Method for adjusting return oil pressure of hydraulic pump shell

A hydraulic pump shell and hydraulic pump technology, applied in the aviation field, can solve problems such as the oil return temperature of the hydraulic shell cannot be cooled, the oil temperature of the system rises, and the system cannot work normally, so as to protect the normal work and ensure the supply Oil quantity, reducing the effect of the fuel cooler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

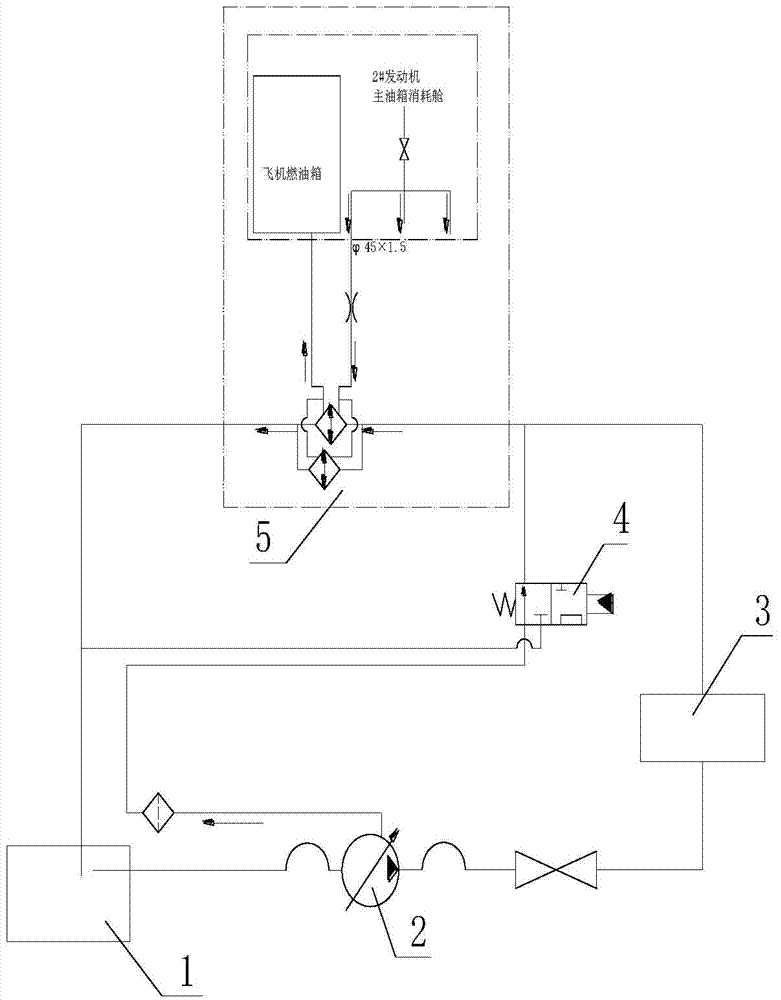

[0012] 1) The hydraulic pump 2 is installed on the output shaft of the engine accessory box through a clamp. When the hydraulic pump rotates, it absorbs oil from the hydraulic oil tank 1, pumps out high-pressure hydraulic oil and returns oil to the casing for cooling and lubricating the hydraulic pump itself;

[0013] 2) The pumped high-pressure hydraulic oil returns to the hydraulic oil tank through the hydraulic load simulation part 3 and the fuel cooling system 5; the hydraulic load simulation part converts the pressure energy of the hydraulic oil into heat energy and consumes it.

[0014] 3) The shell return oil used for the cooling and lubrication of the hydraulic pump itself is connected to the pressure oil port of the electromagnetic reversing valve 4 through a filter;

[0015] 4) Electromagnetic reversing valve 4 is a normally open two-position three-way electromagnetic reversing valve. The pressure oil port of the electromagnetic reversing valve is connected with the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com