Coal petrography reflection rate digital automatic determination method

A measurement method and technology of reflectivity, which are applied in the field of high-efficiency measurement of coal and rock reflectivity, high precision, and digital automatic measurement of coal and rock reflectivity. Accurate rock reflectivity and its distribution, increasing the number of measurement points, and the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

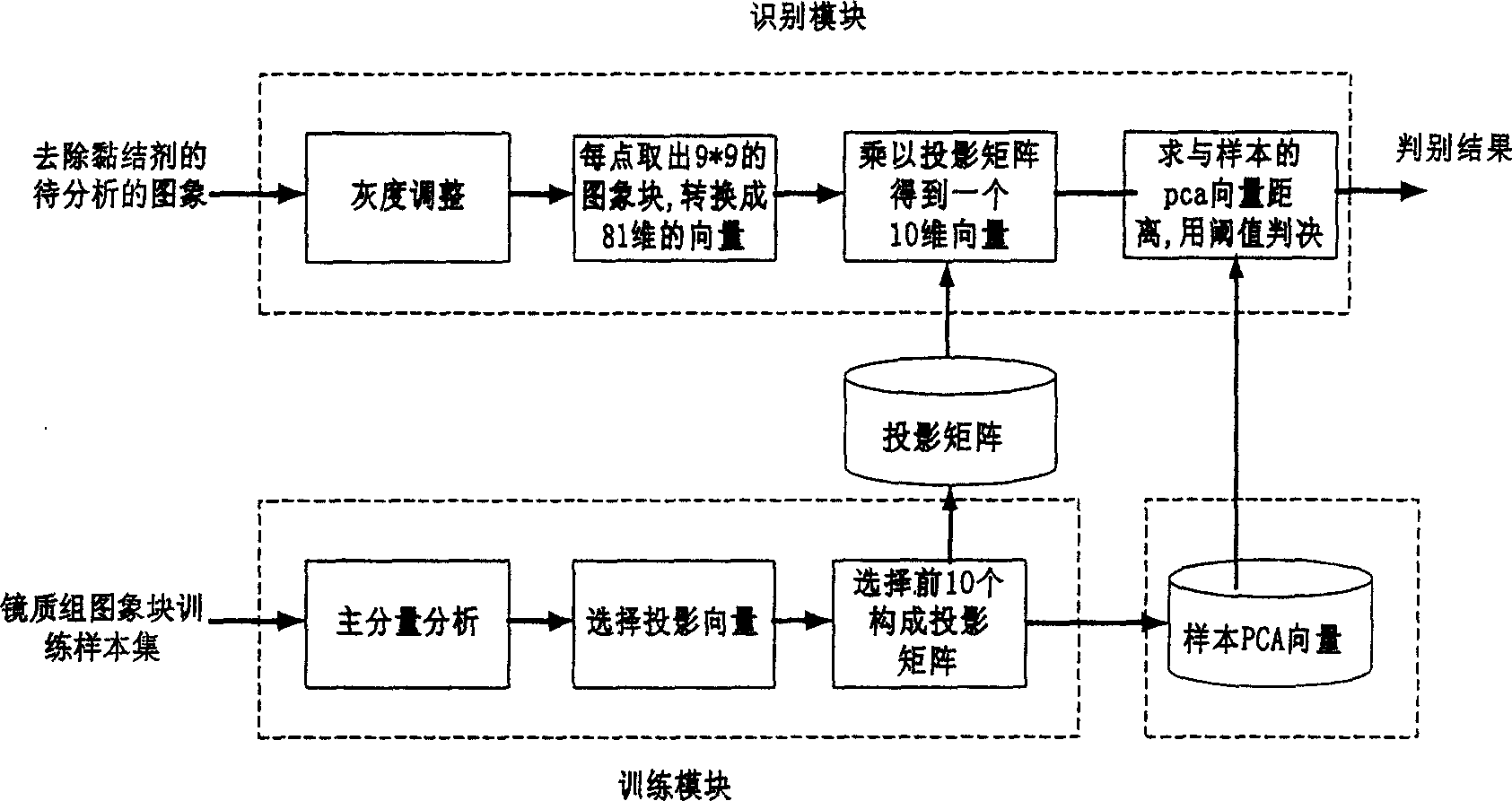

[0023] Combine below Figure 1 to Figure 6 , to illustrate specific embodiments of the present invention.

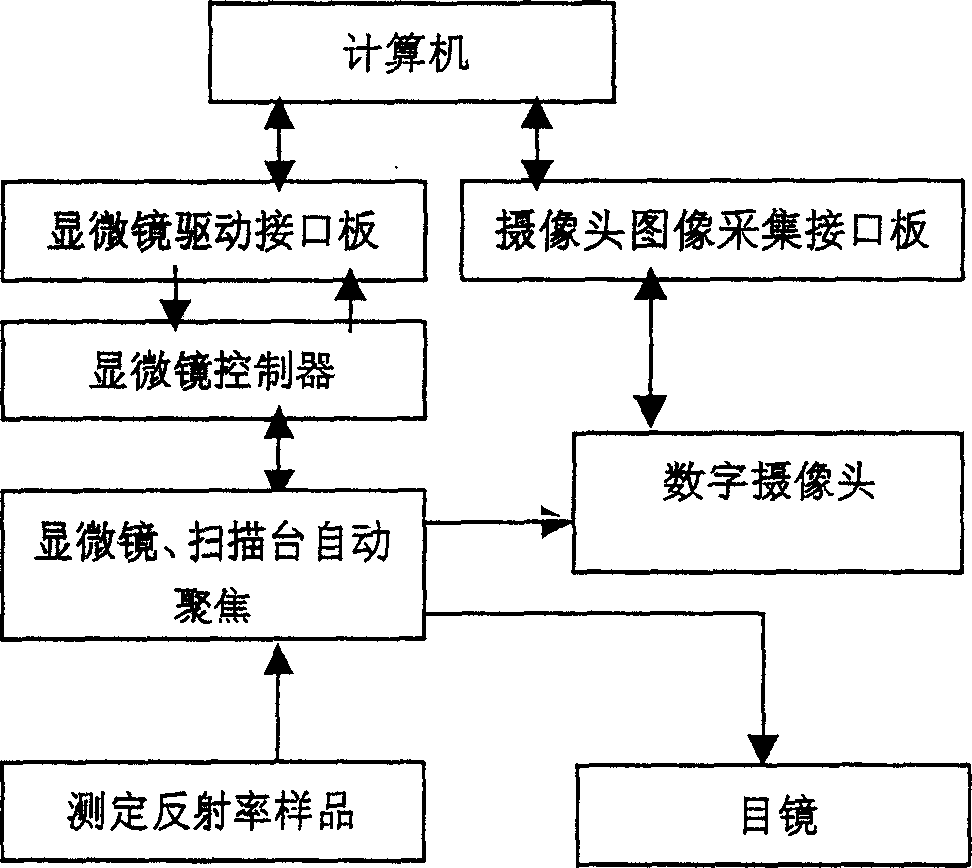

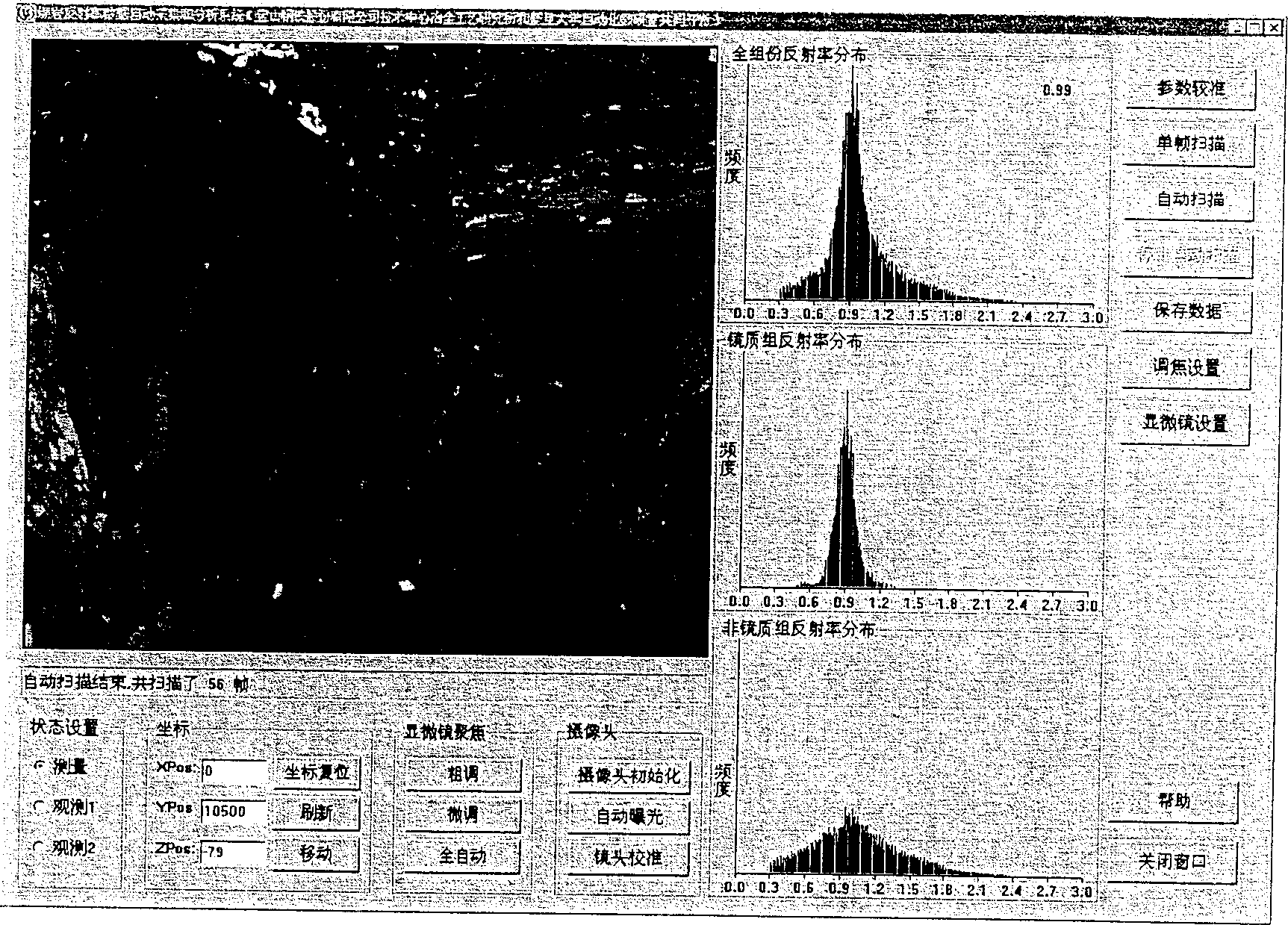

[0024] The main idea of the present invention is to take the advantages of the current two technologies to overcome their shortcomings, utilize the high gray level of the digital camera and the characteristics of changing the exposure time, expand the gray level of the camera, and improve the accuracy of measuring the reflectivity of coal rocks . figure 2 It is a hardware block diagram of the digital coal rock reflectance automatic measurement system of the present invention; image 3 It is the main interface of the digital coal rock reflectance automatic measurement system of the present invention.

[0025] After many experiments, such as Figure 4 As shown, a functional relationship is finally obtained:

[0026] G=a×R×T+b×R+c×T+d

[0027] G - Grayscale,

[0028] R - reflectivity,

[0029] T - exposure time,

[0030] a, b, c, d, - coefficients,

[0031] Befo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com