Rotary type laser drilling positioning tool

A technology for laser drilling and positioning tooling, applied in laser welding equipment, auxiliary devices, manufacturing tools, etc., can solve the problems of high production cost, high cost, complex structure, etc., and achieve low production cost, convenient operation, and high positioning accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

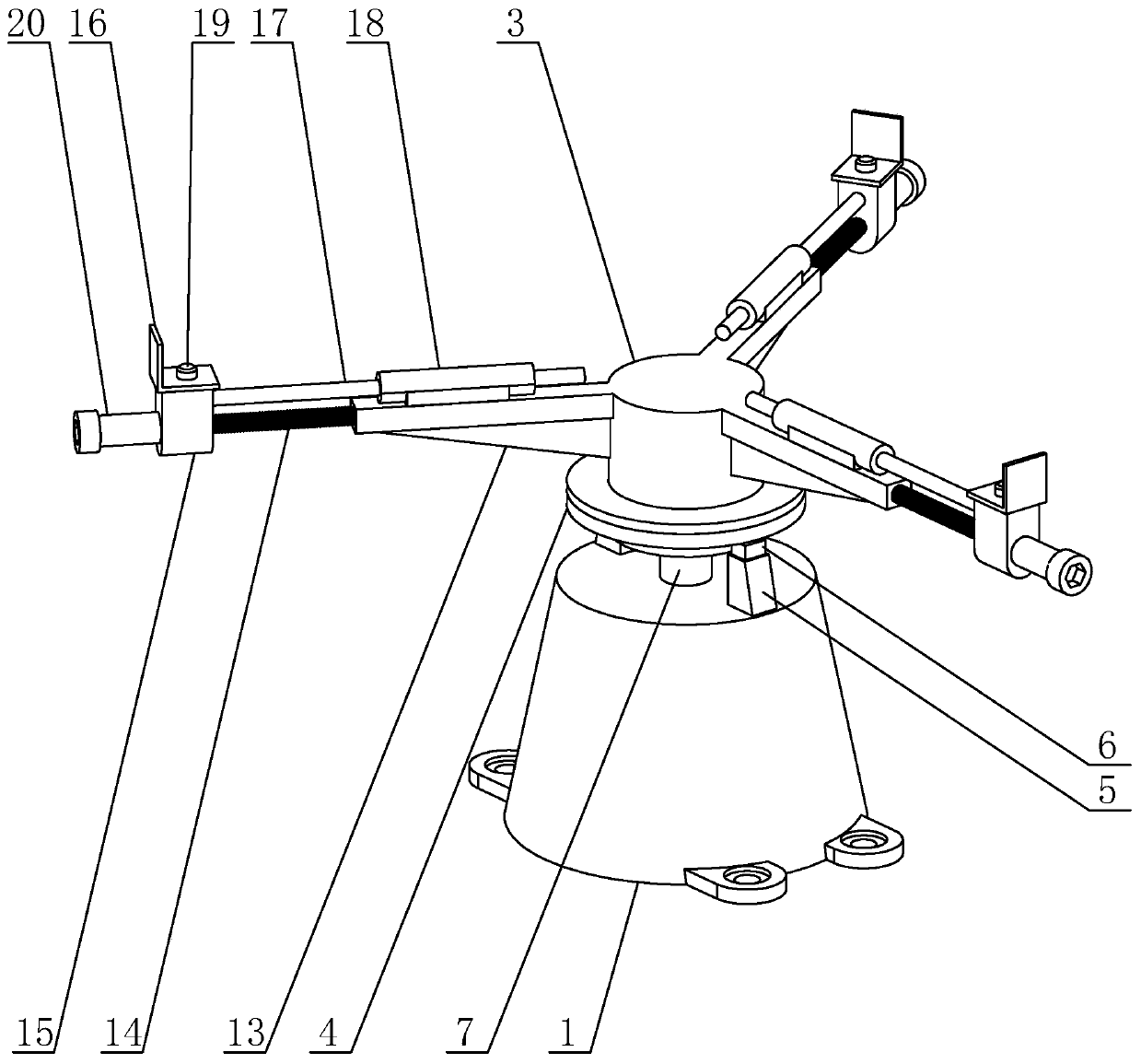

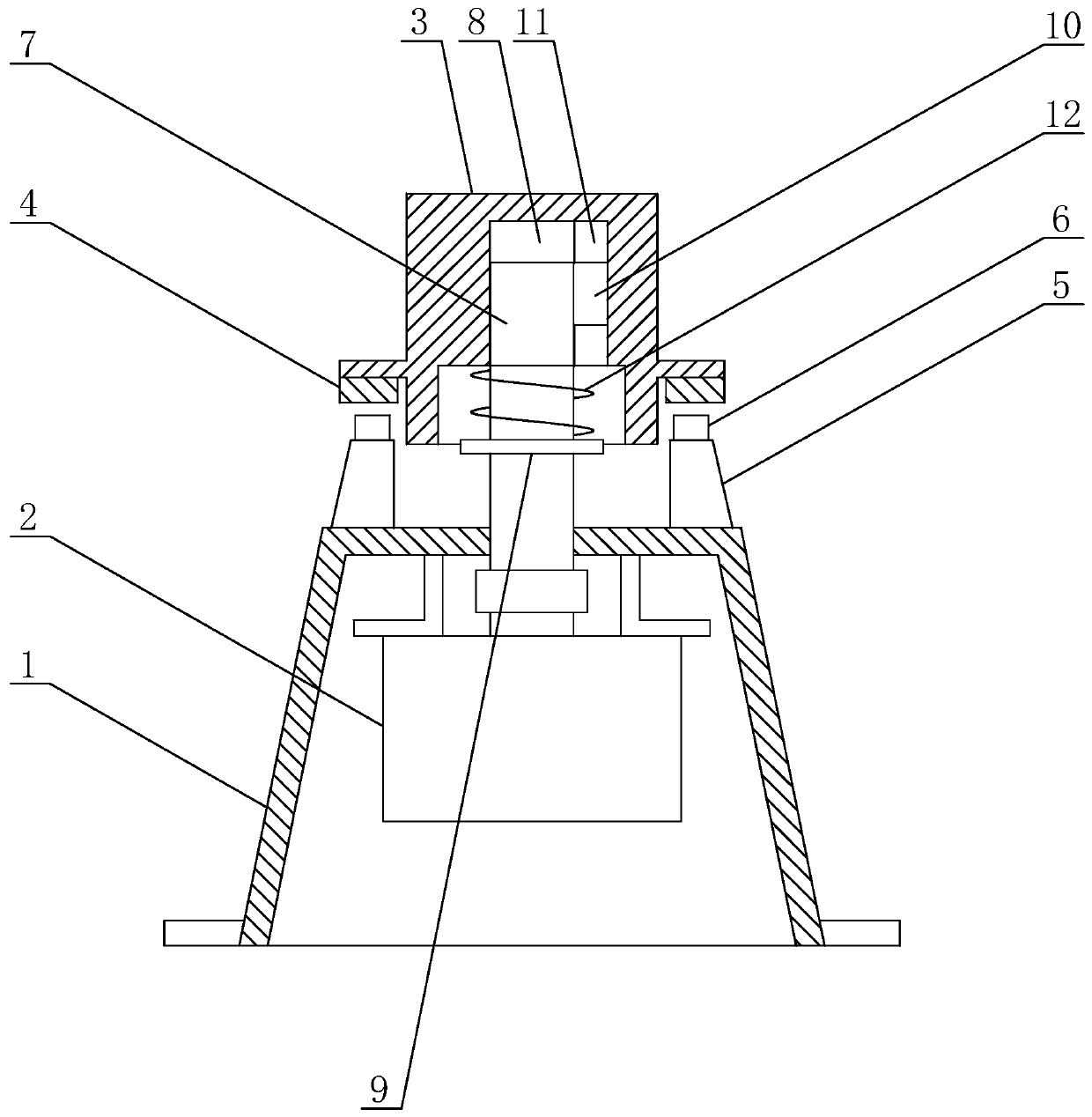

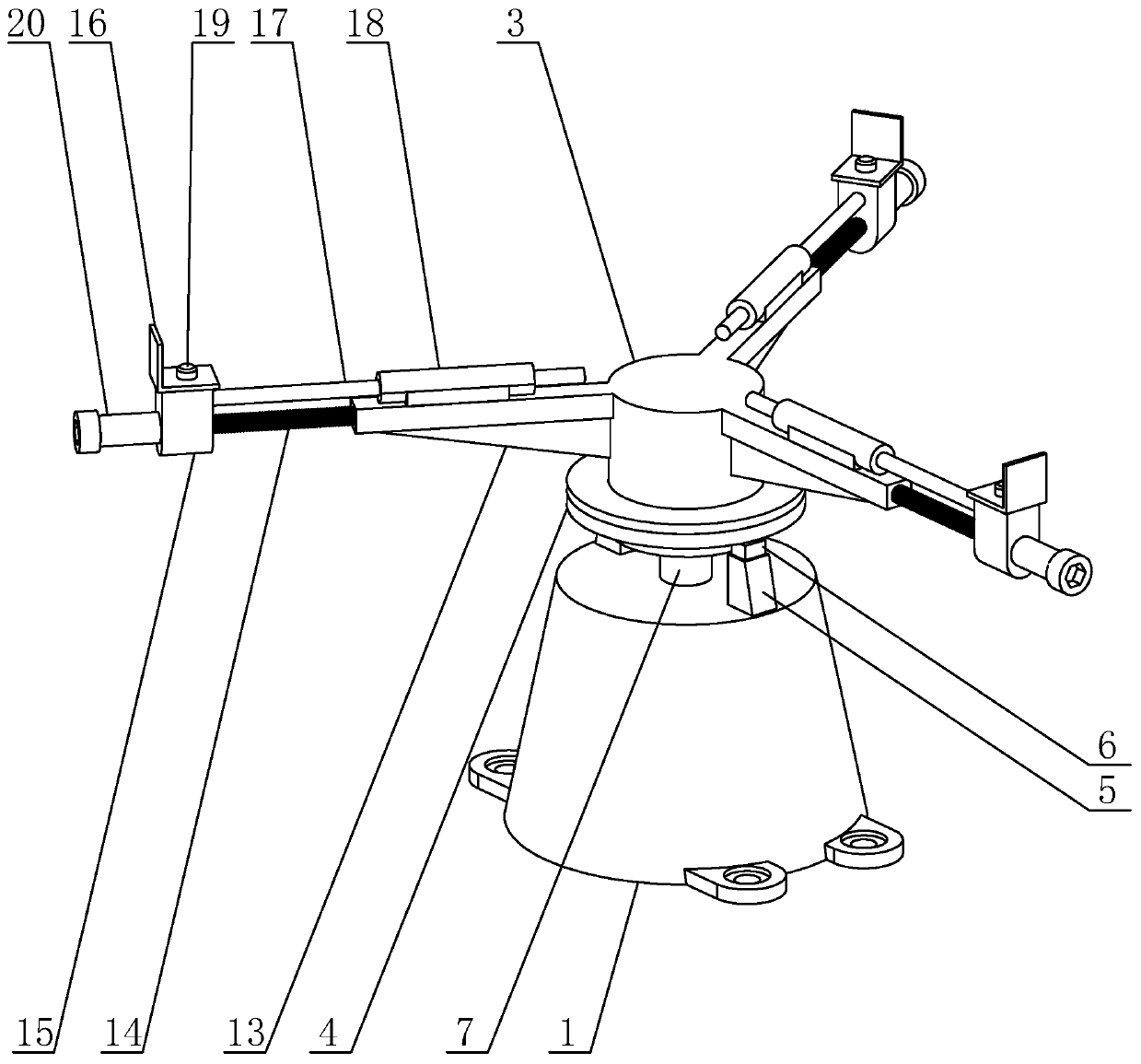

[0035] Embodiment: The invention describes a rotary laser drilling positioning tool, including:

[0036] Base 1, the bottom of the base 1 is provided with a cavity, the cavity of the base 1 is provided with a driving motor 2, the driving motor 2 adopts a stepping motor, and is equipped with a corresponding controller, and the rotation of the driving motor 2 is controlled by the controller Angle, and then adjust the position of the punched hole, the drive motor 2 is fixed in the base 1 through the motor bracket, the bottom of the outer wall of the base 1 is welded with a connecting plate with a mounting hole, and the top of the base 1 is provided with a rotating shaft 7. The bottom end of the rotating shaft 7 is inserted into the base 1 and is rotationally connected with the base 1 through a bearing;

[0037]Support seat 3, the support seat 3 is located on the upper side of the base 1, the bottom of the support seat 3 is provided with a mounting hole 8 compatible with the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com