Degradable drilling fluid used for drilling in soft coal seam

A technology for soft coal seam and drilling fluid, applied in the field of drilling fluid, can solve the problem of insignificant effect, achieve the effect of complete gel breaking, meet environmental protection requirements, and remove damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

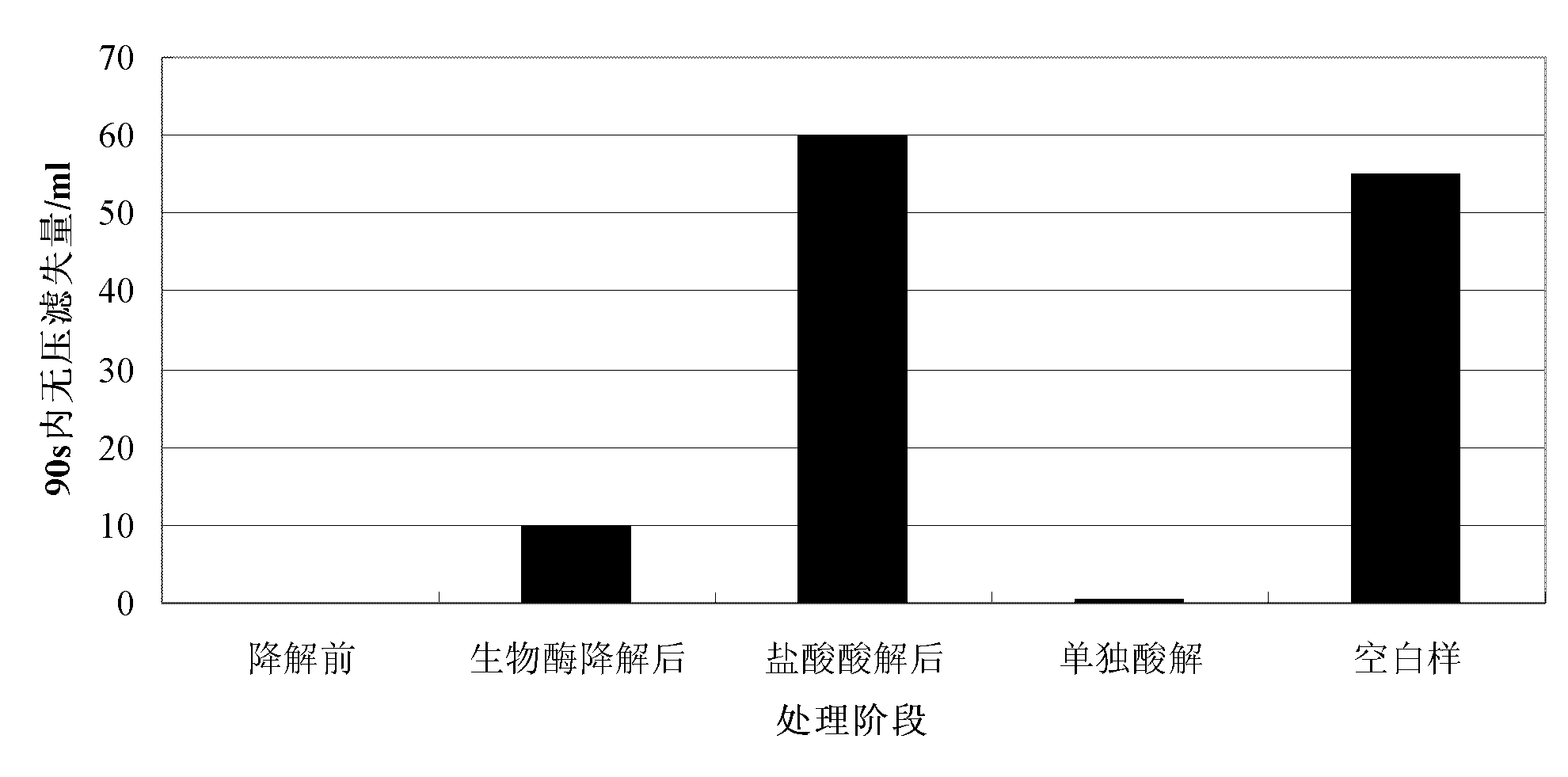

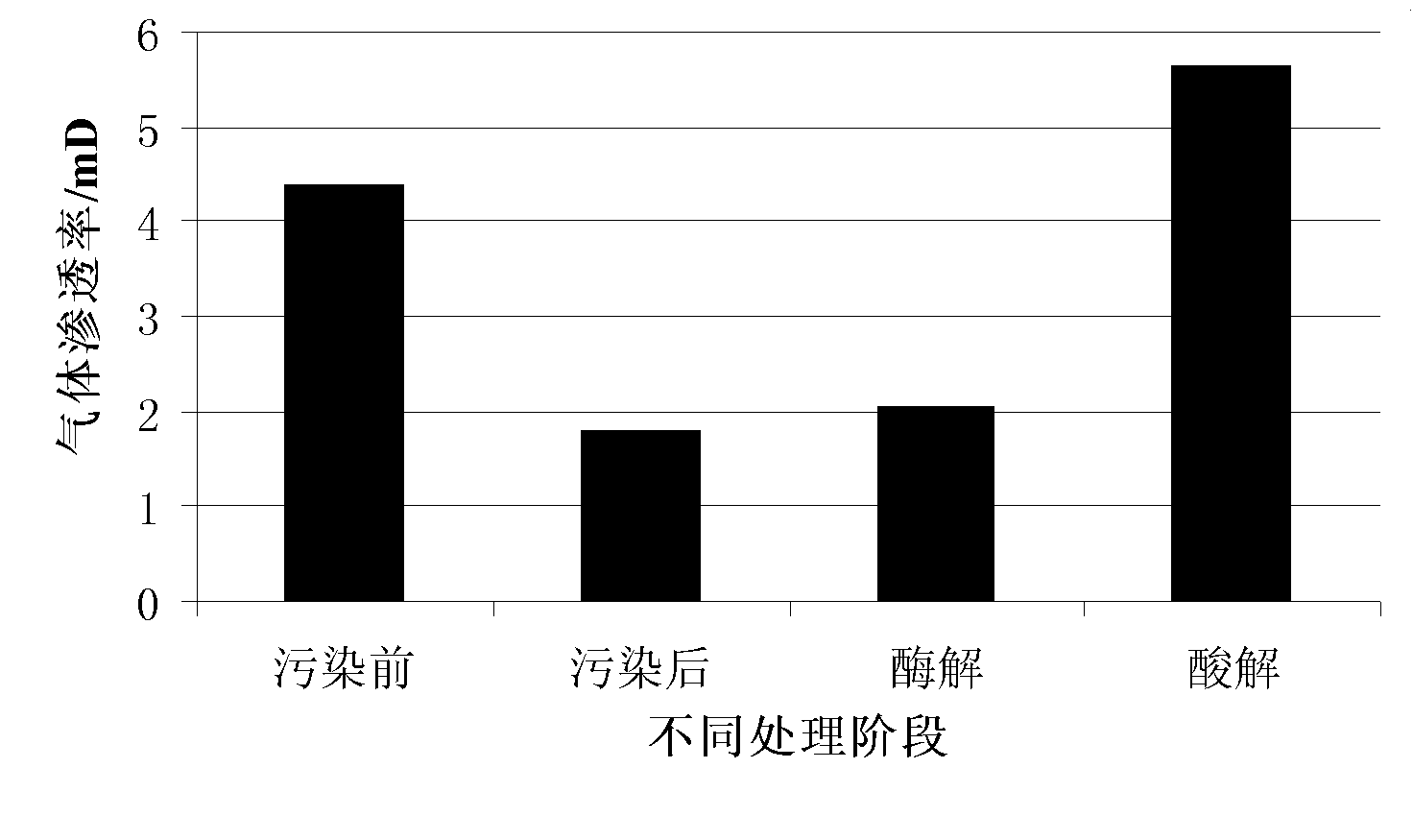

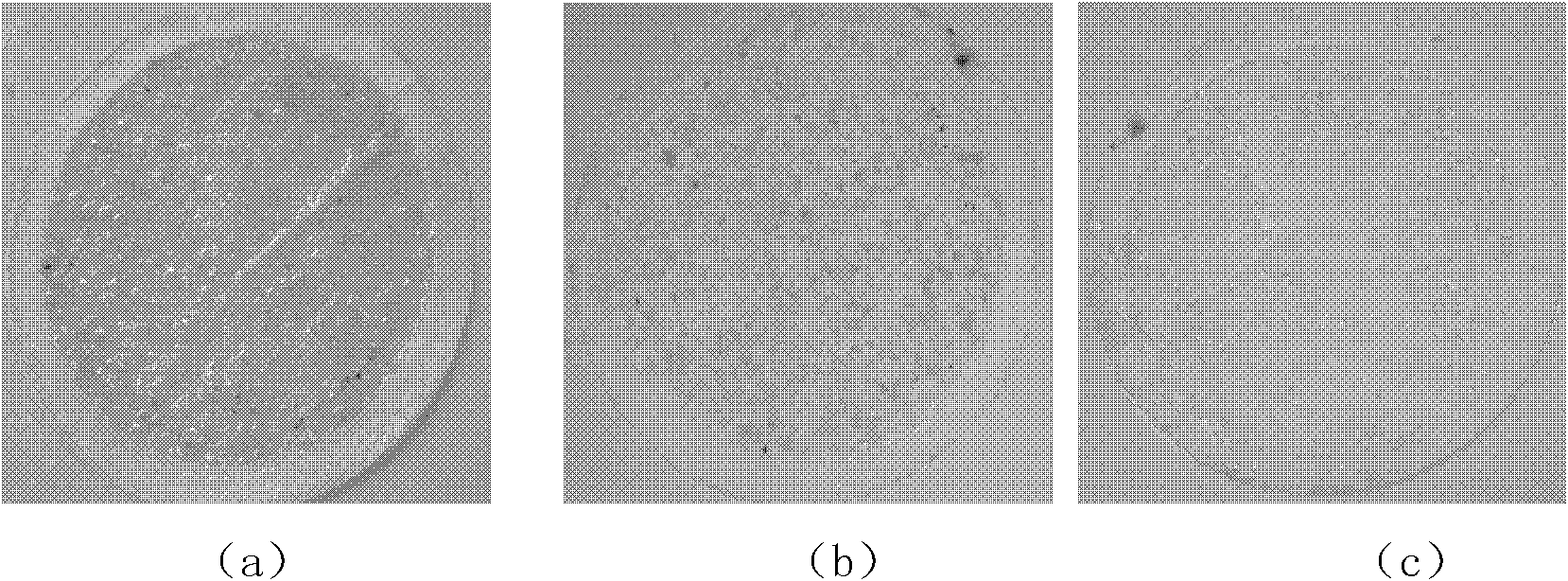

[0026] This example 1 mainly reflects: (1) The basic performance parameters (density, apparent viscosity, filtration loss, pH and filter cake thickness) of the degradable drilling fluid used for drilling soft coal seams; (2) Used for drilling soft coal seams The changes in apparent viscosity of the degradable drilling fluid over time, filter cake removal test results, and coal gas permeability test results.

[0027] 1. Experimental formula

[0028] The degradable drilling fluid used for drilling soft coal seams of this embodiment is composed of water, degradable polymer (medium viscous carboxymethyl cellulose), fluid loss agent (modified starch), bridging agent (ultrafine carbonic acid). Calcium), pH adjuster (ammonium chloride) and biological enzyme breaker; calculated by the amount added per 100 ml of water: 0.6 g of medium-viscosity carboxymethyl cellulose, 1 g of modified starch, superfine calcium carbonate (400 Mesh) 1.2 grams, a little ammonium chloride (adjust the pH to 7) ...

Embodiment 2

[0064] This example 2 mainly reflects: (1) The basic performance parameters (density, apparent viscosity, filtration loss, pH and filter cake thickness) of the degradable drilling fluid used for drilling soft coal seams; (2) Used for drilling soft coal seams The apparent viscosity of the degradable drilling fluid changes over time.

[0065] 1. Experimental formula

[0066] The degradable drilling fluid used for drilling in soft coal seams, calculated by the amount added per 100 ml of water: degradable polymer (medium viscous carboxymethyl cellulose) 0.6 g, bentonite 2 g, fluid loss agent (modified starch) 0.75 g , Bridging agent (ultra-fine calcium carbonate, particle size of 400 mesh, can be adjusted according to the radius of the pore throat of the coal) 1.0 g, JBR breaker 0.1 g, pH adjuster (ammonium chloride) is added to adjust the drilling fluid pH to 7.

[0067] The breaker JBR is white powder, produced by Hubei Jingzhou Jiahua Technology Co., Ltd.

[0068] The preparation met...

Embodiment 3

[0081] This example 3 mainly reflects: (1) The basic performance parameters (density, apparent viscosity, filtration loss, pH and filter cake thickness) of the degradable drilling fluid used for drilling soft coal seams; (2) Used for drilling soft coal seams The apparent viscosity of the degradable drilling fluid changes over time.

[0082] 1. Experimental formula

[0083] The degradable drilling fluid used for drilling in soft coal seams, calculated by the amount added per 100 ml of water: degradable polymer (medium viscous carboxymethyl cellulose) 0.6 g, bentonite 2 g, fluid loss agent (modified starch) 0.75 g , Crosslinking agent (ultra-fine calcium carbonate, particle size of 400 mesh, can be adjusted according to the radius of the pore throat of the coal) 1.0 g, biological enzyme breaker SE-40.01 g, pH regulator (ammonium chloride) is added in Adjust the pH of the drilling fluid to 7.

[0084] Biological enzyme breaker SE-4 is brown liquid, produced by Jiangsu Kunshan Jingkun ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com