Inclined oil hole machining method for sliding rotor of water turbine

A processing method and a technology of inclined oil holes, which are applied in the field of hydraulic turbine rotor processing, can solve problems such as insufficient oil supply to bearings, and achieve the effects of ensuring oil supply, improving efficiency, and ensuring drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

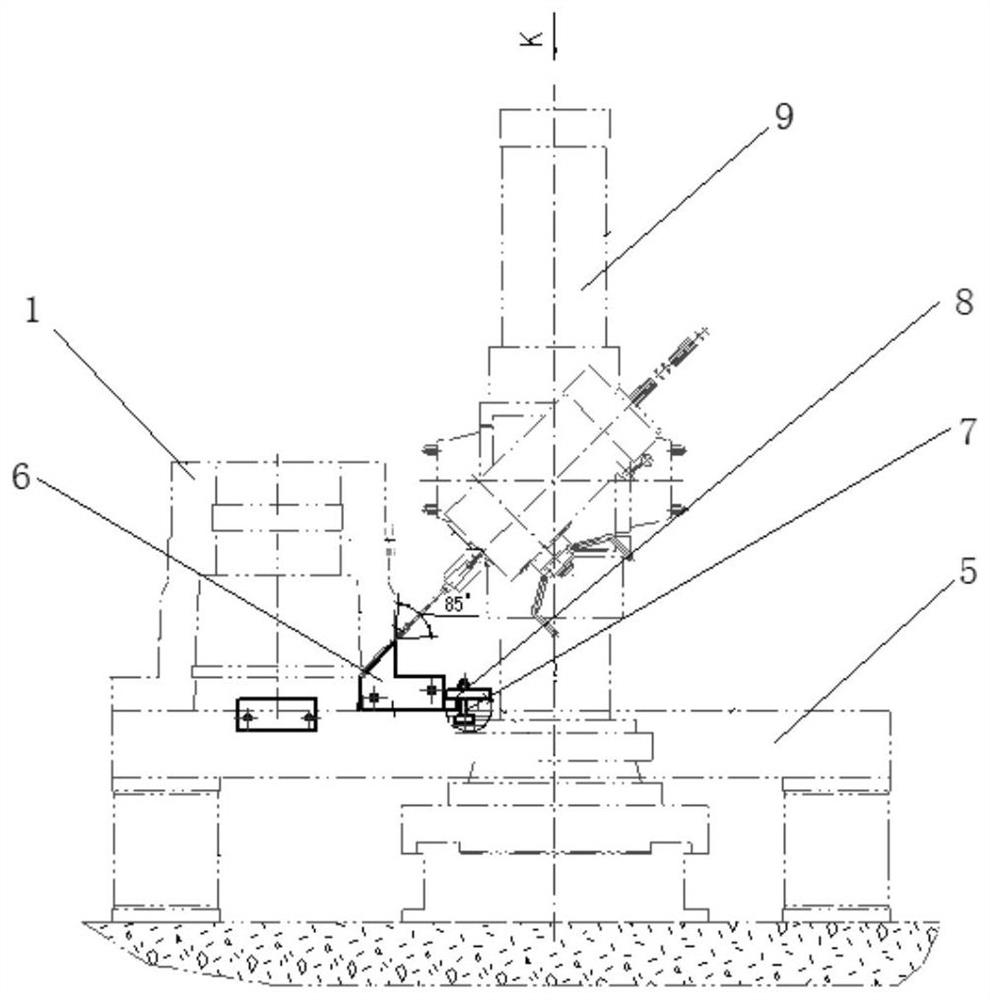

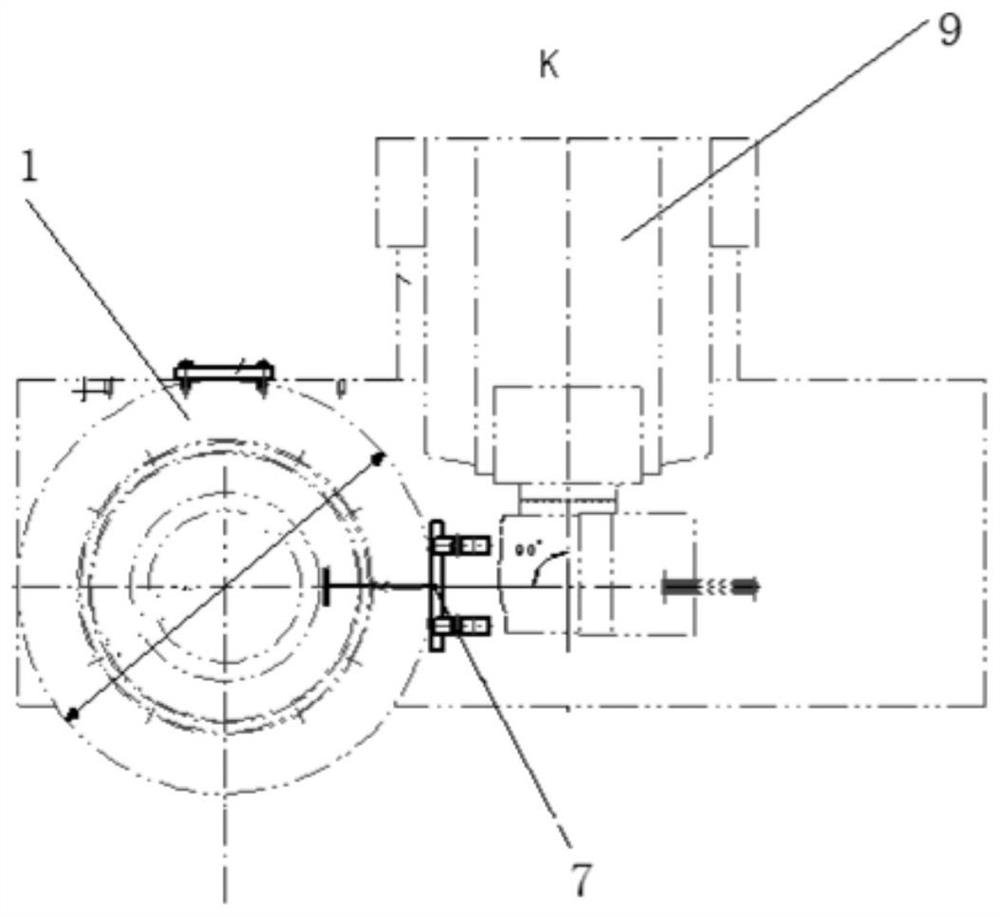

[0022] Such as Figure 1-Figure 5 Shown, a kind of oblique oil hole processing method of hydraulic turbine sliding rotor, specifically comprises the following steps:

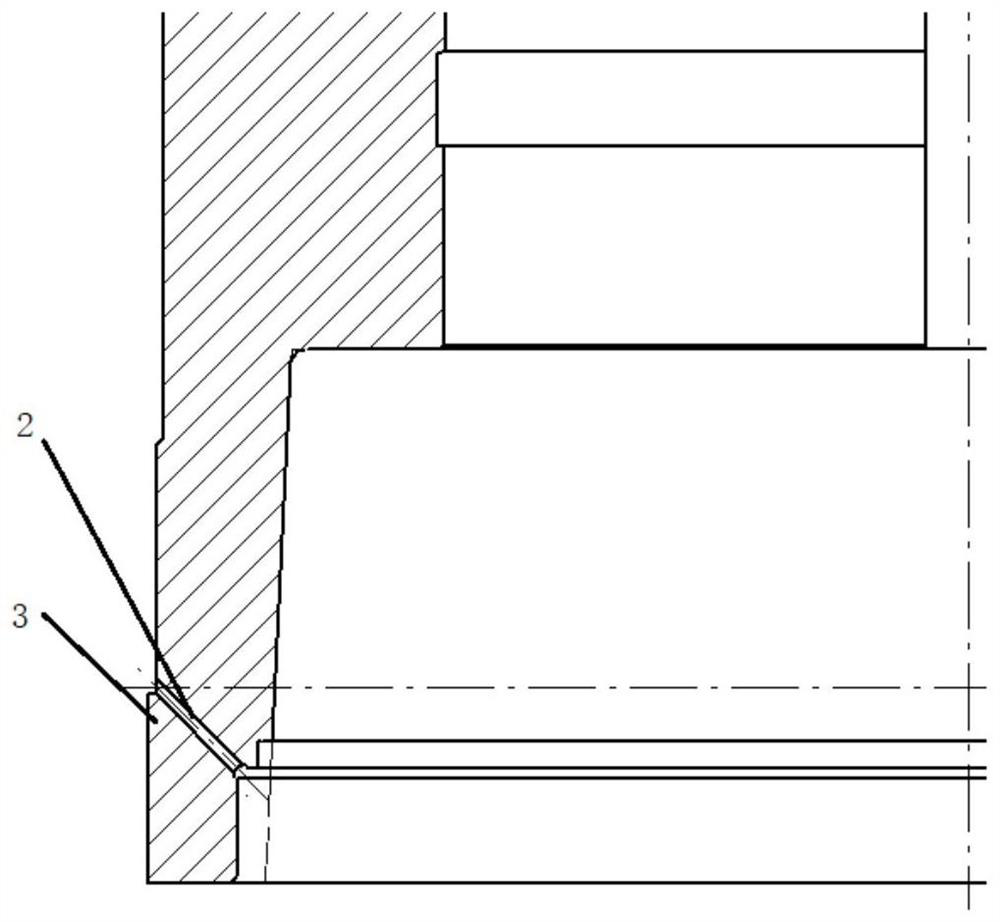

[0023] 1. When using a 2.5-meter vertical lathe to semi-finish each part of the sliding rotor 1, turn a 3mm step 3 at the position of the oblique oil hole 2 on the outer circumference of the sliding rotor 1 to prevent the subsequent drilling of the oblique oil hole 2. Drill bit 4 longitudinal offset;

[0024] 2. Adjust the working plane of the flat plate 5, level the working plane level of the sliding rotor 1 ≤ 0.02mm / m;

[0025] 3. As shown in the K-direction view, determine the installation positions of the drill positioning template 6 and the square iron 7 on the platform according to the outer circle size of the flange after the semi-finishing of the sliding rotor 1 and confirm that the installation is complete, and press the square with the pressure plate 8 Iron 7, use the drill bit positioning template 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com