Microscopic cracking evolution process test equipment for bifacial shearing of coal petrography

A technology of double-sided shearing and evolution process, applied in the direction of applying stable shear force to test the strength of materials, etc., can solve the problem of single loading method, achieve the effect of improving test accuracy, low processing cost, and optimized size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

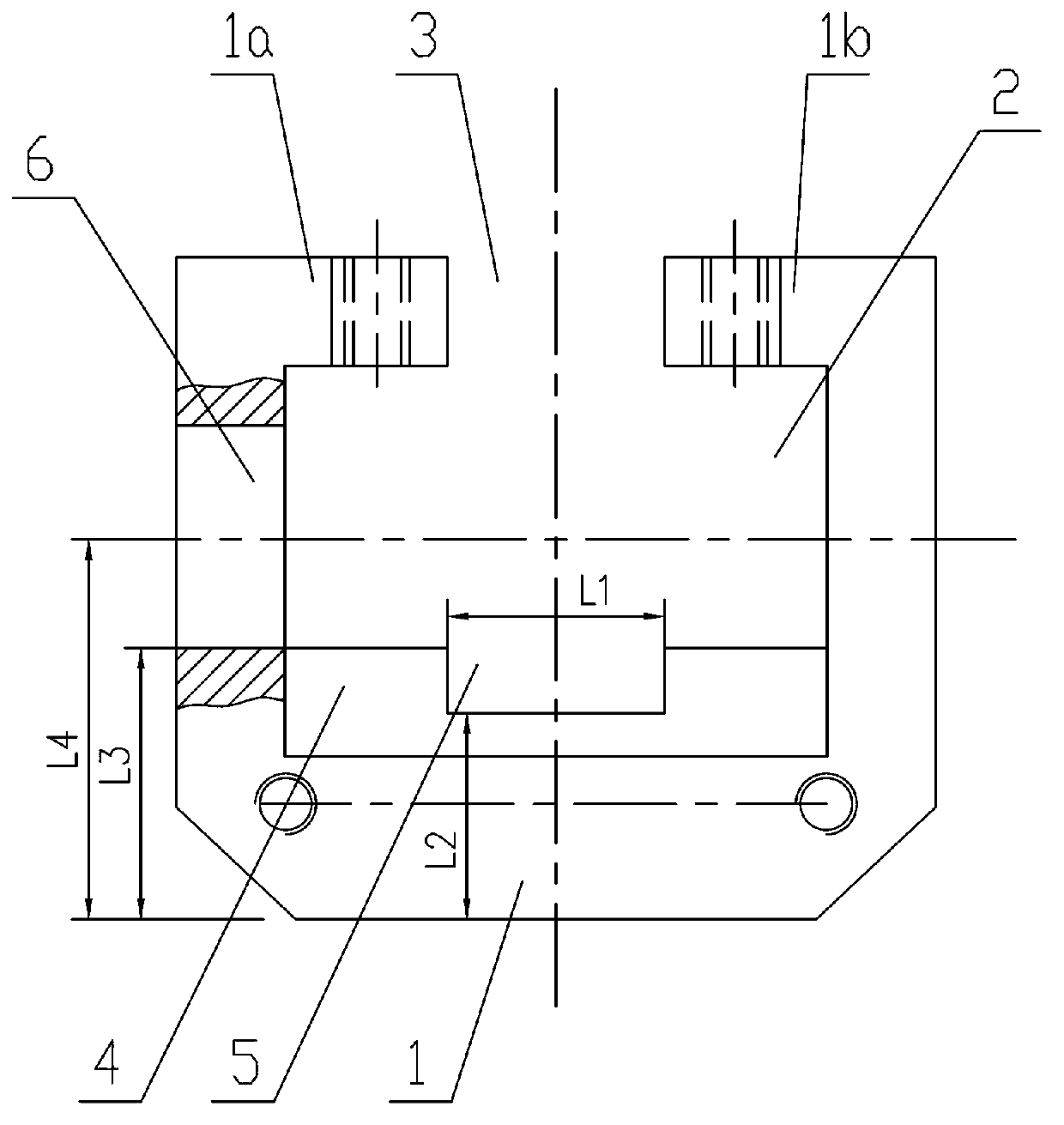

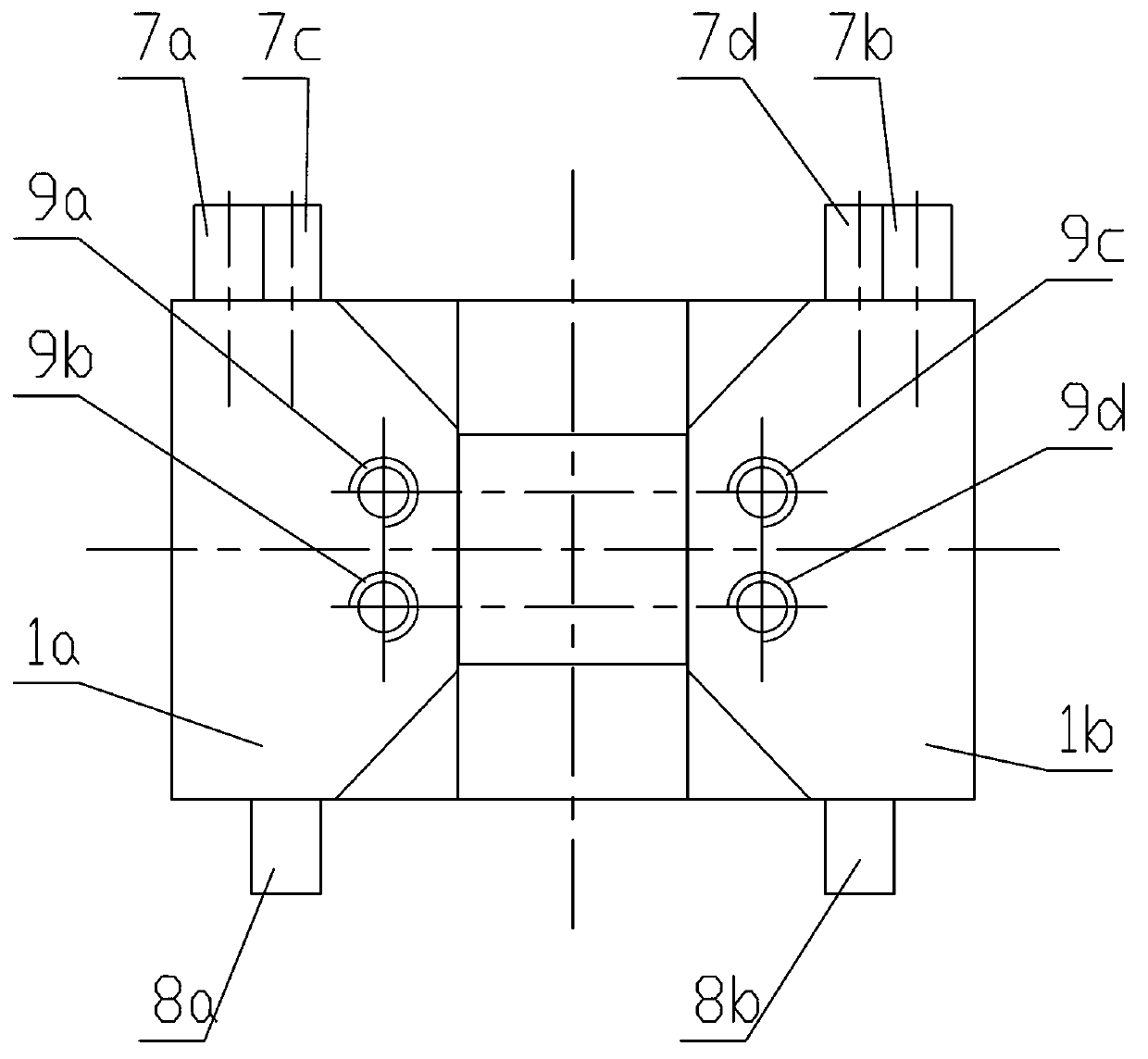

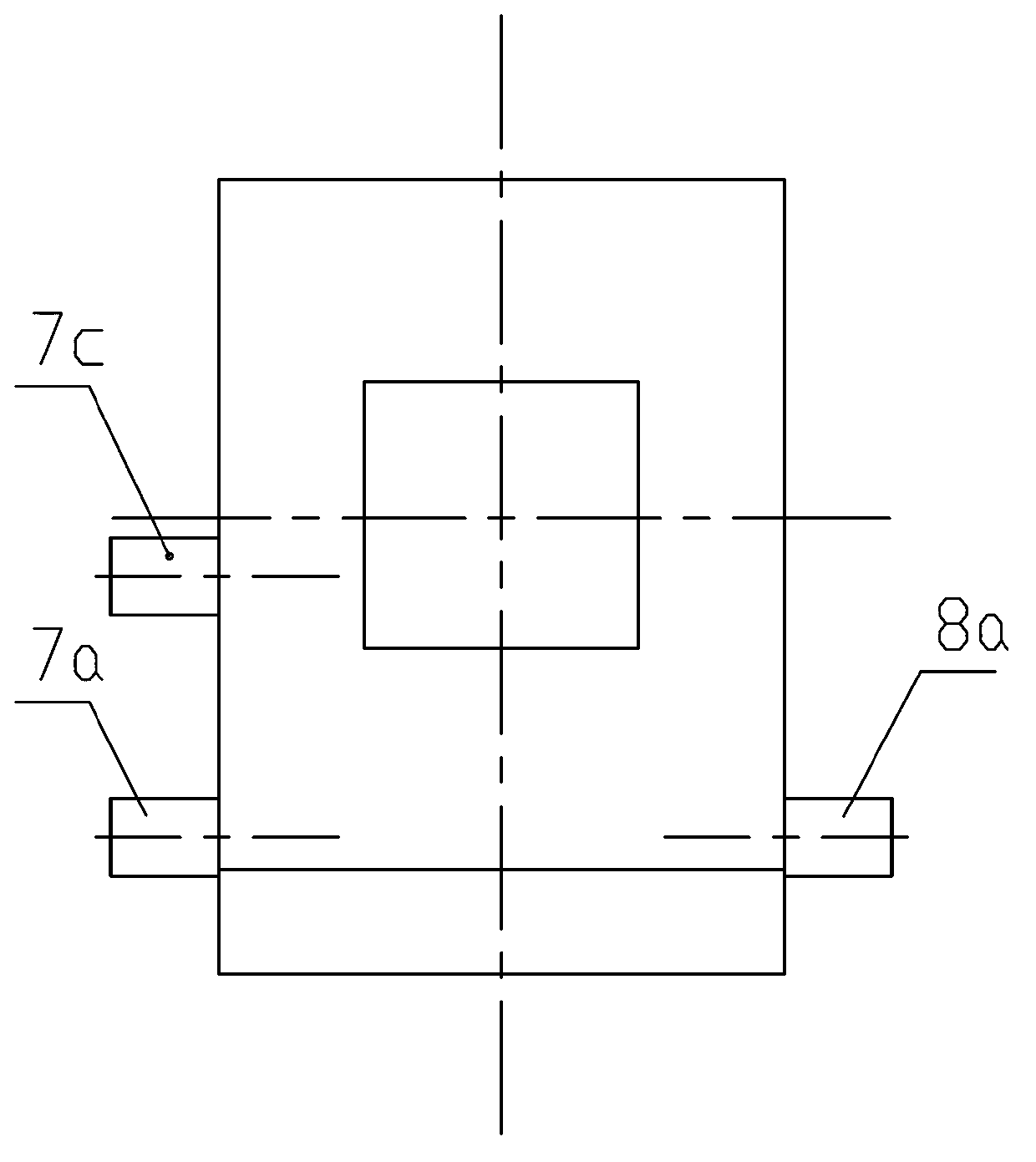

[0026] Such as Figure 1 to Figure 3 As shown, a test device for double-sided shear mesoscopic cracking evolution process of coal and rock includes a body 1 on which a specimen chamber 2 is arranged.

[0027] The top wall of the main body 1 is a split structure, including a left top wall 1a and a right top wall 1b with symmetrical structures. The shapes of the left top wall 1a and the right top wall 1b are rectangles and trapezoids connected end to end, and the upper bottoms of the two trapezoids are opposite.

[0028] Both front and rear ends of the body 1 are openings.

[0029] A support 4 is provided in the test piece cavity 2, and a groove 5 is provided at the position where the support 4 faces the installation port 3 of the indenter. The left side wall of the main body 1 is provided with a guide hole 6 . The width L1 of the groove 5 is 40 mm; the dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com