Completely-premixed gas burner

A gas burner, pre-mixed technology, applied in the direction of gas fuel burner, burner, combustion method, etc., can solve the problems of low combustion flame temperature, incomplete combustion, complex control system, etc., and achieve low pollutant emissions , the effect of complete combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

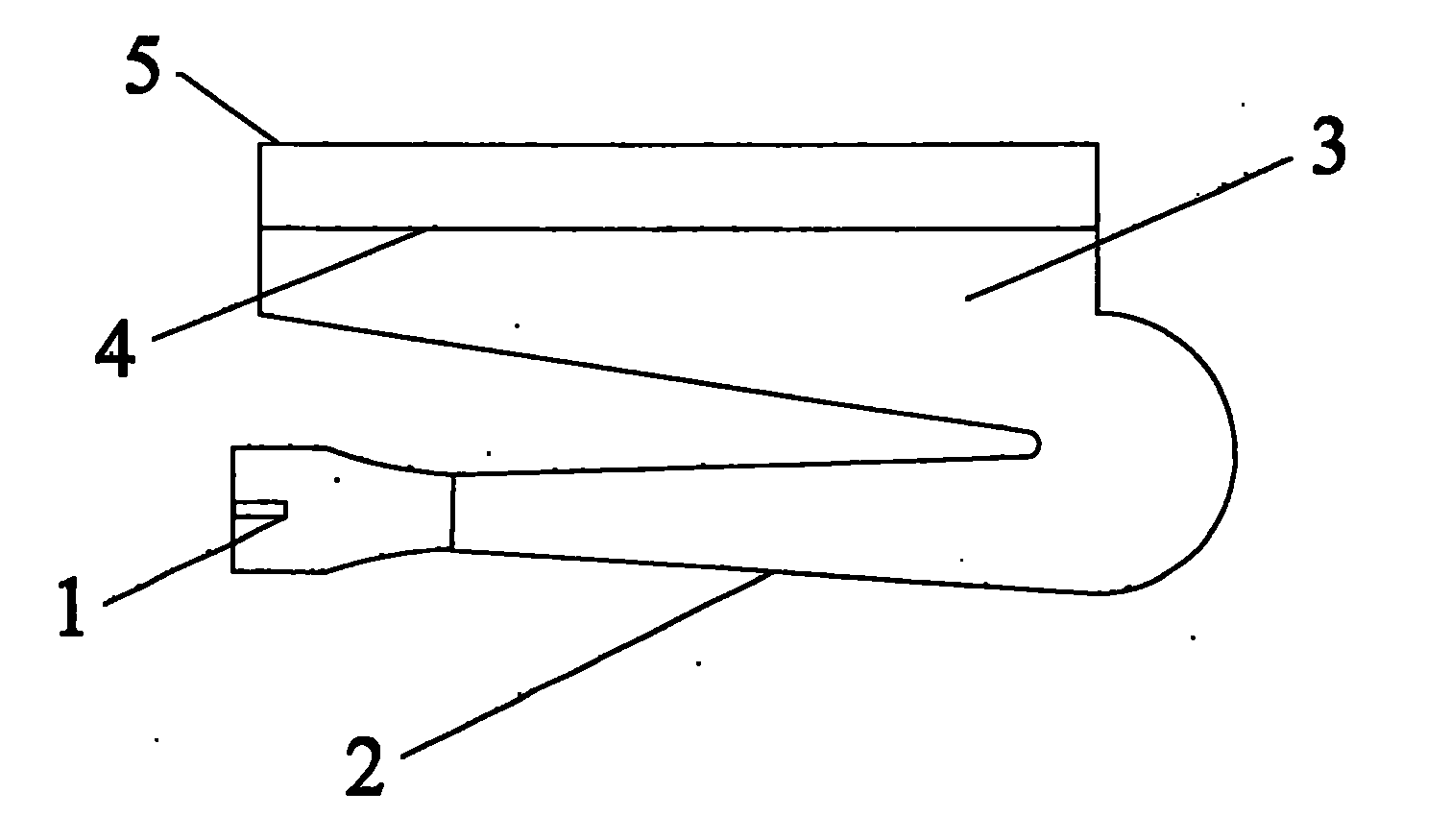

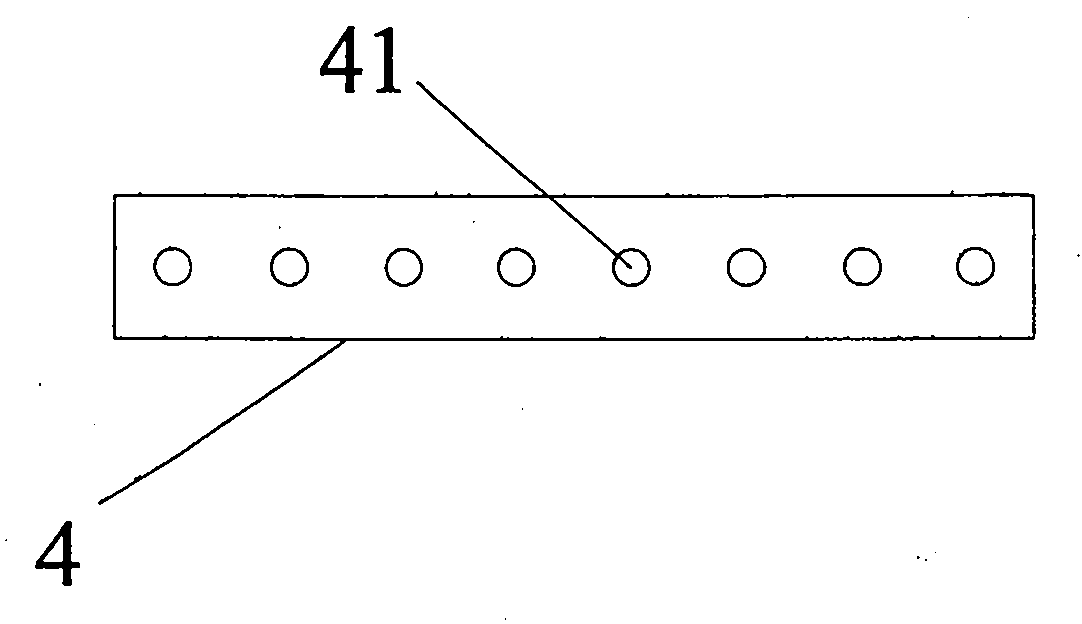

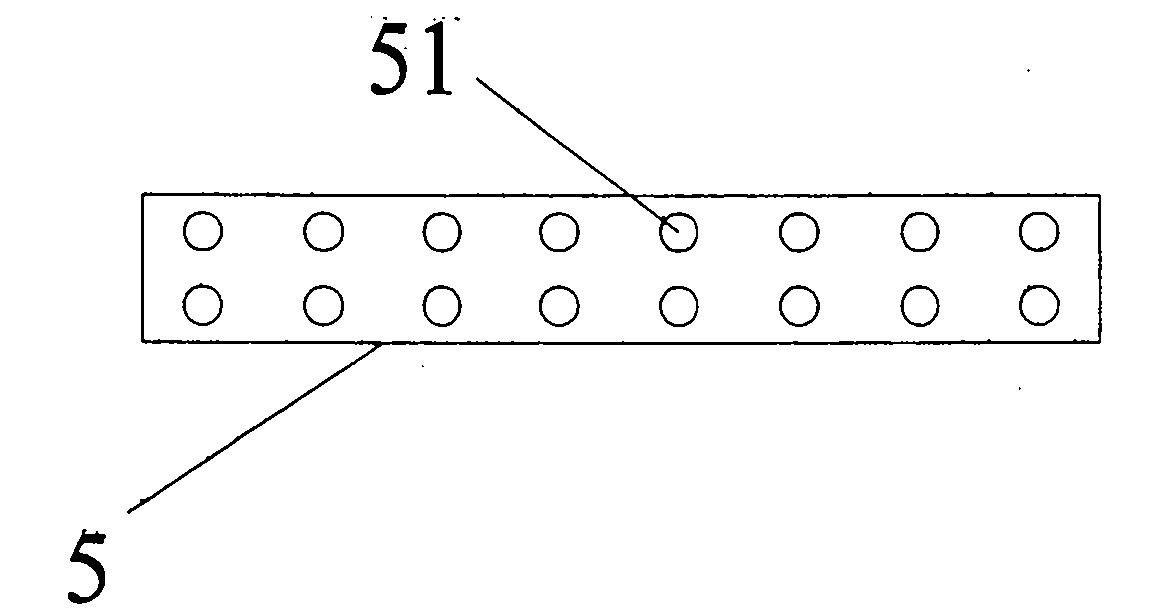

[0023] Such as Figure 1-4 As shown, a completely premixed gas burner includes a nozzle 1, an injector 2, a distribution chamber 3, a splitter plate 4 and a combustion fire orifice 5, and the nozzle 1 is set on the injector 2 One end, the other end of the injector 2 is connected to the distribution chamber 3, the distribution plate 4 is arranged on the distribution chamber 3, the distribution hole 6 is provided on the lower surface of the distribution plate 4, and the burner orifice plate 5 is arranged on the distribution chamber 4 Above, the burner orifice 5 is provided with a fire hole 7, the gas is sprayed into the injector 2 from the nozzle 1, and mixed evenly with the boosted air injected by the injector 2 in the distribution chamber 3, and the gas in the distribution chamber 3 Excessive air, the excess air coefficient can reach a>1, no secondary air is needed during combustion. The mixture of air and gas is fully mixed in the mixing tube in the injector 2, and then ente...

Embodiment 2

[0029] A completely premixed gas burner, the burner includes a nozzle, an injector, a distribution chamber, a splitter plate and a combustion fire orifice, the nozzle is set at one end of the injector, and the other end of the injector is connected to the distribution chamber , the splitter plate is set on the distribution chamber, the burner orifice plate is set above the splitter plate, the gas is injected into the ejector from the nozzle, and mixed with the boosted air injected by the ejector in the distribution chamber Evenly, the air in the distribution chamber is excess, and the excess air coefficient can reach a>1, and no secondary air is needed during combustion. The mixture of air and gas is fully mixed in the mixing tube in the injector, and then enters the distribution chamber at the lower part of the combustion chamber for air flow organization, so that the pressure distribution of the mixed gas is relatively uniform. Finally, the air flow passes through the splitt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com