Beneath-soil through-tunnel superlarge diameter pipe curtain construction method

A technology with super large diameter and construction method, applied in tunnels, earthwork drilling, tunnel lining, etc., can solve the problems of difficult-to-adjacent buildings, road protection, etc., and achieve the effect of avoiding disturbance, ensuring drilling accuracy and hole quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further illustrate the present invention, each step of the present invention is described in detail through the following examples, but the protection scope of the present invention is not limited to the description of the following examples.

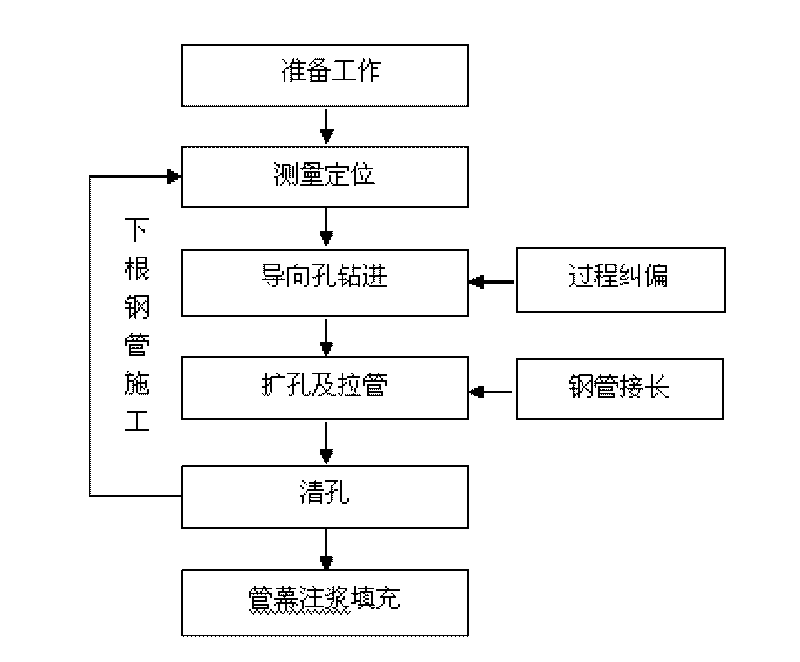

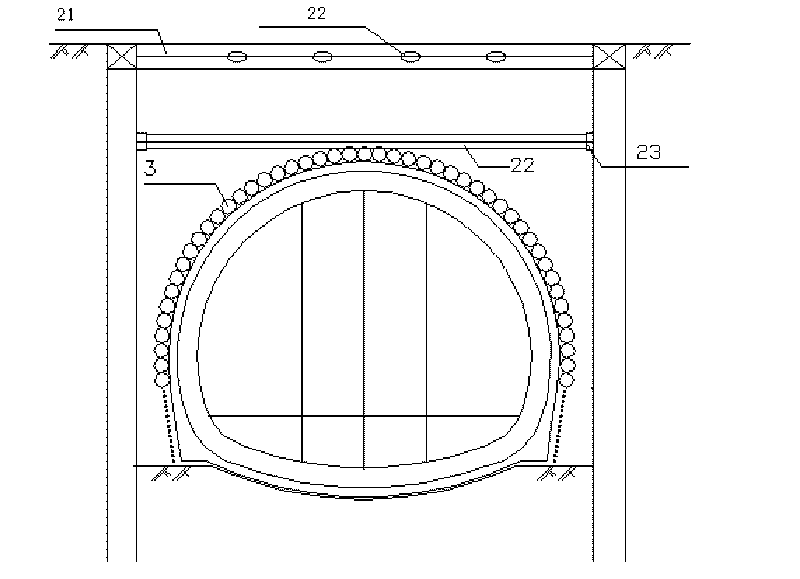

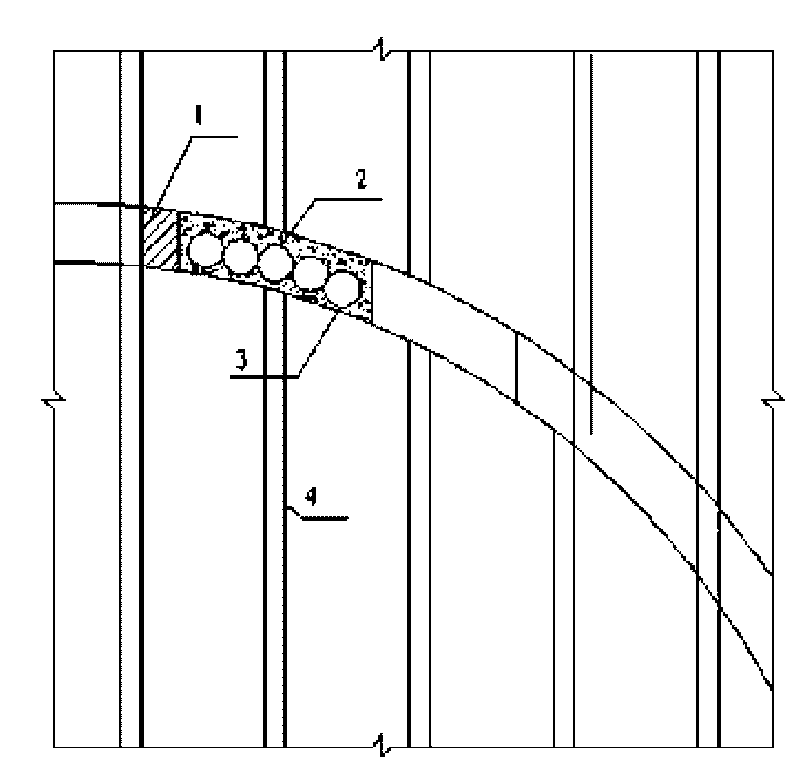

[0033] Located in Anshan City, Liaoning Province, the Anshan Tunnel of the Harbin-Dalian Railway Passenger Dedicated Line is a double-track underpass tunnel with a total length of 2440m and a clearance area of 100m 2 . The underground excavation section is 50m below the special line of the army railway, where the stratum is silty clay and silt, the thickness of the tunnel top cover soil is 4-5m, and the maximum excavation depth is about 18.2m. In order to control the settlement of the ground during the tunnel construction, especially the special line for troops, the maximum span outside the excavation contour of the underground excavation section is protected by Φ300 (wall thickness 10mm) pipe curtain in advance gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com