Pressure control injection yield increase method for coalbed methane well

A technology for coalbed methane wells and coal reservoirs, which is applied in the field of new production stimulation technology, can solve the problems of coal rock fragmentation, collapsed and fly ash accumulation, etc., and achieves the effect of avoiding the concentration of coal rock stress and inhibiting the generation of coal dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

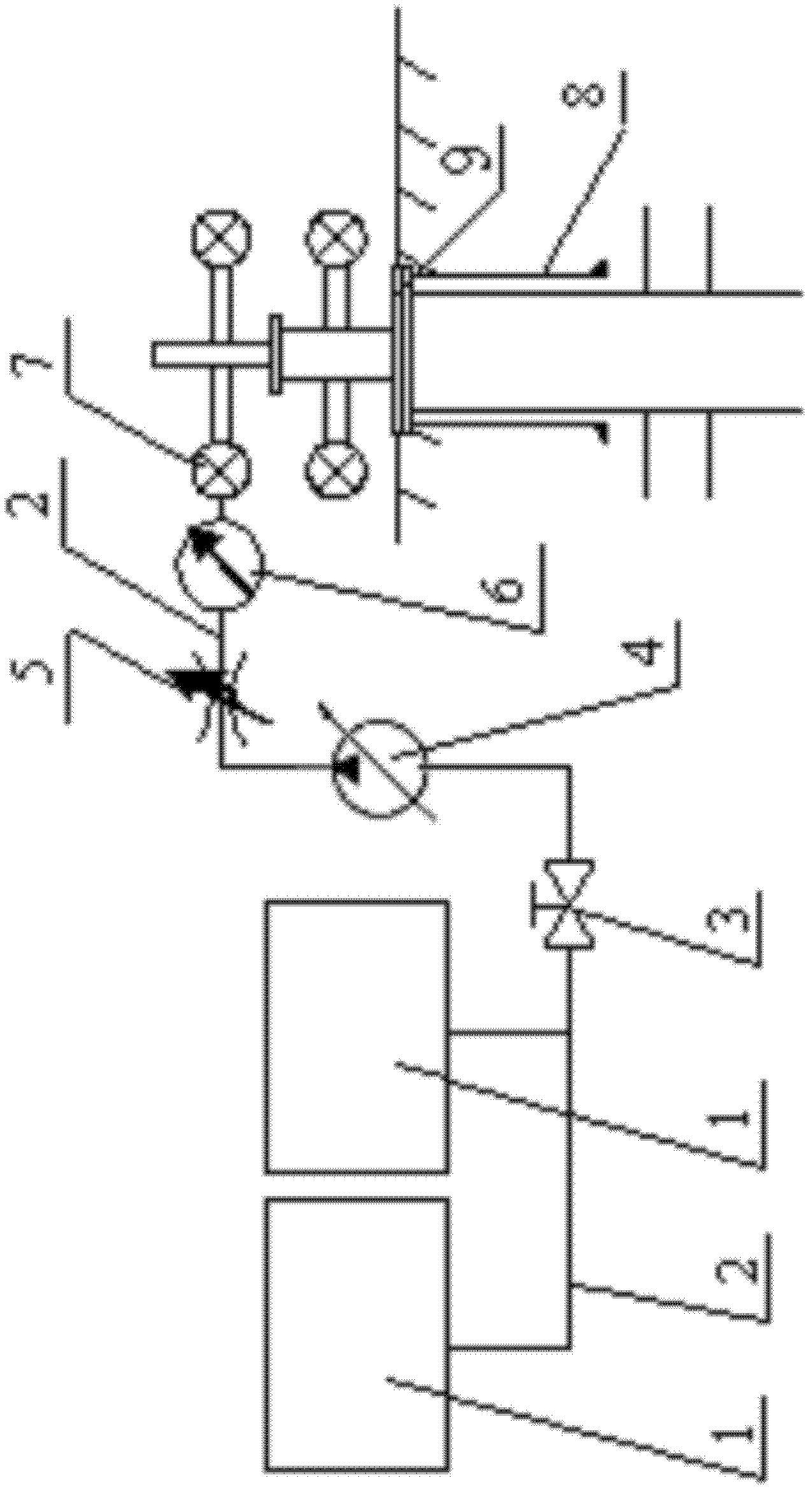

[0038] Embodiment 1: Taking a method of increasing production by pressure-controlled injection of a coalbed methane well as an example, the present invention will be further described in detail.

[0039] The present invention utilizes the plunger pump 4 in high-rank coal reservoirs with a small displacement, no proppant and pressure-controlled injection, so that the cleats and fissures of the coal rock themselves are fully connected, the desorption area is enlarged, and the gas production rate is increased.

[0040] The specific implementation steps are as follows:

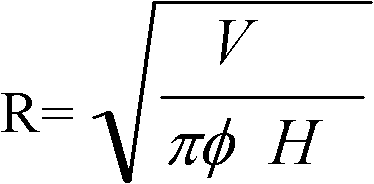

[0041] Step A. Collect the gas content and gas production of high-rank coal and rock reservoirs, and calculate the gas volume of coal reservoirs; gas content per ton of coal: 23m 3 / t; gas production after fracturing 44589m 3 , coal specific gravity 1.46t / m 3 ,

[0042] The volume of coal occupied by the gas produced m 3 : Gas production / ton coal gas content / coal specific gravity

[0043] Namely: 44589 / 23 / 1.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com