Method for anthracology coal blending

A technology for blending coal and coal rock, applied in the field of coking coal blending, can solve problems such as inability to quantitatively blend coal, and achieve the effects of accurate coal blending and improving coke quality

Inactive Publication Date: 2008-10-29

武汉钢铁有限公司

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

This new technology allows for better utilization of coal by controlling its properties such as specific calorific values or compositions during combustion process. It also includes an element called volatility (volumetric) concentration, bondability Index(adherence), and monocarbon ratio (MCC). By measuring these quantities, it helps predict future behavior when producing charcoal compared to previous methods based on their original source material. Overall this innovation improves efficiency and accuracy in making carbon materials from different sources while ensures they meet certain standards set down internationally.

Problems solved by technology

The technical problem addressed in this patented text relates to accurately mixing different types of carbon material used in making high temperature materials such as ceramics or refractory products that require specific properties like tensile strength at various processing stages during production processes without losing their effectiveness due to poor heat transfer caused by insufficient cooling effects.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

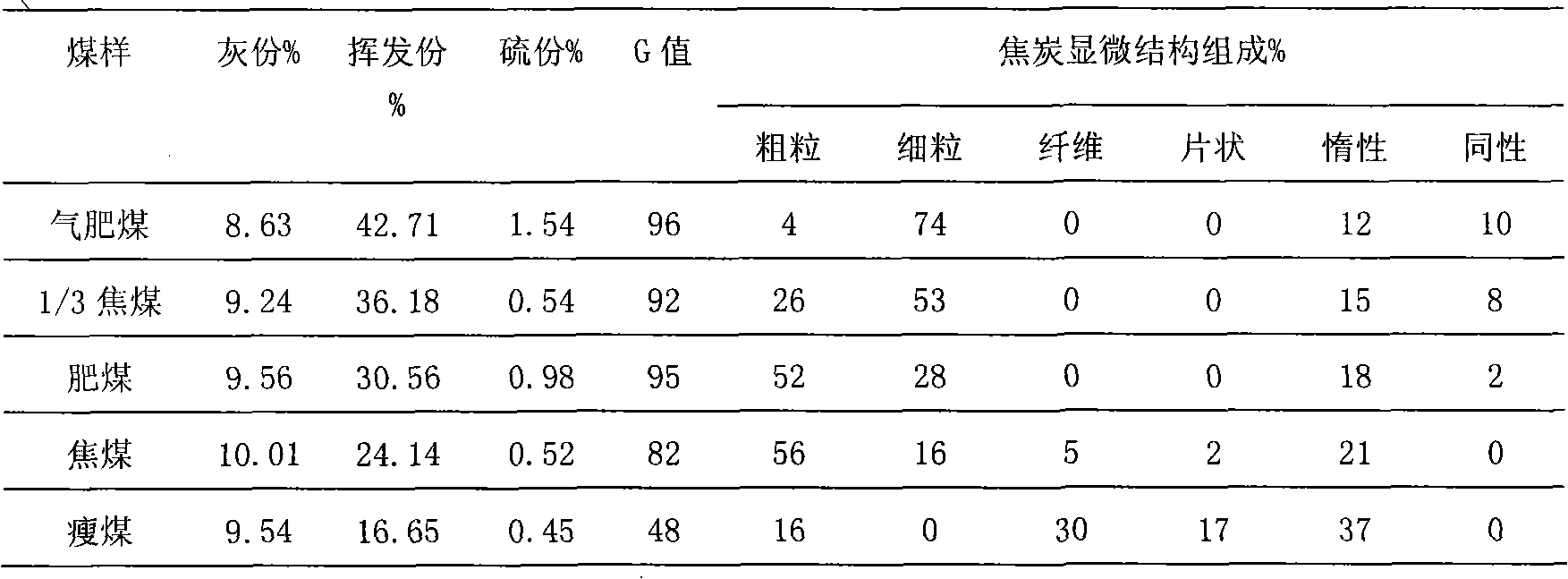

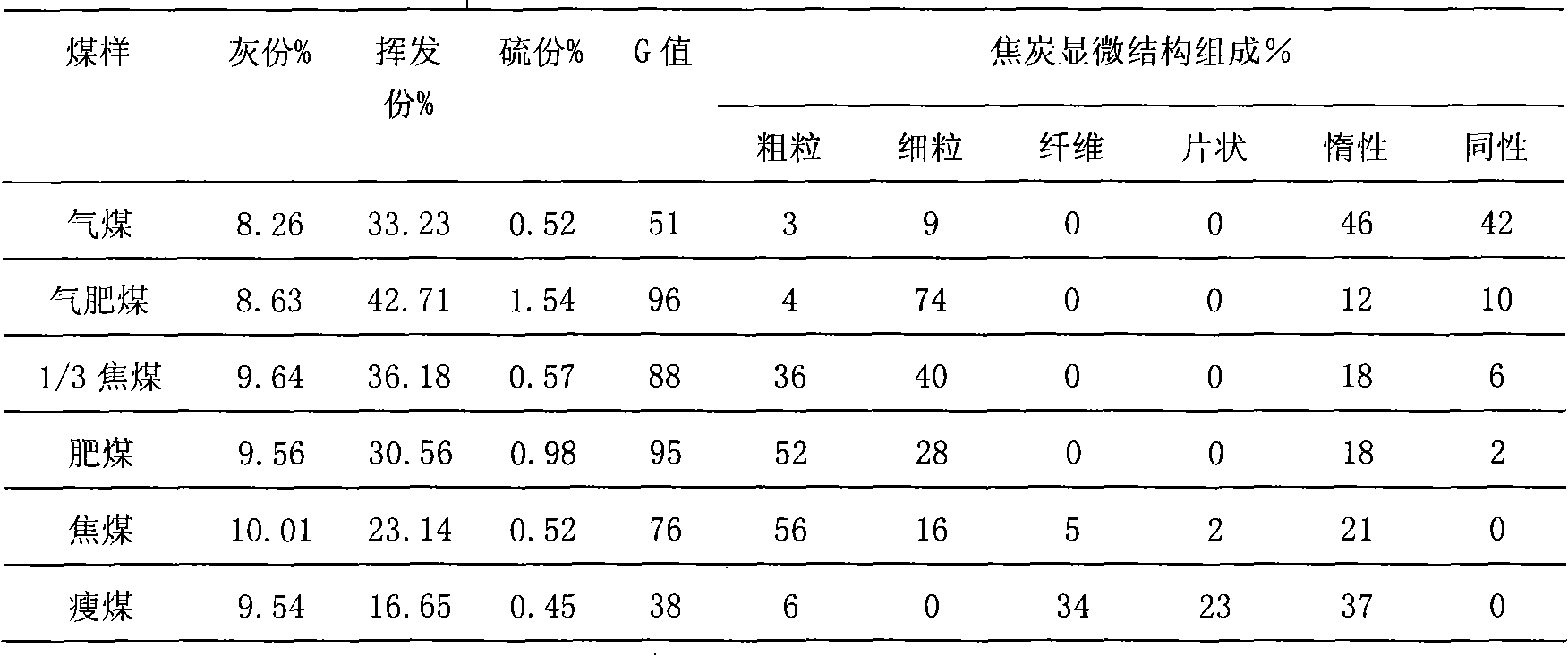

The invention relates to a method for coal blending of coal petrography, comprising the following steps: (1) each single coking coal is detected, and the detection consists of fugitive constituents, a bonding index G value and microstructure of coke; (2) coal-blending rate of each single coking coal is designed in the condition that coal blending coke : coarse grand mosaic component is more than 33 percent, inert component is 20 percent to 27 percent, isotropic structure component is less than 6 percent and coal-blending fugitive constituents are 25 percent to 30 percent, thus obtaining the coal-blending rate and coal blending; (3) the coal-blending sample is taken to detect the coal-blending bonding index G value; (4) the selection is done according to the detected result, the coal-blending bonding index G value is between 75 and 82, and the coal-blending is completed; or the coal-blending bonding index G value is not between 75 and 82, and the step (2) is cycled; the method of the invention can use each single coking coal with particular origin reasonably.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Owner 武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com