Gas turbine combustor nozzle and method for premixing fuel and air in nozzle

A gas turbine and combustion chamber technology, which is applied to combustion methods, combustion chambers, continuous combustion chambers, etc., can solve the problems of insufficient number of fuel holes on rotating blades, high flame combustion temperature, and high NOx emission, and achieves improvement of thermoacoustic oscillation. Characteristics, shortened axial length, effect of simple combustion chamber structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

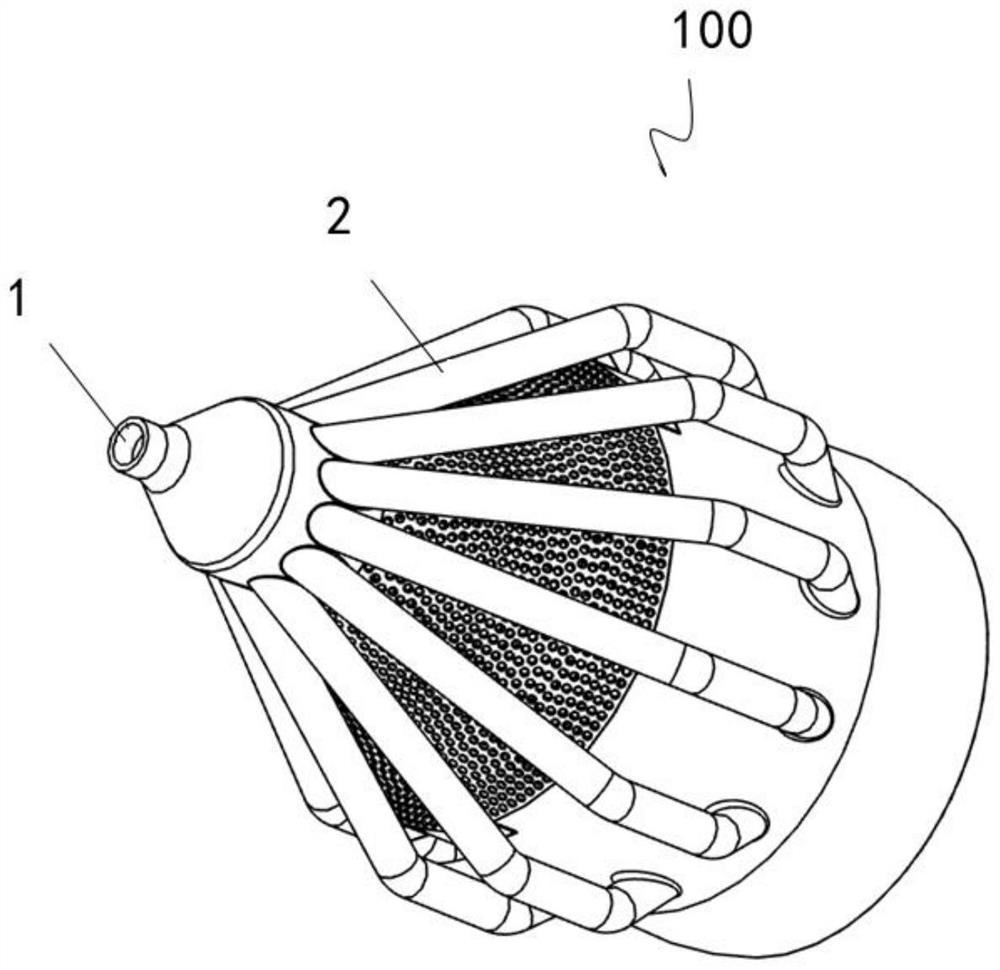

[0065] Depend on Figure 3-4 As shown, the gas turbine combustor nozzle 100 is divided into three parts, which are a fuel delivery main pipe 1 , a fuel flow channel 2 and a fuel-air premixing pipe 3 .

[0066] The diameter of the fuel delivery main pipe 1 changes from small to large according to the fuel flow direction. On the cylindrical structure with a fixed radius of the fuel delivery main pipe 1, a number of fuel outlet holes 12 are arranged in the circumferential direction, and the fuel outlet holes 12 are equidistant in a circular shape. Evenly distributed, each fuel outlet hole 12 corresponds to at least one fuel flow channel 2 . The fuel flow channels 2 are radially arranged with the axis of the fuel delivery main pipe 1 as the geometric center. The fuel flow channels 2 on the same ring layer are at the same axis angle as the fuel delivery main pipe 1 .

[0067] There are several fuel-air premixing pipes 3 , which are evenly distributed in multiple rows along the ra...

Embodiment 2

[0074] Depend on Figure 3-4 As shown, the gas turbine combustor nozzle 100 is divided into three parts, which are a fuel delivery main pipe 1 , a fuel flow channel 2 and a fuel-air premixing pipe 3 .

[0075] The diameter of the fuel delivery main pipe 1 changes from small to large according to the fuel flow direction. On the cylindrical structure with a fixed radius of the fuel delivery main pipe 1, a number of fuel outlet holes 12 are arranged in the circumferential direction, and the fuel outlet holes 12 are equidistant in a circular shape. Evenly distributed, each fuel outlet hole 12 corresponds to at least one fuel flow channel 2 . The fuel flow channels 2 are radially arranged with the axis of the fuel delivery main pipe 1 as the geometric center. The fuel flow channels 2 on the same ring layer are at the same axis angle as the fuel delivery main pipe 1 .

[0076] There are several fuel-air premixing pipes 3 , which are evenly distributed in multiple rows along the ra...

Embodiment 3

[0082] Depend on Figure 3-4 As shown, the gas turbine combustor nozzle 100 is divided into three parts, which are a fuel delivery main pipe 1 , a fuel flow channel 2 and a fuel-air premixing pipe 3 .

[0083] The diameter of the fuel delivery main pipe 1 changes from small to large according to the fuel flow direction. On the cylindrical structure with a fixed radius of the fuel delivery main pipe 1, a number of fuel outlet holes 12 are arranged in the circumferential direction, and the fuel outlet holes 12 are equidistant in a circular shape. Evenly distributed, each fuel outlet hole 12 corresponds to at least one fuel flow channel 2 . The fuel flow channels 2 are radially arranged with the axis of the fuel delivery main pipe 1 as the geometric center. The fuel flow channels 2 on the same ring layer are at the same axis angle as the fuel delivery main pipe 1 .

[0084] There are several fuel-air premixing pipes 3 , which are evenly distributed in multiple rows along the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com