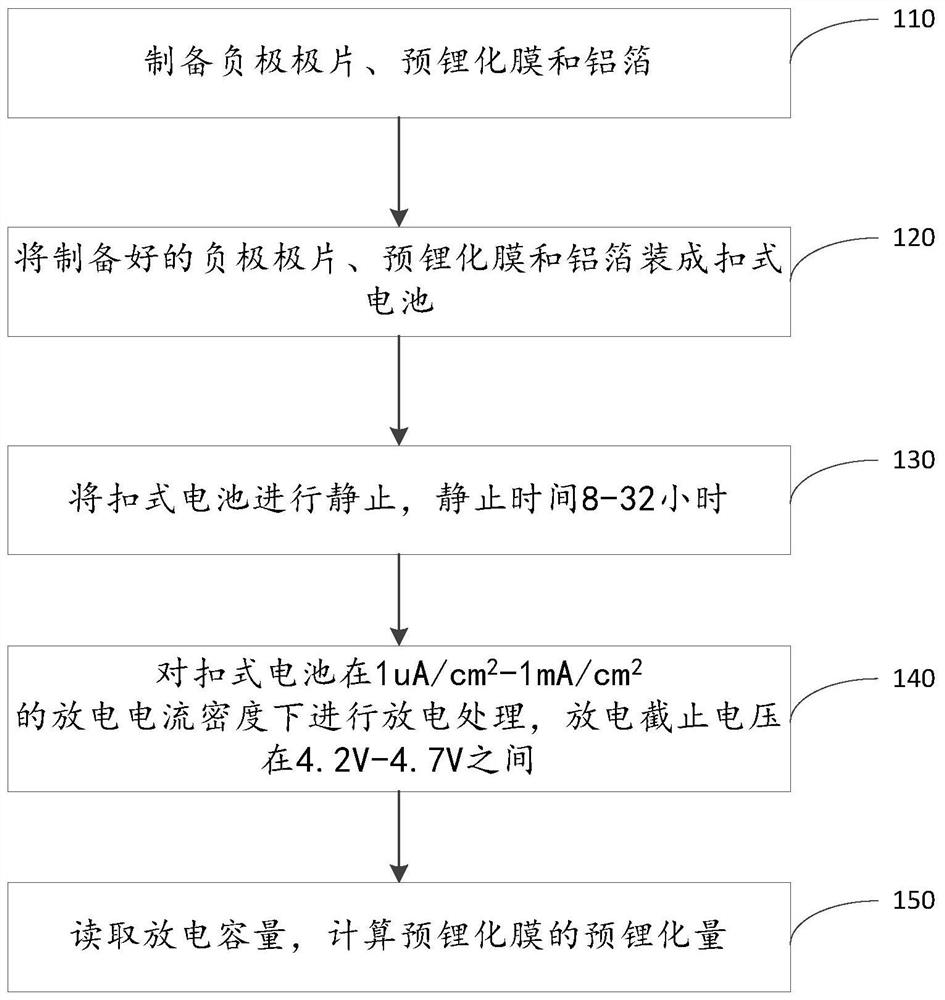

Pre-lithiation amount detection method of pre-lithiation film

A detection method and pre-lithiation technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., to achieve the effect of reliable testing means, high measurement accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

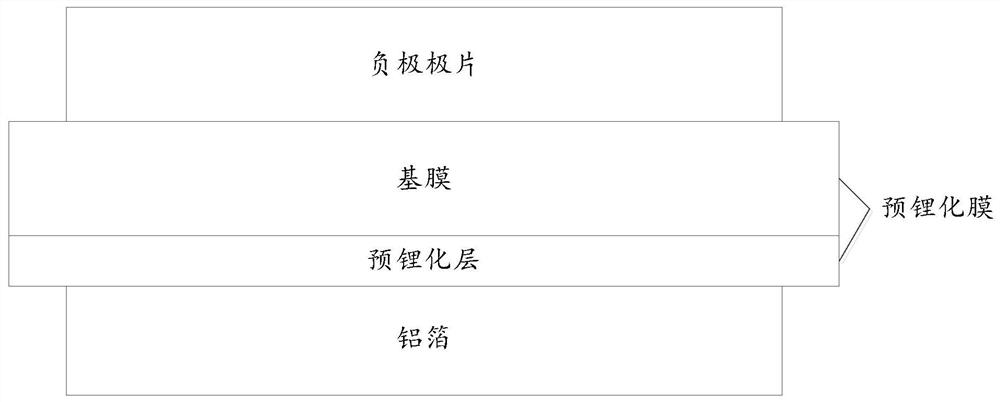

Method used

Image

Examples

Embodiment 1

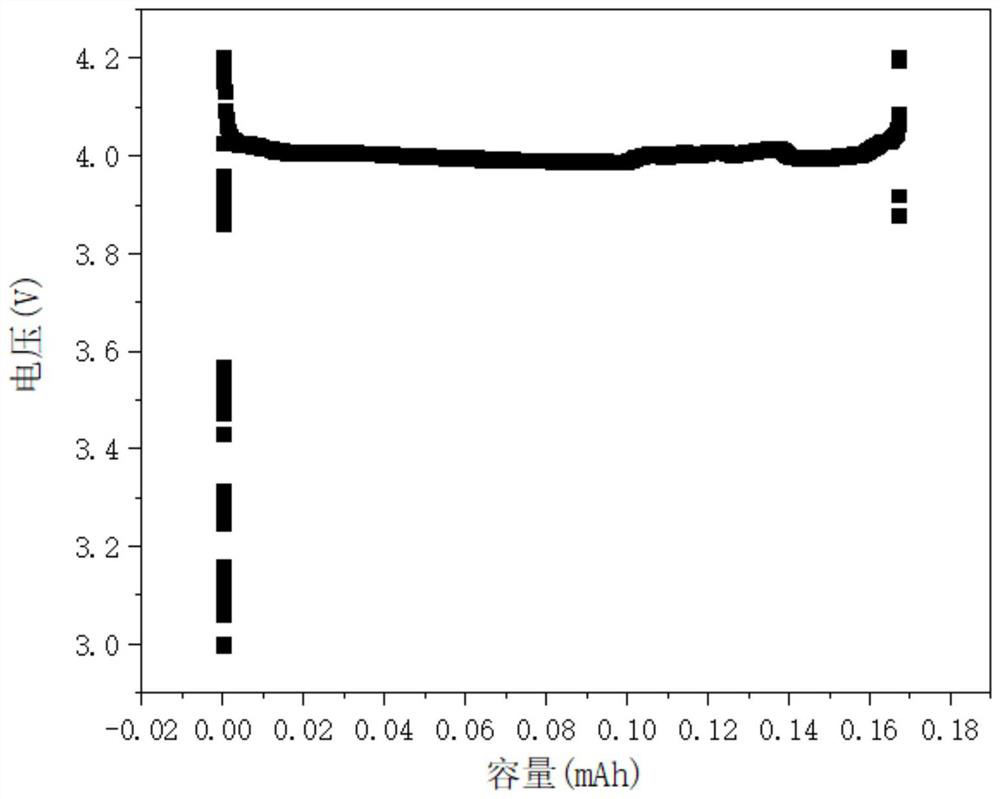

[0078] The button battery assembly of this embodiment 1 adopts: the negative pole piece is a lithium metal sheet with a diameter of 14 mm, the aluminum foil is a circular sheet with a diameter of 14 mm, the pre-lithiated film is a diameter of 16.5 mm, and the electrolyte is 1 mole of LiPF 6 (EC / DMC 1:1). The discharge current is 10uA, and the cut-off voltage is 4.2V. The test results are as follows: image 3 , the capacity is 0.1672mAh, after calculation, the pre-lithiation amount is 0.1086mAh / cm 2 .

Embodiment 2

[0080] The button cell assembly of the present embodiment 2 adopts: the negative pole piece is a graphite negative pole piece of 14mm, the aluminum foil is a circular piece with a diameter of 14mm, the pre-lithiated film is a diameter of 16.5mm, and the electrolyte is 1 mole of LiPF 6 (EC / DMC 1:1). The discharge current is 10uA, and the cut-off voltage is 4.2V. The test results are shown in the figure, and the capacity is 0.1408mAh. After calculation, the pre-lithiation amount is 0.091mAh / cm 2 .

Embodiment 3

[0082] In Example 3, the negative pole piece is a nano-silicon-carbon composite pole piece with a diameter of 14 mm, the aluminum foil is a circular piece with a diameter of 14 mm, the pre-lithiated film is a diameter of 16.5 mm, and the electrolyte is 1 mole of LiPF 6 (EC / DMC 1:1). The discharge current is 10uA, the cut-off voltage is 4.35V, the test results are as follows image 3 , the capacity is 0.3256mAh, after calculation, the pre-lithiation amount is 0.2115mAh / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com