Coal petrography interface identification and positioning method based on machine visual sense

A positioning method and machine vision technology, applied in character and pattern recognition, instruments, computer parts, etc., can solve problems such as staying in theoretical research, difficulty in real-time accurate measurement, and safety threats in underground mines, and improve the level of coal mining automation. , the effect of improving the coal recovery rate and improving the efficiency of coal mining operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

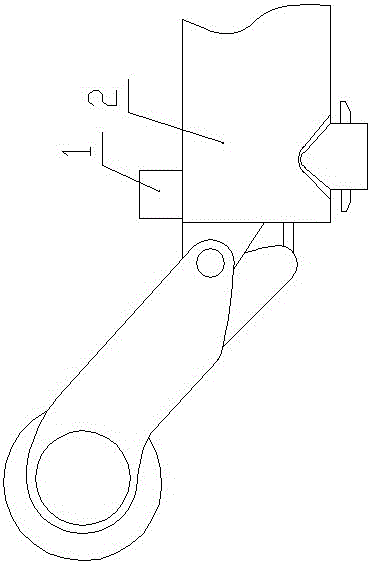

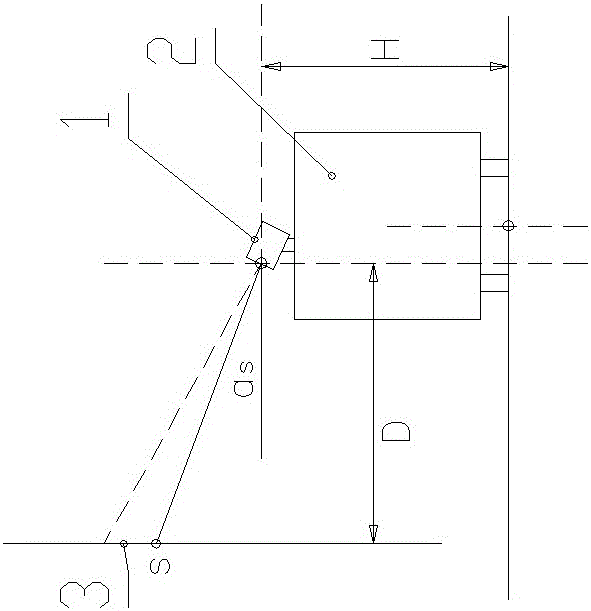

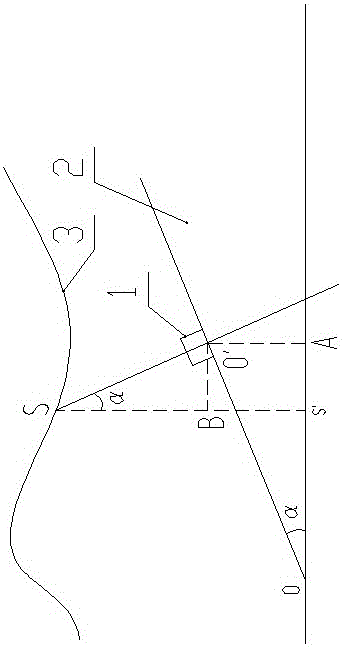

[0030] Such as Figure 1-8 As shown, a kind of coal-rock interface recognition and location method based on machine vision of the present invention comprises the following steps:

[0031](1) Install the camera 1 on the body of the coal shearer 2 through the quick connection mechanism 4, use the camera 1 to collect the coal mining face 3 to obtain a picture of the coal mining face 3, and extract the original image from the information collected by the camera 1 through image preprocessing Convert to a grayscale image, and then perform image enhancement, grayscale stretching and median filtering on the grayscale image;

[0032] (2) Use the morphological processing of corrosion and closed operation to filter out the influence of light reflection, coal dust, and gangue on the grayscale image, and finally obtain a complete coal-rock interface curve picture;

[0033] (3) Use the algorithm in the MATLAB library function to obtain the pixel coordinate information of the coal-rock inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com