Drilling device for construction metal plates

A technology for sheet metal and drilling equipment, applied in metal processing equipment, drilling/drilling equipment, boring/drilling, etc., can solve the problem of decreased drilling accuracy, affecting drilling accuracy, and drill pipe grinding and cutting deviation and other problems, to achieve the effect of preventing debris from splashing, facilitating subsequent processing, and preventing slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

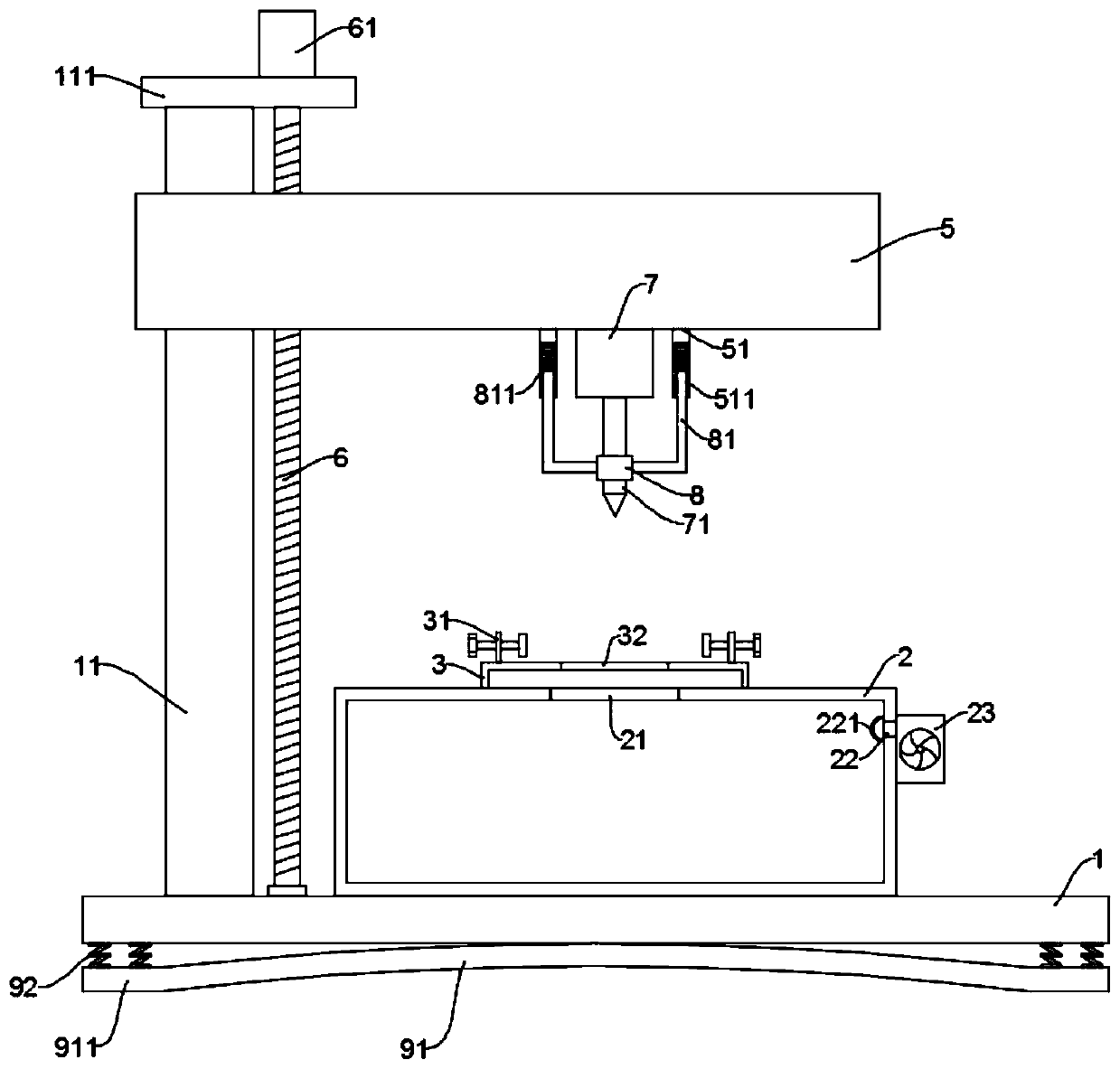

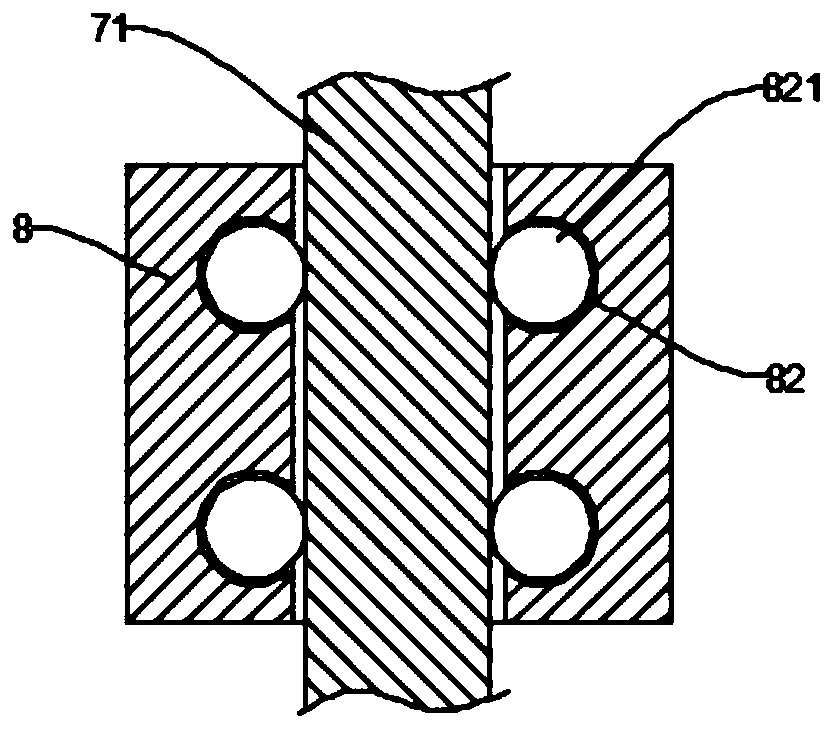

[0023] See Figure 1~2 In the embodiment of the present invention, a drilling equipment for building sheet metal includes a base 1, a workbench 2, and a movable frame 5; the top of the base 1 is fixed with a guide column 11, and the movable frame 5 is slidably installed on the guide column On 11, it is used to limit the movement direction of the movable frame 5. A top plate 111 is fixed on the top of the guide column 11, and a screw rod 6 is rotatably connected between the top plate 111 and the base 1. The screw rod 6 is connected to the movable frame 5 through threaded fit. A feed motor 61 that drives the screw 6 to rotate is installed on the top plate 111. During operation, the feed motor 61 drives the screw 6 to rotate, thereby driving the moving frame 5 to rise and fall to complete the drilling and feeding work. Transmission can make the lifting of the mobile frame 5 more stable;

[0024] A storage table 3 is fixed on the top of the workbench 2, and a clamping member 31 for f...

Embodiment 2

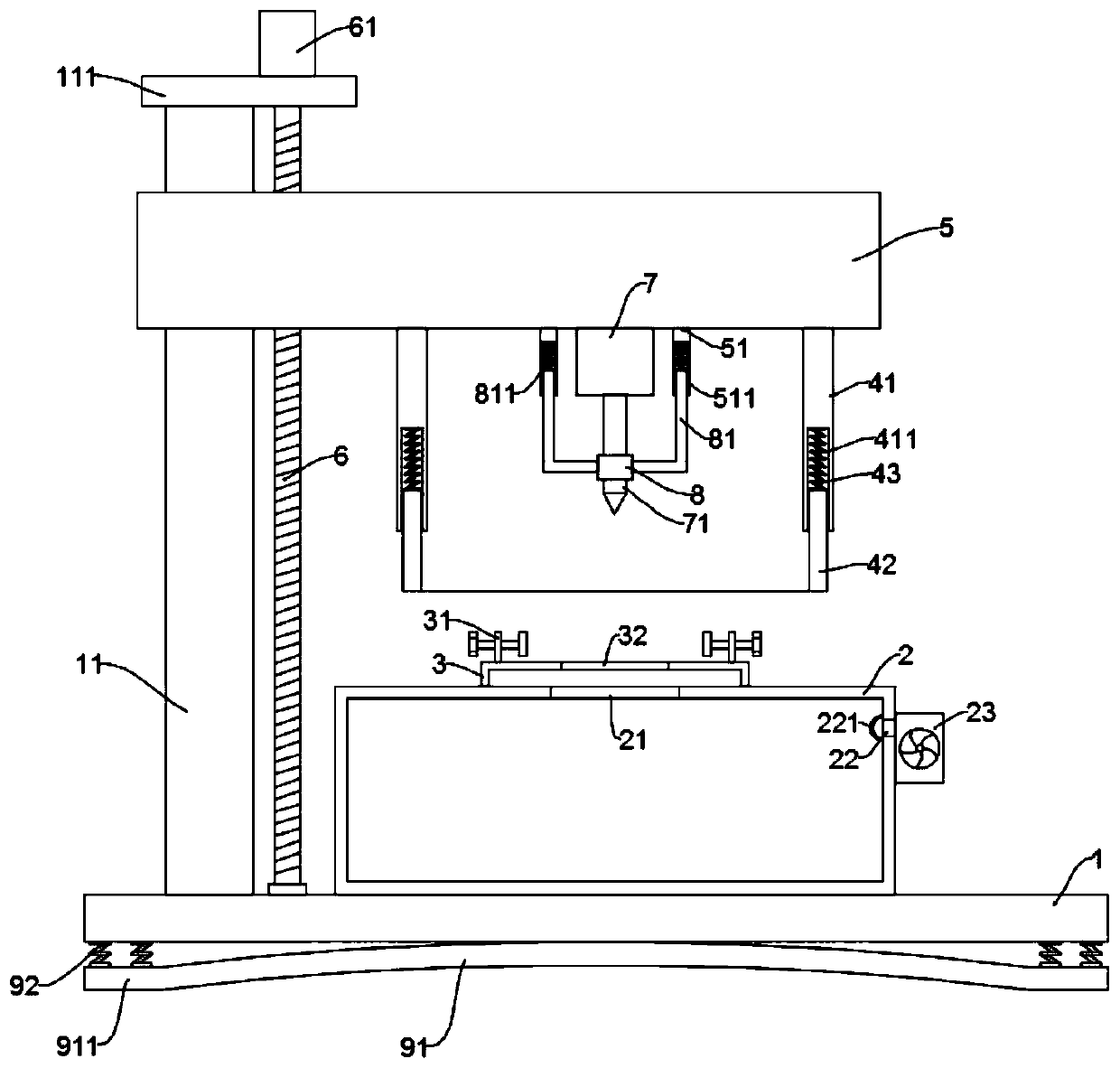

[0031] See Figure 3~4 The embodiment of the present invention is optimized on the basis of embodiment 1, mainly to solve the problem of debris splashing during the drilling process, specifically:

[0032] The bottom of the movable frame 5 is also fixed with a sealing cover which covers the table 3; the sealing cover includes a fixed cover 41 and a movable cover 42, wherein the fixed cover 41 is connected to the mobile frame 5, The bottom of the fixed cover 41 is provided with an annular slot 411. The upper part of the movable cover 42 extends into the slot 411 and is connected to the slot 411 through a connecting spring 43. When the connecting spring 43 is in a normal state, the movable cover The lower end surface of the body 42 is lower than the drill rod 71. During the drilling process, the sealing cover will form a closed space with the movable frame 5 and the worktable 2 to effectively prevent the debris from splashing. The plug-in fixed cover 41 and movable The cover 42 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com