A method for detecting the amount of pre-lithium in a pole piece

A pole piece and pre-lithium technology, which is applied in the field of detecting the pre-lithium amount of the pole piece, can solve the problems of lack of pre-lithium amount, etc., and achieve the effects of test stability, simple operation, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for detecting the amount of pre-lithium in a pole piece, comprising the steps of:

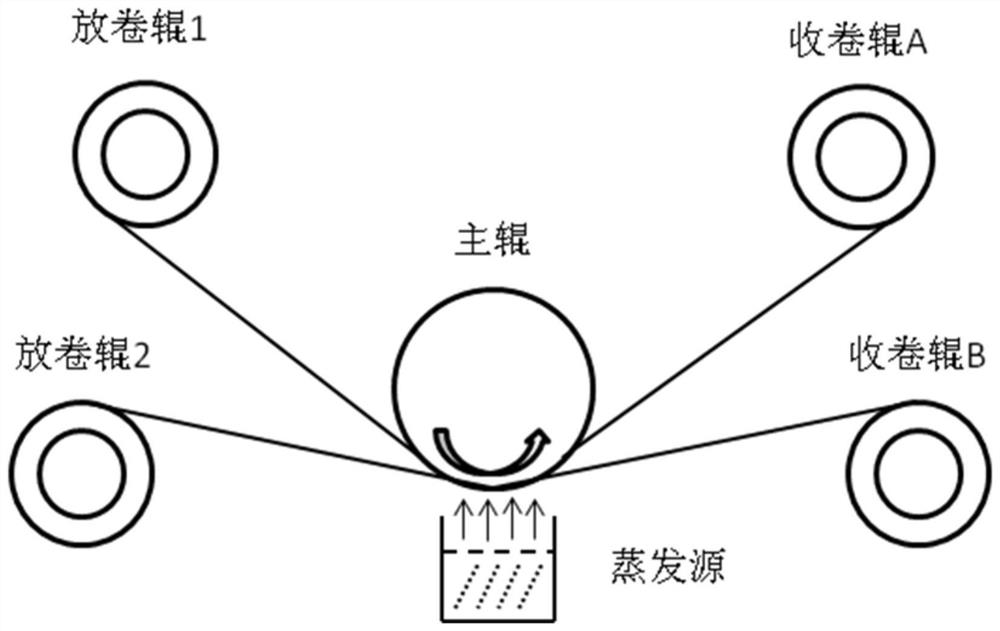

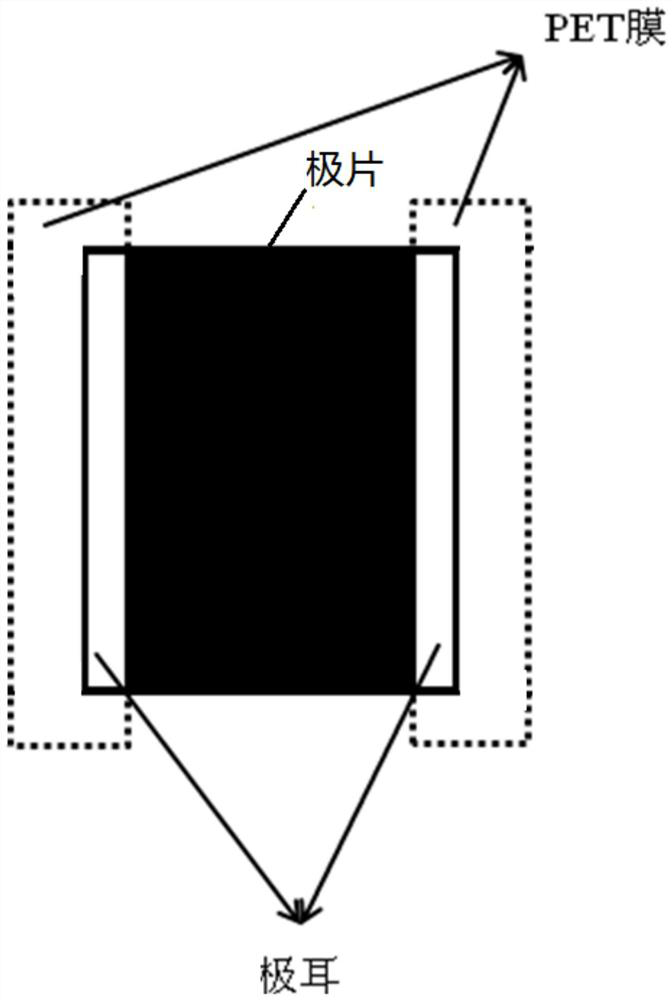

[0023] according to figure 1 As shown, the graphite negative roll is placed on the unwinding roll 1 of the evaporation equipment, and the belt is passed through the main roll, and finally to the winding roll A; the PET film is placed on the unwinding roll 2, and the belt is passed through the main roll, Finally to the winding roller B, adjust the unwinding position so that the PET film (50mm wide, 50μm thick) completely covers the tabs (24mm high) at both ends of the negative electrode roll; the evaporation source is located directly below the main roller, and then the temperature of the evaporation source is adjusted to 515°C, main roll speed is 10m / min, and vacuum lithium plating treatment is carried out on the negative electrode roll and PET film at the same time;

[0024] After the lithium plating is finished, cut a 10mm×10mm PET film at a distance of 5m from the winding ro...

Embodiment 2

[0027] A method for detecting the amount of pre-lithium in a pole piece, comprising the steps of:

[0028] according to figure 1 As shown, the graphite negative roll is placed on the unwinding roll 1 of the evaporation equipment, and the belt is passed through the main roll, and finally to the winding roll A; the PET film is placed on the unwinding roll 2, and the belt is passed through the main roll, Finally to the winding roller B, adjust the unwinding position so that the PET film (50mm wide, 100μm thick) completely covers the tabs (24mm high) at both ends of the negative electrode roll; the evaporation source is located directly below the main roller, and then the temperature of the evaporation source is adjusted to At 495°C, the main roll speed is 0.44m / min, and the negative electrode roll and PET film are vacuum-plated with lithium at the same time;

[0029] After lithium plating is finished, cut a 10mm×10mm PET film at a distance of 10m from winding roller B, put it in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com