Parallel system of multiple high-pressure cavity compressors

A technology for compressors and high-pressure chambers, applied to compressors, refrigerators, refrigeration components, etc., can solve problems such as unfavorable system oil return control, refrigeration oil backflow to other containers, etc., to ensure oil supply and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

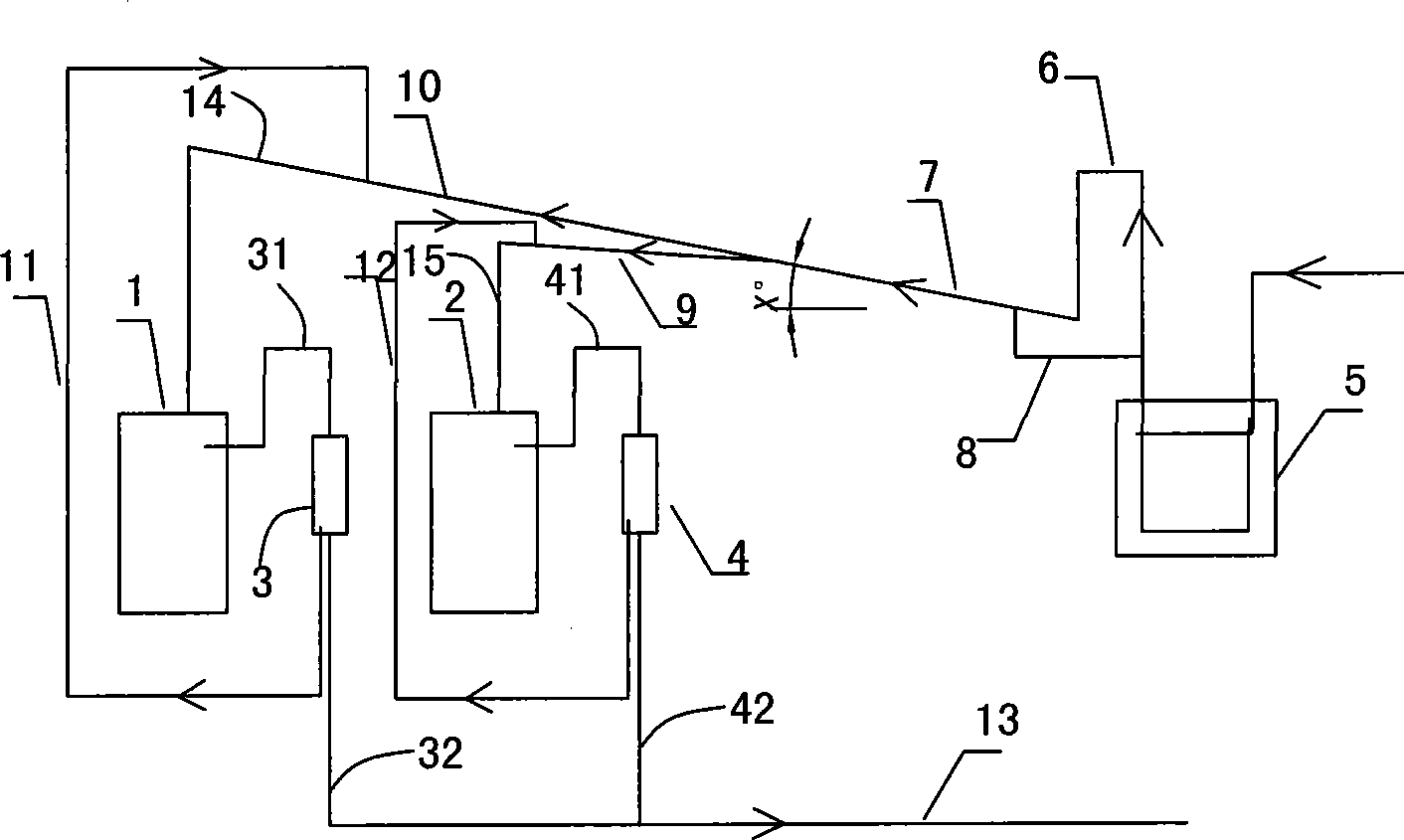

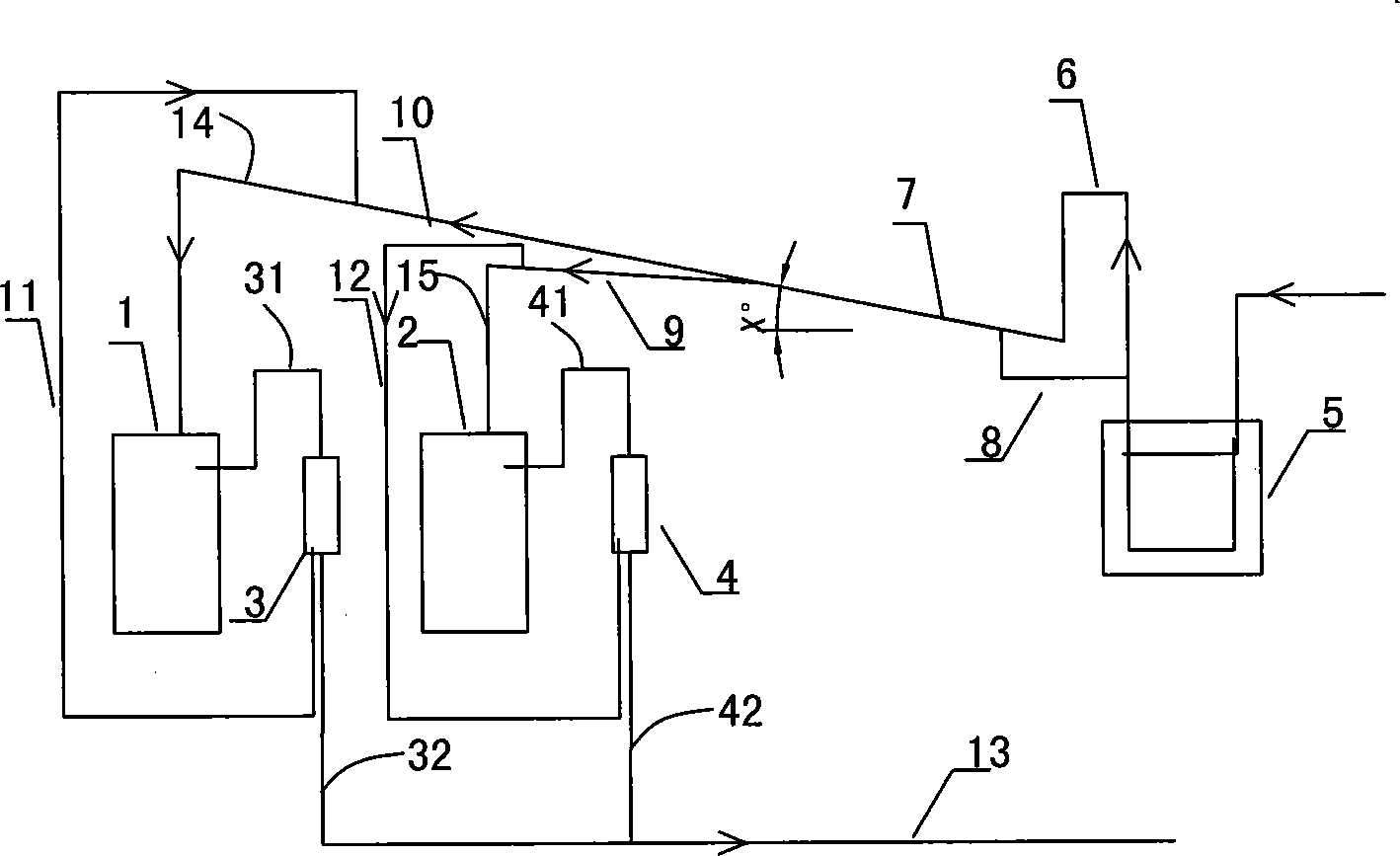

[0018] Such as figure 1 As shown in FIG. 2 , it illustrates the flow diagram of the refrigeration machine oil when the compressors of the parallel system of multiple high-pressure chamber compressors of the present invention stop running. Multiple high-pressure chamber compressor parallel systems, which can connect multiple compressors in parallel, share the same gas-liquid separator, and directly exhaust through the exhaust main pipe. In this embodiment, two compressors share the same gas-liquid separator .

[0019] Multiple high-pressure cavity compressor parallel system, which includes compressor 1 and compressor 2, oil separator 3 and oil separator 4, gas-liquid separator 5, oil separator oil return pipe 11 and oil separator oil return pipe 12, and The suction pipe 14 connected to the compressor 1 and the suction pipe 15 connected to the compressor 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com