Hydrodynamic three-stage cavitation device

A fluid power and pipe body technology, applied in the field of fluid power three-stage cavitation device, can solve the problems of secondary pollution, high energy consumption, low efficiency, etc., and achieve the effect of improving efficiency, improving cavitation efficiency, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

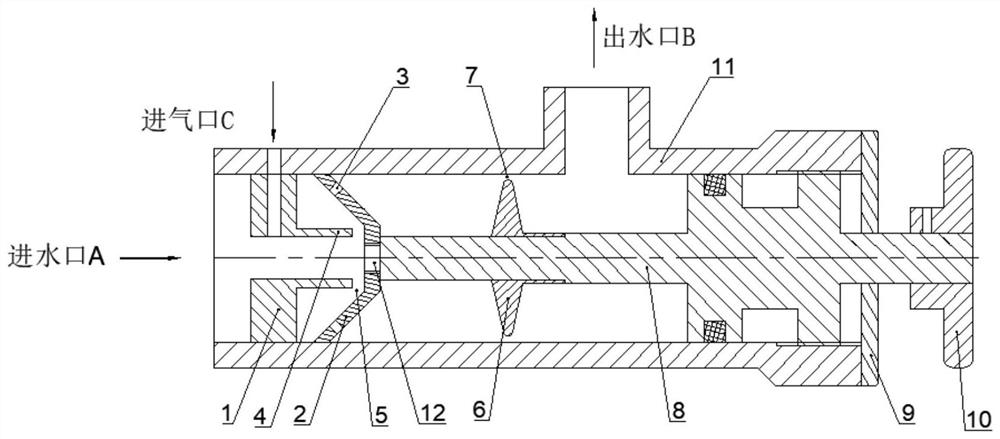

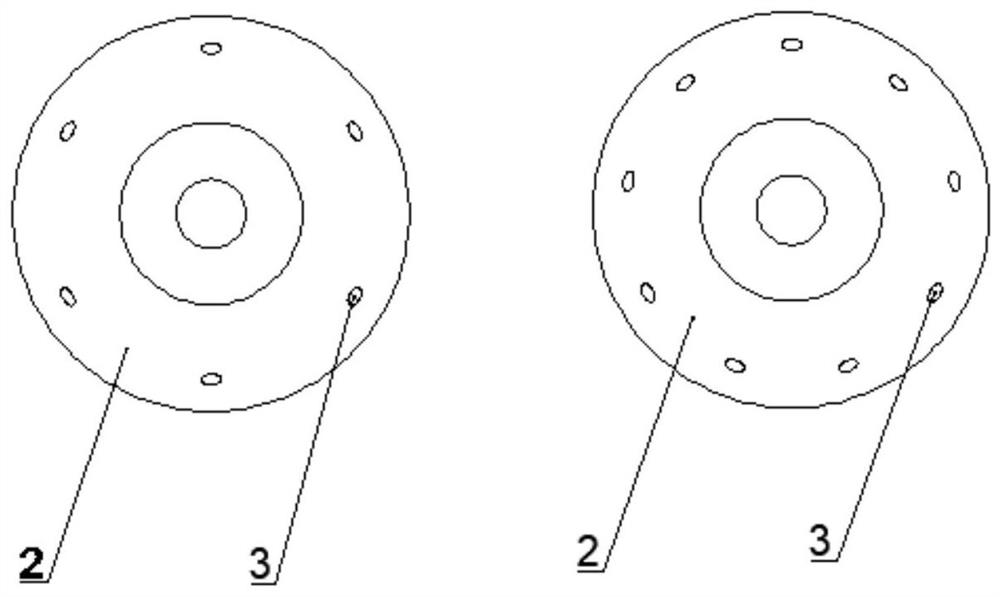

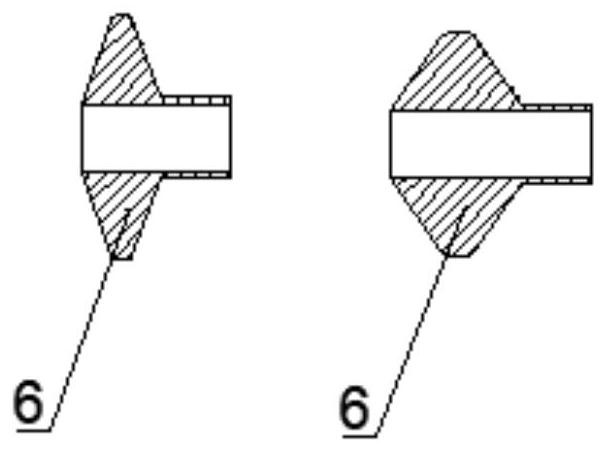

[0019] The specific structure and implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as Figures 1 to 3 , a hydrodynamic three-stage cavitation device, including an orifice plate 1, a frustum-shaped orifice plate 2, a baffle element 6, a long rod 8, an end cap 9, a handle 10, and a cavitation pipe body 11. The orifice plate 1 is installed at a designated position near the water inlet A, and the gas can pass through the orifice plate 1 and enter the fluid through the air inlet hole C, and the orifice plate 1 and the cavitation pipe 11 are fixed by screw connection or other connection methods. The orifice plate 1 and the cylinder 4 are integrally structured, and the gap between the cylinder 4 and the frustum-shaped orifice plate 2 forms the first annular hole 5; the bottom surface opening 12 of the frustum-shaped orifice plate 2 is screwed to the long rod 8 or fixed by other connection methods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com