Fireproof and damp-proof subway cable

A subway and fire-resistant technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor fire resistance and moisture resistance, and achieve the effects of high practicability, improved flame retardant performance, and good fire retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

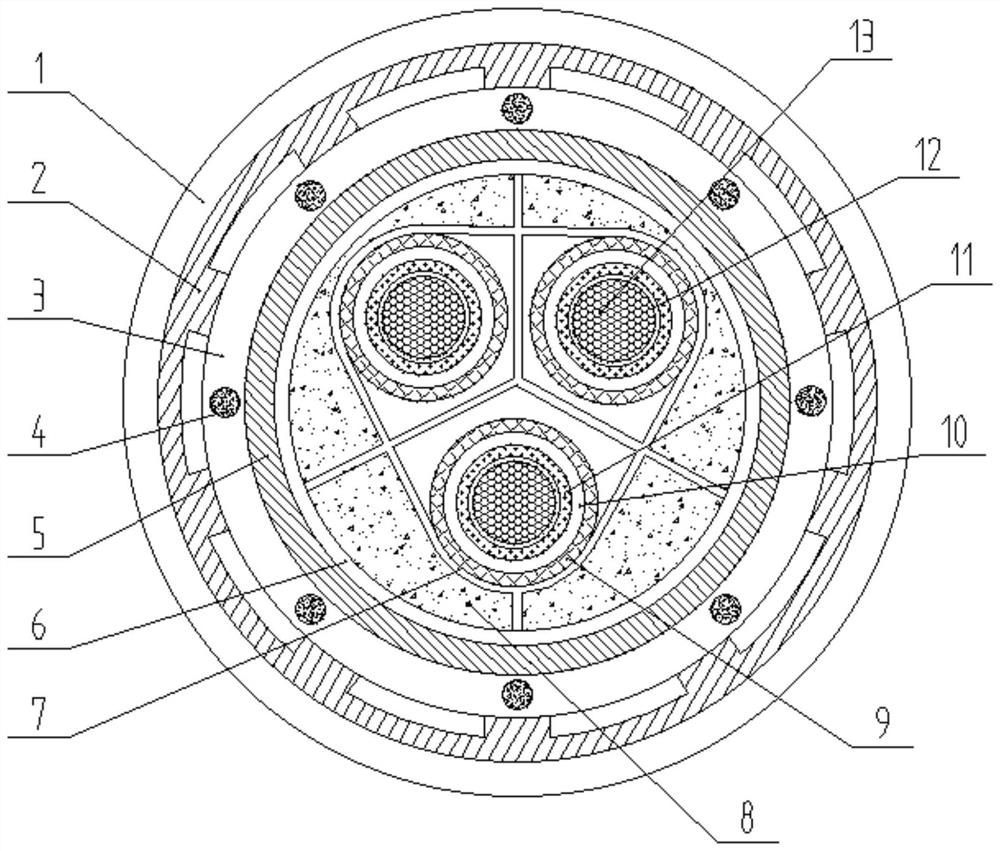

[0018] like figure 1 The shown fire-resistant and moisture-proof subway cable includes several cable cores 13, and the outside of the cable cores 13 is sequentially provided with an insulating layer 12, a shielding layer 11, a protective layer 10 and a fireproof layer 9, and the cable cores 13 are arranged in the fire-proof bracket 7. The fire-proof bracket 7 is fixed on the water-blocking layer 6, and the water-blocking layer 6 is covered with a moisture-proof layer 5, a flame-retardant layer 3, an elastic isolation layer 2 and a wear-resistant layer 1 in sequence, and the fire-proof bracket 7 separates each cable core 13 in a separate cavity. Several hollow flame-retardant tubes 4 extending along the length direction of the cable core 13 are arranged in the flame-retardant layer 3 , and the inner tubes of the flame-retardant tubes 4 are filled with flame retardant. Between the water blocking layer 6 and the fire-proof bracket 7 , the cavity between each cable core 13 and th...

Embodiment 2

[0027] like figure 1The shown fire-resistant and moisture-proof subway cable includes several cable cores 13, and the outside of the cable cores 13 is sequentially provided with an insulating layer 12, a shielding layer 11, a protective layer 10 and a fireproof layer 9, and the cable cores 13 are arranged in the fire-proof bracket 7. The fire-proof bracket 7 is fixed on the water-blocking layer 6, and the water-blocking layer 6 is covered with a moisture-proof layer 5, a flame-retardant layer 3, an elastic isolation layer 2 and a wear-resistant layer 1 in sequence, and the fire-proof bracket 7 separates each cable core 13 in a separate cavity. Several hollow flame-retardant tubes 4 extending along the length direction of the cable core 13 are arranged in the flame-retardant layer 3 , and the inner tubes of the flame-retardant tubes 4 are filled with flame retardant. Between the water blocking layer 6 and the fire-proof bracket 7 , the cavity between each cable core 13 and the...

Embodiment 3

[0029] like figure 1 The shown fire-resistant and moisture-proof subway cable includes several cable cores 13, and the outside of the cable cores 13 is sequentially provided with an insulating layer 12, a shielding layer 11, a protective layer 10 and a fireproof layer 9, and the cable cores 13 are arranged in the fire-proof bracket 7. The fire-proof bracket 7 is fixed on the water-blocking layer 6, and the water-blocking layer 6 is covered with a moisture-proof layer 5, a flame-retardant layer 3, an elastic isolation layer 2 and a wear-resistant layer 1 in sequence, and the fire-proof bracket 7 separates each cable core 13 in a separate cavity. Several hollow flame-retardant tubes 4 extending along the length direction of the cable core 13 are arranged in the flame-retardant layer 3 , and the inner tubes of the flame-retardant tubes 4 are filled with flame retardant. Between the water blocking layer 6 and the fire-proof bracket 7 , the cavity between each cable core 13 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com