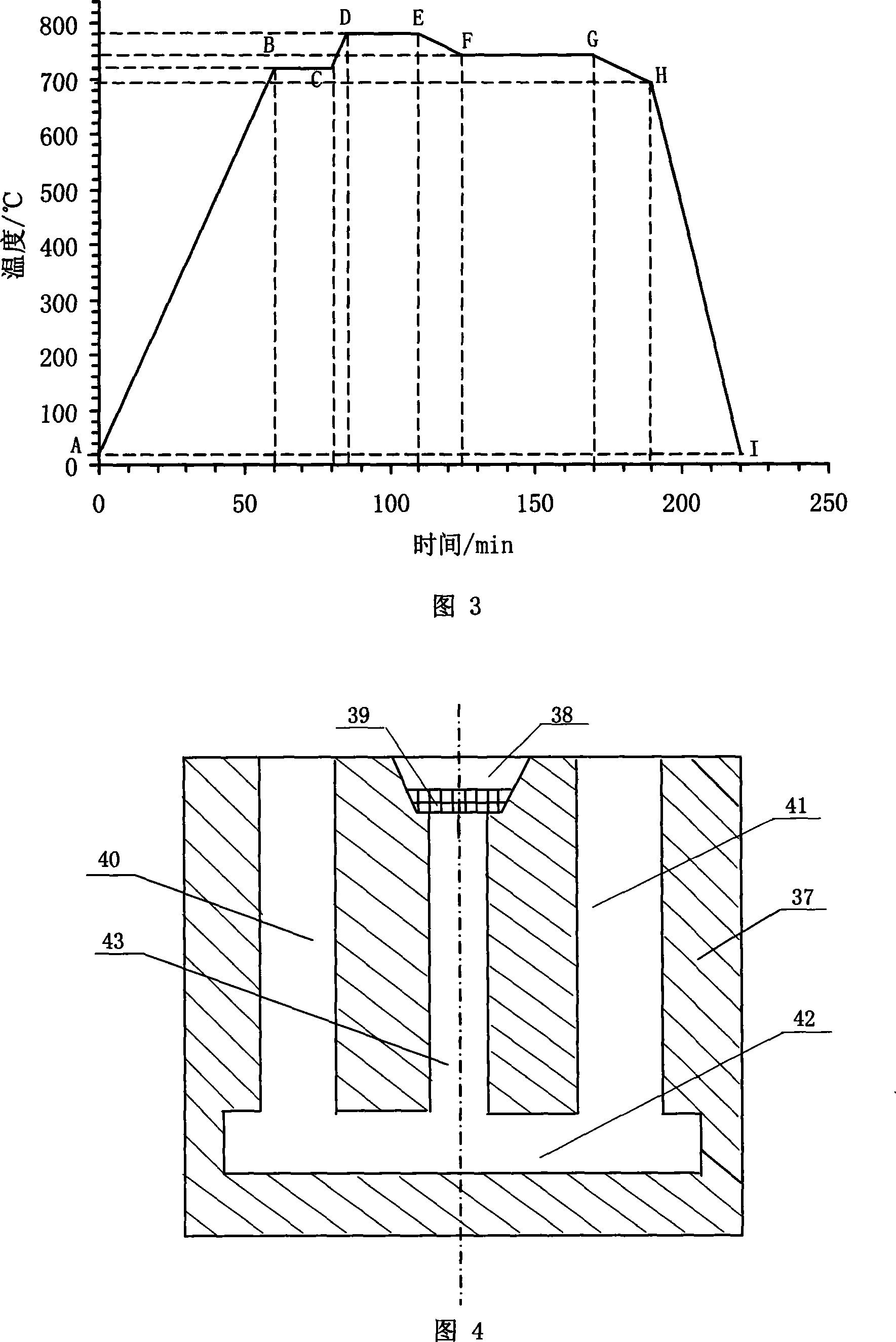

[0100] The present invention will be further described below in conjunction with accompanying drawing:

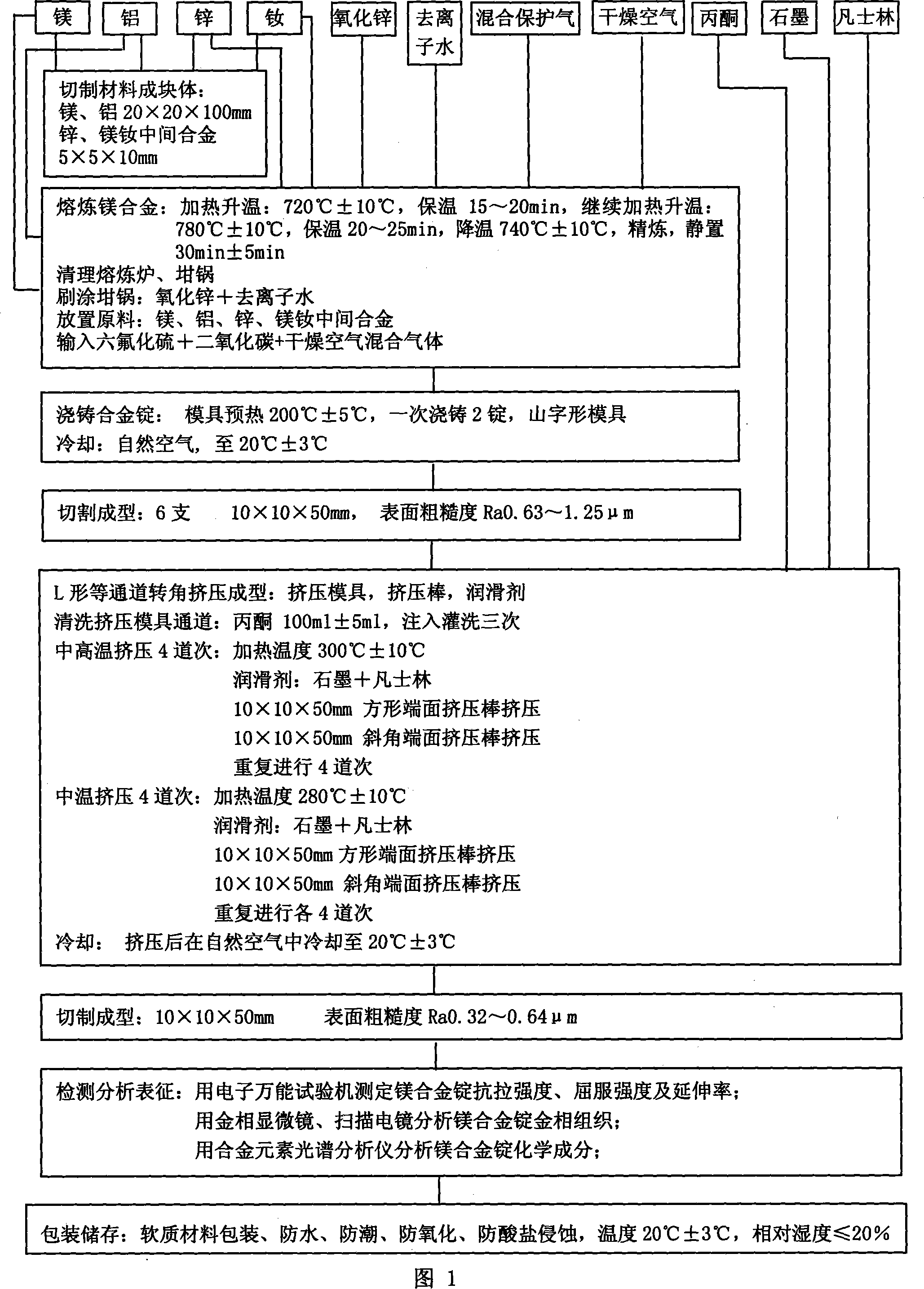

[0101] As shown in Figure 1, it is a flow chart of the preparation process, which must be strictly followed by the preparation process and operated in sequence.

[0102] The combination ratio of chemical substances and materials required for preparation is calculated and determined according to the preset values in grams, milliliters, centimeters 3 It is a unit of measurement, and when it is produced industrially, it is expressed in kilograms, liters, or meters 3 as the unit.

[0103] The mass ratio of magnesium, aluminum, zinc, and neodymium required for preparation is 82:15:2:1, and the aluminum element accounts for 15%. Due to the abundant aluminum resources, low price, and low density, the weight gain of the alloy brought about by aluminum alloying The negative impact is relatively light, and it belongs to the same non-ferrous metal as magnesium, and its melting poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com