Experimental method for simulating mechanical properties of gas-bearing coal under uniaxial compression

A technology of mechanical properties and uniaxial compression, which is used in material inspection products, fuel testing, preparation of test samples, etc., can solve problems such as difficulty in gas preservation, and achieve good sealing, enhanced sealing effect, and easy assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

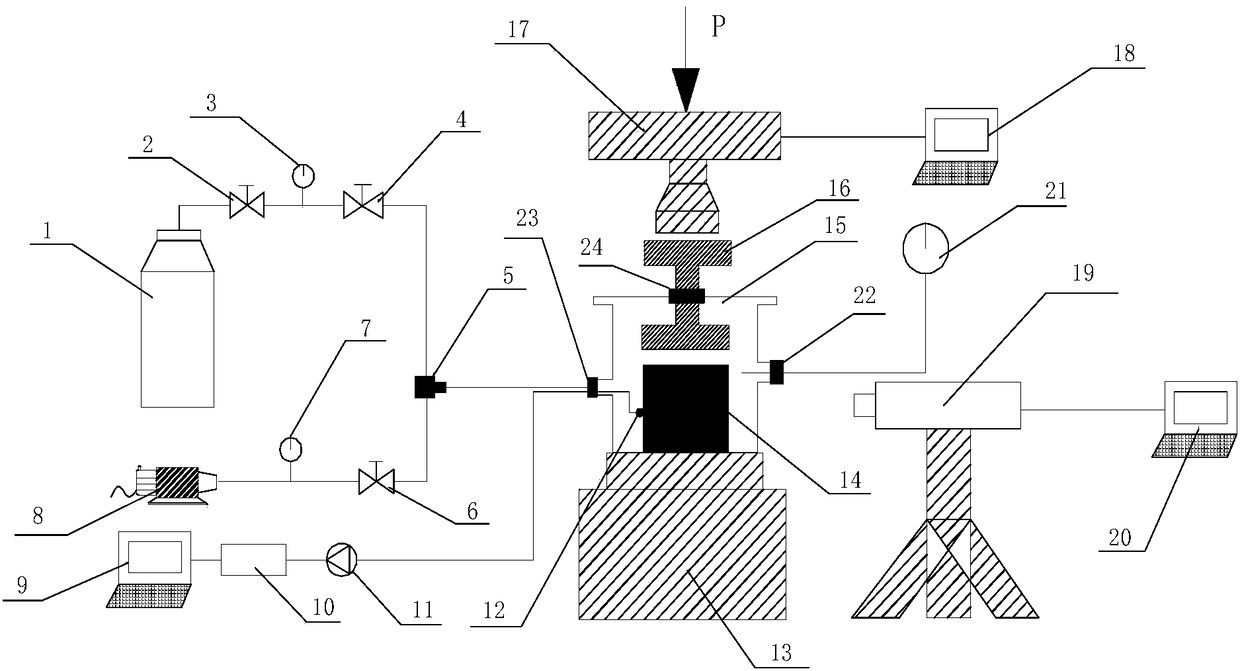

[0075] Such as figure 1 As shown, the experimental device for simulating the mechanical characteristics of gas-containing coal under uniaxial compression of the present invention includes a coal sample container 15, a stress loading system, a gas filling system, a gas detector 21, a VIC-3D non-contact full-field strain measurement system, and Acoustic emission system

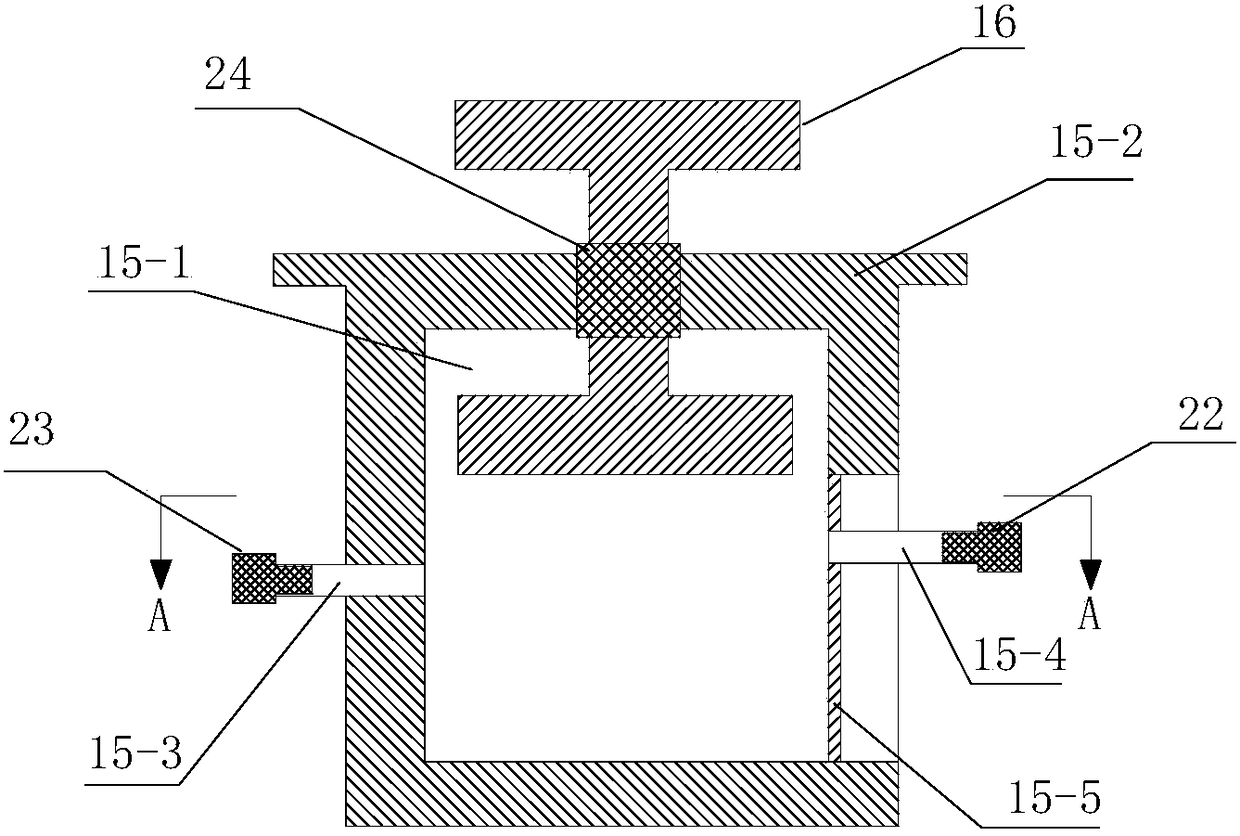

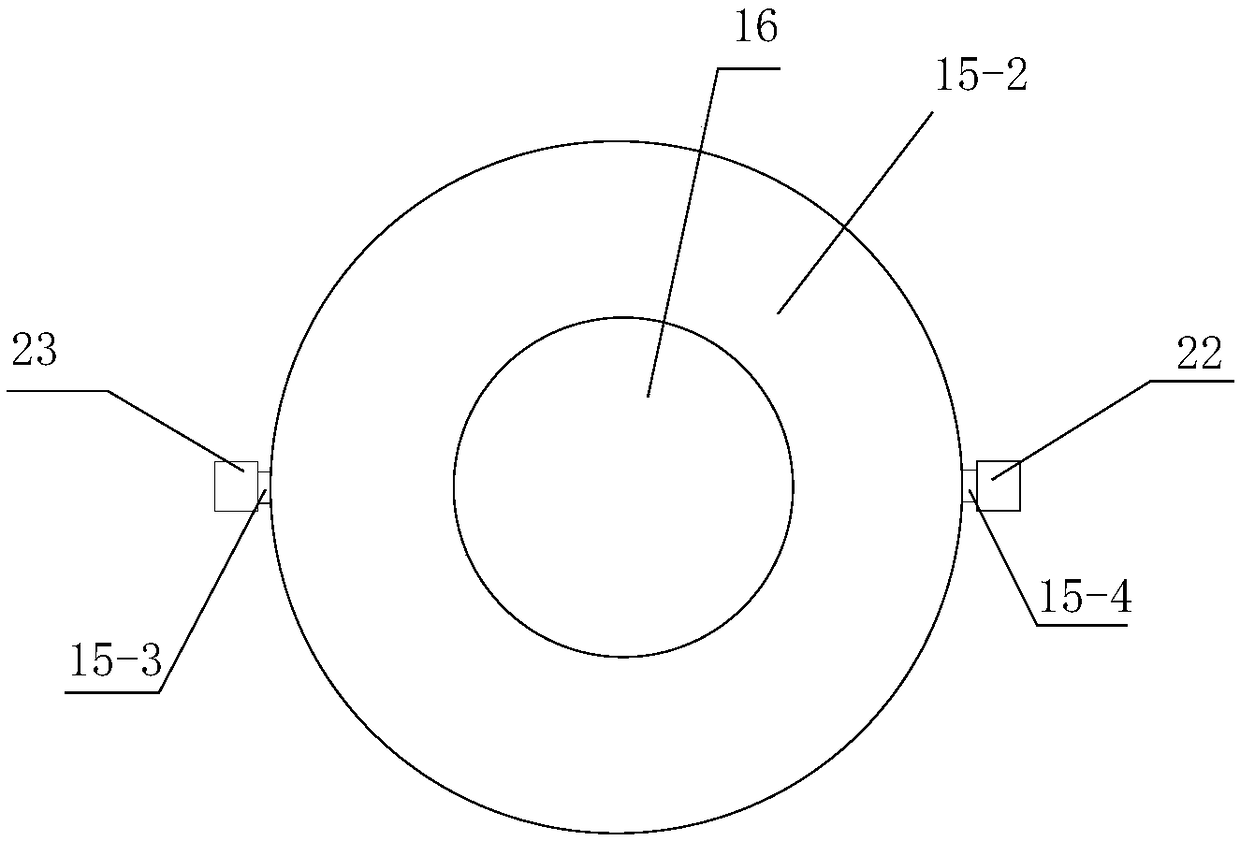

[0076] Combine figure 2 , image 3 with Figure 4 The coal sample container 15 includes a coal sample container shell 15-2 and a coal sample placement cavity 15-1 arranged in the coal sample container shell 15-2, and the top of the coal sample container shell 15-2 is sealed A piston 16 is connected, one side of the coal sample container shell 15-2 is provided with a first multi-purpose air hole 15-3, and the other side of the coal sample container shell 15-2 is provided with a second multi-purpose air hole 15-4 and the transparent mirror 15-5, the first multi-purpose air hole 15-3 is provided with a first sealing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com