Bolt drilling mechanical equipment for hardware processing

A drilling machine and bolt technology, which is applied in the field of hardware processing bolt drilling machinery and equipment, can solve the problems of general cooling effect at the drilling site and affect the quality of hardware drilling, so as to ensure the drilling quality, improve the anti-skid effect, and increase the rotation speed. moment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

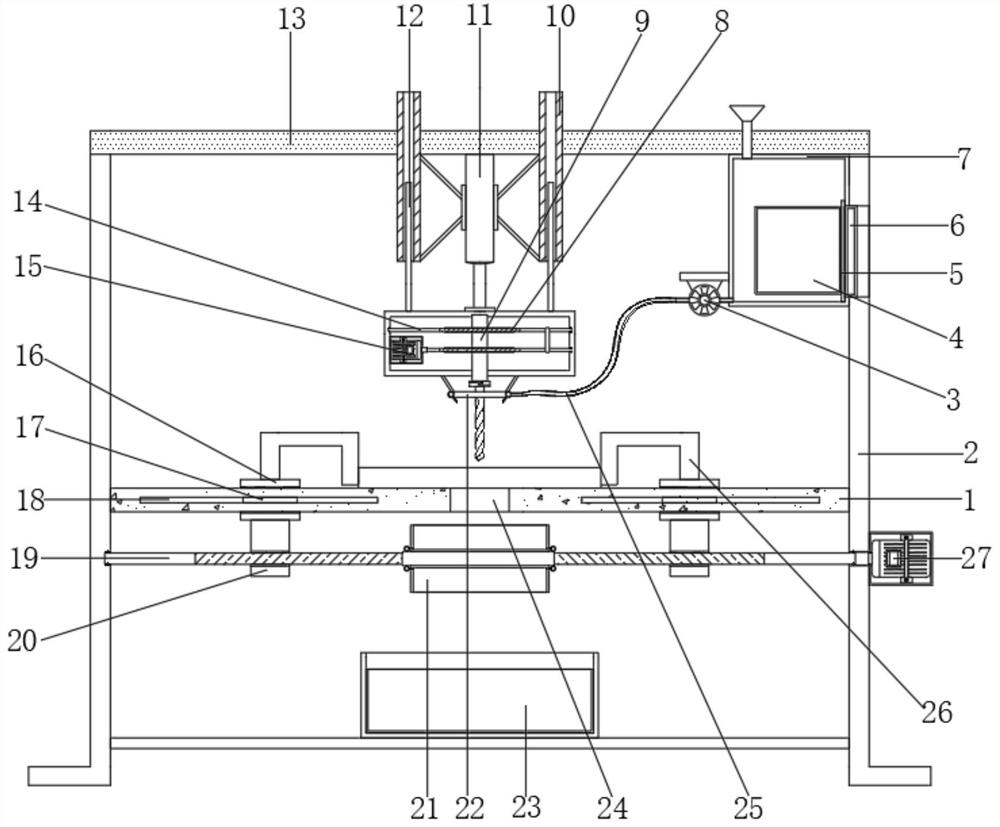

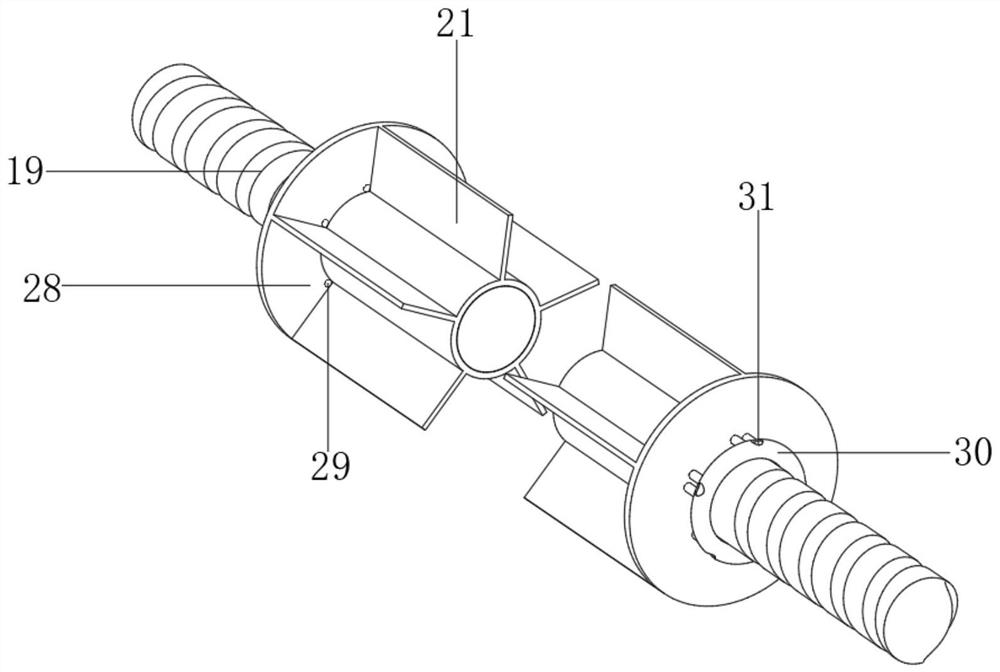

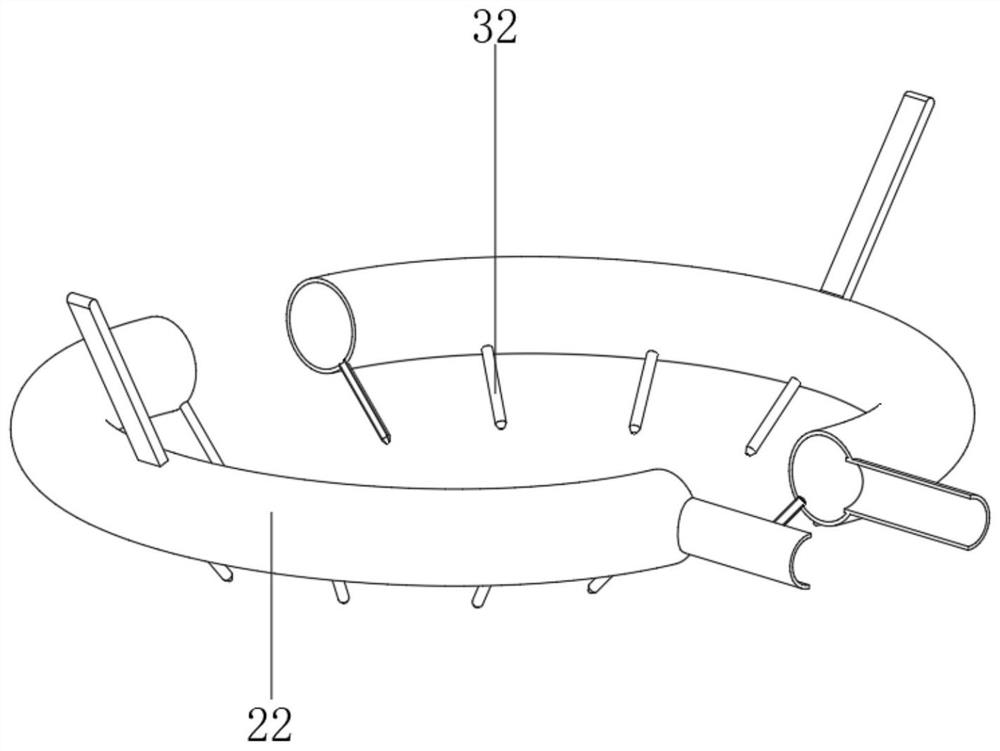

[0030] refer to Figure 1-4 , a kind of metal processing bolt drilling mechanical equipment, including a workbench 1, side risers 2 are vertically welded on both sides of the workbench 1, and the bottom outer wall of the side riser 2 is fixed with a hydraulic rod 11 by bolts, the hydraulic rod The end of the extension rod of 11 is fixed with the drive box by bolts, and the inner wall of the drive box is connected with the transmission column 9 through the bearing rotation, and the two ends of the transmission column 9 are key-connected with the worm wheel 8, and one side of the inner wall of the drive box is fixed by bolts There is a drive motor 15, the output shaft of the drive motor 15 and the top of the drive box are respectively connected with a worm 14 compatible with the worm wheel 8 through a coupling and a bearing, and one end of the two worms 14 is sleeved with a belt to form a transmission fit , the bottom end of the transmission column 9 is fixedly connected with a ...

Embodiment 2

[0041] refer to Figure 5 , a metal processing bolt drilling mechanical equipment, this embodiment compared with embodiment 1 also includes that the opposite side of the splint 26 is bonded with inverted A-shaped convex strips 35 distributed equidistantly, and the opposite side of the splint 26 Both are provided with oblique grooves 34 alternately distributed with inverted A-shaped convex strips 35 .

[0042] When the present invention is in use: the reverse A-shaped convex strip 35 is provided on the opposite side of the splint 26, which can effectively improve the anti-skid effect of the splint 26 in different directions, and cooperate with the inclined groove 34 arranged on the splint 26 to effectively improve the anti-skid effect of the splint 26. The clamping effect of the device on the workpiece ensures the smooth progress of the drilling operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com