Graduated adjustable drilling guide tool

An adjustable and guide technology, which is applied in the direction of manufacturing tools, drilling molds for workpieces, clamping, etc., can solve the problems of long processing cycle, long preparation cycle, and high cost, so as to reduce processing costs and improve drilling efficiency , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

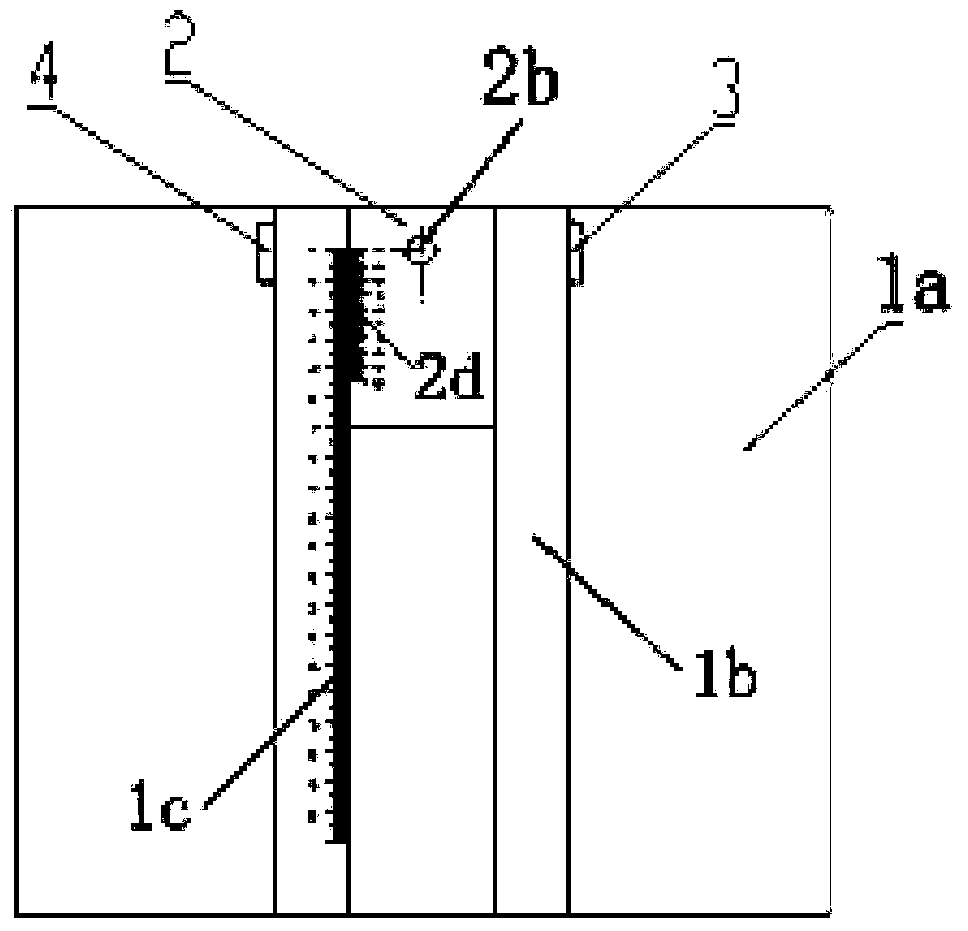

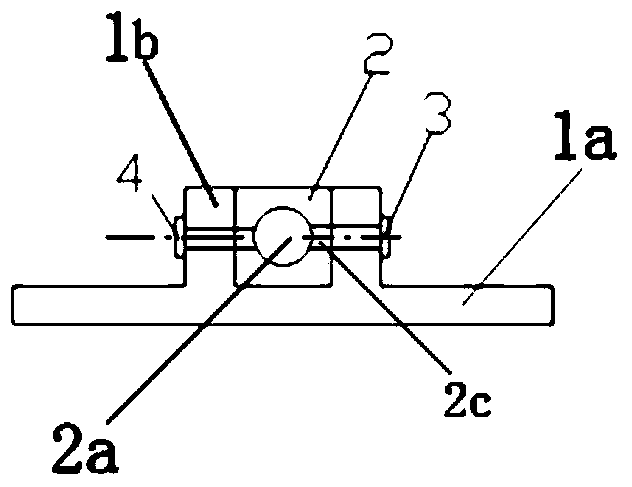

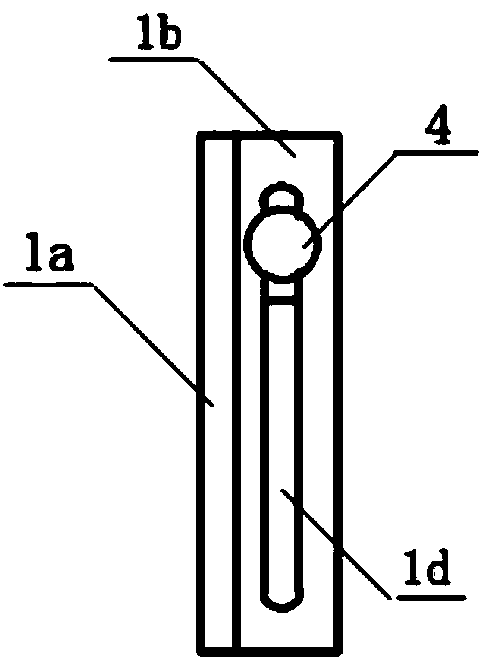

[0014] Combine below Figure 4 to Figure 5 Explain the specific implementation process. The workpiece 5 processes three parallel holes in the axial direction. Hole 5a is 15±0.1mm from the left end of the workpiece, hole 5b is 20±0.1mm from the left end of the workpiece, hole 5c is 28±0.1mm from the left end of the workpiece, and the diameter of workpiece 5 is Φ8f7mm. First, select the slider 2 with the workpiece mounting hole 2a size Φ8H8mm. Then the slider 2 is installed in the base 1, and the workpiece is installed in the workpiece mounting hole 2a of the slider 2. The zero scale line of the main scale 1c on the upper surface of the guide plate 1b is 10 mm from the front end of the base. Move the slider 2 and align the vernier 2d on the slider 2 with the 5mm scale on the main scale 1c. Tighten the slider fastening screw 4 to fix the slider 2 on the base 1, then tighten the workpiece fastening screw 3 to fix the workpiece, and use the drill 6 to drill the hole 5a. Move th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com