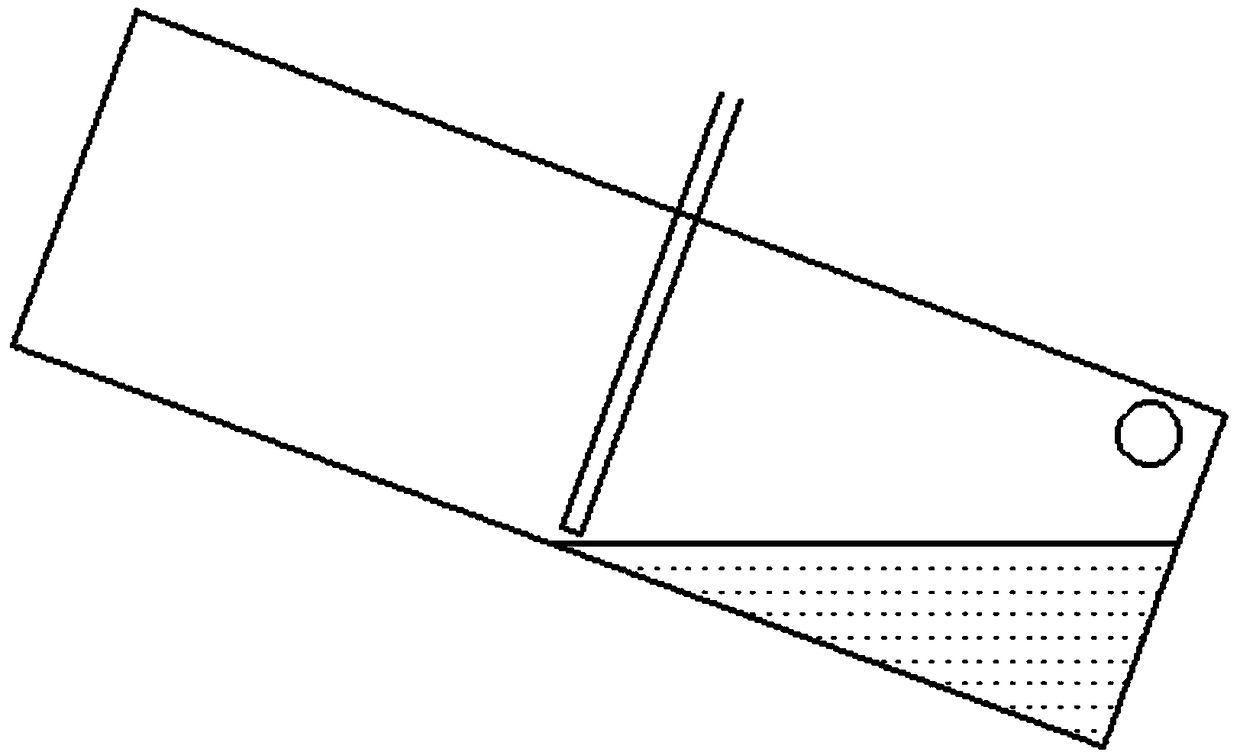

Fuel-tank of motor vehicle

A fuel tank and motor vehicle technology, which is applied to the layout, power plant, vehicle parts, etc. combined with the fuel supply of internal combustion engines, can solve the problems of small application value, the depth of grooves cannot be too deep, personal and property losses, etc., and achieves convenient installation. and maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

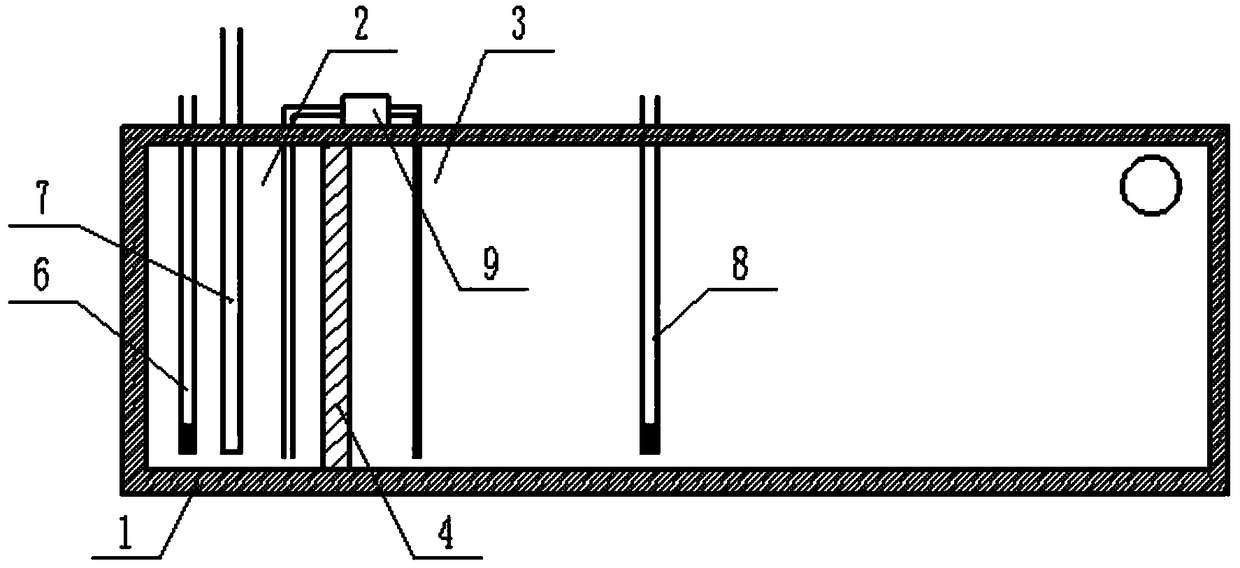

Embodiment 1

[0034] The specific oil delivery device is set as an oil delivery pump 9, and an oil suction tank liquid level detection device 6 is arranged in the oil suction tank 2, and the oil suction tank liquid level detection device 6 controls the oil delivery pump 9 to supply oil from the crude oil tank 3 to the oil suction tank 2 according to the liquid level .

[0035] In the present invention, the oil delivery pump 9 is used to supply fuel oil to the oil suction tank 2 through the crude oil tank 3, and then combined with the oil suction tank liquid level detection device 6 to control the oil delivery pump 9 to supply oil from the crude oil tank 3 to the oil suction tank 2 according to the liquid level, so as to ensure that the oil suction tank The fuel in 2 is kept at a certain liquid level all the time. Even if the tank 1 is tilted in the face of uphill and downhill slopes, the fuel in the suction tank 2 can ensure a certain distance of travel.

[0036] Partition plate 4 of the pr...

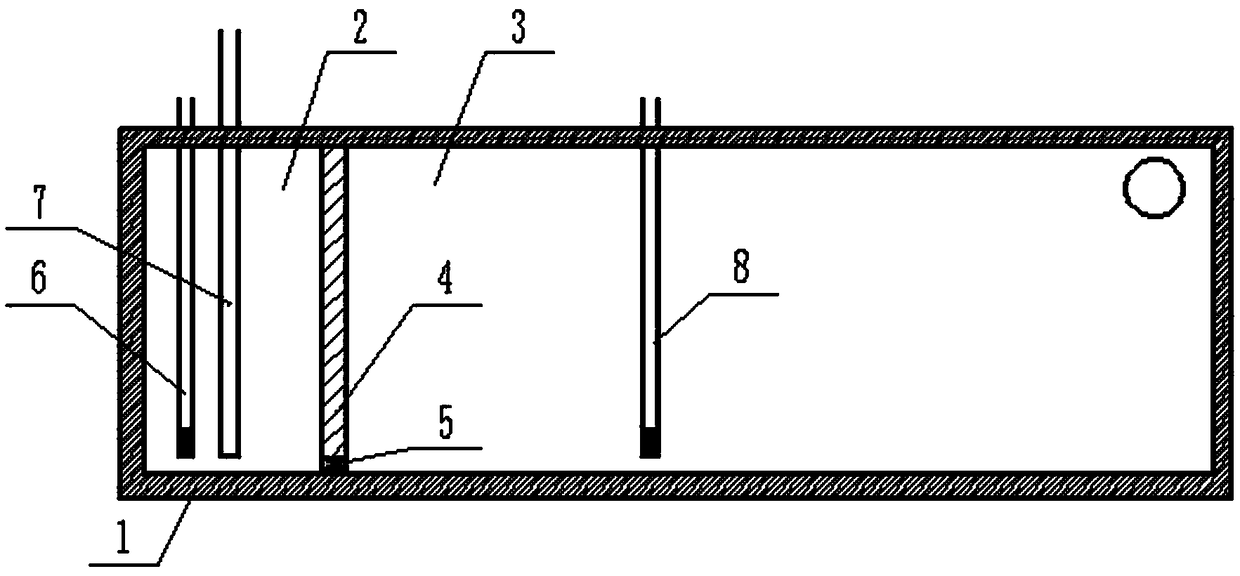

Embodiment 2

[0039] The oil delivery device of the present invention can also be set as a one-way valve 5, and the one-way valve 5 is arranged on the bottom position of the dividing plate 4, and the fuel oil can only flow from the crude oil tank 3 to the oil suction tank 2 through the one-way valve 5, and the oil in the oil suction tank 2 Fuel oil will drop along with use liquid level, and at this moment the liquid level of crude oil tank 3 is supplemented by check valve 5, and oil suction tank 2 of the present invention is preferably arranged at the rear position of casing 1.

[0040] Specifically, it is explained through the uphill and downhill process. In the face of the uphill and then downhill process, the fuel oil in the crude oil tank 3 can be replenished in time through the check valve 5 when climbing the slope first, and then when facing the downhill, the fuel oil in the oil suction tank 2 can be guaranteed. In the face of going downhill and then uphill, because the downhill itself...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com