Deep preparation technology of coal for direct coal liquefacation

A preparation process and a direct technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of high inertinite content, affecting oil yield, low exinite content, etc., and achieve good results , easy operation, and the effect of improving oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

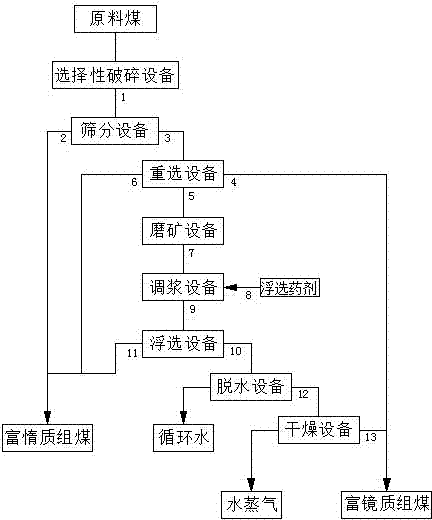

[0015] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0016] The advanced preparation process of coal for direct coal liquefaction of the present invention:

[0017] a. First, the raw coal is sent to the selective crushing equipment with a crushing particle size of 13mm, 6mm or 3mm for crushing, and the crushed product 1 is sent to the screening device for classification, and the under-screen product 2 with a particle size of less than 0.5mm is the final product rich inert quality coal;

[0018] b. The sieve product 3 with a particle size greater than 0.5 mm is sent to the gravity separation equipment for separation. The clean coal 4 obtained by gravity separation is the final product rich in vitrinite coal, and the tailing coal 6 obtained by gravity separation is the final product rich in inert matter Coal grouping, re-selected medium coal 5 is sent to grinding equipment for grinding, and the content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com