Drilling device for building construction

A drilling device and building construction technology, applied in work accessories, manufacturing tools, stone processing tools, etc., can solve problems such as affecting installation, excessive depth, drill verticality error, etc., to achieve easy cleaning and replacement, convenient and fast operation, The effect of ensuring drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

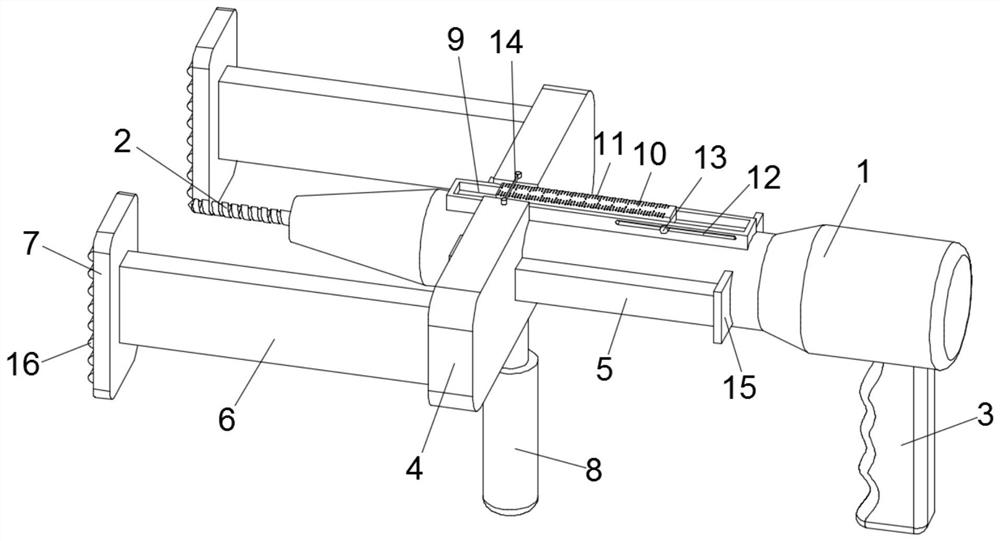

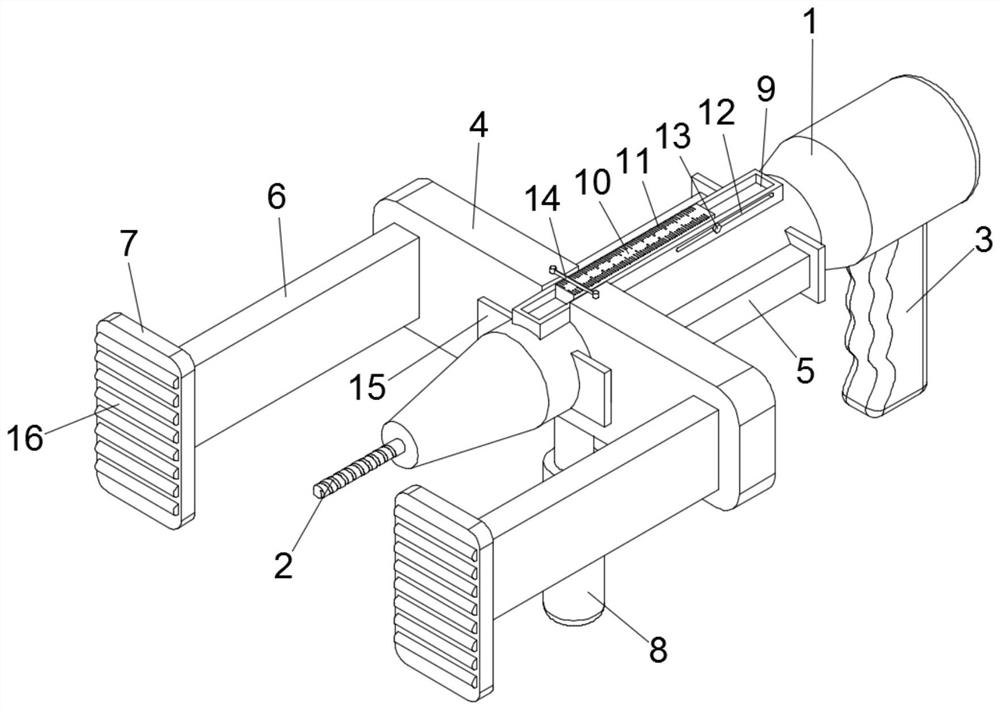

[0025] see Figure 1-2 , a drilling device for building construction, including a fuselage 1, a drill bit 2 is detachably installed at one end of the fuselage 1, a handle 3 is installed at the tail of the fuselage 1, and a sleeve plate 4 is also included, and the two sides of the fuselage 1 are A slide block 5 is arranged symmetrically on the side, and the fuselage 1 is slid and clamped in the sleeve plate 4 through the slide block 5. Both sides of the end face of the sleeve plate 4 facing the drill bit 2 are vertically fixed with supporting legs 6, and the supporting legs The end of the 6 is provided with a support plate 7;

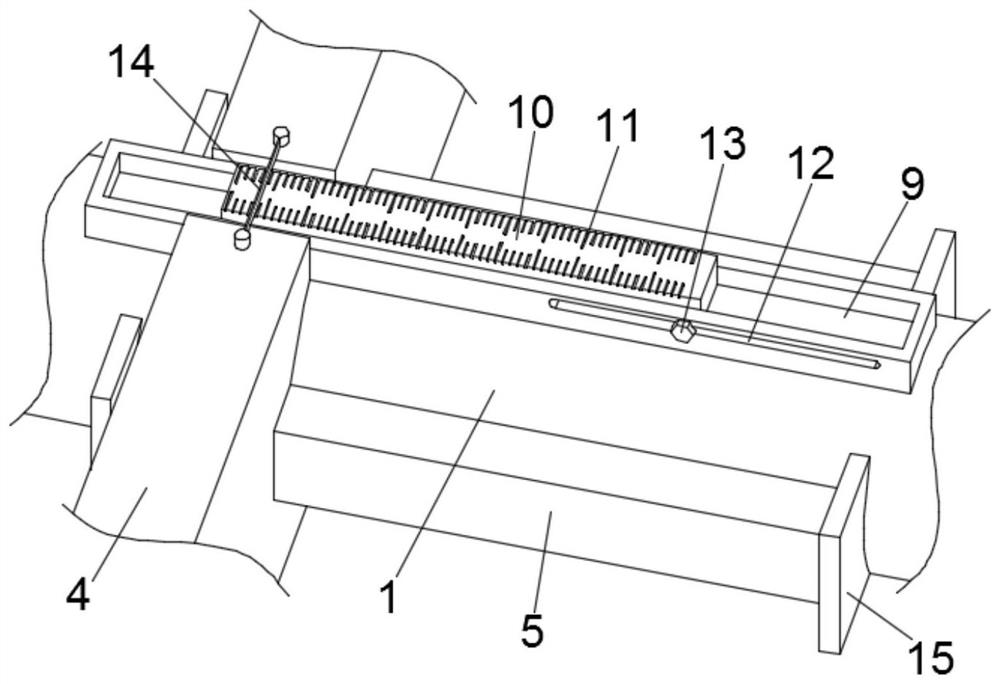

[0026] see image 3 The fuselage 1 is also provided with a hole depth measurement mechanism, the hole depth measurement mechanism includes a slide rail 9 and a slide plate 10, the slide rail 9 is horizontally fixed on the upper end of the fuselage 1, and the slide rail 9 is slide-embedded A slide plate 10 is provided, and the slide plate 10 is provided...

Embodiment 2

[0036] A drilling device for building construction, comprising a fuselage 1, a drill bit 2 is detachably installed at one end of the fuselage 1, a handle 3 is installed at the tail of the fuselage 1, and a cover plate 4 is also included, and the two sides of the fuselage 1 are A slider 5 is symmetrically arranged, and the fuselage 1 is slid and clamped in the cover plate 4 through the slide block 5. Both sides of the end face of the cover plate 4 facing the drill bit 2 are vertically fixed with supporting legs 6, and the supporting legs 6 The end is provided with a support plate 7;

[0037] The fuselage 1 is also provided with a hole depth measuring mechanism, which includes a slide rail 9 and a slide plate 10, the slide rail 9 is horizontally fixed on the upper end of the fuselage 1, and the slide rail 9 is slide-embedded There is a slide plate 10, the slide plate 10 is provided with a scale line 11, the end of the scale line 11 facing the drill bit 2 is set as a zero point, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com