Automatic automobile metal plate drilling device with positioning function

A drilling device and automobile technology, applied in the field of automobile sheet metal processing, can solve the problems of extrusion damage of processed parts, inaccuracy of precision, and inability to automatically fix or unfix the processed parts, so as to improve processing efficiency and ensure drilling The effect of hole accuracy

Active Publication Date: 2022-06-21

CHENGDU UNIV

View PDF13 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

1. In the comparison document, although the drilling accuracy of the device to the workpiece is ensured by setting the horizontal movement component and the vertical movement component, but for some processing that needs to be drilled with a circular trajectory centered on a certain point, only the horizontal movement component And the vertical movement component makes the drill bit drill holes on the specified point on the workpiece may have errors in accuracy;

2. For the structure in the comparison file, when drilling workpieces, only after one group of workpieces are completely processed and replaced can the next group of workpieces be drilled, and the second group of workpieces cannot be drilled. During the process of the workpiece being drilled, the previous set of workpieces is replaced, thereby reducing the processing efficiency of the entire drilling device;

3. There is no structure for fixing the workpiece in the comparison file, and it is impossible to automatically fix or unfix the workpiece. Usually, the operator needs to hold the workpiece by hand or fix the workpiece through a telescopic cylinder, and the workpiece cannot be fixed by hand. Ensure the stability of the workpiece during processing, while the telescopic cylinder may cause extrusion damage to the surface of the workpiece;

4. At the same time, in the comparison file, when the workpiece needs to be replaced, the workpiece is in a horizontal state, which is not conducive to the operator to manually replace the workpiece. After the workpiece is processed, one end of the workpiece cannot be automatically propped up for easy operation. Personnel pick and place workpieces

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

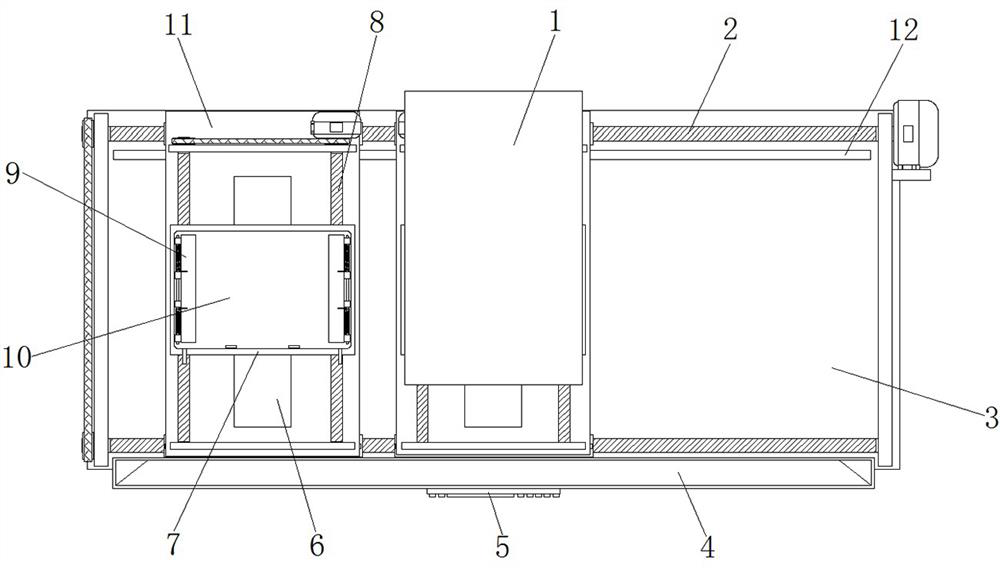

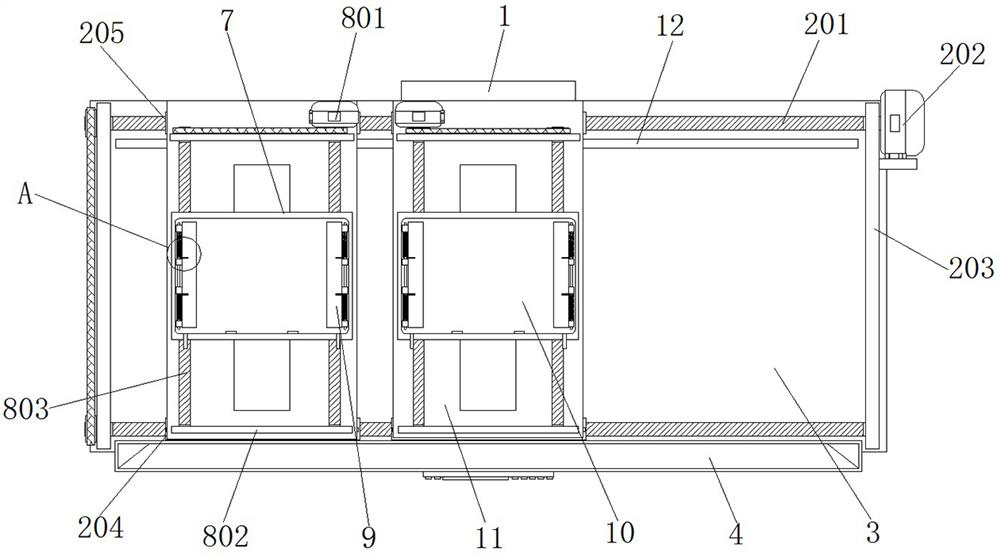

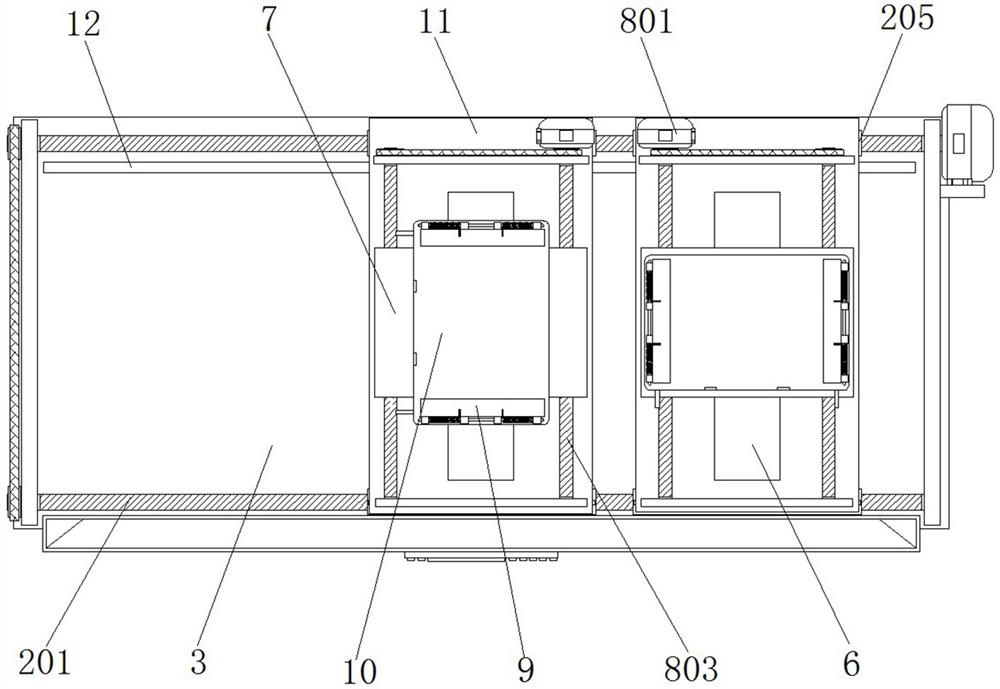

The automobile metal plate automatic drilling device with the positioning function comprises a mounting table, an L-shaped frame is mounted in the middle of one side of the mounting table, an electric push rod is mounted in the middle of the top in the L-shaped frame, and a rotating motor is mounted at the output end of the electric push rod; a drill bit is mounted at the output end of the rotating motor, a transverse moving assembly is arranged at the top of the mounting table, and two first moving plates are arranged at the top of a moving part of the transverse moving assembly. Two sets of first moving plates are designed, when two sets of first lead screws are controlled to synchronously rotate, the machining tables on the two sets of first moving plates can alternately move to the position below an L-shaped frame, and therefore in the machining process of automobile metal plates on one set of machining tables, the machining efficiency is improved, and the machining efficiency is improved. And an operator can replace the machined automobile metal plates on the other set of machining table, and the machining efficiency of the drilling device on the automobile metal plates is further improved.

Description

technical field [0001] The invention relates to the technical field of automobile sheet metal processing, in particular to an automatic drilling device for automobile sheet metal with a positioning function. Background technique [0002] Automobile sheet metal processing is an important link in the whole vehicle manufacturing process. Sheet metal processing includes traditional cutting and blanking, punching, bending and forming, drilling and other processes. Among them, vehicle sheet metal drilling is the connection of vehicle parts. Foundation. [0003] The comparison document is the patent of authorized notification number CN214871112U, which discloses a drilling device for printed circuit boards. The patent realizes the adjustment of the horizontal displacement of the drilling component on the top surface of the base by providing a horizontal moving component and a vertical moving component, so as to ensure the accuracy of processing. The drilling effect of the parts, b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23B41/00B23Q3/06

CPCB23B41/00B23Q3/062Y02P70/10

Inventor 吴昊荣孙付春李晓晓董恺凌肖华玮罗子棋

Owner CHENGDU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com