Fluid-solid coupling coal petrography shear-seepage test shearing and sliding combined shearing box

A technology of fluid-solid coupling and shear box, which is applied in the direction of applying stable shear force to test material strength, permeability/surface area analysis, suspension and porous material analysis, etc. Test error and other problems, to achieve the effect of data acquisition and accurate calculation, improve test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

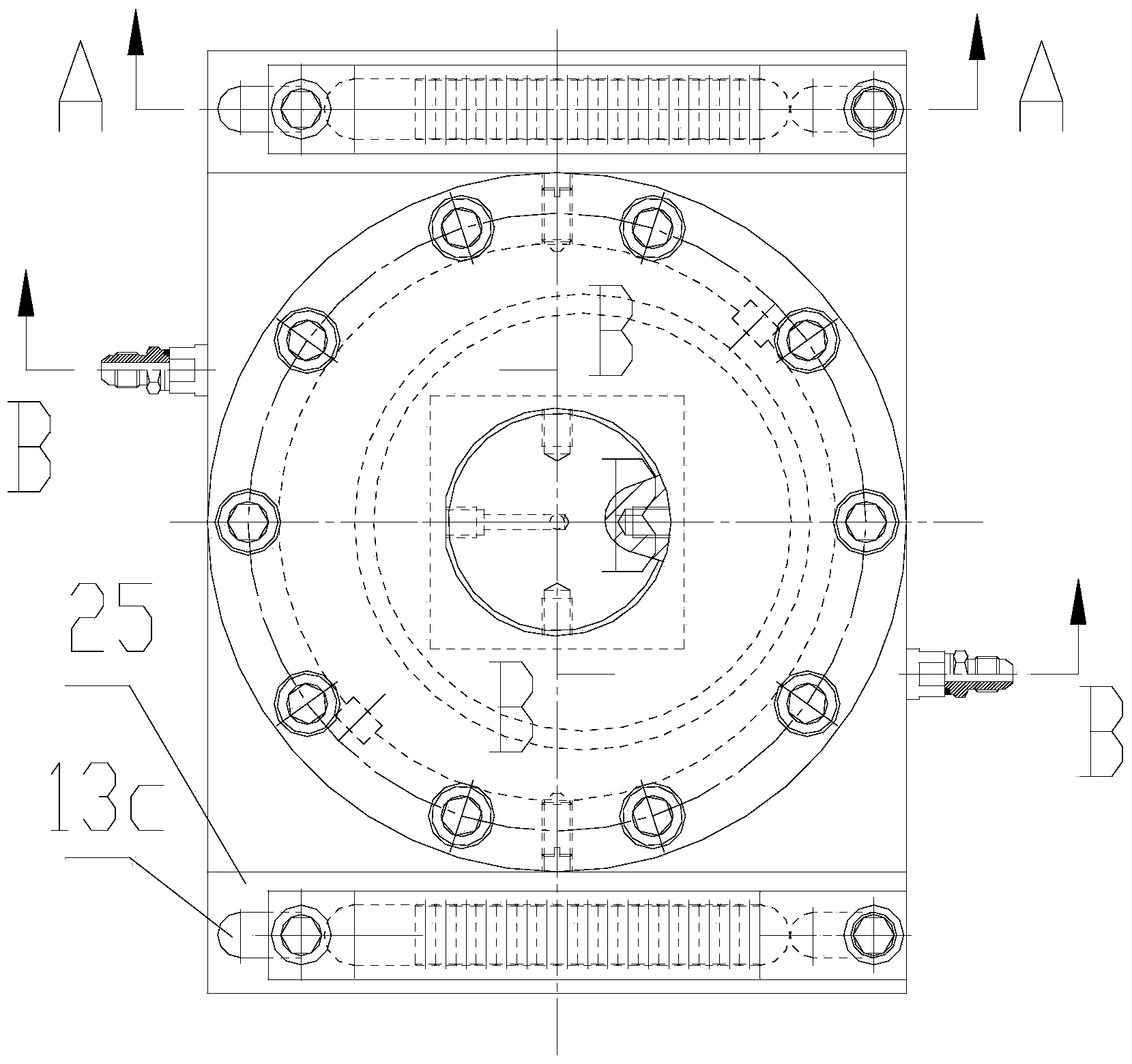

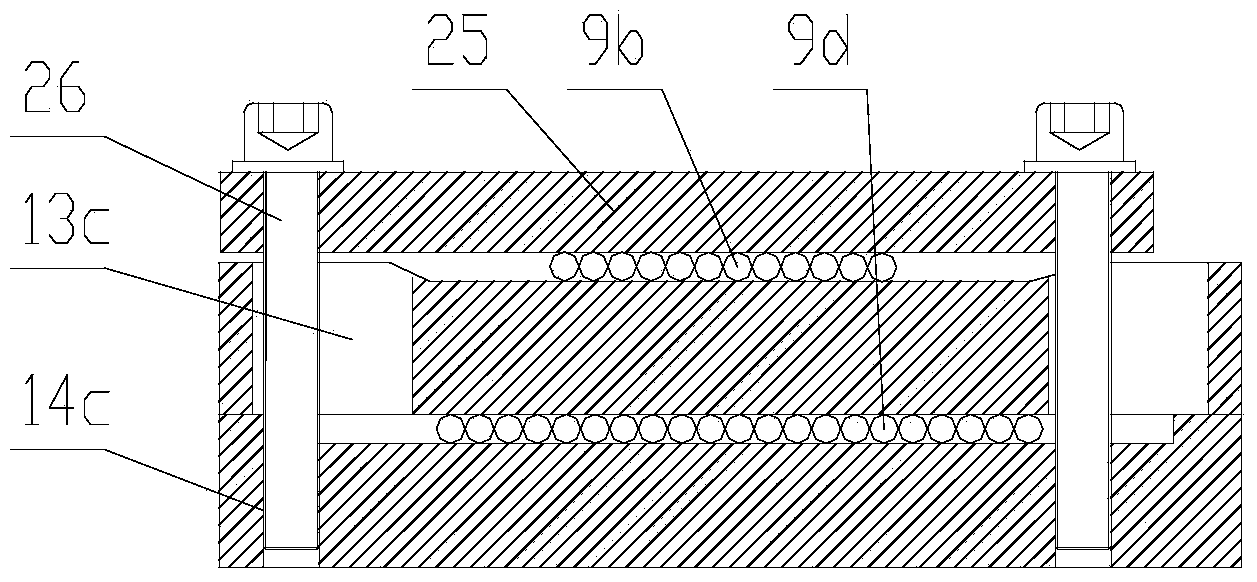

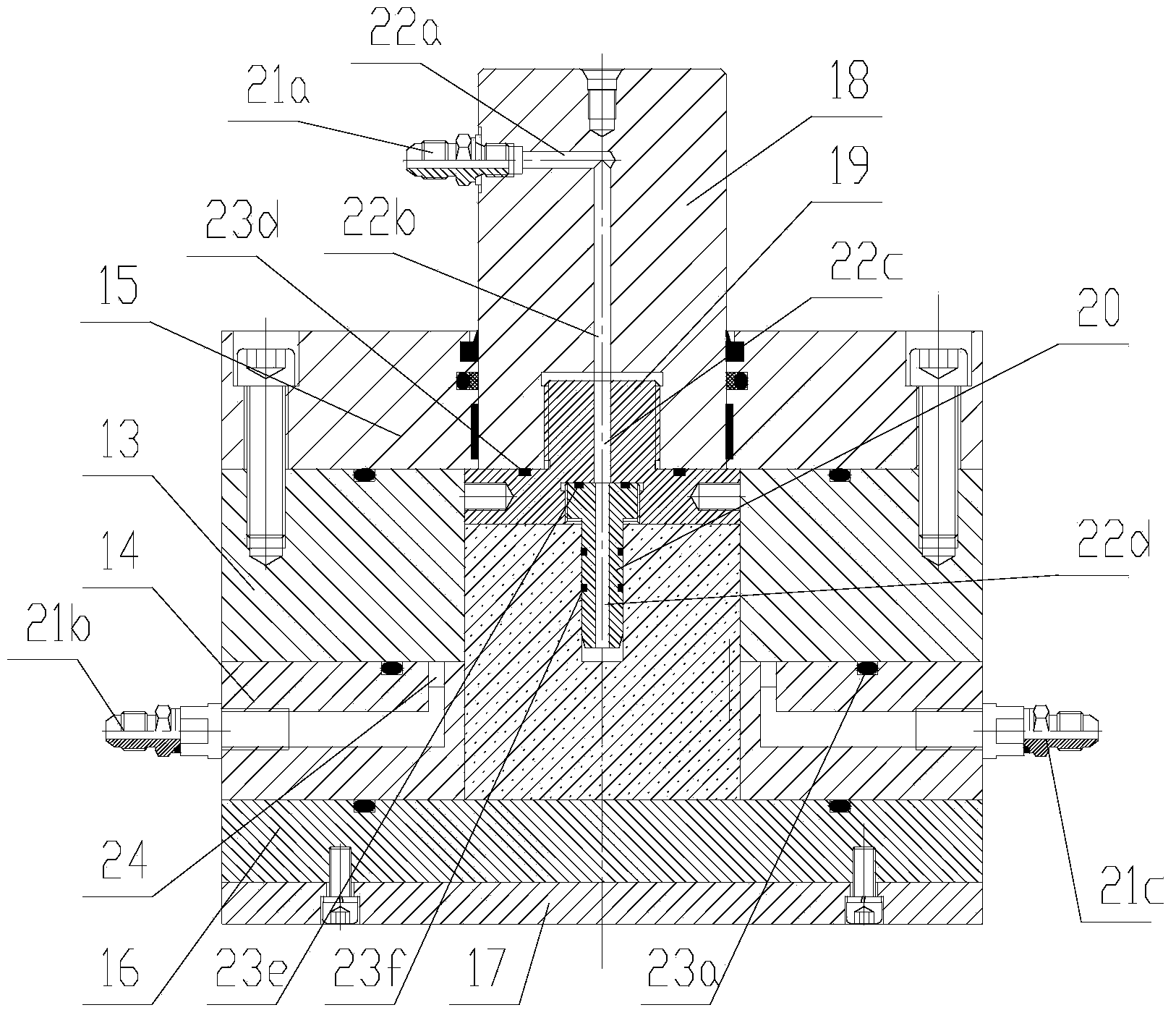

[0024] Such as Figure 1 to Figure 4 As shown, a fluid-solid coupled coal-rock shear-seepage test shear sliding combination shear box includes an upper box body 13 and a lower box body 14 that are fixedly connected to each other, and the upper box body 13 and the lower box body 14 are provided with housings cavity of the test piece.

[0025] The upper box body 13 is fixedly connected with the upper cover 15 , the lower box body 14 is fixedly connected with the lower cover 16 , and the lower cover 16 is fixedly connected with the backing plate 17 .

[0026] The upper cover 15 is equipped with a pressure rod 18 , the end of the pressure rod 18 close to the test piece is threaded with a test piece indenter 19 , and the end of the test piece indenter 19 close to the test piece is threaded with a test piece connector 20 .

[0027] The pressure rod 18 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com