Water combustion boiler

A boiler and water-burning technology, applied in the field of heating boilers, can solve the problems of large energy consumption, increased heating costs, environmental pollution, etc., and achieve the effects of long service life, simple structure, and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

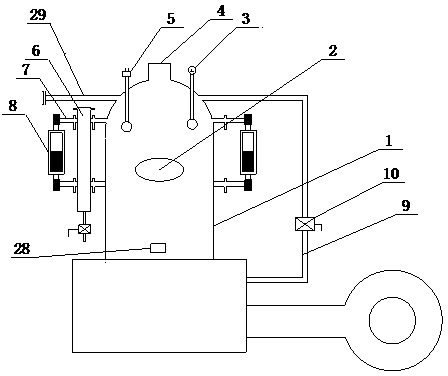

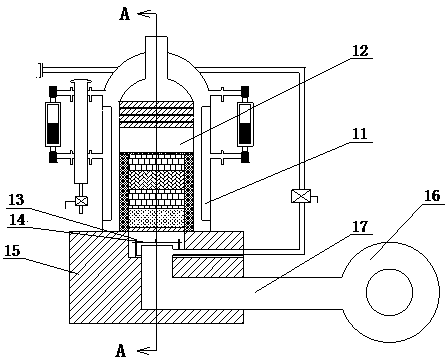

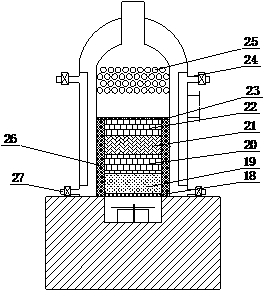

[0046] This embodiment is a water-fired boiler with a structure such as Figure 1-3 As shown, it includes a furnace body 1 with an inner cavity. The shape of the furnace body 1 is n-shaped, a columnar structure with a dome, and is fixed on a furnace base 15 .

[0047]The inner cavity of the furnace body 1 has a diameter of 1700 mm and a height of 3100 mm. The inner cavity of the furnace body 1 is covered with an n-shaped water jacket with the inner wall of the furnace body 1 as the outer wall. The inner wall of the water jacket and the inner wall of the furnace body 1 are n-shaped. The water storage chamber 11, the inner diameter of the columnar part of the water storage chamber 11 is 1400mm, and the outer diameter is 1800mm. The water storage chamber 11 is used to supply water to the boiler and keep the temperature of the combustion chamber 12. The area enclosed by the inner wall of the water jacket is the combustion chamber 12 . The stove base 15 has a section of cylindrica...

Embodiment 2—5

[0068] Embodiment 2-5 is a kind of water-fired boiler respectively, and their difference with embodiment 1 only lies in:

[0069] The weight proportions of rhenium, niobium, magnesium and molybdenum in the combustion-supporting alloy layer 21 are different, see the table below for details.

[0070]

[0071] The structure of embodiment 2-5 is exactly the same as embodiment 1, see for reference figure 1 — image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com